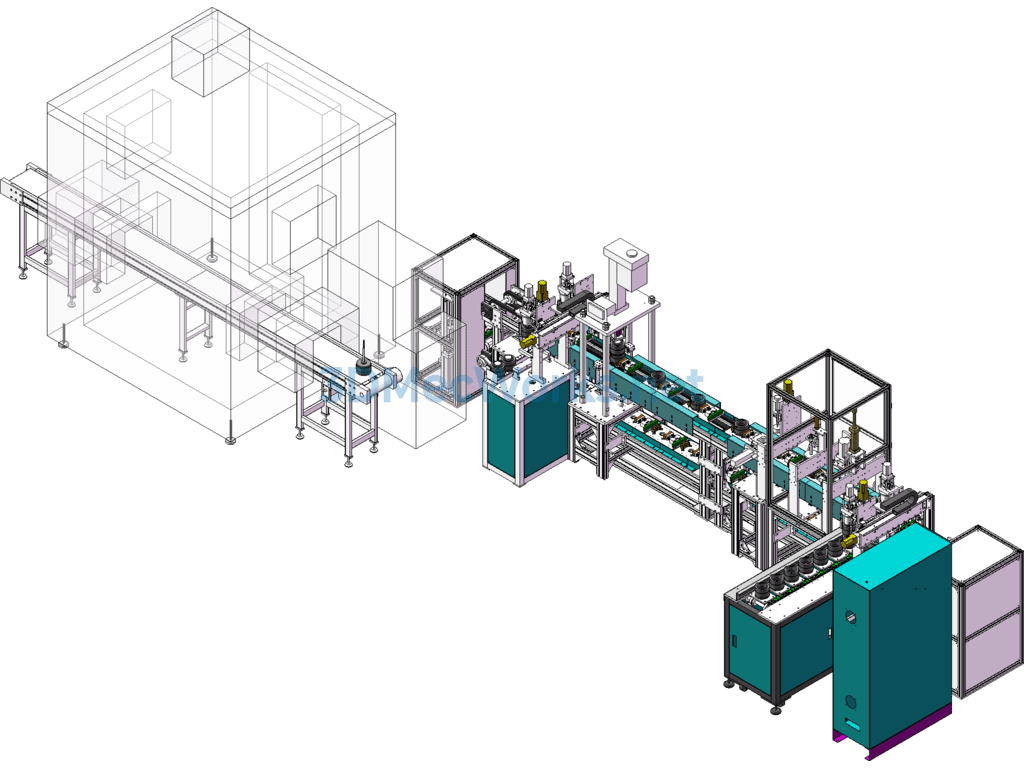

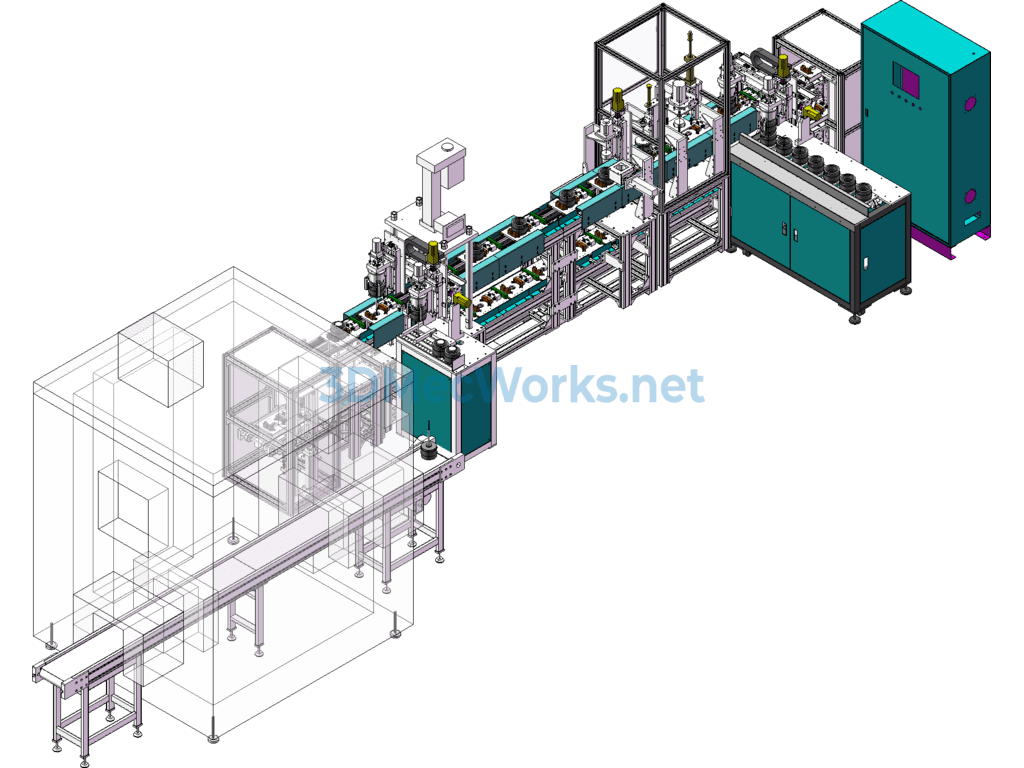

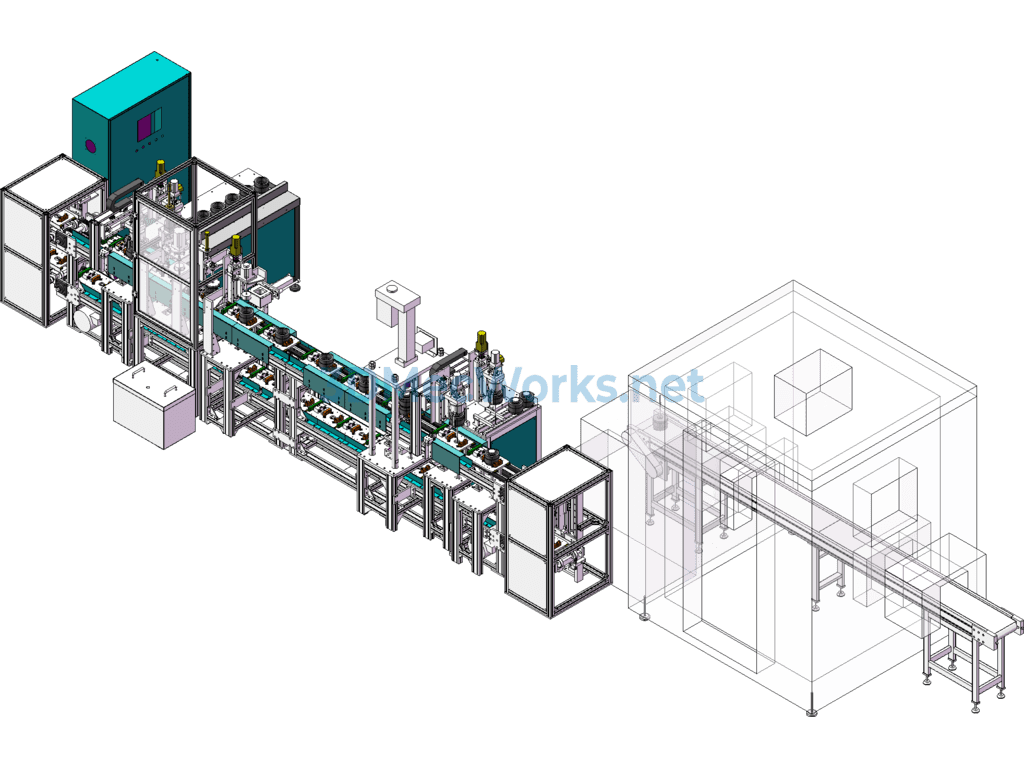

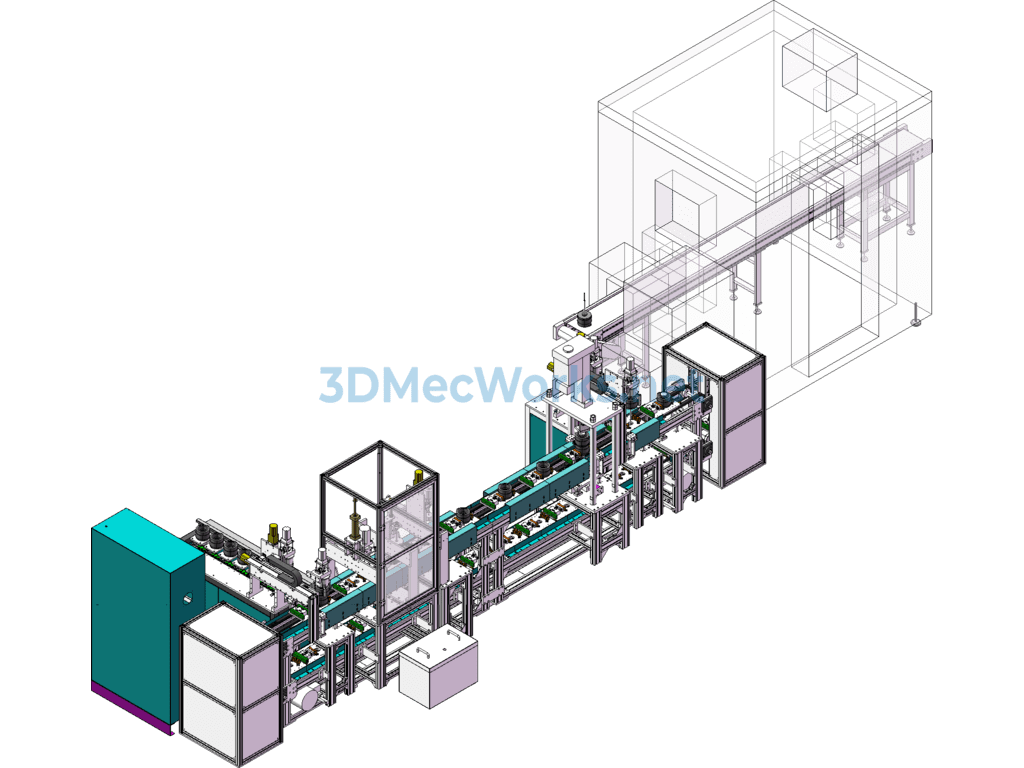

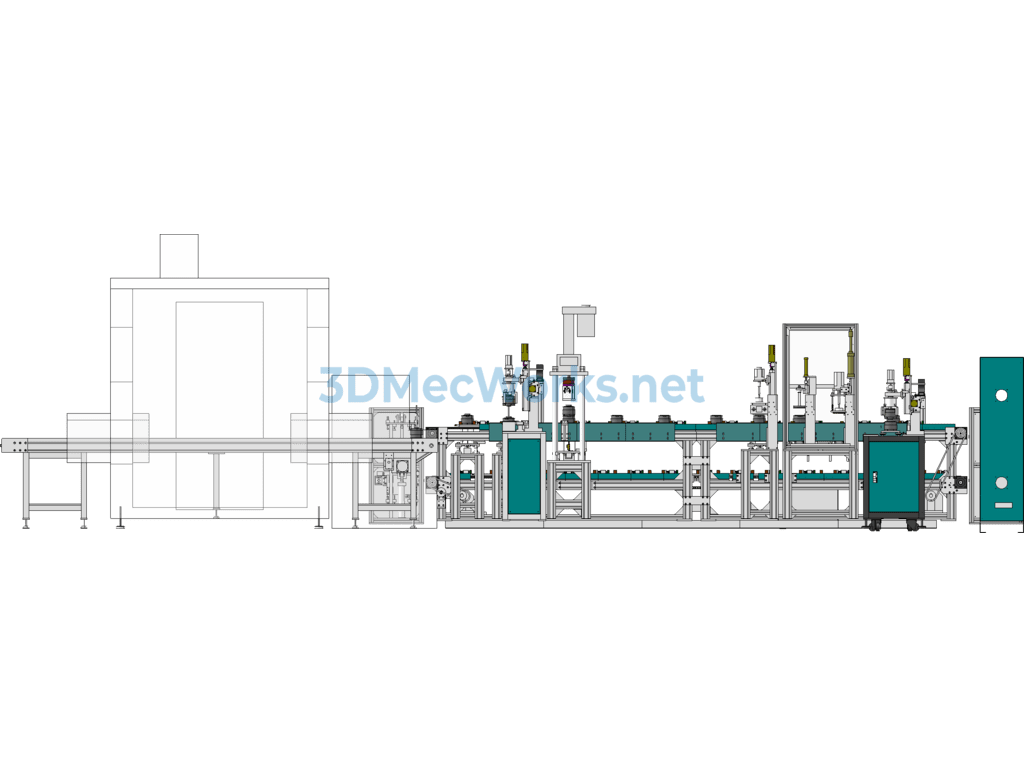

Fully automatic stator shaft assembly line, this model includes engineering drawings and a BOM list, and is a large customized assembly line for automated non-standard assembly of various complex parts.

The working principle and sequence of the non-standard automatic production line’s fully automatic stator shaft assembly line:

A. The special tooling plate enters the tooling plate stacking area from the lift platform.

B. When the tooling plate for placing the BMC stator is empty, the tooling plate enters this station from the stacking area. (The stopper blocks the tooling plate, and the tooling plate stops, similarly below.) The robot places the BMC stators (2 sets in total) into the corresponding positions on the special tooling plate, the foot switch is pressed, the tooling plate descends, and enters the next stacking area.

