Luke Daugherty

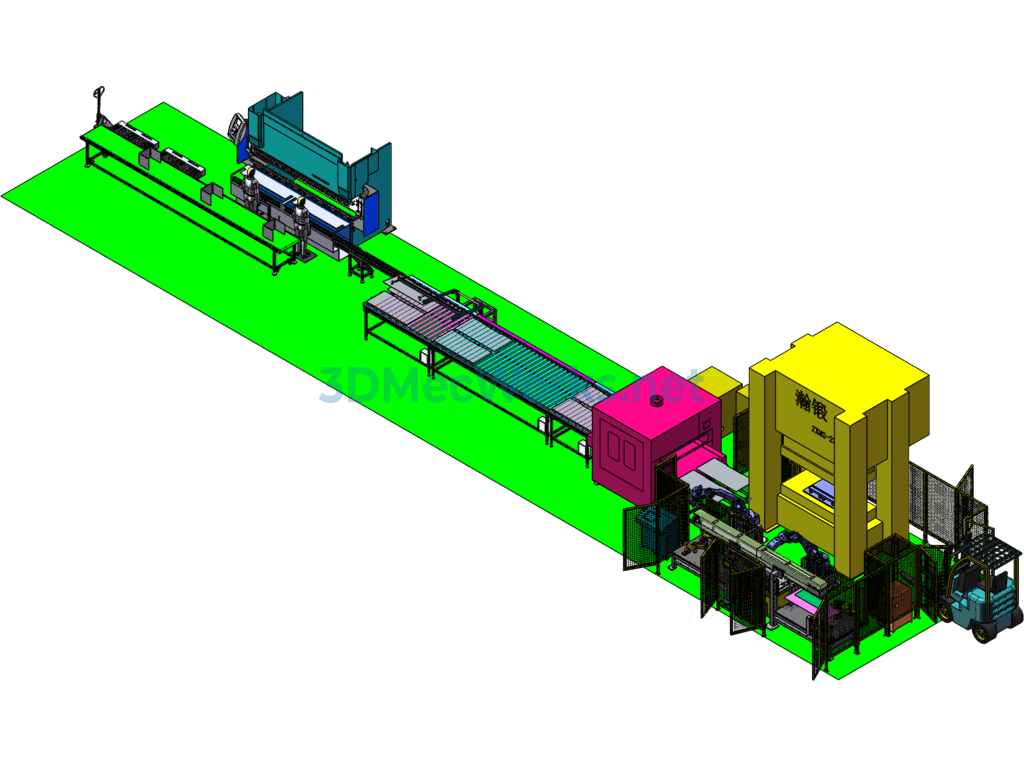

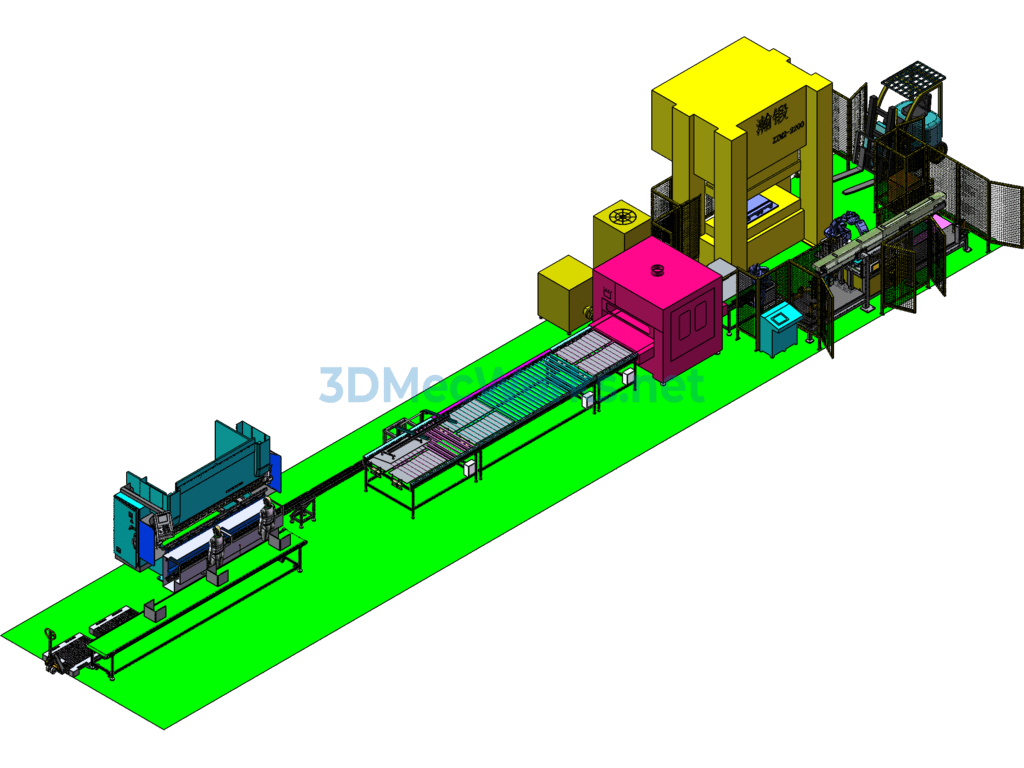

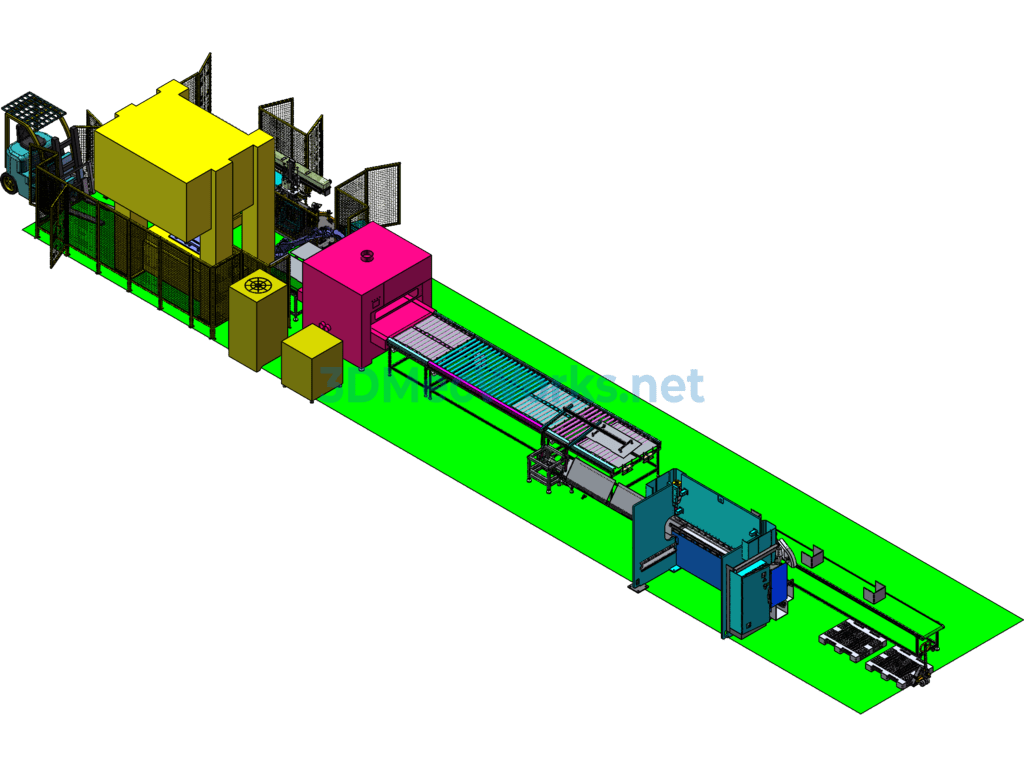

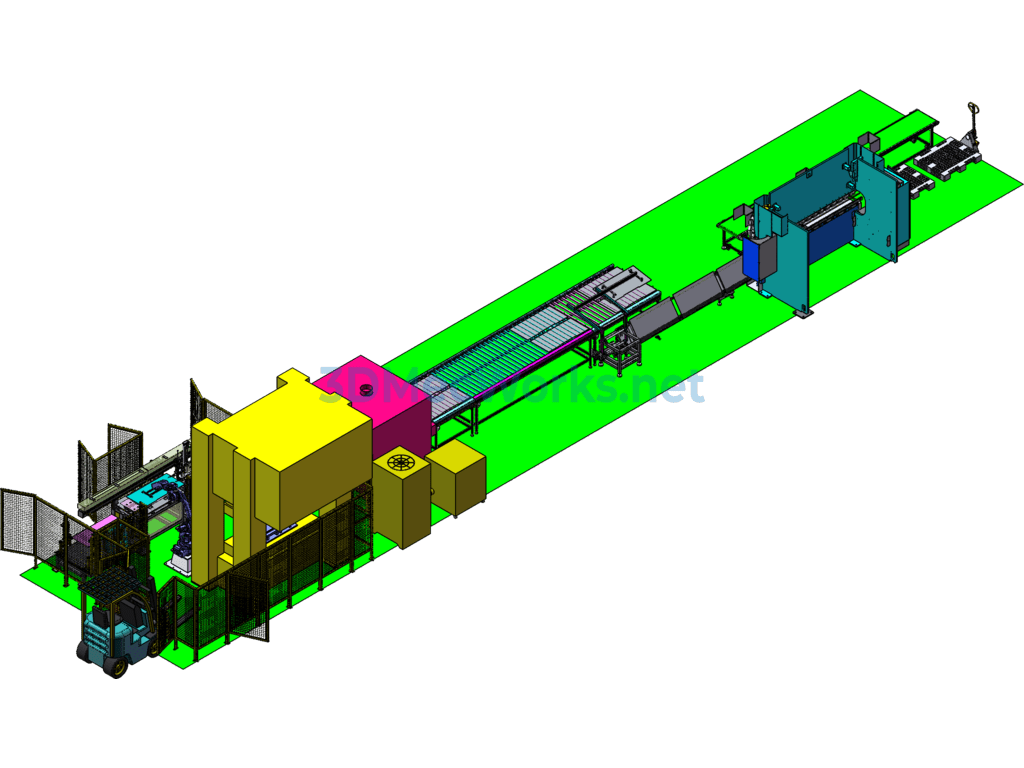

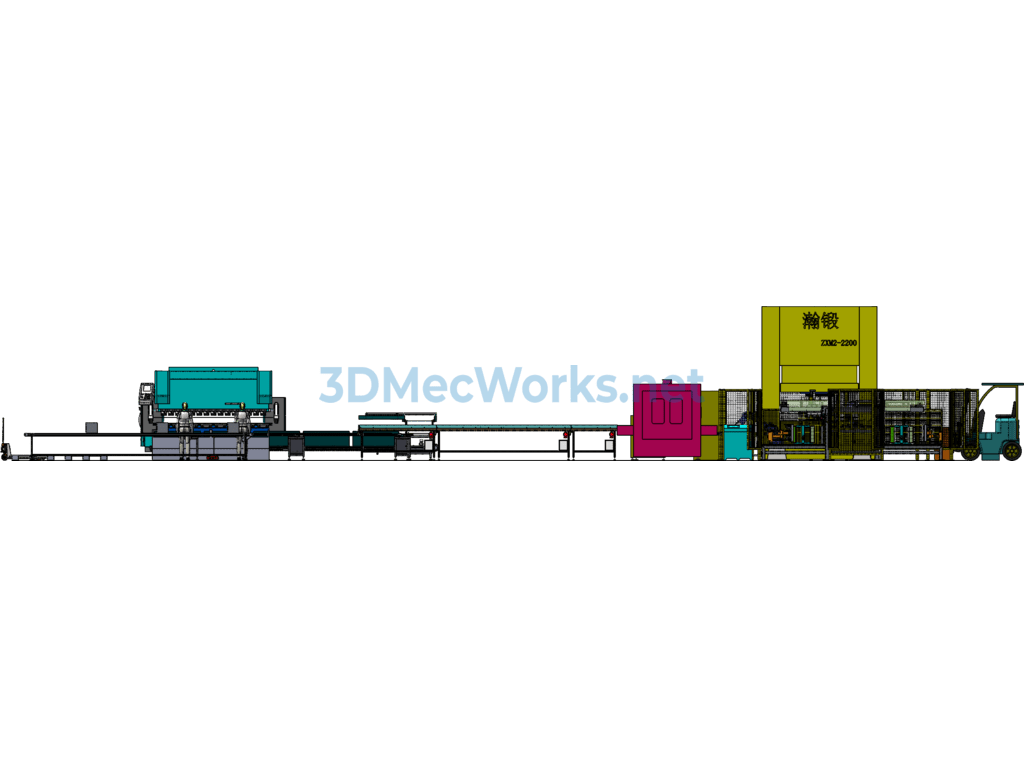

This is a home appliance sheet metal stamping, deburring, and bending production line. Workers place 400 sheets of thin plates per pallet on the loading table. Two robots in the stamping area complete the loading and unloading of the thin plates. The thin plates are transported via logistics to the deburring area for deburring, then they are transferred through a 90° rotation mechanism to a non-tilting slide table to satisfy the reorientation and delivery to the inclined conveyor line. In the bending area, workers complete the bending and forming of the thin plates, and at the end of the finished product assembly line, the products are manually transferred to the pallet in the unloading area. Parts are finely and completely fabricated and ready for drawing-based processing.

Specification: Household Appliance Sheet Metal Stamping Deburring and Bending Production Line

|

User Reviews

Be the first to review “Household Appliance Sheet Metal Stamping Deburring and Bending Production Line” Cancel reply

You must be logged in to post a review.

There are no reviews yet.