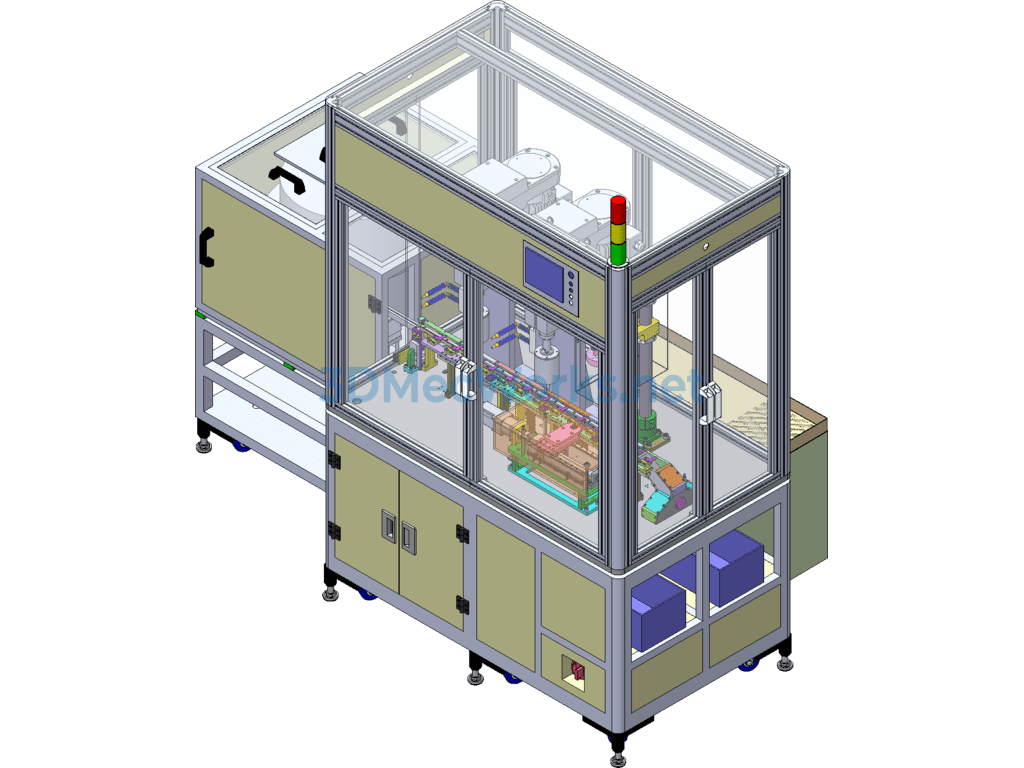

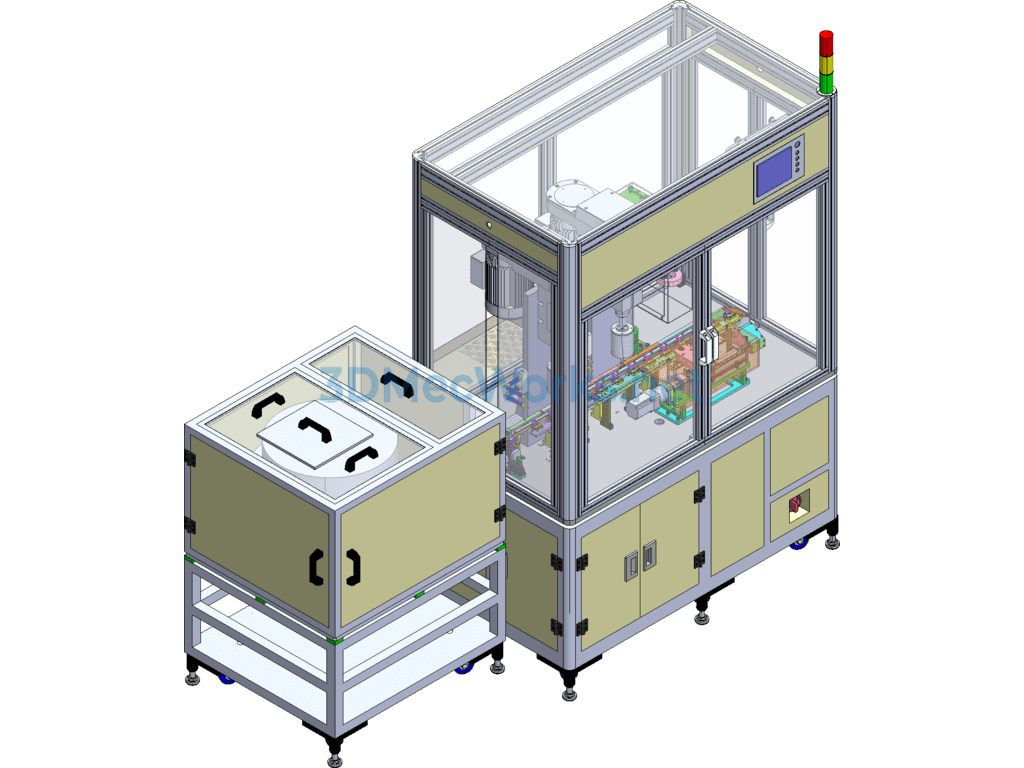

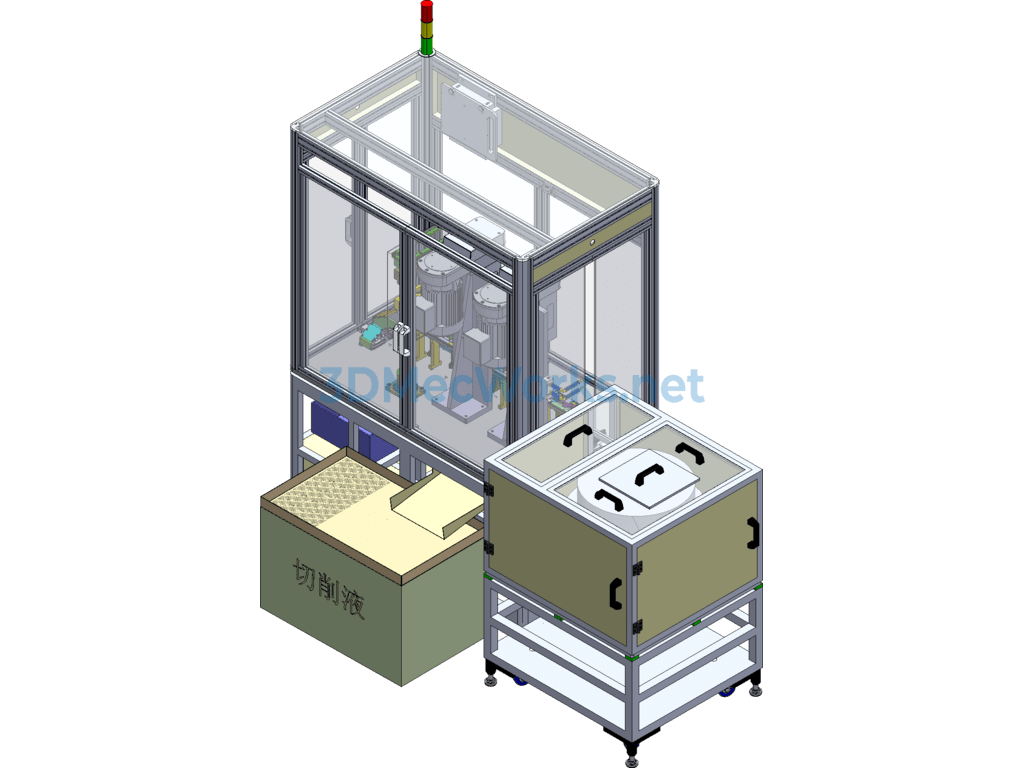

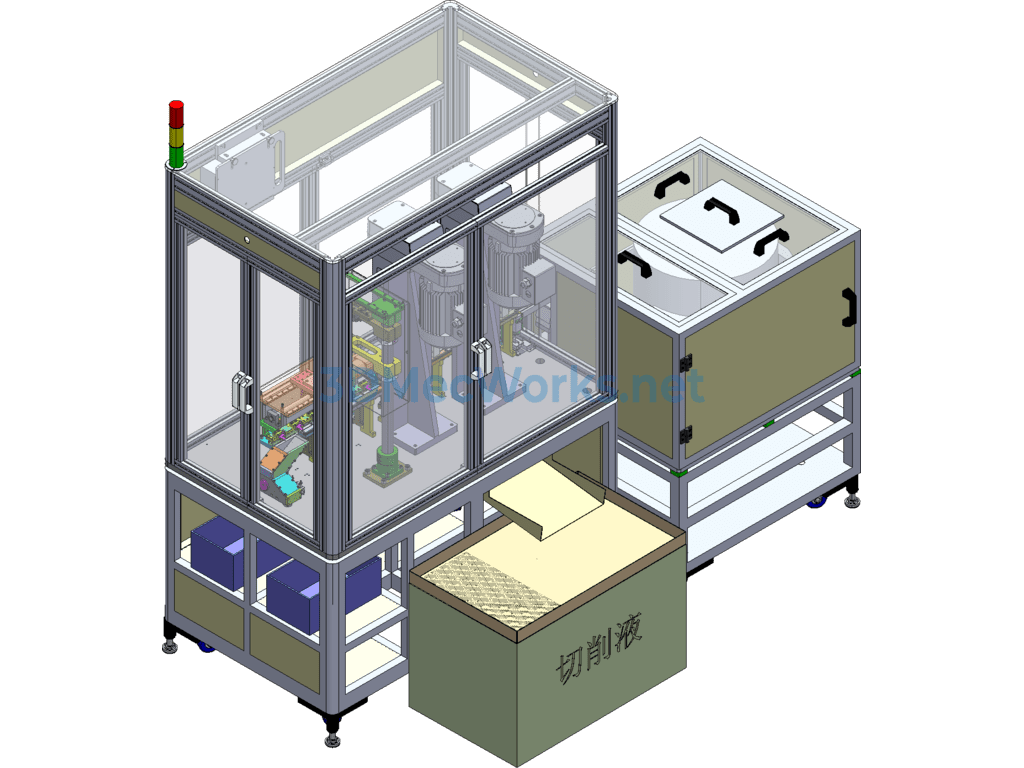

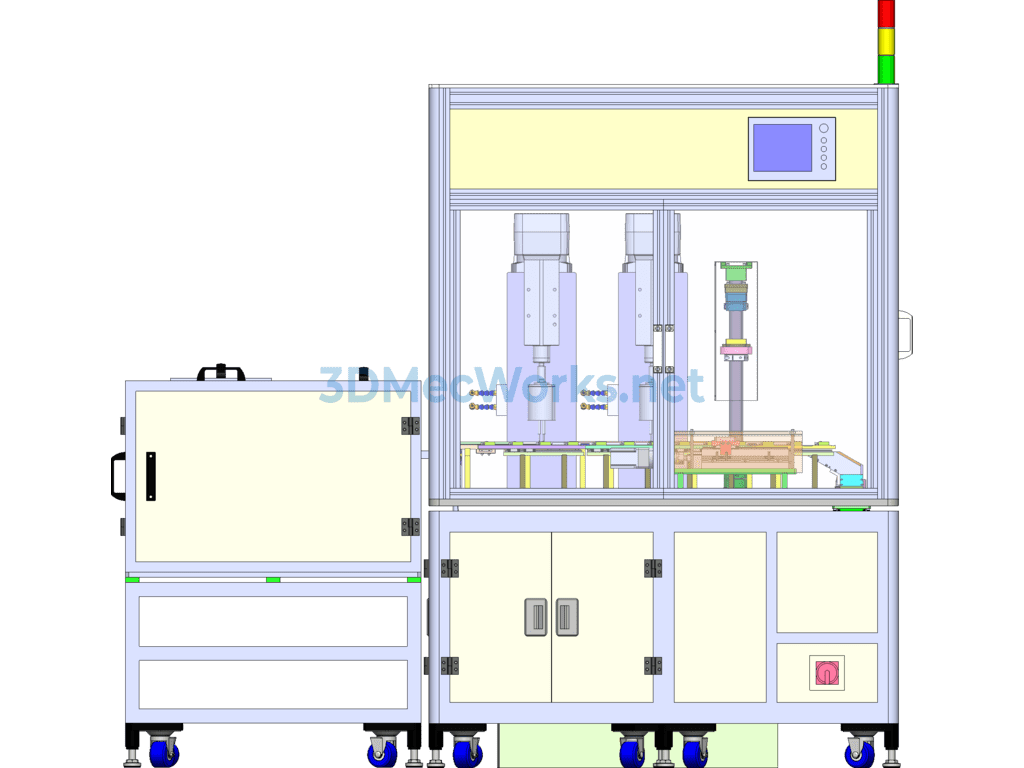

The fully automatic drilling and tapping machine uses a vibrating plate feeding method. After entering the equipment, a servo screw is used to carry the push head to complete the transplanting action of the product in the flow channel. The first station completes the automatic drilling action, the second station completes the automatic tapping process, and the third station uses visual inspection to distinguish between OK/NG through an automatic sorting module. The overall structure of the equipment is mature and has been mass-produced, with high control and simple production.

Specification: Fully Automatic Drilling and Tapping Equipment (equipment Already in Production)

|

User Reviews

Be the first to review “Fully Automatic Drilling and Tapping Equipment (equipment Already in Production)”

You must be logged in to post a review.

There are no reviews yet.