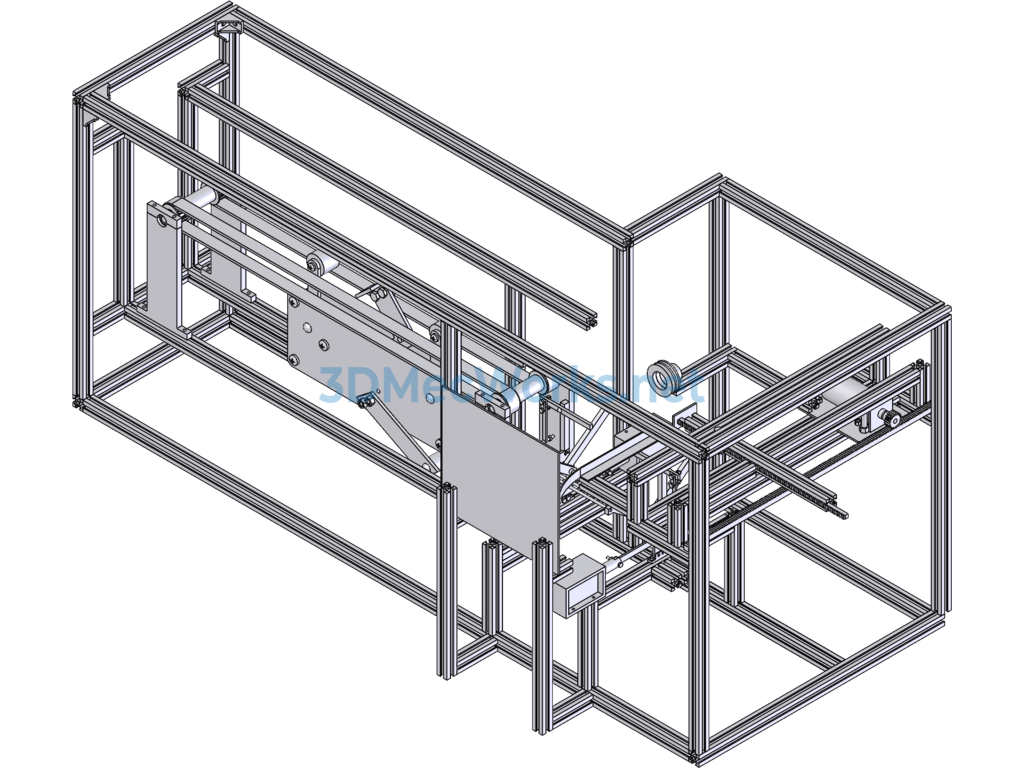

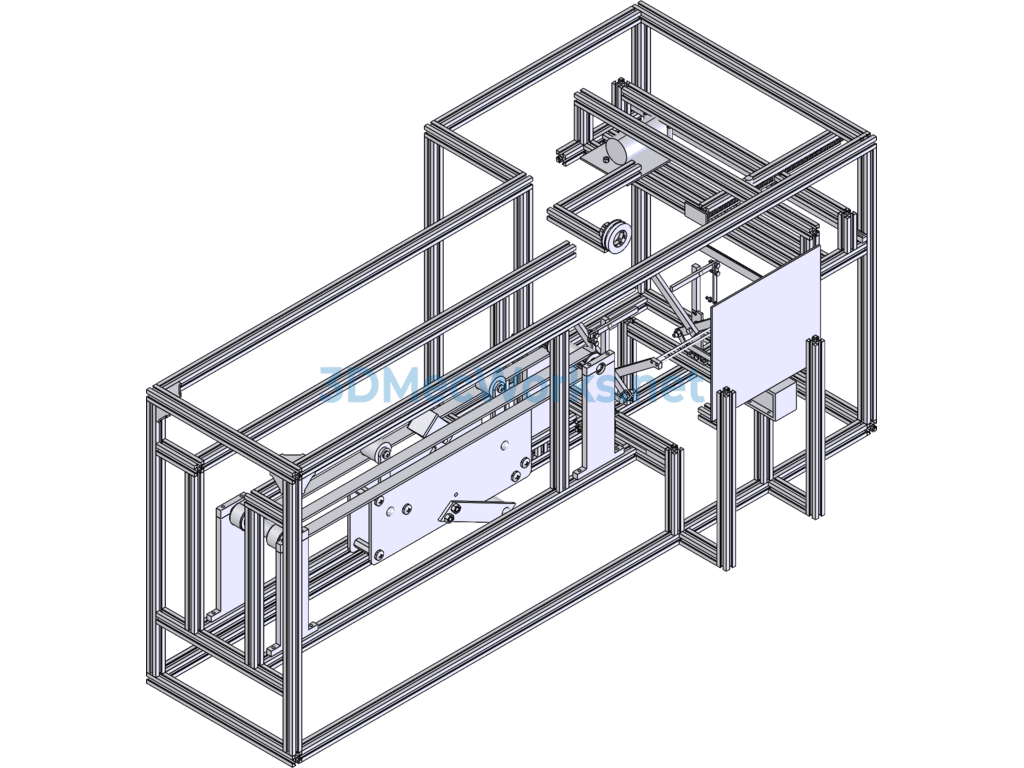

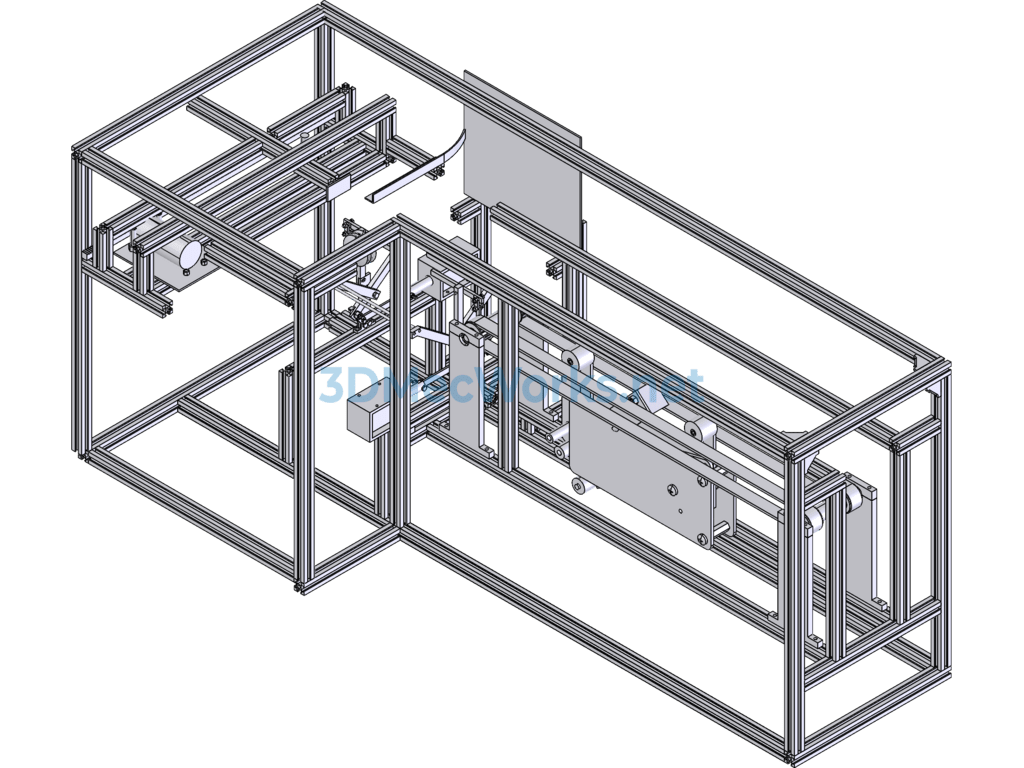

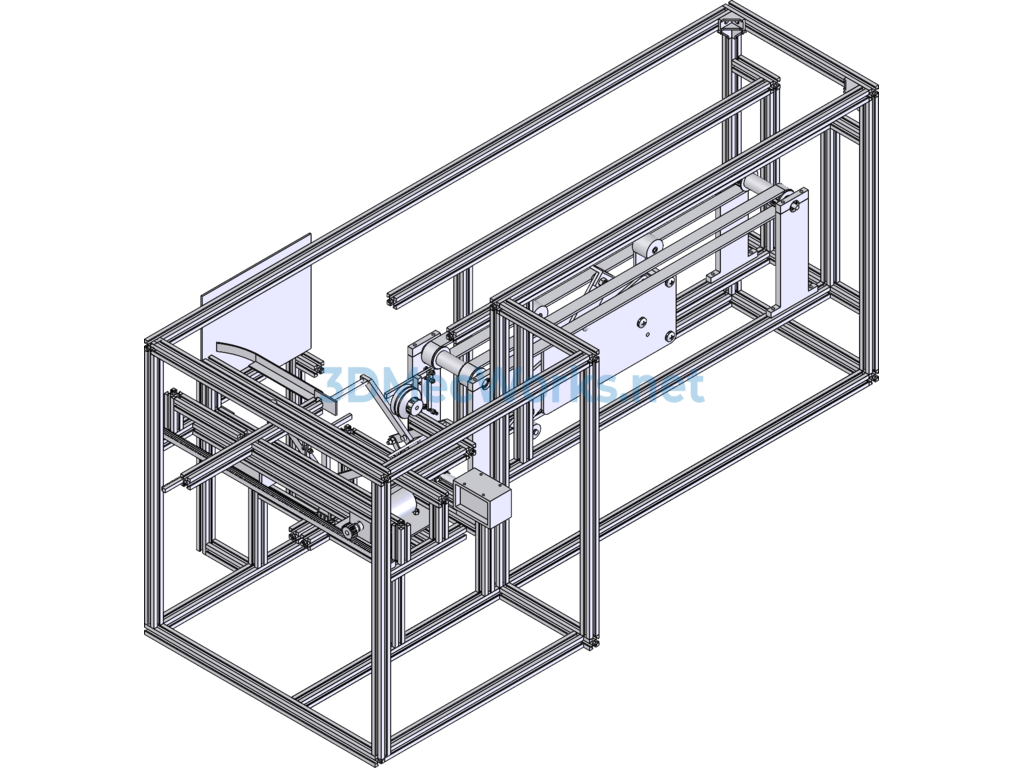

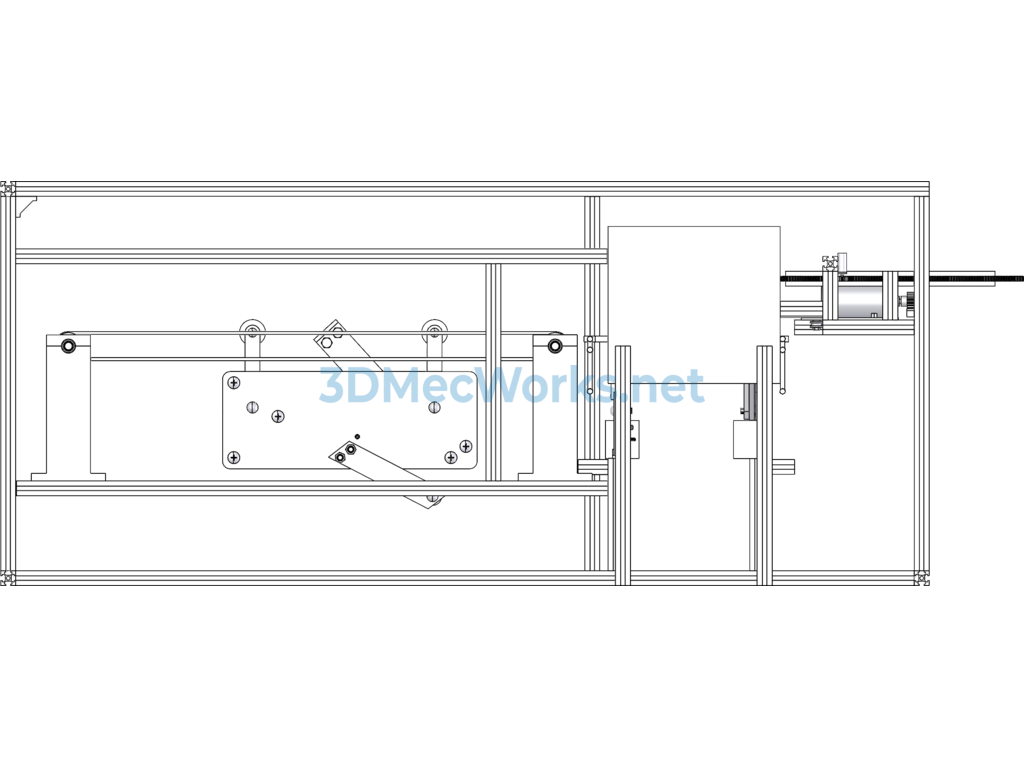

The works I designed are mainly manufactured using aluminum materials. This not only reduces production costs but also improves production efficiency. The model uses three mechanisms to simulate the process of a carton from a compressed state to adhering to the bottom surface, which are the suction mechanism, the turning mechanism, and the adhesive application mechanism.

The suction mechanism first expels air to adhere to one side of the cardboard, then uses a motor to drive a rack and pinion mechanism to open the cardboard. Next, a small motor drives another rack and pinion mechanism to send the opened cardboard to the turning mechanism.

The turning mechanism begins to work by using electromagnets on both sides in the Y direction to drive a linkage mechanism, which strikes the lower edge panels of the cardboard, making the skirt panels level. Subsequently, the electromagnets on both sides in the X direction are also energized, functioning similarly to the Y direction electromagnets, thus closing the front and rear skirt panels to a horizontal state. Then, Motor 2 starts to work, using a rack and pinion mechanism to output a rack, thereby pushing the folded carton toward the adhesive application mechanism.

The adhesive application mechanism begins to work, with a motor driving a pulley system. The transparent tape is adsorbed in reverse onto a roller, as the belt drives the carton forward and applies the transparent tape to the bottom surface of the carton. When the carton passes through the adhesive application mechanism, the tape is cut short using a heating wire, completing the taping of a single carton.

Specification: Fully Automatic Rigid Board Packaging Machine

|

User Reviews

Be the first to review “Fully Automatic Rigid Board Packaging Machine”

You must be logged in to post a review.

There are no reviews yet.