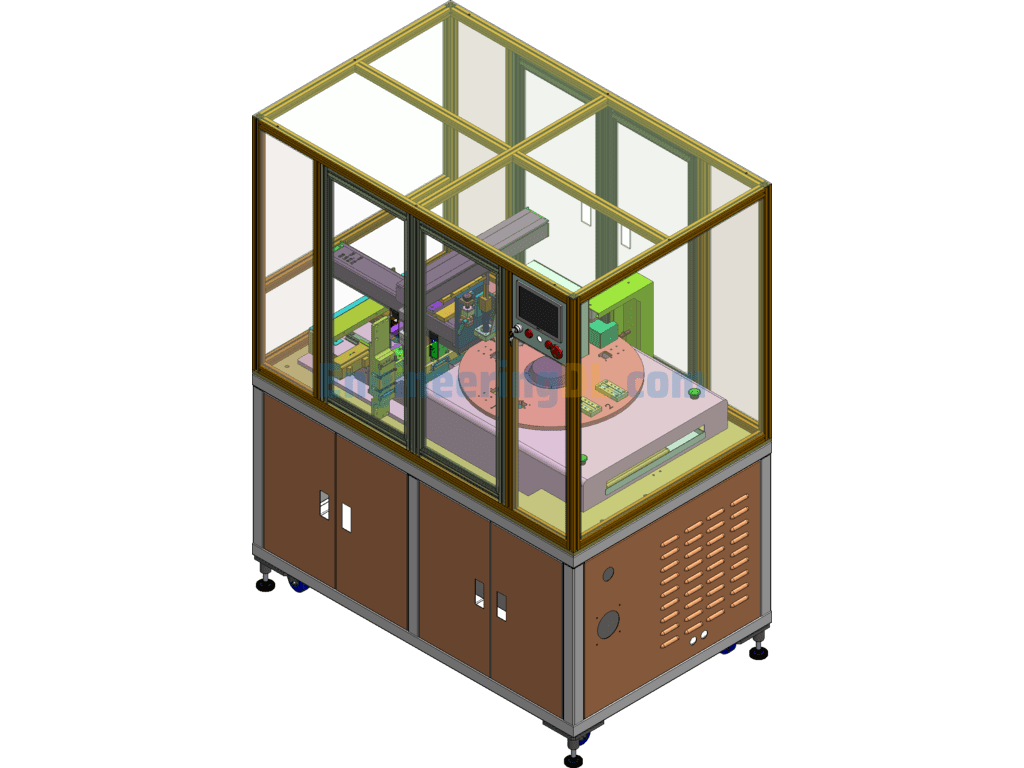

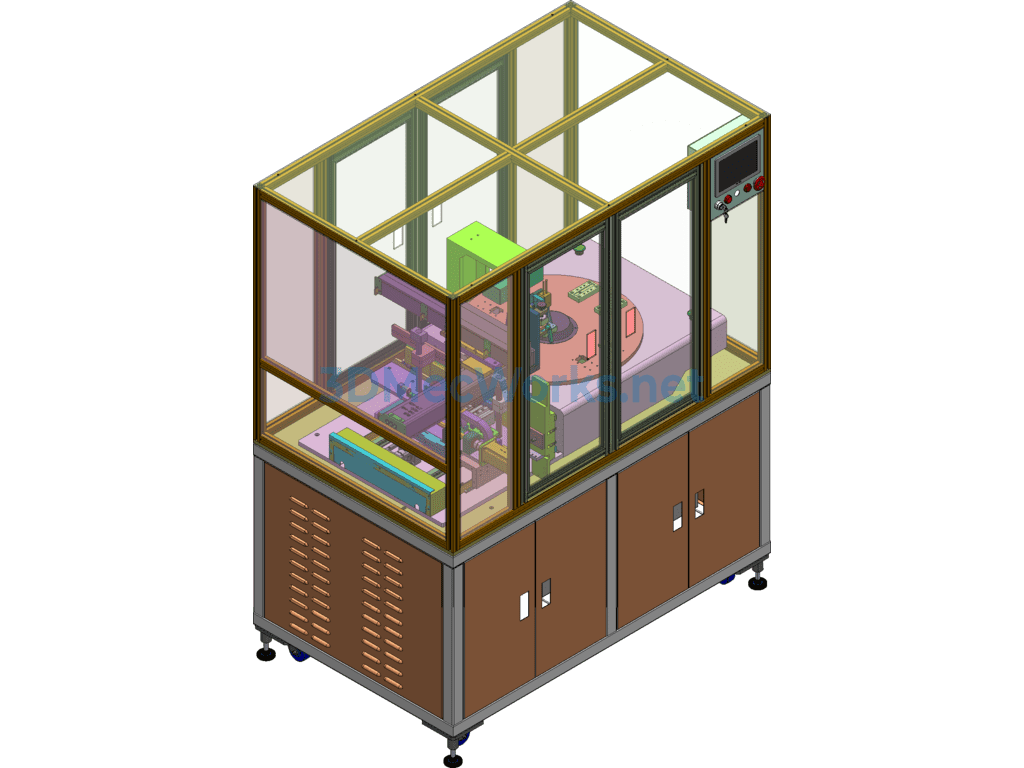

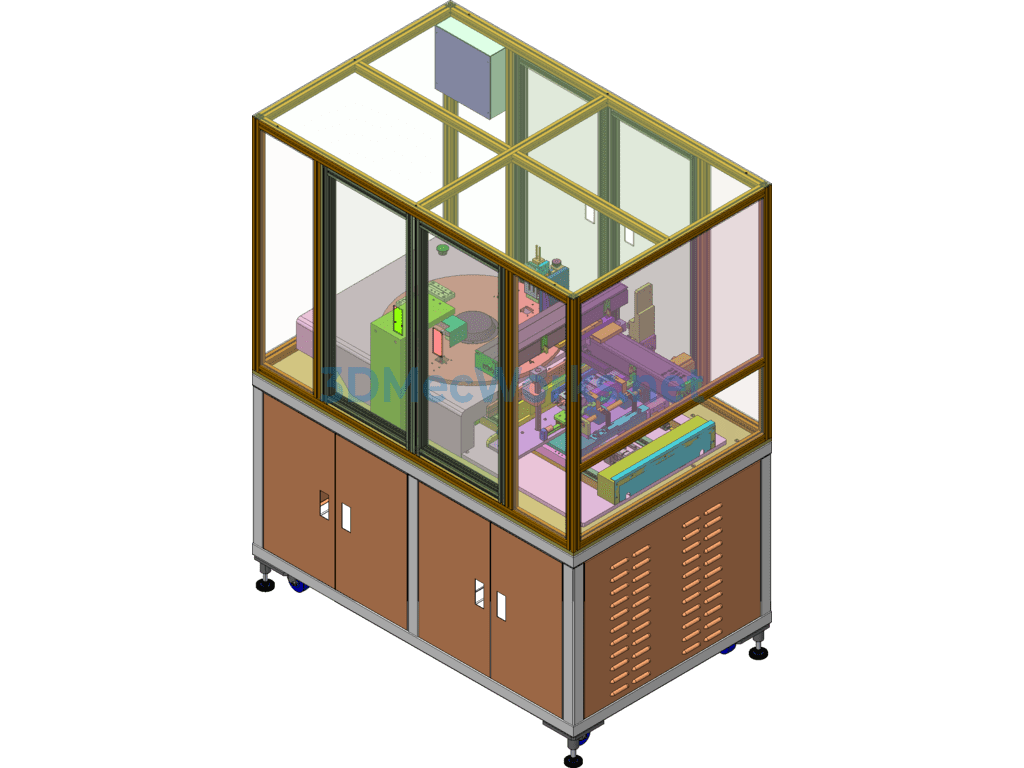

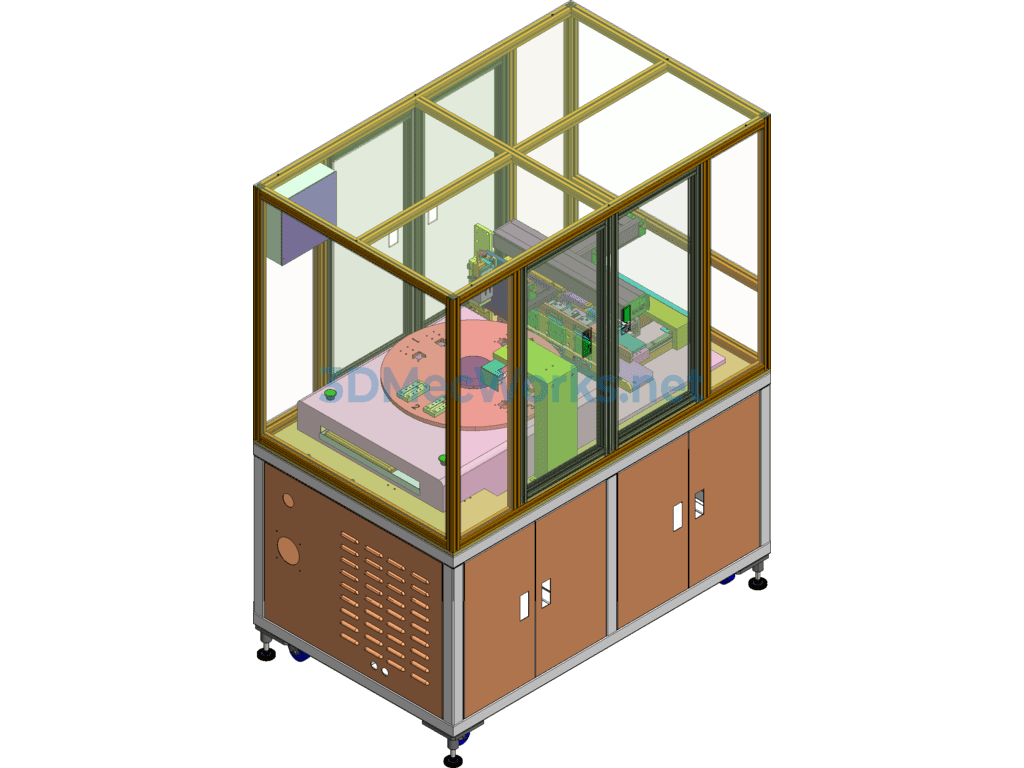

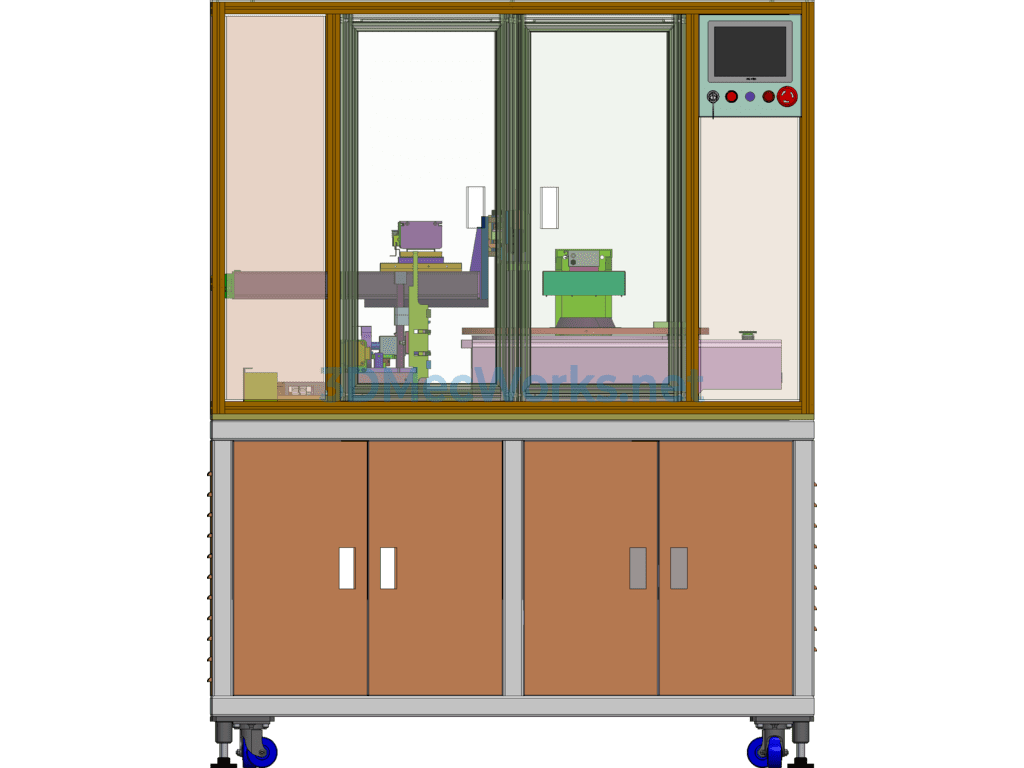

This equipment mechanism is designed using SW2016, featuring editable parts. It is mainly used for welding plastics such as PETG, TPU, PU, and various polyvinyl chloride containing 30% (PVC). Applications include: double blister vacuum packaging, blister with paper card heat sealing, upper and lower paperboard + blister heat sealing, foldable boxes, hardware tools, LED energy-saving lamps, toothbrushes, stationery, cosmetics, sandwich blister packaging, etc. It also automatically welds and trims plastic materials of various blister or clamshell shapes. It handles patterns of various concave and convex shapes, PVC cushions, sleeping mat heat sealing, and letter pressing. A precision indexer is used as a rotary drive device, with an automatic rotating disc worktable that rotates smoothly; a highly sensitive NL5557 spark protection device effectively suppresses sparks to prevent mold damage. The robot automatically feeds materials and extracts finished products, providing high-speed operation. The reinforced frame is PLC controlled with a human-machine interface touch screen operation, making it simple to operate. The equipment includes an automatic turntable high-frequency machine and a fully automatic turntable high-frequency machine with dual robots, offering fast welding speed and labor savings. It supports STP and UG universal editable formats.

Specification: Heat Sealing Automatic Equipment

|

User Reviews

Be the first to review “Heat Sealing Automatic Equipment”

You must be logged in to post a review.

There are no reviews yet.