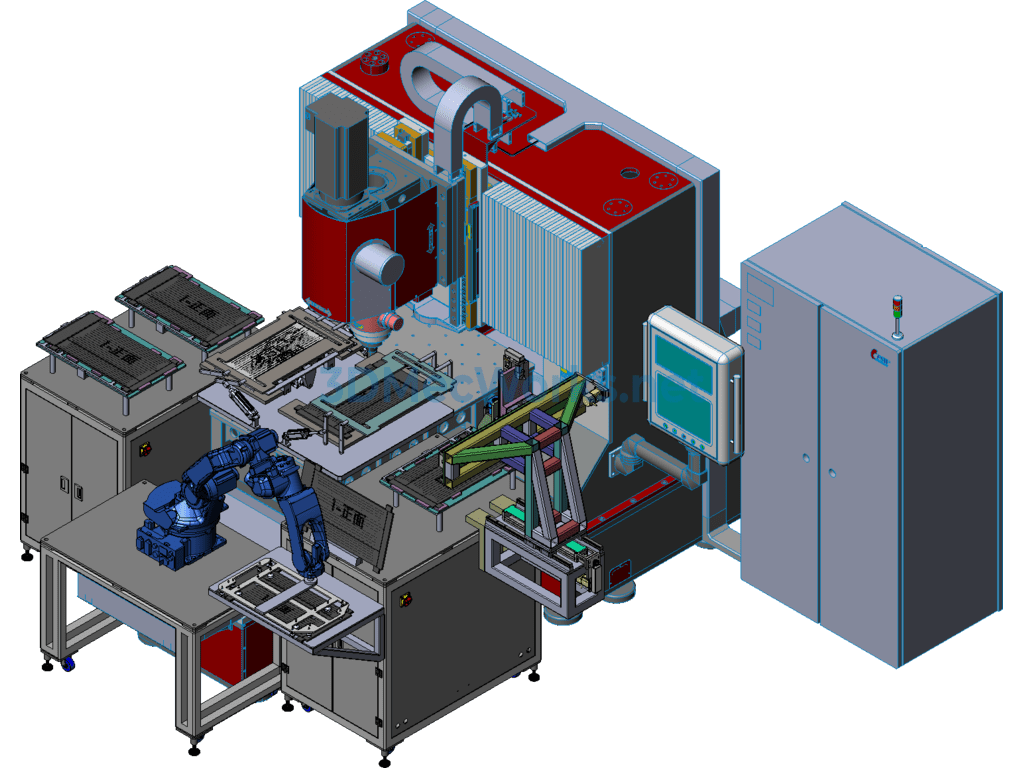

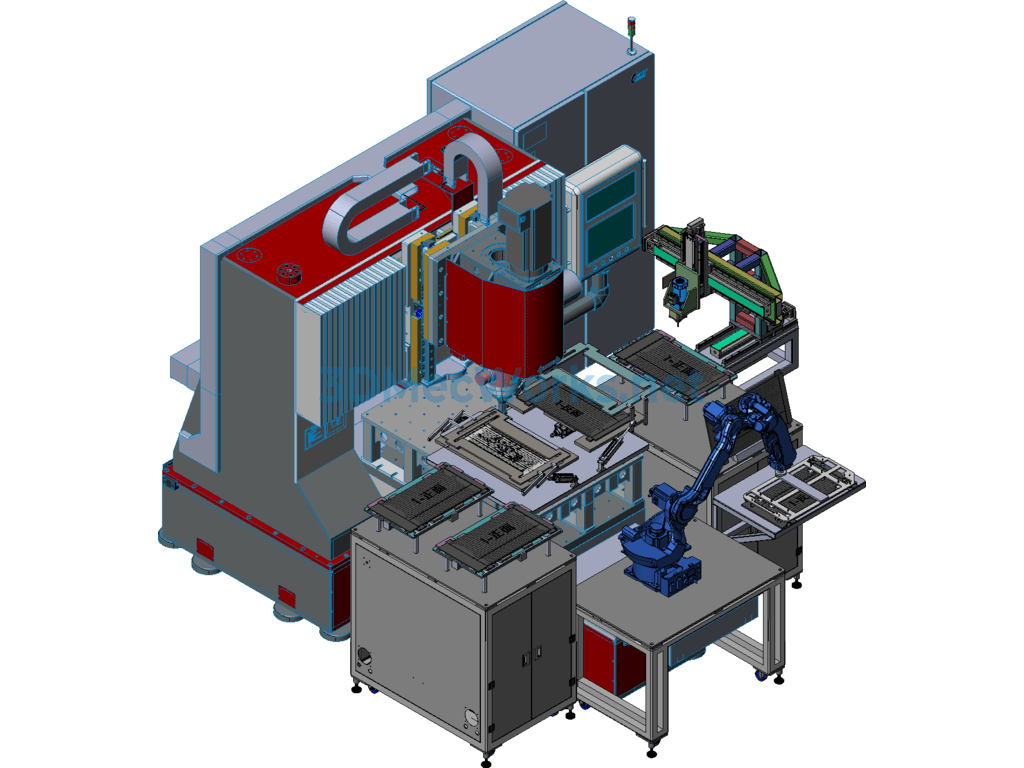

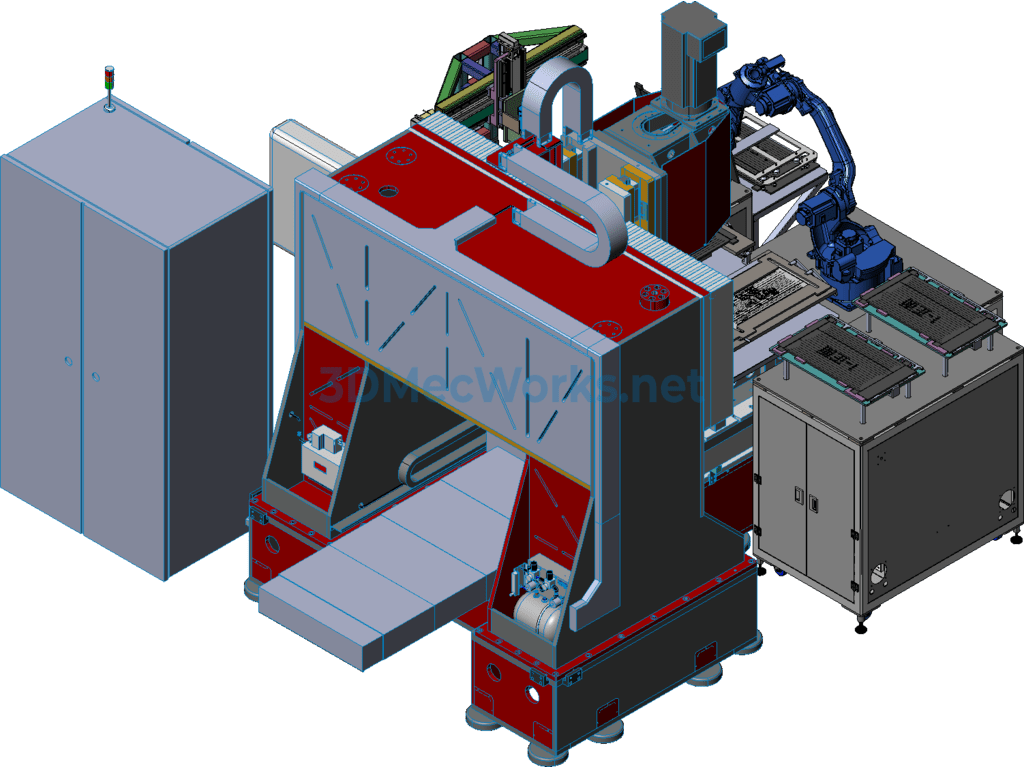

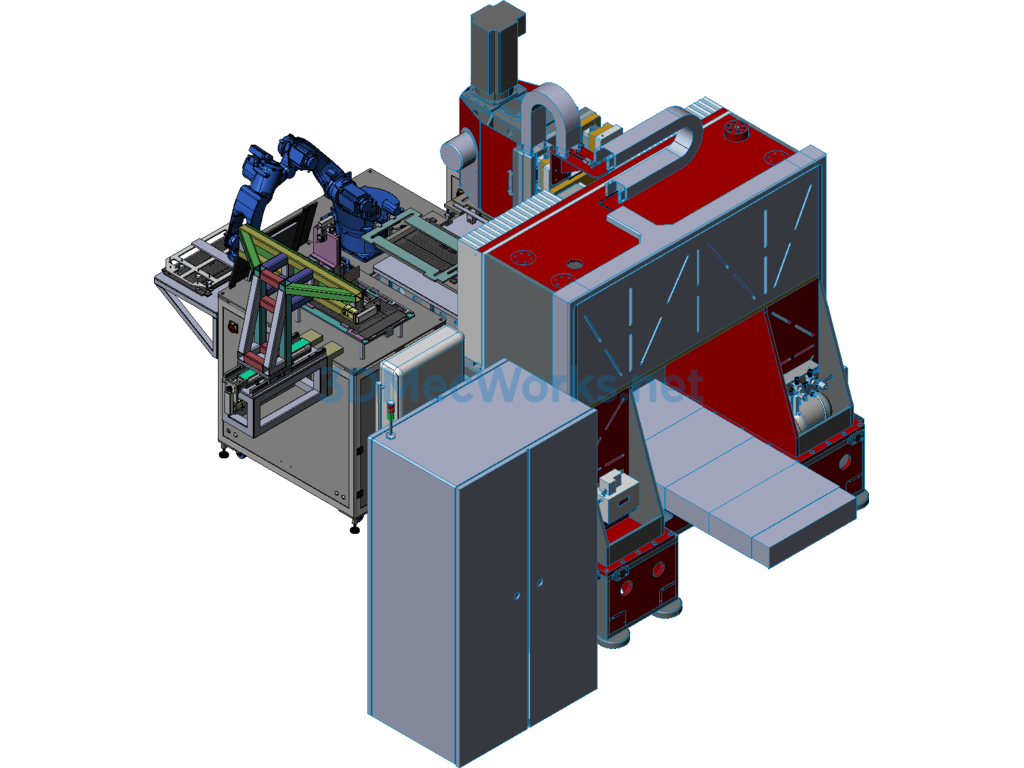

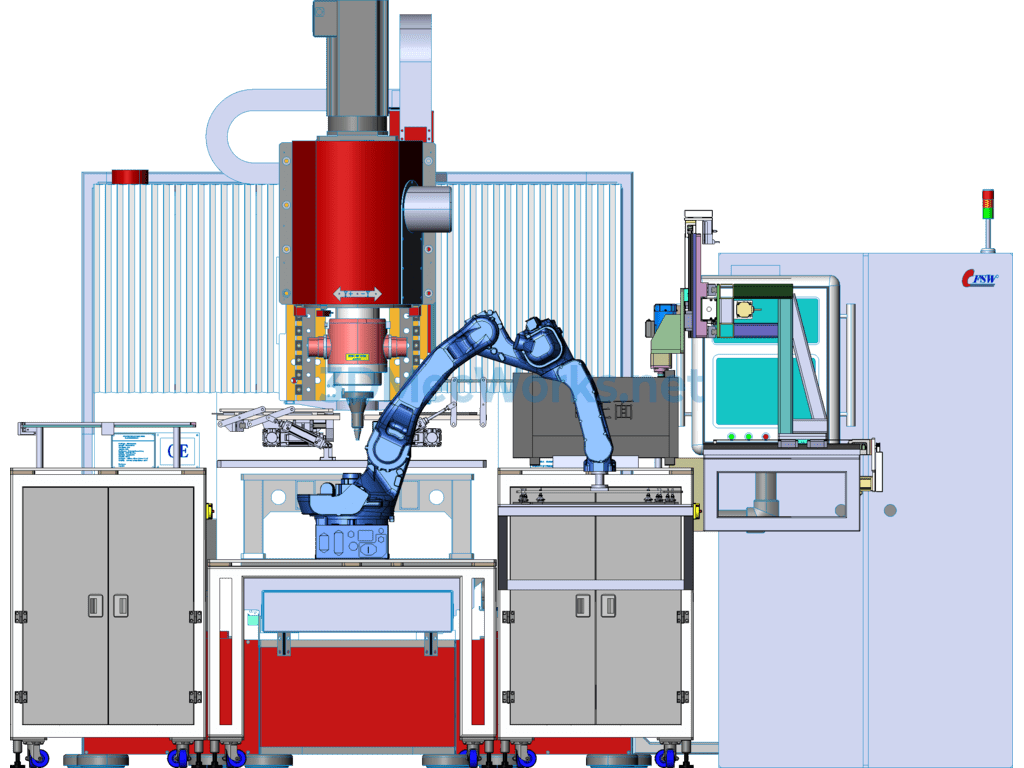

Fully automatic extrusion, welding, palletizing, and deburring equipment. The robot arm retrieves materials from loading stations 1 and 2 and places them for cold welding. The robot arm places the materials into cold welding positions 1/2, where side cylinders clamp and position them. A down-pressure cylinder tightly holds the materials in place within the welding station. The robot arm places them in the deburring station for deburring. The cold welder continues with the materials in cold welding position 1 (simultaneously). The robot arm retrieves materials from cold welding position 1 and moves them to the deburring station. The reverse side of materials in cold welding station 1 is deburred. After deburring is completed, the robot arm places the materials into the unloading area, and then retrieves new materials and places them into cold welding positions 1 and 2 (repeated action).

Specification: Fully Automatic Extrusion Welding, Stacking, and Deburring Equipment (already in Production)

|

User Reviews

Be the first to review “Fully Automatic Extrusion Welding, Stacking, and Deburring Equipment (already in Production)”

You must be logged in to post a review.

There are no reviews yet.