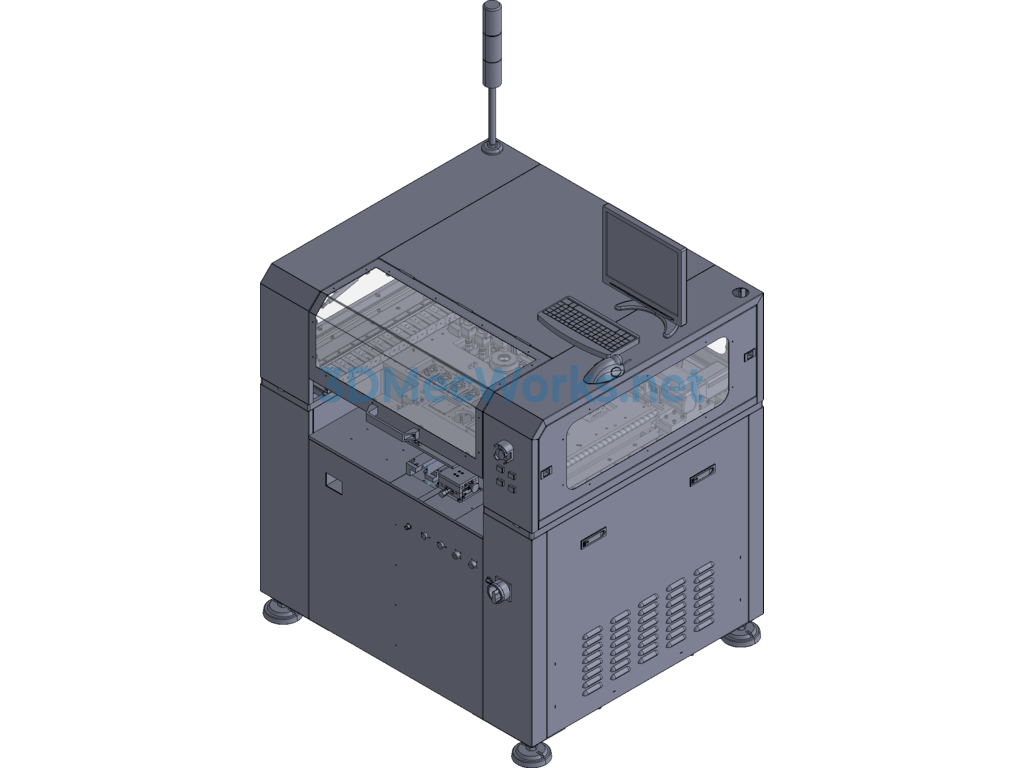

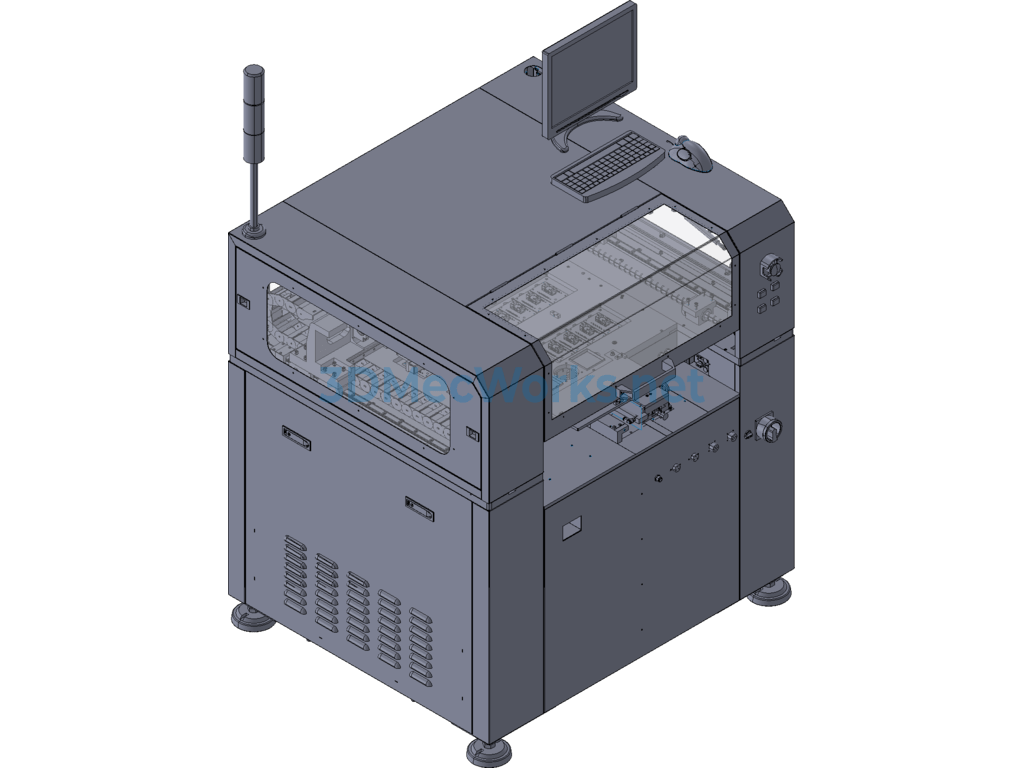

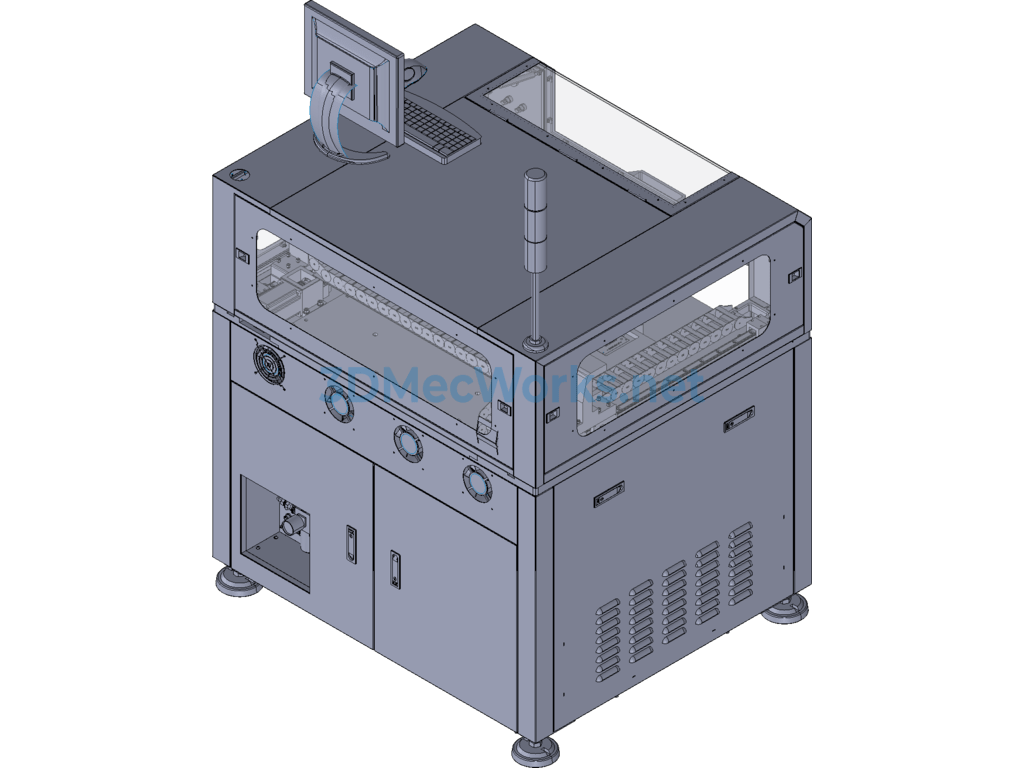

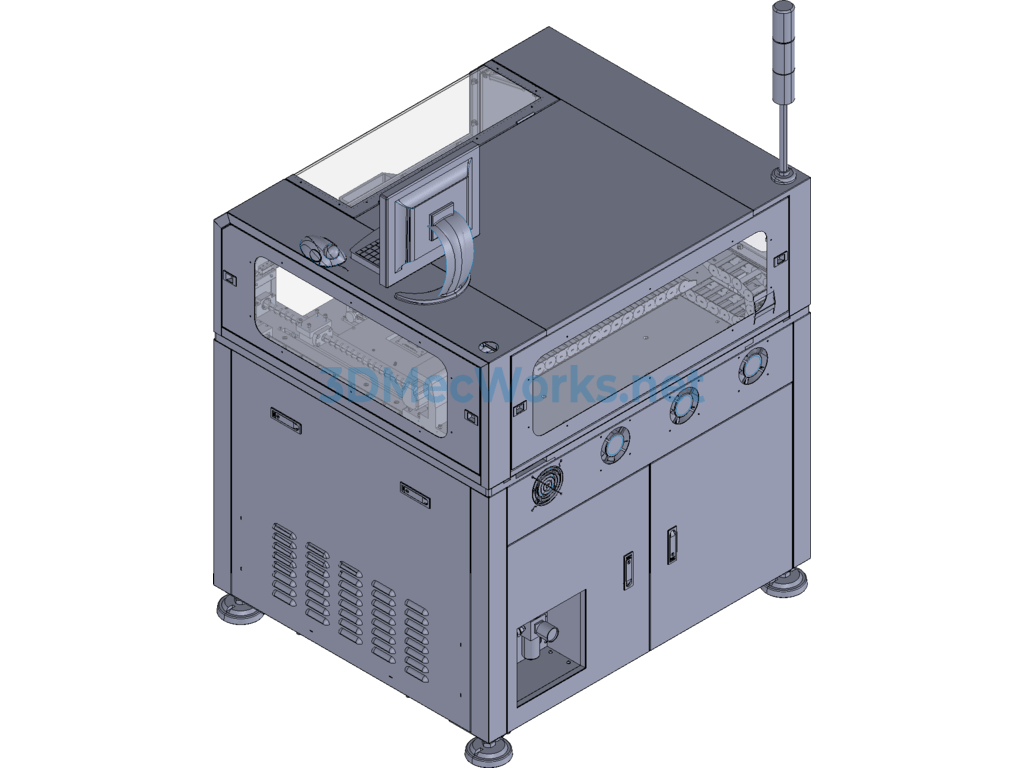

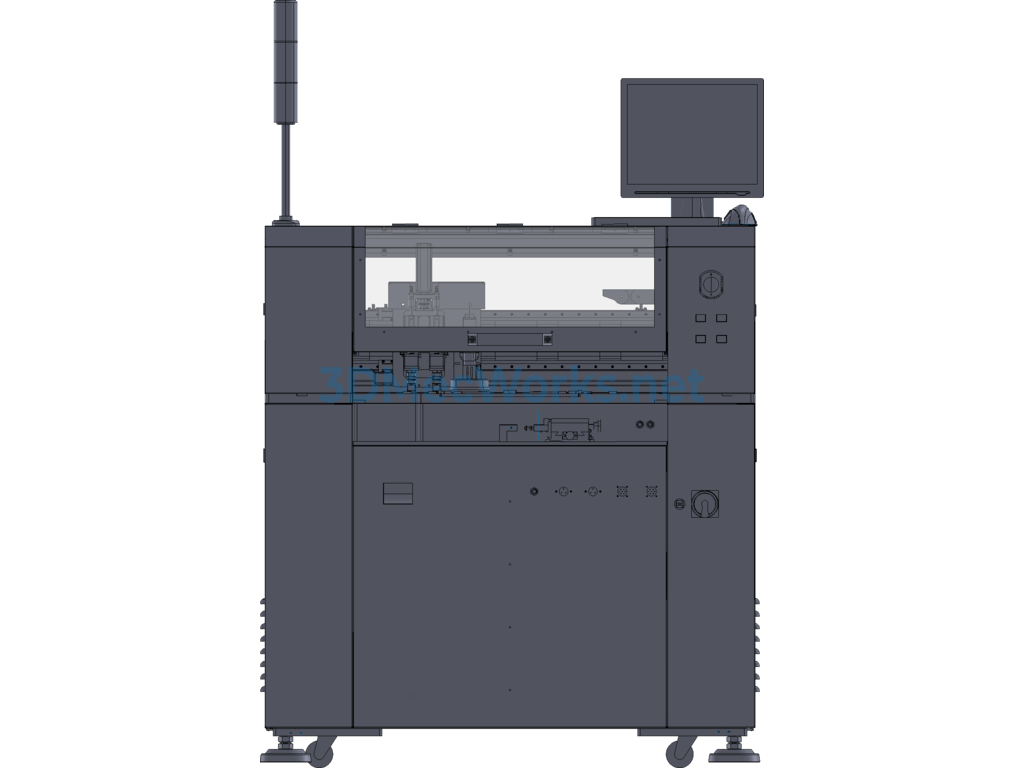

Automatic IC chip programming equipment for automatic writing of programs, capable of working with both SMT and plug-in machines in 3D models. This set of fully automatic IC chip programming equipment is mainly used to program IC chips and other chips. The equipment is composed of X, Y, and two Z axes, and W four axes, which means there are two Z axes for up-and-down movements, each operating independently, and two rotary axes for driving the nozzles to perform rotational angle corrections. The XY structure is similar to the movement of a placement machine with very high speed, driven by a 400W and a 750W servo motor and lead screw. Inside the equipment, there are four sets of programmers simultaneously writing programs. The feeder on the front of the equipment supplies materials, so this four-axis robot arm picks up products from the feeder trays and places them into the programmer. All structures and movements are designed to prevent interference with the placement machine. The feeder can stack 20 trays at once to keep the equipment running, with a stacking structure of two groups. The outermost group is for trays containing materials, while the inner group near the equipment is used to push up and recycle empty trays as they automatically come out with the help of cylinders. The complete assembly drawing is named: PG17-000000-01 Automatic IC Chip Programmer. The equipment is designed for unmanned operation, featuring excellent structures and design approaches. The complete drawings of this feeder offer great learning opportunities; those with similar equipment can reference these structures. We welcome everyone to download; here you will find the best and most complete set of drawings with the highest quality. Thank you.

Specification: Fully Automatic Machine Ic Chip Programming System for Automatic Writing Devices Applicable for Both Surface-Mount and Through-Hole Technology

|

User Reviews

Be the first to review “Fully Automatic Machine Ic Chip Programming System for Automatic Writing Devices Applicable for Both Surface-Mount and Through-Hole Technology”

You must be logged in to post a review.

There are no reviews yet.