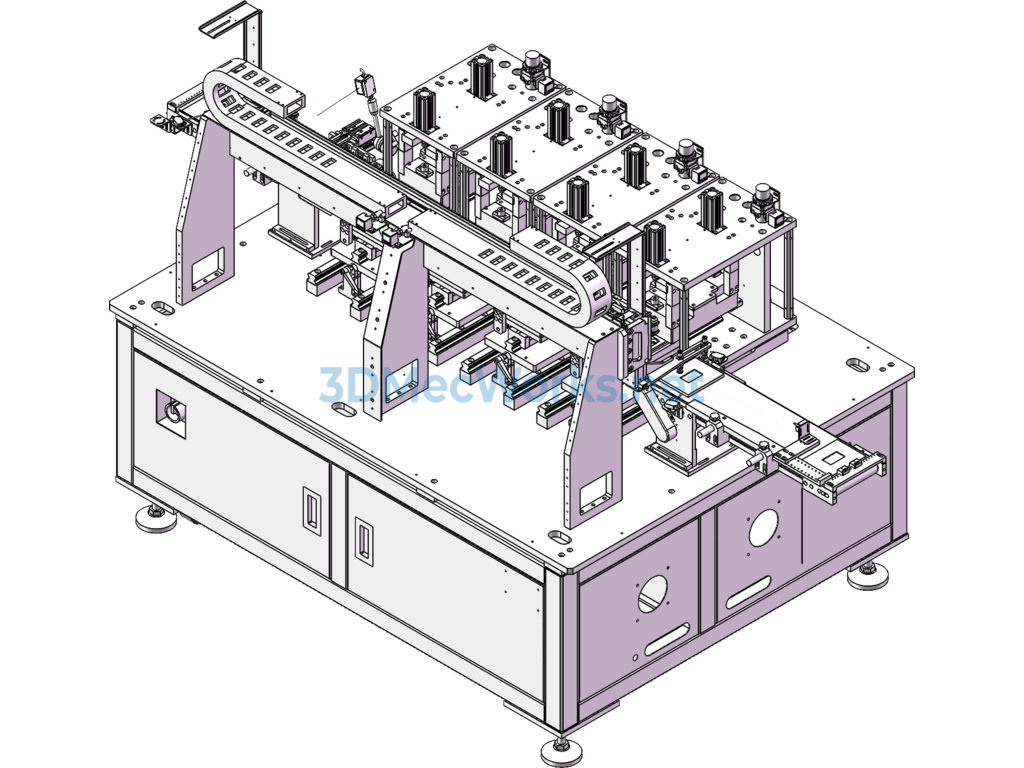

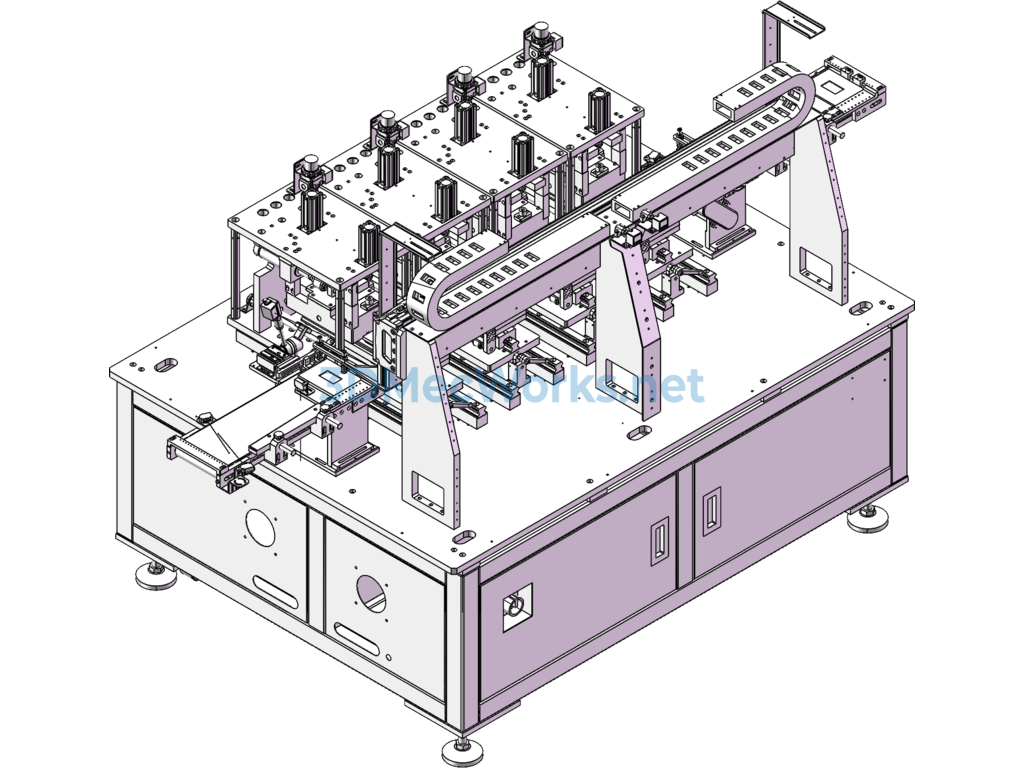

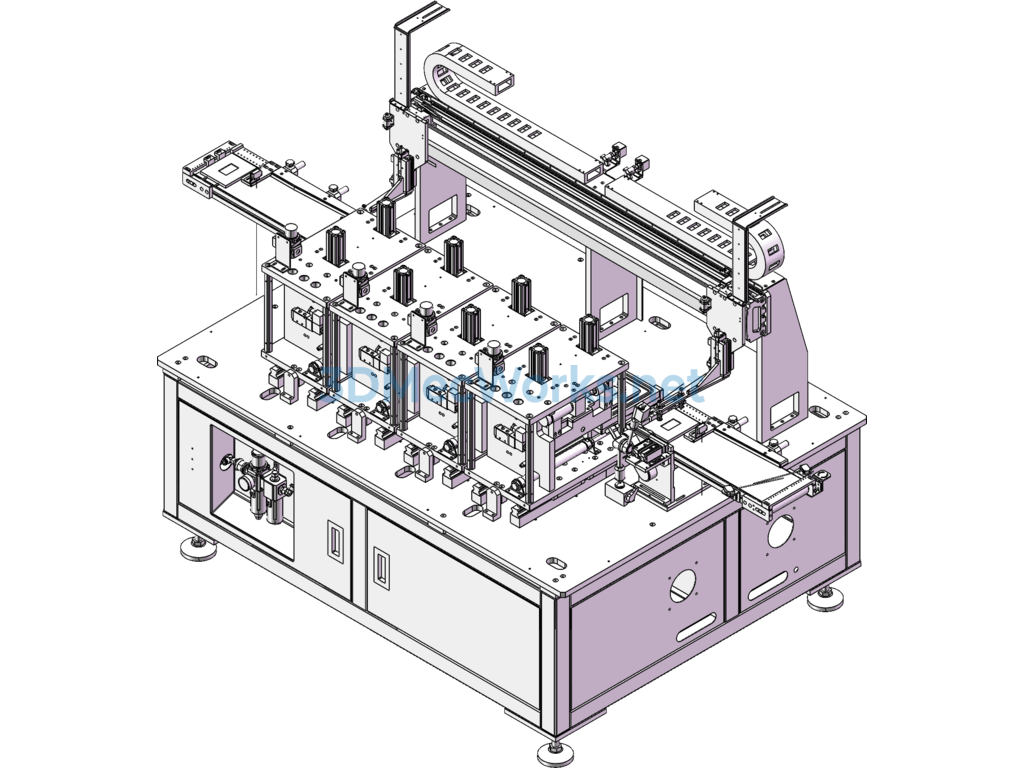

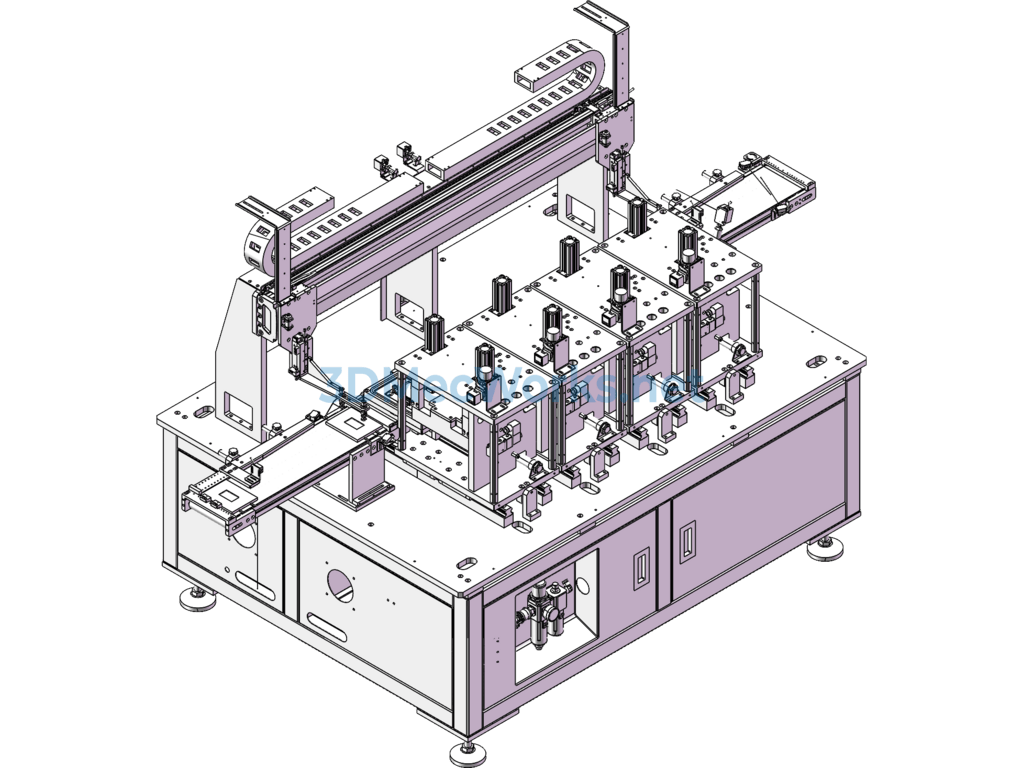

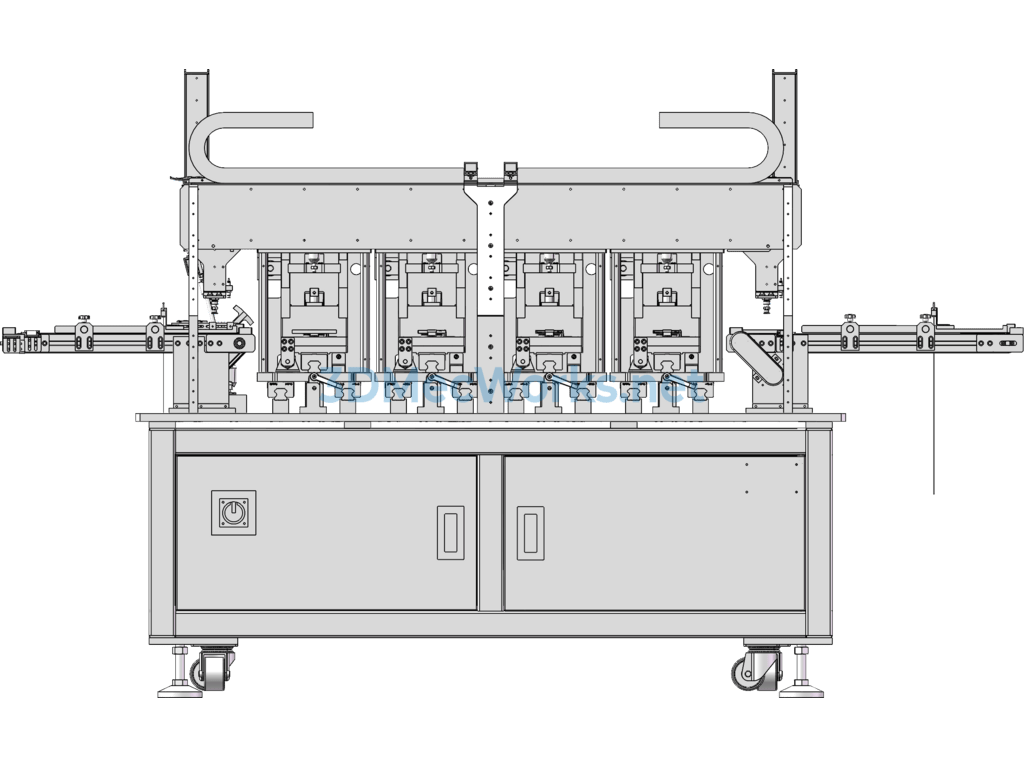

This equipment is used in the phone battery production line for the battery leakage detection process. Phone battery processing involves multiple steps, and during these processes, batteries are inevitably subject to some degree of damage. When the battery’s aluminum film is damaged, it must be scrapped. This particular process is designed to distinguish whether the battery is damaged or not. The basic principle involves using four suction cups on each side of the battery cell to hold it. Within a sealed chamber, negative pressure is applied inside the suction cups. When there is no damage, the part of the battery cell in contact with the suction cups will not undergo deformation or change. When there is damage, the air in the chamber connects with the inside of the battery cell, creating a pressure difference between inside and outside the suction cups, causing the aluminum film to deform and form bulges. These are manually identified and selected out. The equipment includes automatic belt feeding and unloading, with a 4-channel detection module. A linear module is used to increase handling speed, enhancing equipment capacity. The designed capacity of the equipment is 1000 PCS/h, with dimensions of 1200X1600X1900 mm. The details of each module are clearly and ingeniously designed for reference in solution purposes.

Specification: Four-Channel Leak Detection Machine

|

User Reviews

Be the first to review “Four-Channel Leak Detection Machine”

You must be logged in to post a review.

There are no reviews yet.