Annika Haley

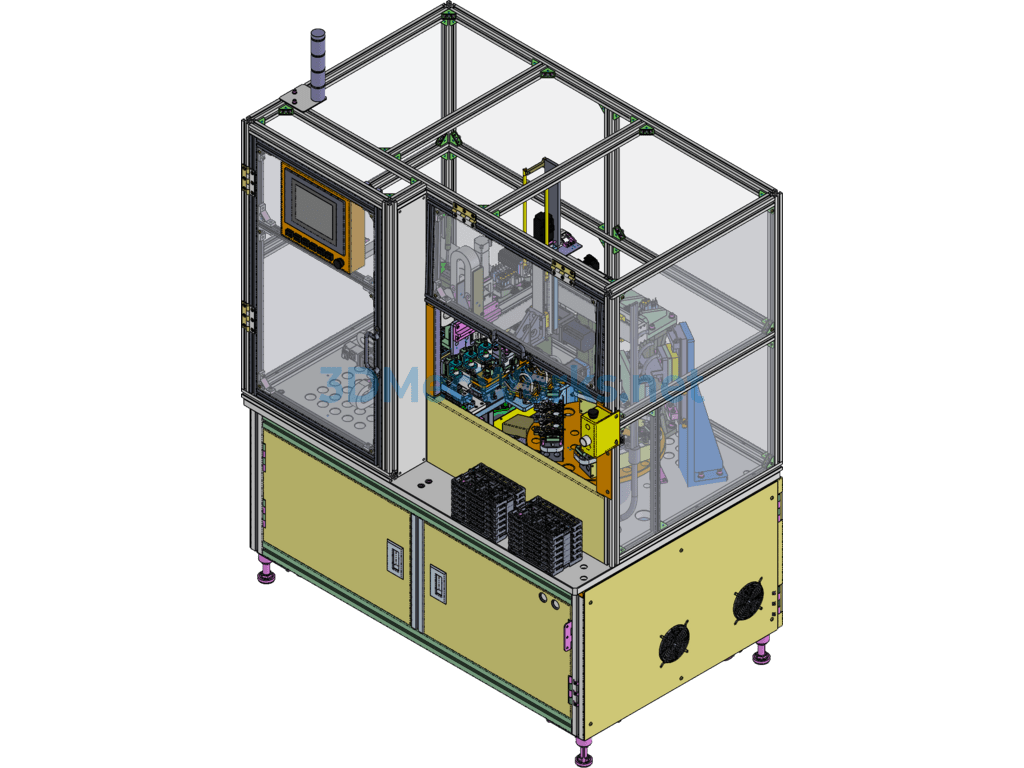

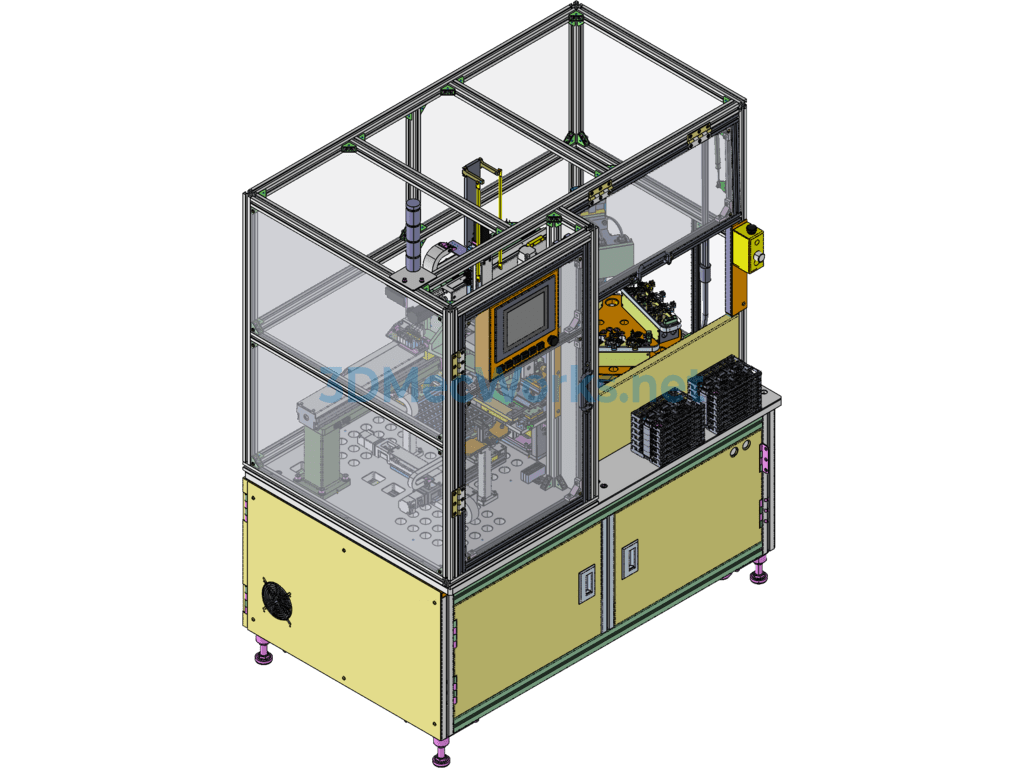

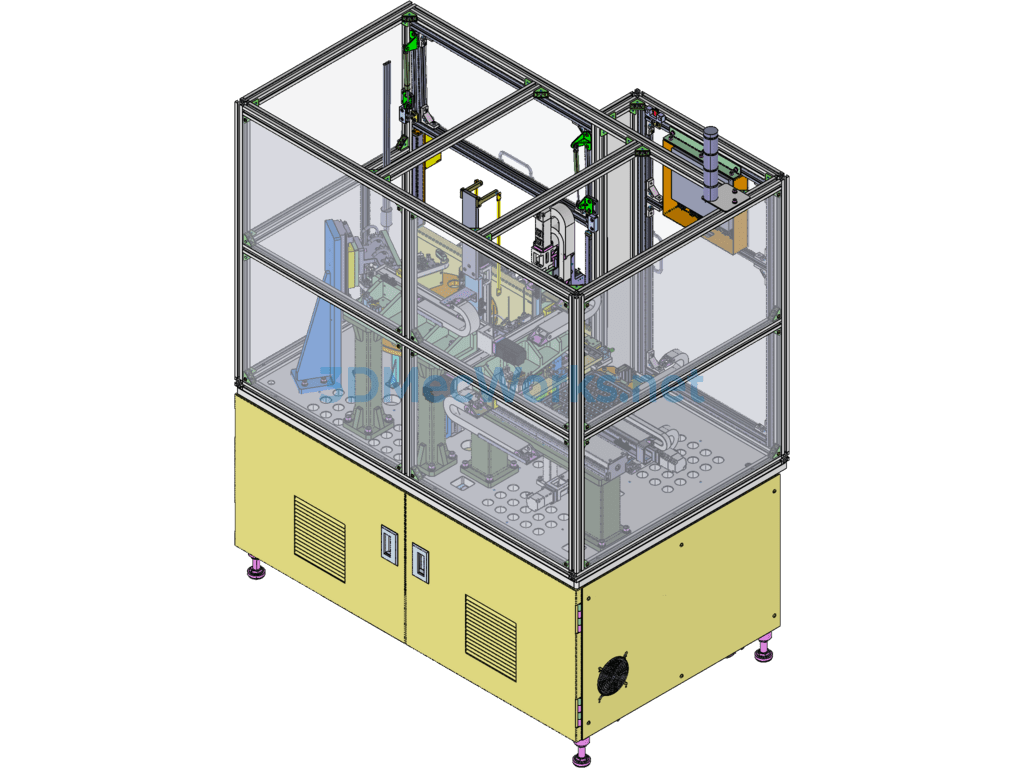

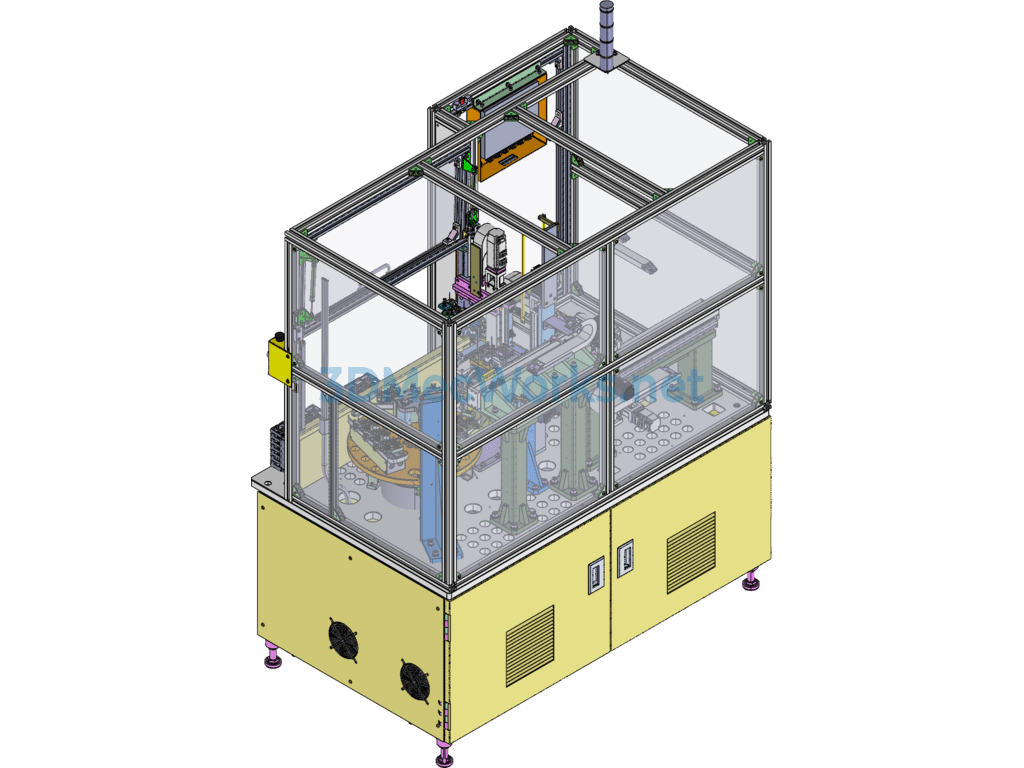

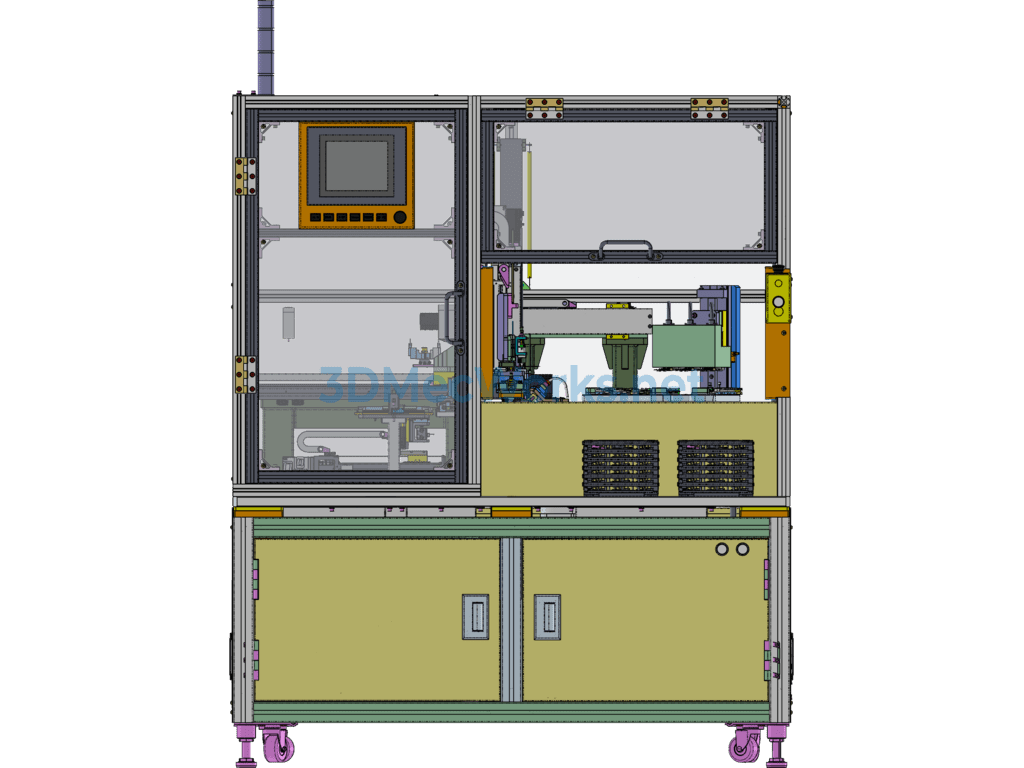

The function of the hard disk actuator arm bearing glue application machine is to evenly coat a layer of UV glue around the outer wall of the bearing, then press the bearing into the installation hole of the hard disk actuator arm bearing, and finally cure the glue with ultraviolet light. The incoming bearings are in blister boxes. Since the blister boxes are relatively soft and the material position is unstable, the pre-positioning component first clamps the bearing in place, and the suction nozzle then picks up the bearing and moves it to the glue application station. At the glue application station, the bearing rotates while the glue is being applied. After the glue is applied, another suction nozzle picks up the bearing and moves it to the pressing station, where the bearing is pressed into the actuator arm. Finally, it undergoes UV light curing. After completion, materials are manually loaded and unloaded.

Specification: Hard Disk Actuator Bearing Adhesive Application Machine

|

User Reviews

Be the first to review “Hard Disk Actuator Bearing Adhesive Application Machine” Cancel reply

You must be logged in to post a review.

There are no reviews yet.