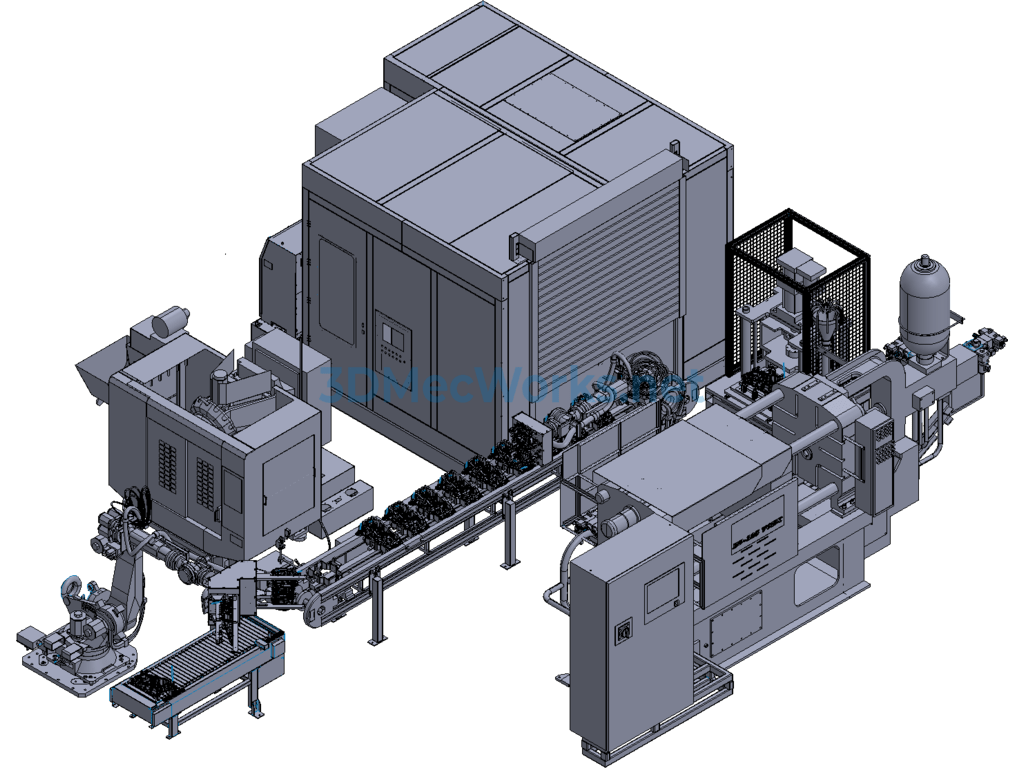

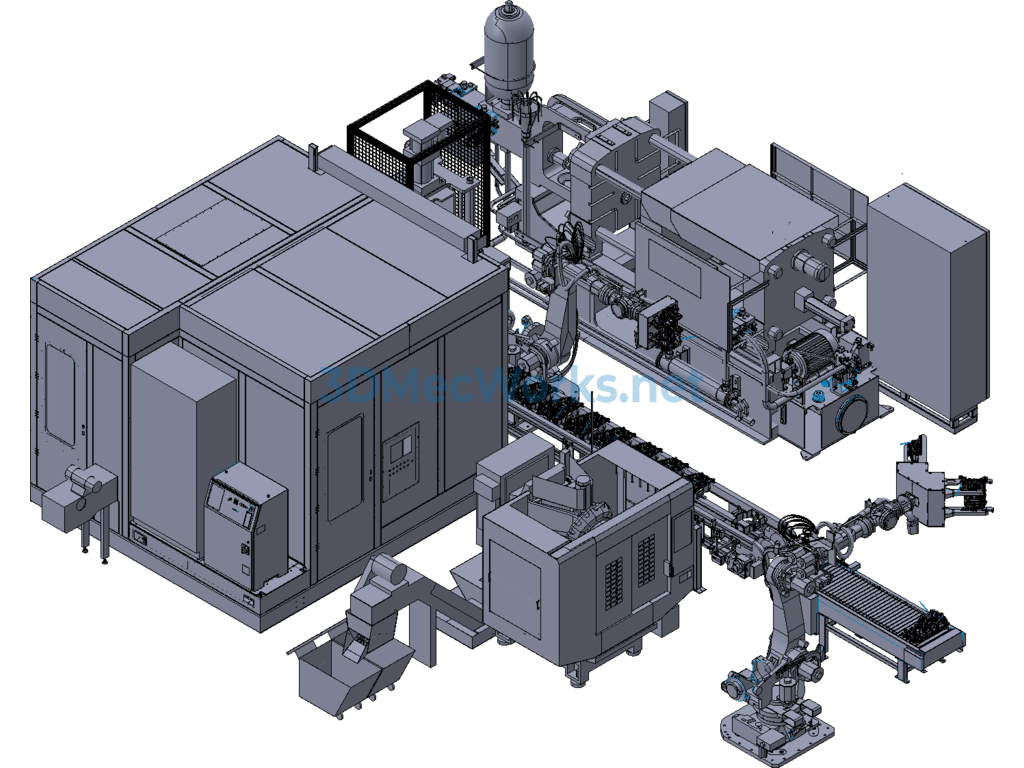

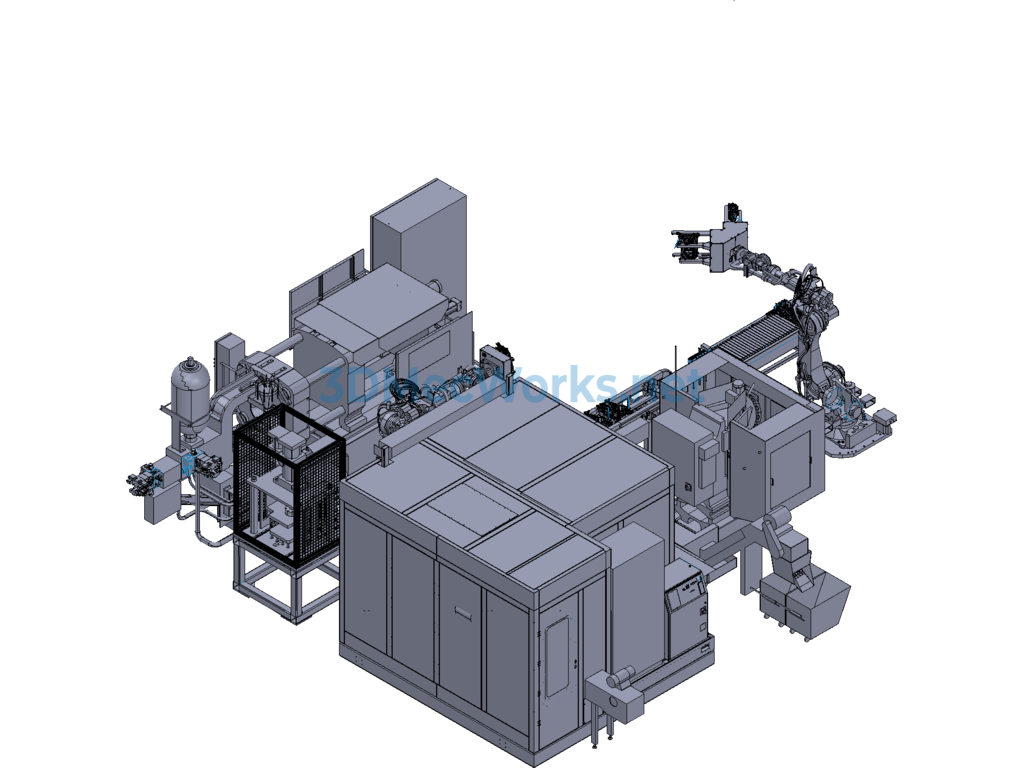

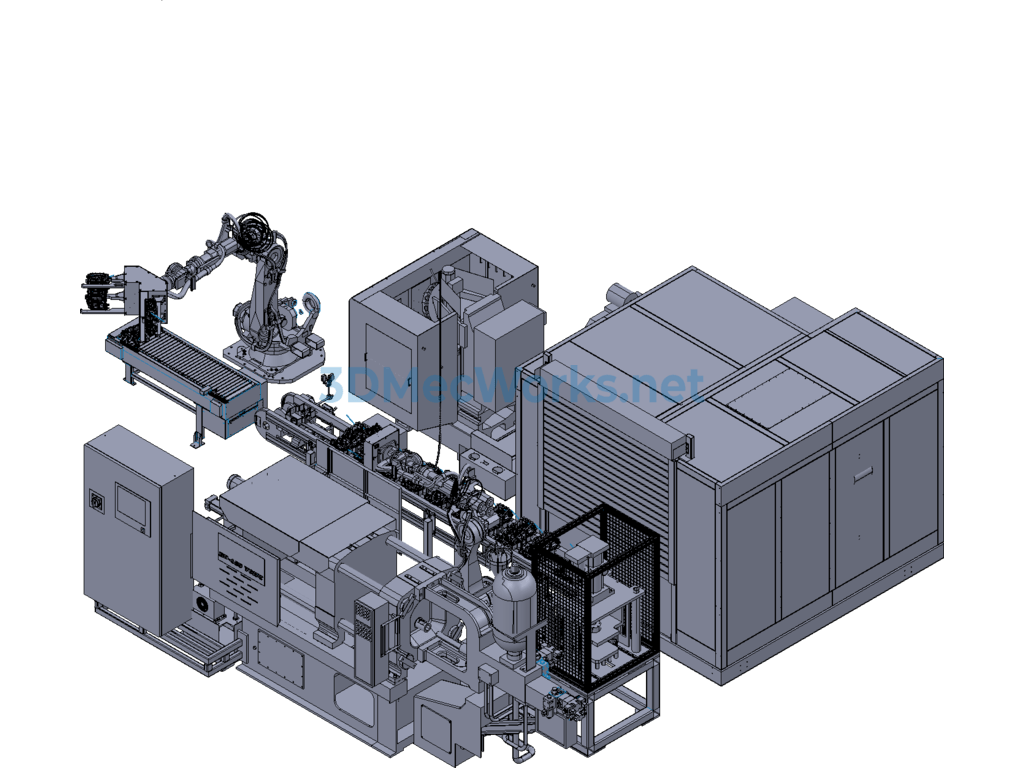

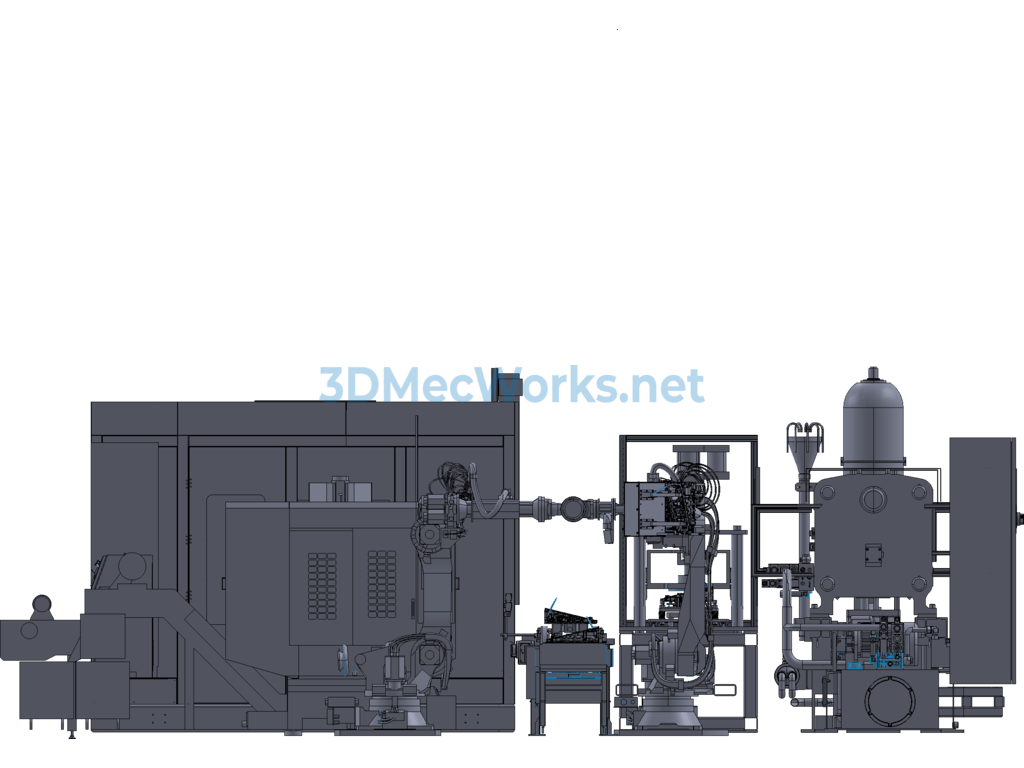

A complete and refined die-casting cell, including aluminum alloy product extraction, precise deburring, and precision machining automation line. Fully replaces manual operations for seamless production processing. In the traditional die-casting cell, after a robot extracts the workpiece, it is cooled and transported to the back-end workshop, where manual phased post-processing is conducted. Through automation integration, deburring and precision machining parts are placed next to the machine, reducing logistics turnover. The robot adopts the FANUC 2000ib165f model, meeting the handling and processing requirements for large workpieces.

Specification: High-Pressure Die Casting Aluminum Alloy Die-Casting Island With Precision Trimming, Deburring, and Finishing Integrated Line

|

User Reviews

Be the first to review “High-Pressure Die Casting Aluminum Alloy Die-Casting Island With Precision Trimming, Deburring, and Finishing Integrated Line”

You must be logged in to post a review.

There are no reviews yet.