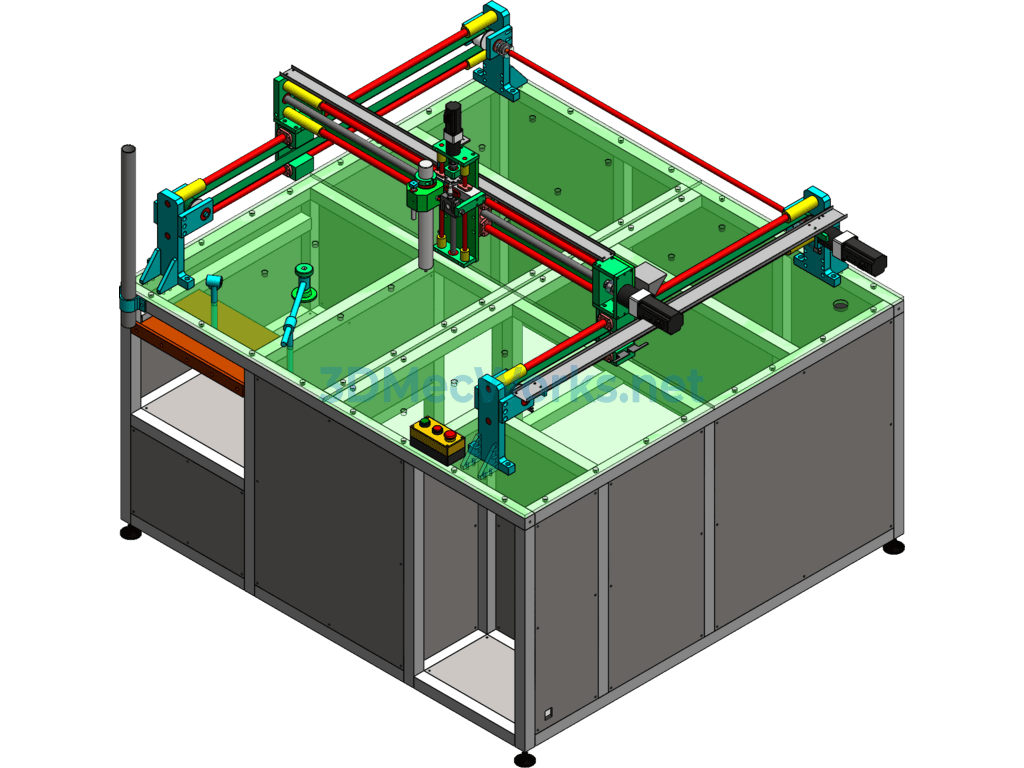

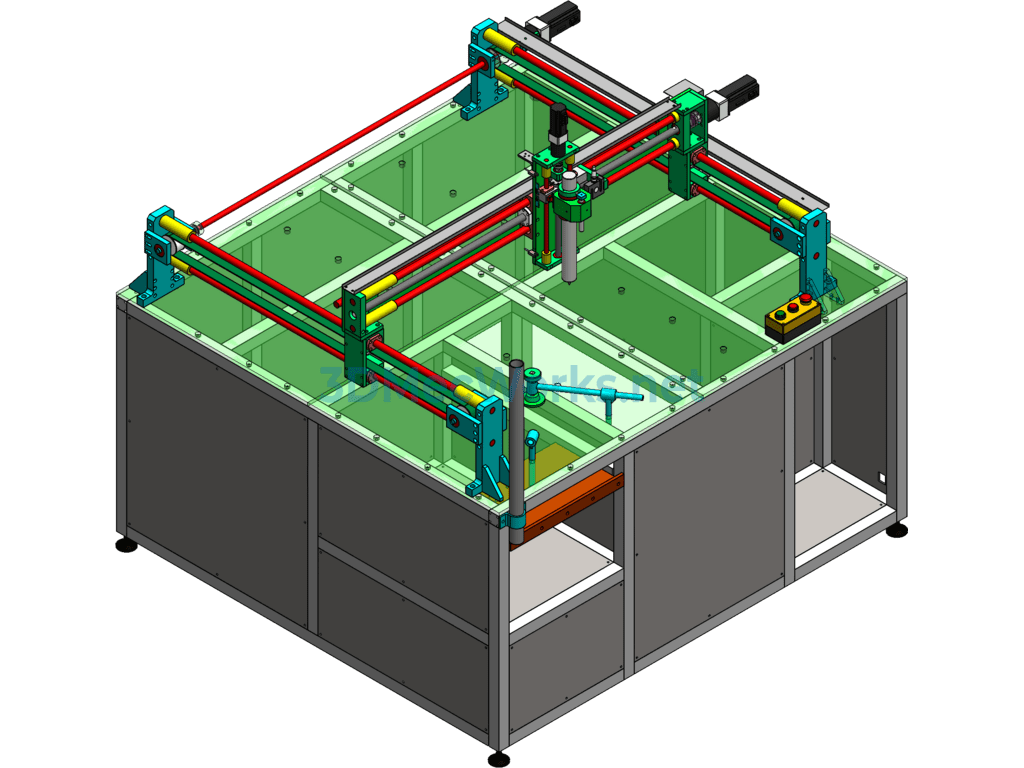

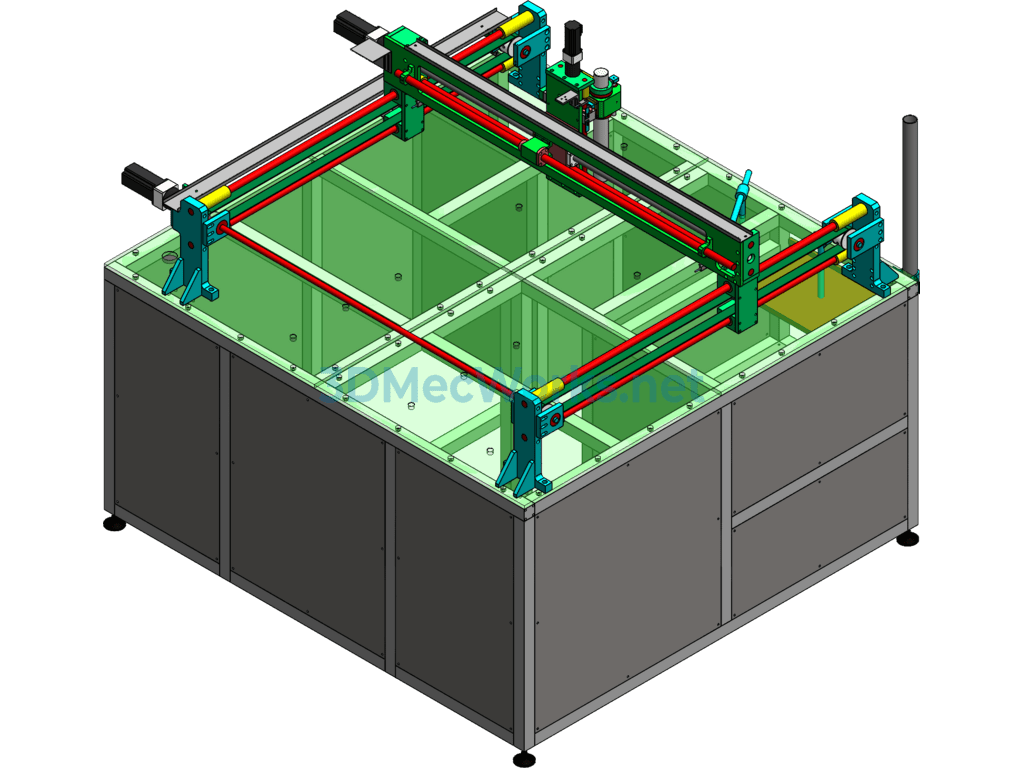

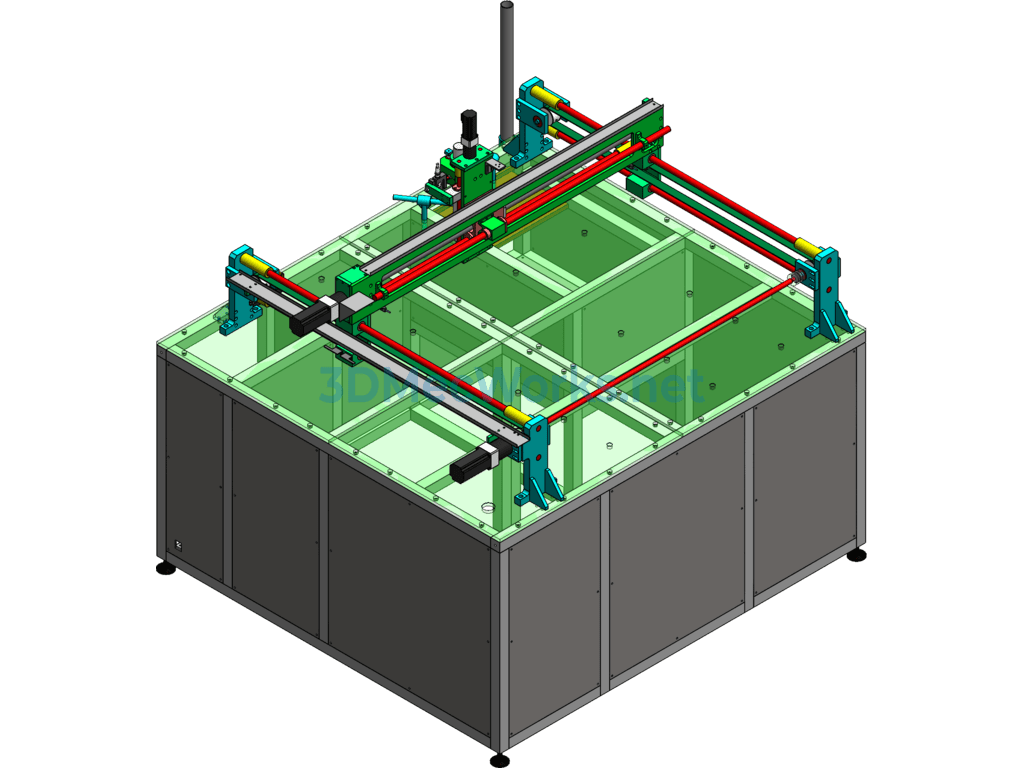

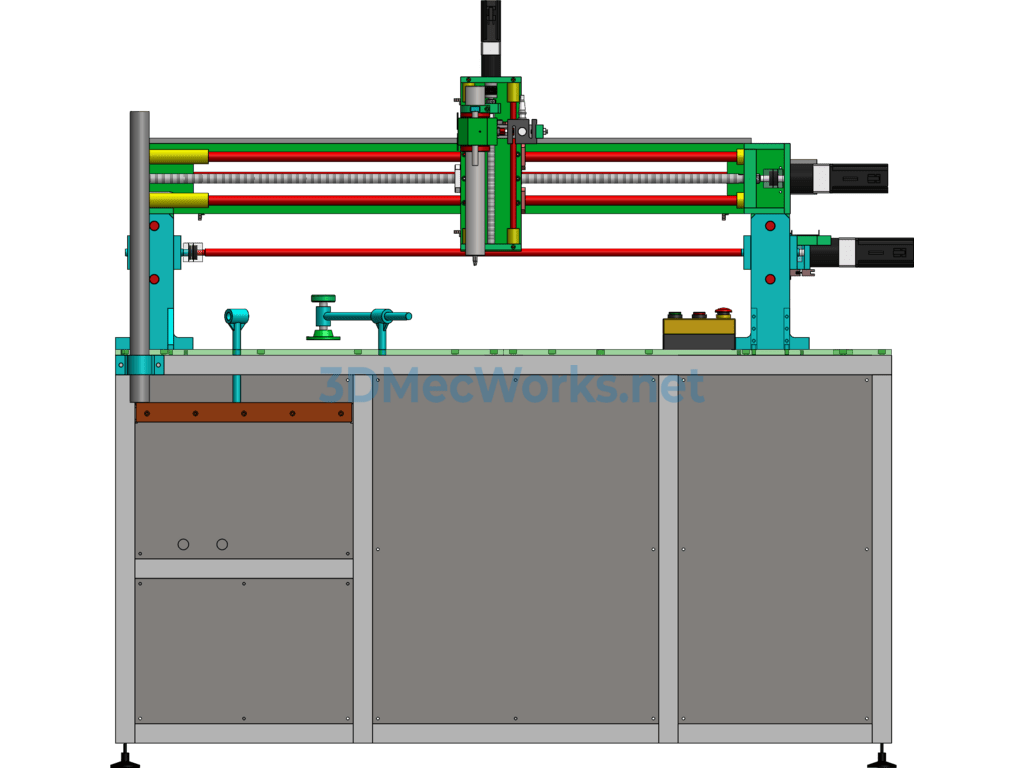

A highly functional gantry-type three-axis non-standard scratch testing machine 3D model. This equipment is used for testing the surface hardness of copper tubes in refrigerators’ condensers. An alloy steel scraper is installed on the Z-axis, which descends to the surface of the copper tube. The front and rear axes begin to move slowly, creating scratches on the copper tube. The depth of the scratches is used to determine the pass/fail status. This equipment is controlled by an industrial computer, with all driving systems using servo motors and planetary gear reducers. The Z-axis and left and right axes use screw rods, while the front and rear axes use timing belts, featuring a classic design for transmission and driving mechanisms. The drawings are complete and can be directly used for manufacturing physical equipment. The parameters can be edited, with the format being SW2010. Welcome to download for reference.

Scratch Needle: As shown in Figure 102 of GB4706.13, the design includes a mechanism that follows the contour changes of the tested sample.

Control System: Consists of an industrial computer, driver card, data acquisition device, etc., to achieve program-controlled actions for the X, Y, Z three axes, fully automatically completing unidirectional sequential scratch actions.

Sensors: Vertical force: 35N±3N; Parallel force: <250N, using sensors to display, monitor, and store data over time.

Sliding Rate: Achieved through servo motors and large-ratio gear reducers, ensuring smooth and reliable operation at 1mm/s, with adjustable speed.

The drawings include 3D model SW source files + some CAD drawings + BOM list.xls + materials list.xls. Welcome to download.

Specification: Gantry-Style Three-Axis Module Scratch Non-Standard Testing Machine

|

User Reviews

Be the first to review “Gantry-Style Three-Axis Module Scratch Non-Standard Testing Machine”

You must be logged in to post a review.

There are no reviews yet.