C. When the stations for placing the rotor, PG board, and BB cover are empty, the tooling plate automatically enters this station, and then the foot switch is pressed, and the tooling plate automatically moves to the next station’s temporary storage area.

D. When the station for pressing the BB cover is empty, the tooling plate automatically enters this station, automatically presses the BB cover checks for shifting amount, etc., and after pressing, the foot switch is pressed, and the tooling plate automatically moves to the next station for temporary storage.

E. When the performance testing station is empty, the tooling plate automatically moves to this station, and performance is manually tested. After the performance testing is completed, the foot switch is pressed, and the tooling plate automatically moves to the tooling plate lift platform stacking area.

F. Execute the next cycle.

3. The total length of the line is 5 meters (including the lift platforms at both ends) (subject to actual design), the total width is 300mm (subject to the designed dimensions) (excluding the protruding parts of the lift platforms at both ends), the upper layer includes a tooling plate height of 800 mm (subject to actual design), and the height between the two layers is 400 mm (subject to actual design). The height of the line’s support frame is adjustable, with a range of ±30mm.

4. The line adopts a double-layer return plate structure, with the upper layer used for motor transmission and the lower layer for quick return of tooling plates.

a. The line is driven by roller chains; using independent power.

Specification: Fully Automatic Stator Shaft Assembly Line, Large Custom Assembly Line

|

User Reviews

Be the first to review “Fully Automatic Stator Shaft Assembly Line, Large Custom Assembly Line”

You must be logged in to post a review.

There are no reviews yet.