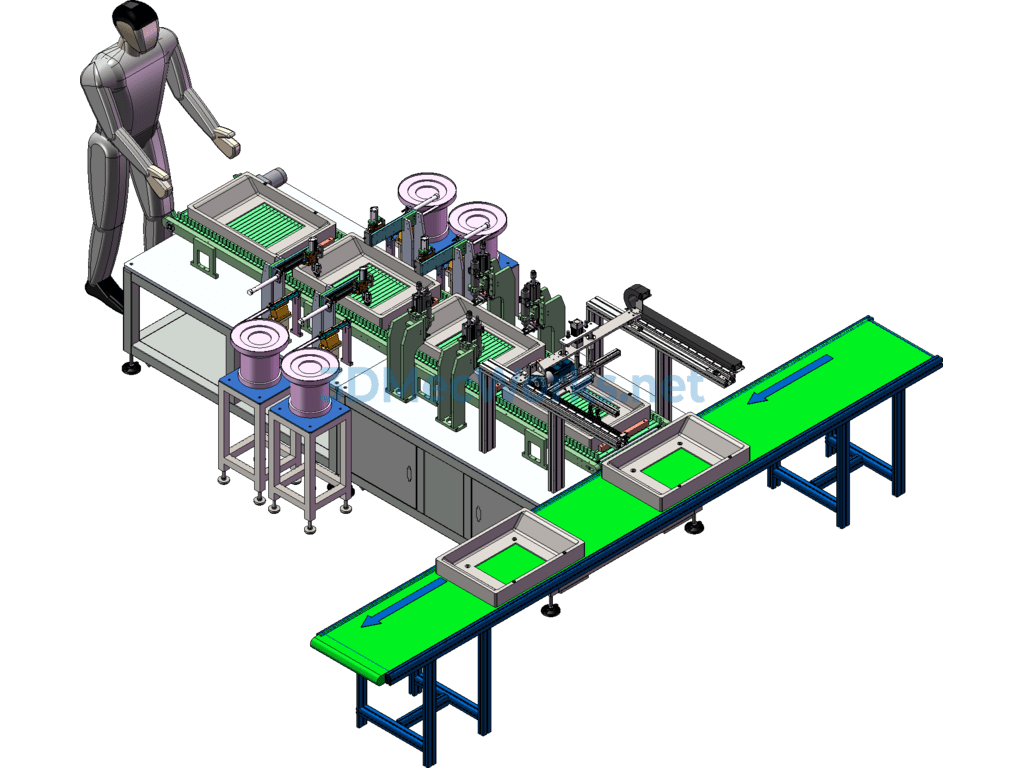

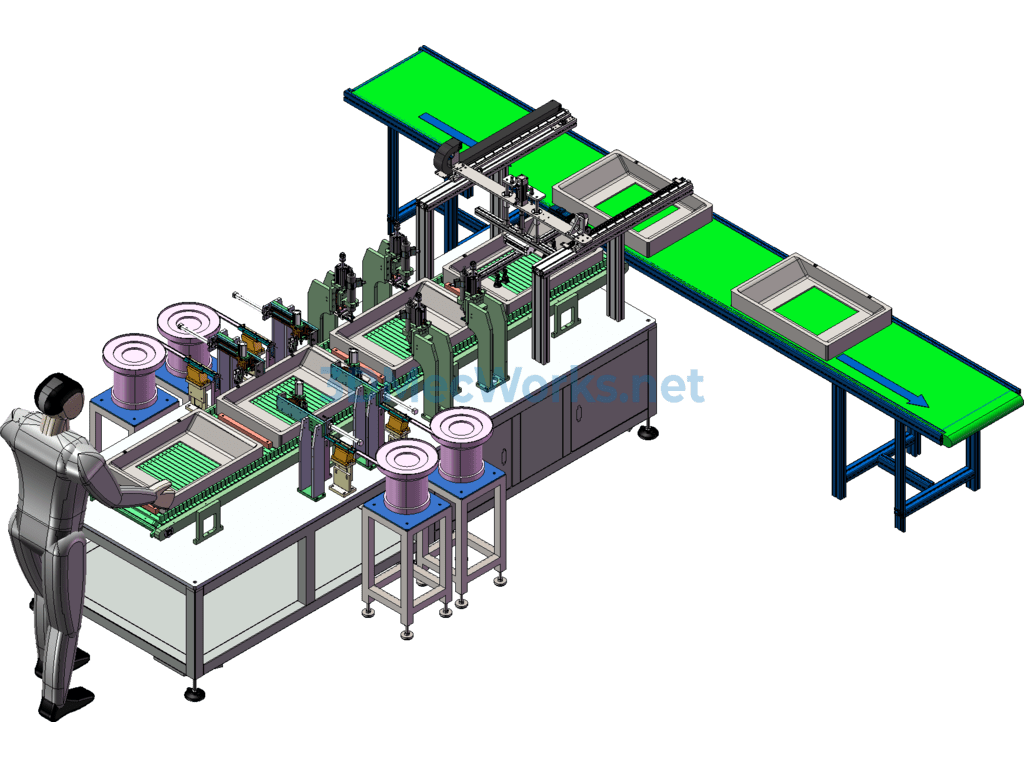

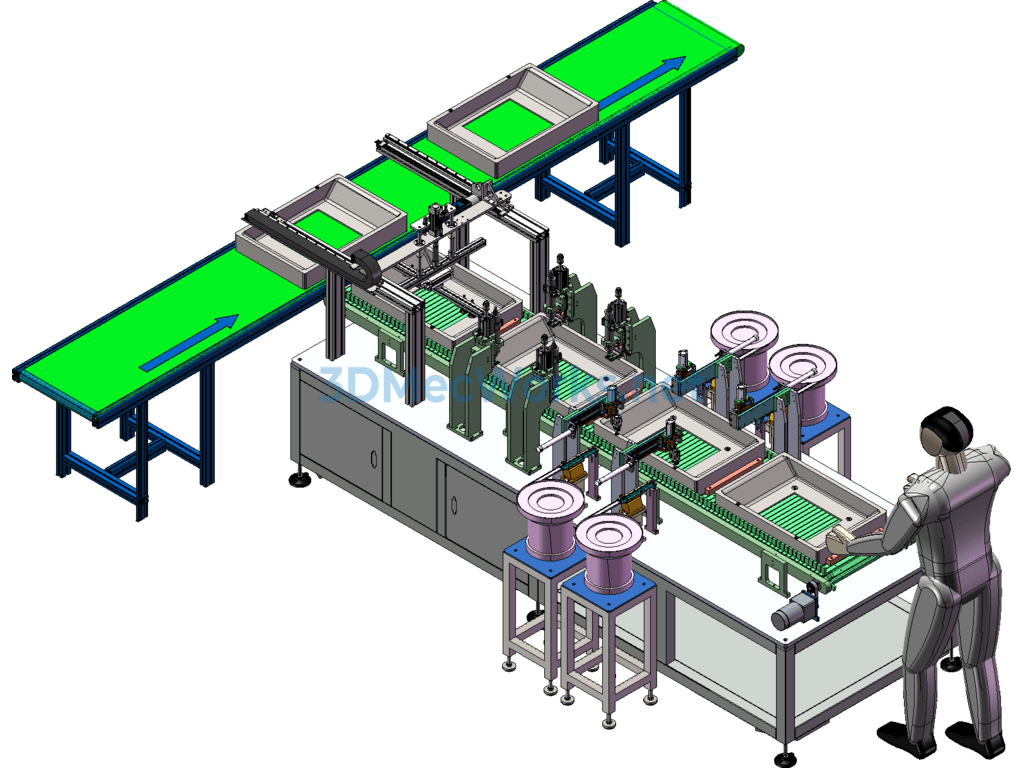

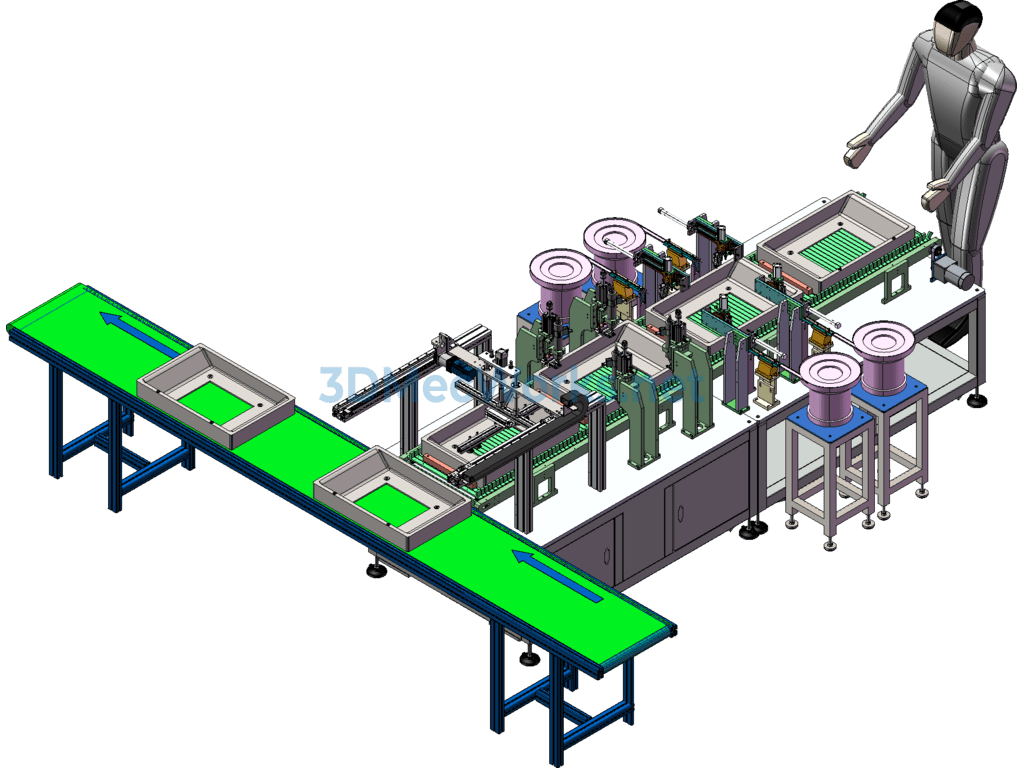

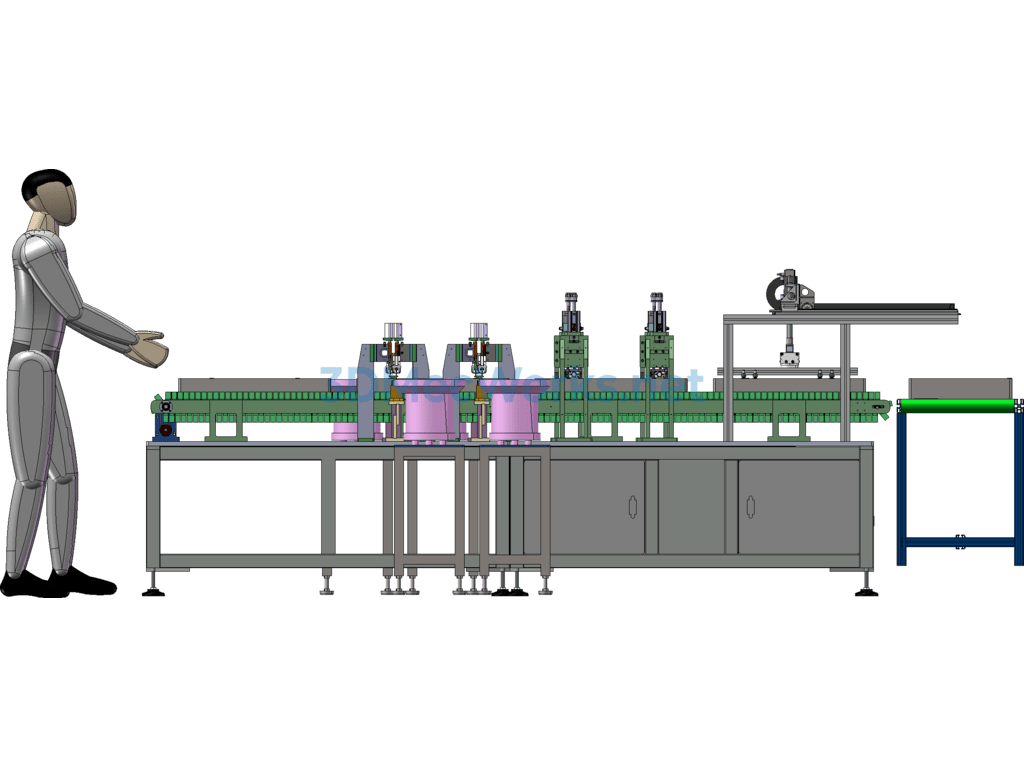

Fully Automatic Nut Installation and Riveting Nut Online Nut Riveting Equipment 3D Model is the FOTILE Wind-Receiving Frame Nut Installation Machine Equipment Drawing. This automatic nut installation machine can achieve automatic nut supply, automatic riveting of nuts, automatic discharging, and can significantly improve production efficiency. Basic Operating Principle: Start the machine; 1. The operator places the product onto the stepping-type conveying mechanism. 2. Nut installation station (nuts are fed from the vibrating plate and installed onto the wind-receiving frame by the manipulator, with 4 nuts being installed simultaneously). 3. Nut riveting station (4 nuts are riveted simultaneously), 4. The handling manipulator rotates the product 90 degrees and sends it onto the production line. 5. Cycle repeats. The operator only needs to place the product onto the stepping-type conveying mechanism to simultaneously supply 4 nuts and rivet 4 nuts, including rotating angle discharging. Completing this series of actions only takes 10 seconds, while it takes 30 seconds for manual operation, thus this machine improves efficiency by 3 times. Machine outer dimensions: 3000X1500X1200 Input voltage: AC200V-AC240V, 50HZ Internal voltage: 24VDC Input air pressure: 0.4MP-0.8MP Operating mode: Automatic/Manual Working efficiency: About 10 seconds per product.

Specification: Fully Automatic Nut Installation and Online Riveting Nut Equipment for Pull-Rivet Nuts

|

User Reviews

Be the first to review “Fully Automatic Nut Installation and Online Riveting Nut Equipment for Pull-Rivet Nuts”

You must be logged in to post a review.

There are no reviews yet.