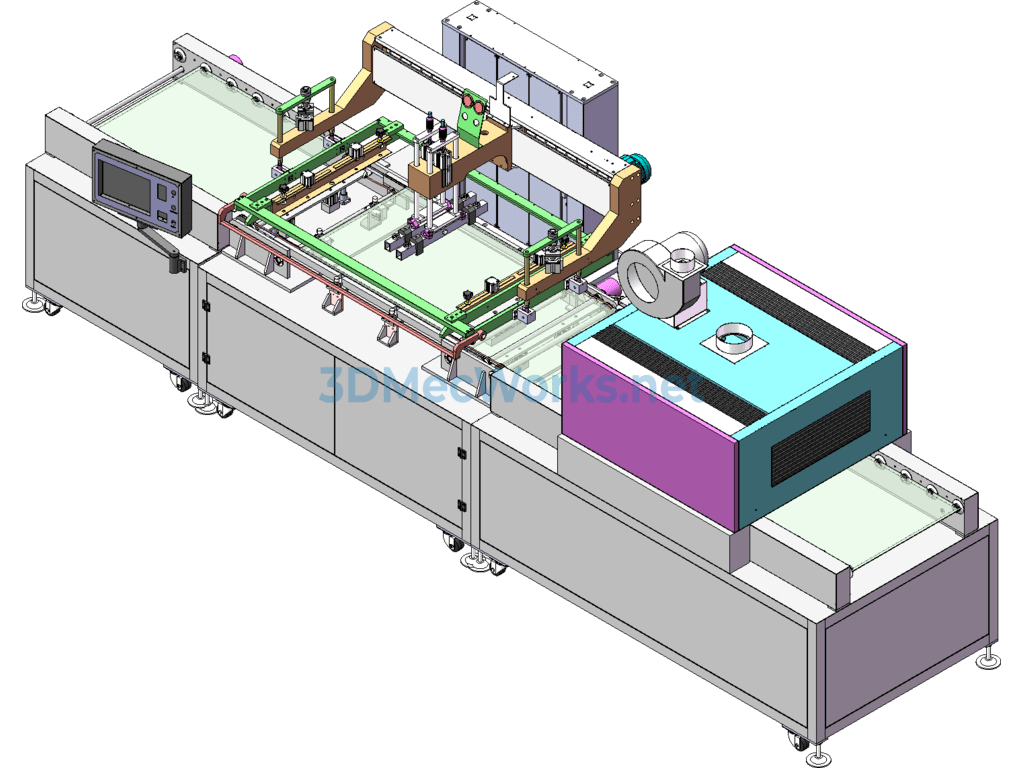

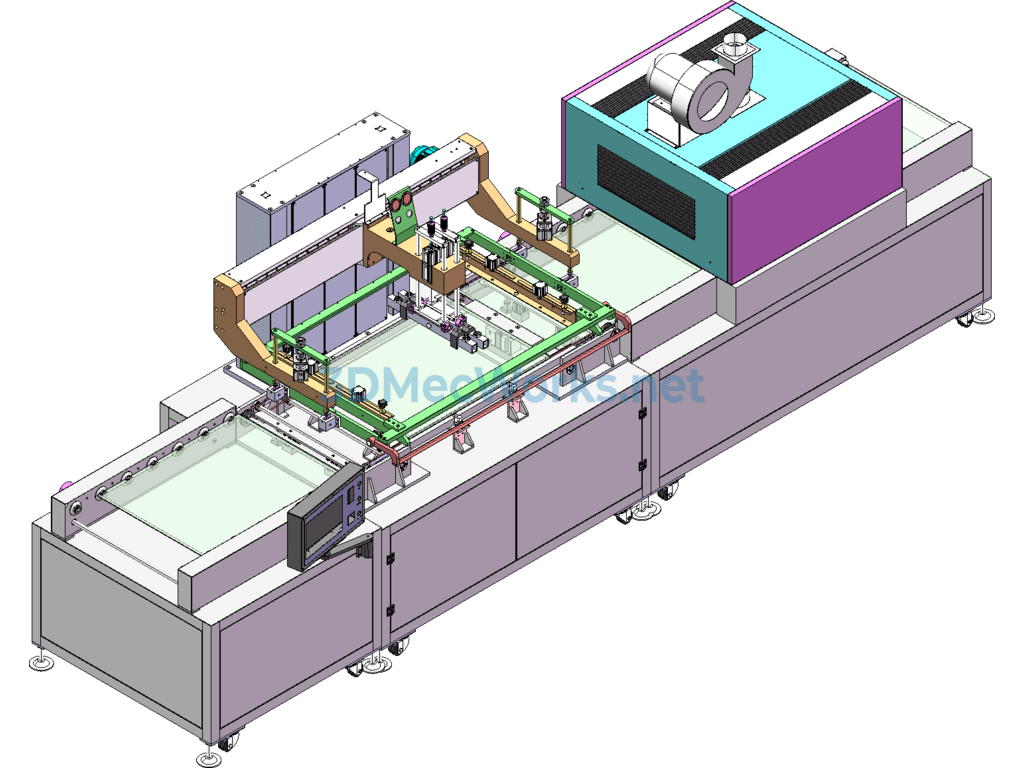

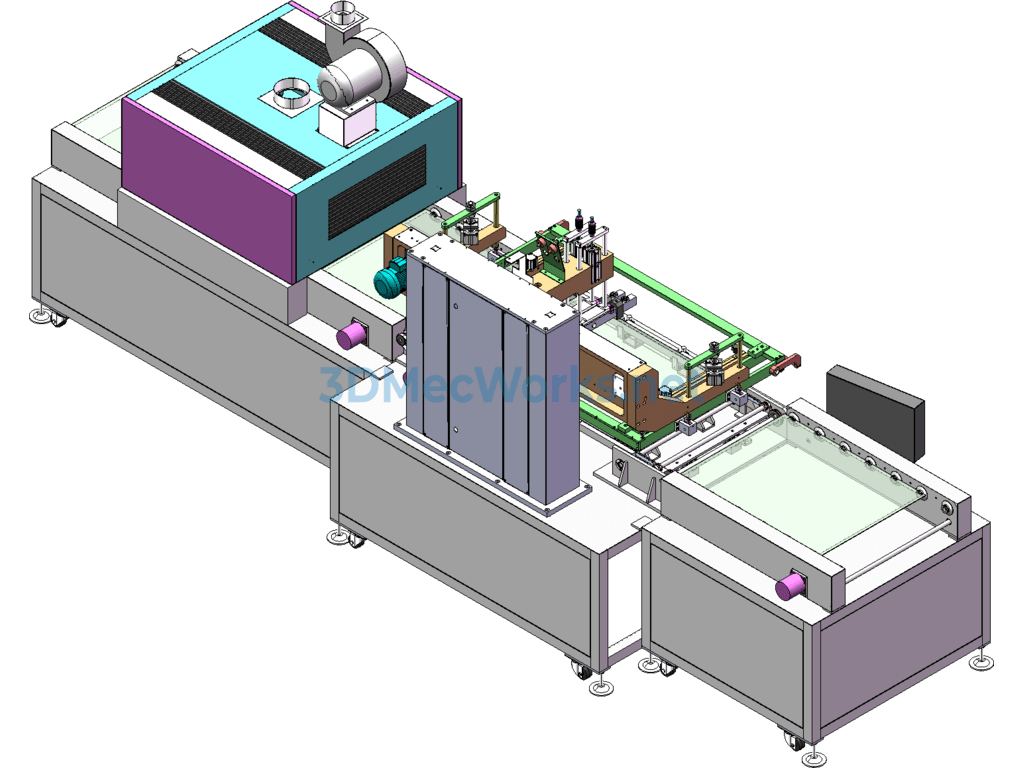

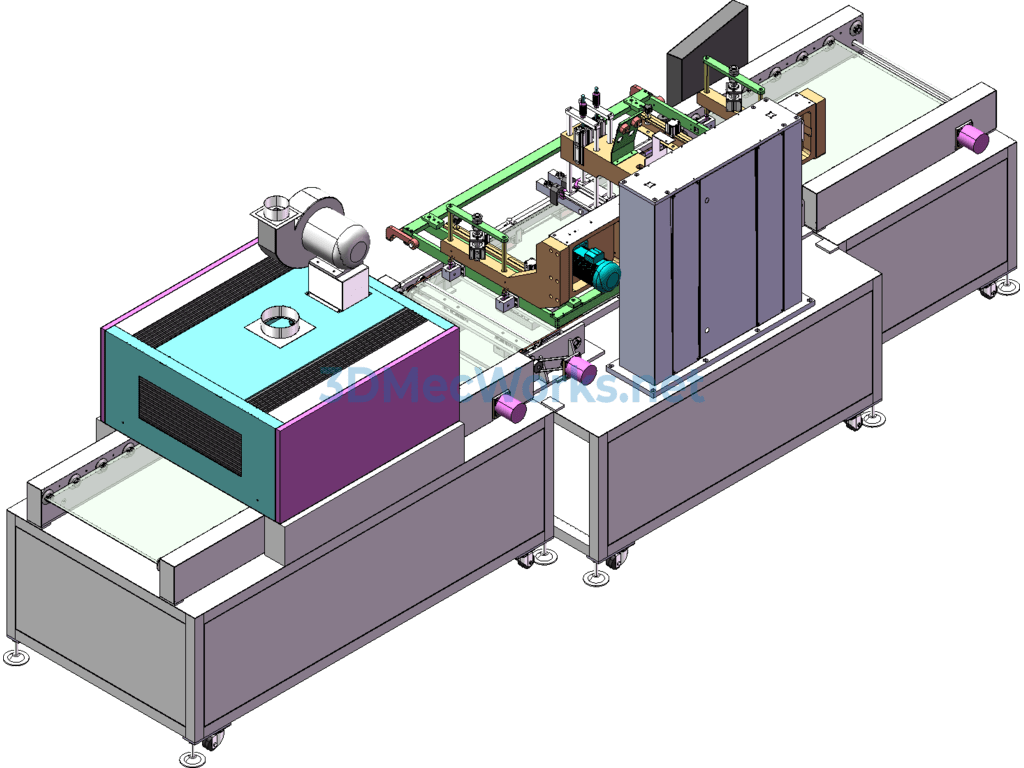

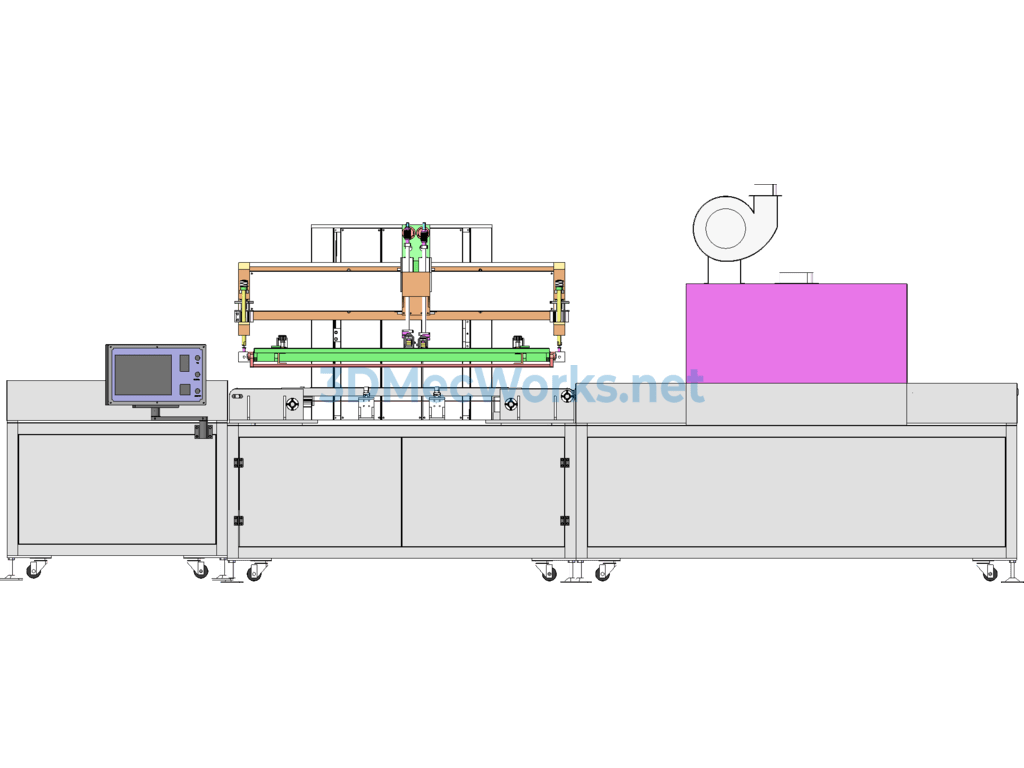

Full automatic screen printing machine 3D model, full automatic screen printing machine, maximum printing area 800*600, the main features of the equipment are 360° stopped rotary drum, ultra-high printing precision; LCD human-machine interface; 4-9mm adjustable mesh (mesh plate and drum mesh distance); pull-out mesh plate frame, which makes it easier to check the paper feed status and clean the mesh plate; PLC controlled centralized lubrication oiler to ensure the lubrication of the transmission part, reducing the wear and tear of key parts and extending service life; photoelectric full monitoring of empty and misaligned sheets during the printing process, effectively reducing scrap rate. Process flow: raw materials — automatic feeding (double-sided dust removal, film peeling, static elimination) — automatic printing (punching positioning holes, inspection lamp) — automatic baking and winding (automatic varnishing, protective film, tape adhesion, release paper, etc.) — subsequent processes can achieve automatic die-cutting — finished product. Full automation requires only 1-2 people to operate, a full set of automation requires only 15-20 square meters. Design plan for the full automatic screen printing machine included.

Specification: Fully Automatic Screen Printing Machine

|

User Reviews

Be the first to review “Fully Automatic Screen Printing Machine”

You must be logged in to post a review.

There are no reviews yet.