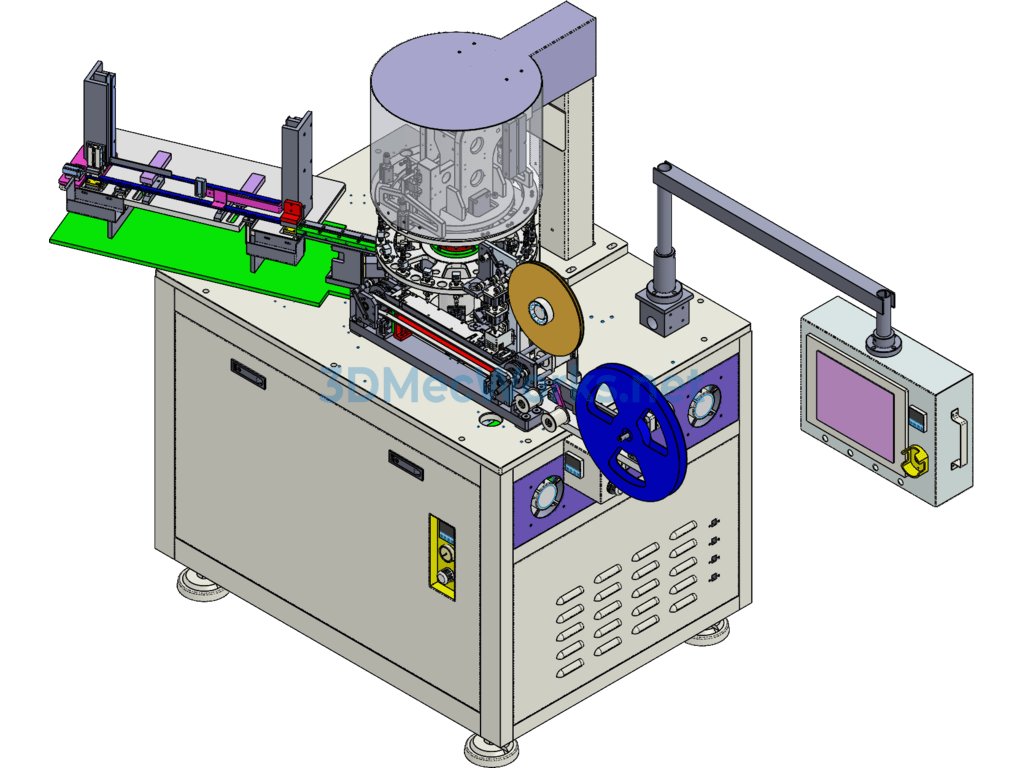

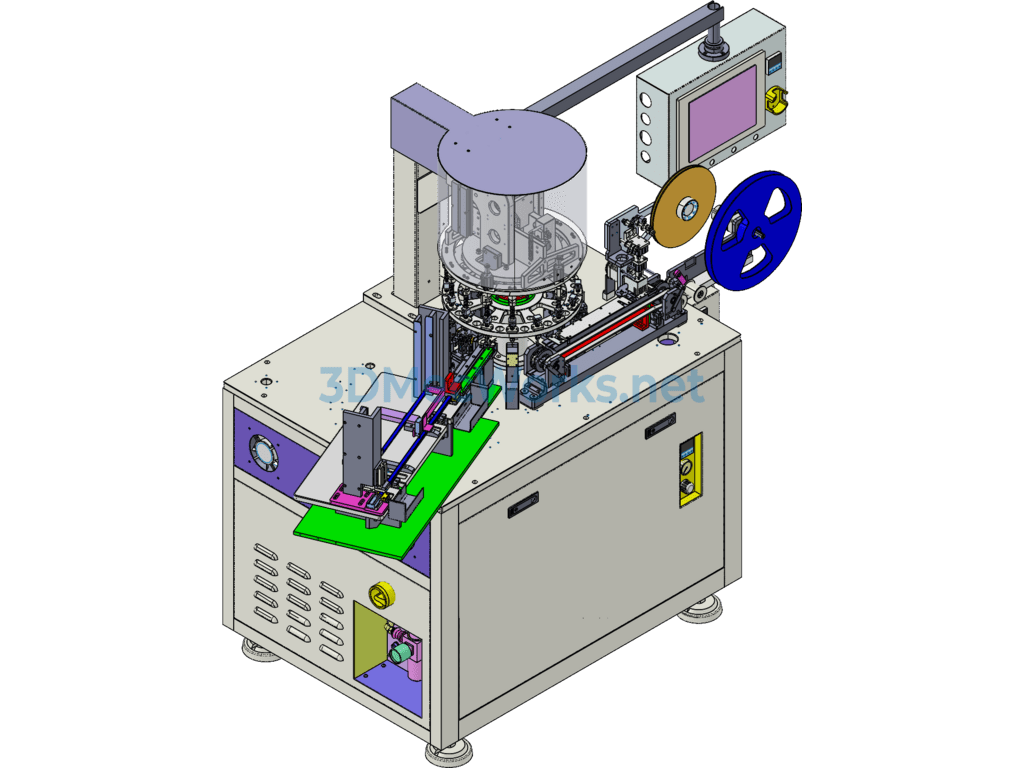

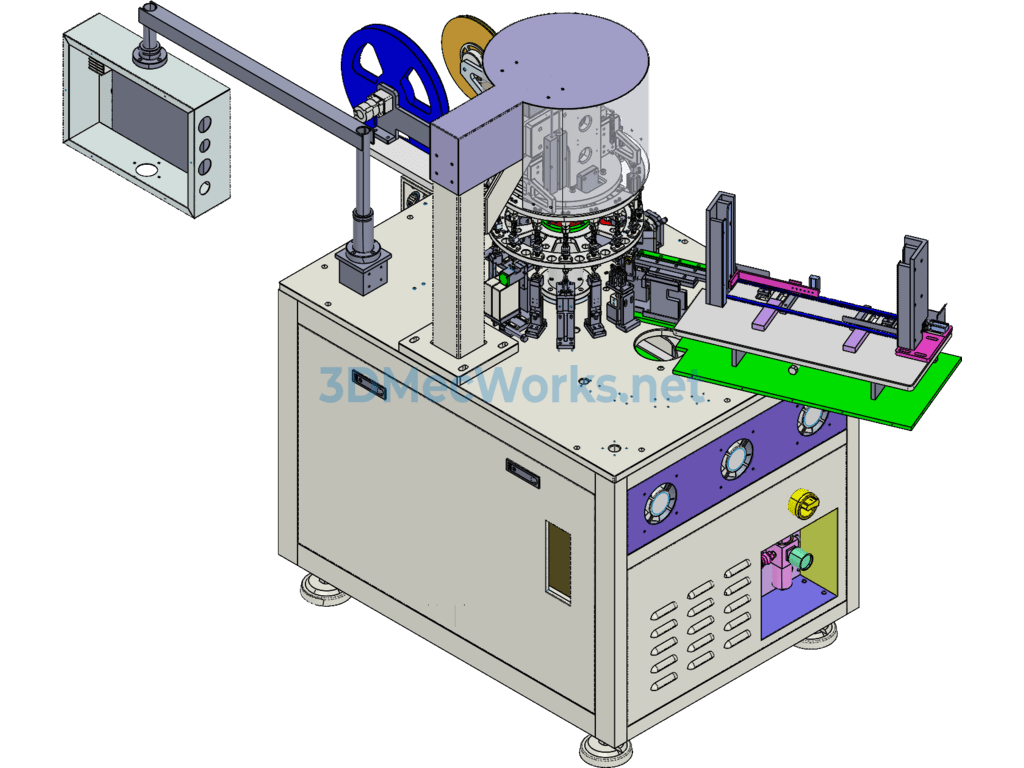

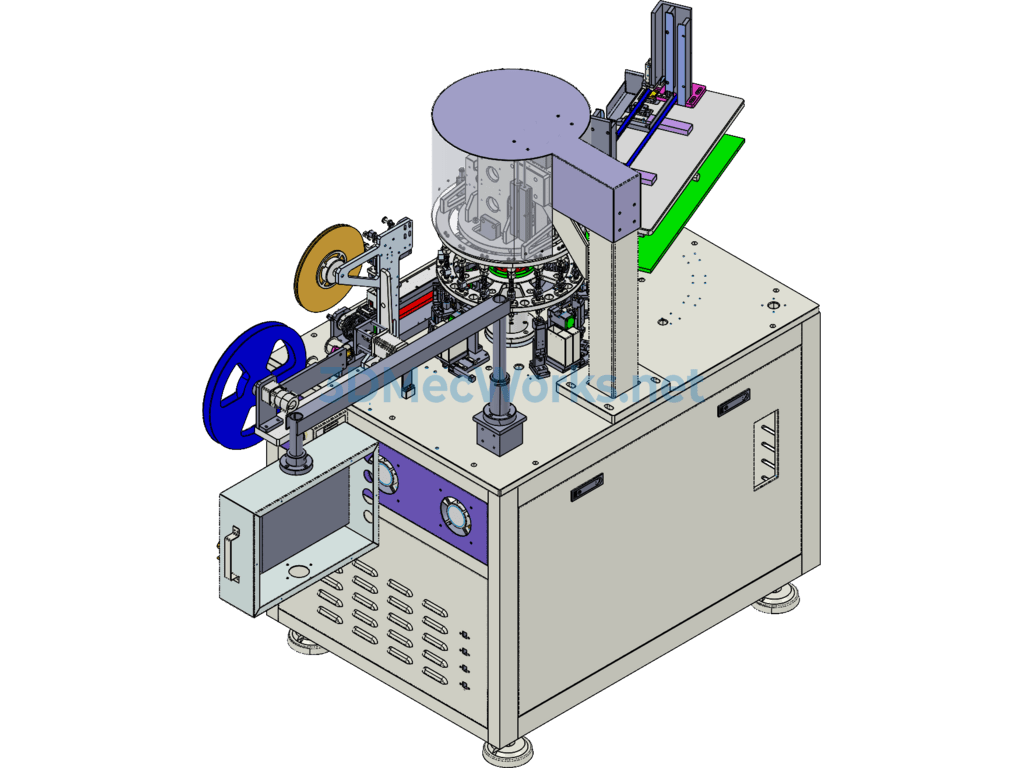

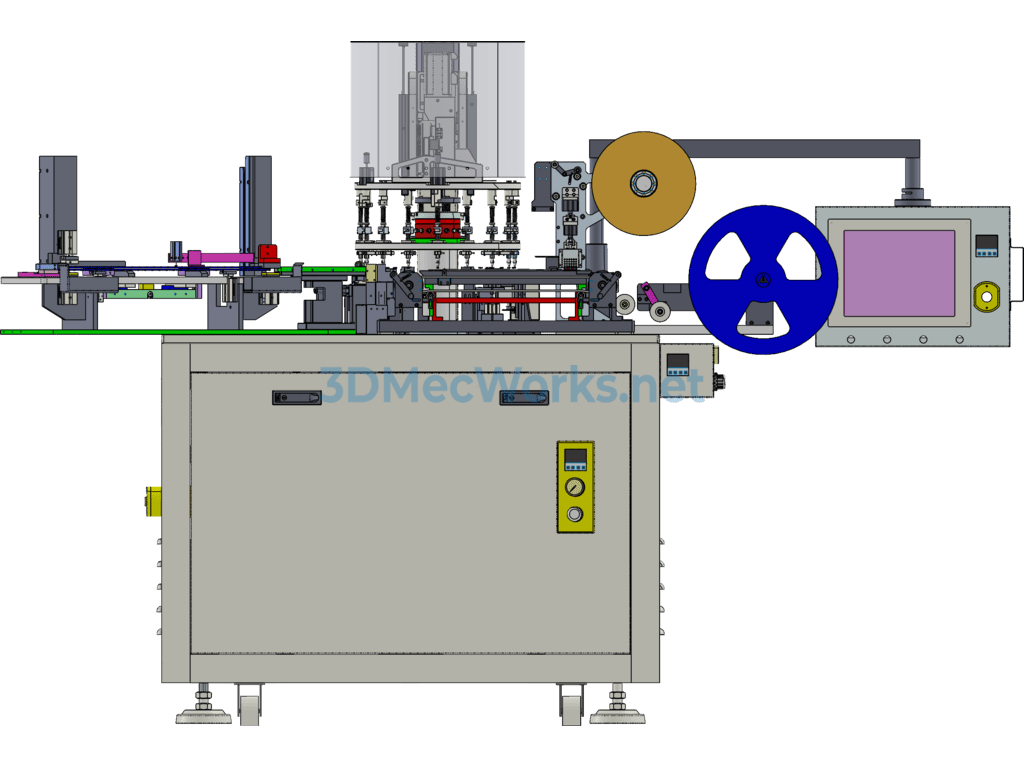

The fully automatic taping machine, designed with PROE5.0, is an integrated device for inductance taping and testing NG sorting. This set of drawings is a complete 3D model, applied to the testing, sorting, and packaging of components such as SMD, inductors, IC, SOP8, SOP1015, and LEDs. The feeding method is tube type stacking, followed by cylinder pushing out one tube for feeding; the feeding mode is air-blow type, and the feeding speed is very fast. The assembly drawing is: qbd20-000000.asm, and both parts and assembly drawings are complete and editable with parameters! STEP documents are also provided to meet the reference needs of most technicians.

The fully automatic taping machine, also known as the inductor automatic taping packaging machine, has main functions such as testing polarity, testing inductance, testing NG, and testing withstand voltage. This is a very complex drawing, especially the middle rotating disk part, which has 16 suction nozzles. Each nozzle must be responsible for sucking products, and after reaching the designated station, it must release the vacuum. The design of the middle vacuum distribution disk structure is also very ingenious, achieving suction and blowing at different workstations. There are many testing stations, correction stations, rotating stations, etc., at the bottom. Interested friends are welcome to download, and other drawings are available on the homepage.

Specification: Fully Automatic Taping Machine, Multifunctional Integrated Machine for Inductor Taping, Testing, and Ng Sorting

|

User Reviews

Be the first to review “Fully Automatic Taping Machine, Multifunctional Integrated Machine for Inductor Taping, Testing, and Ng Sorting”

You must be logged in to post a review.

There are no reviews yet.