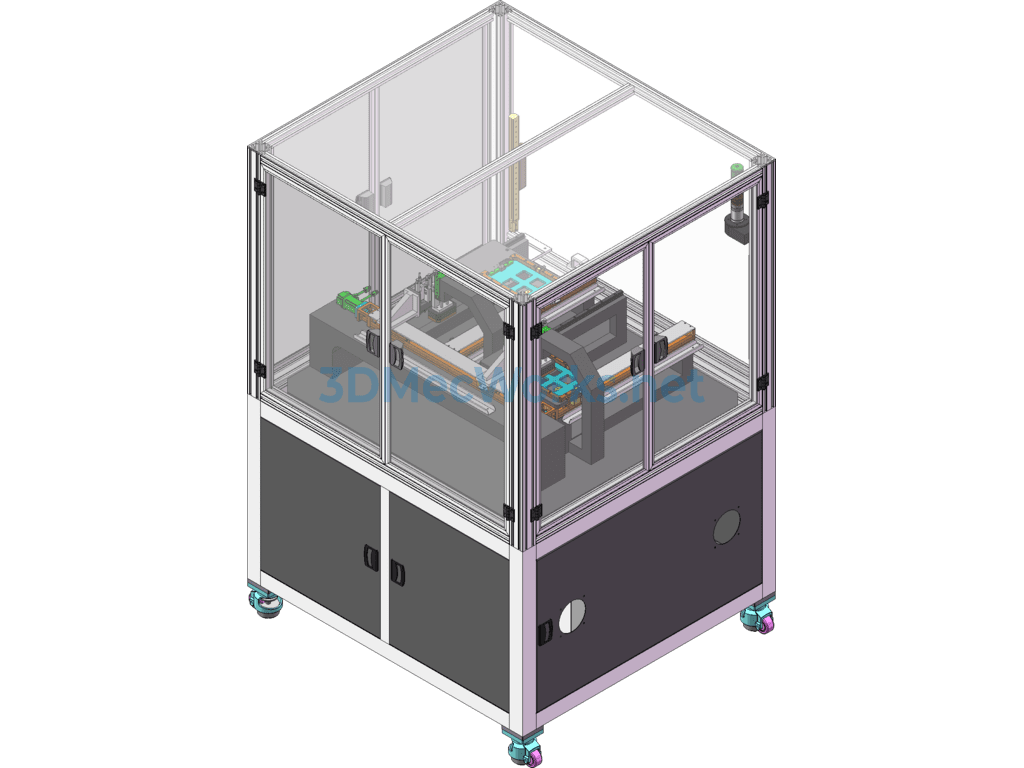

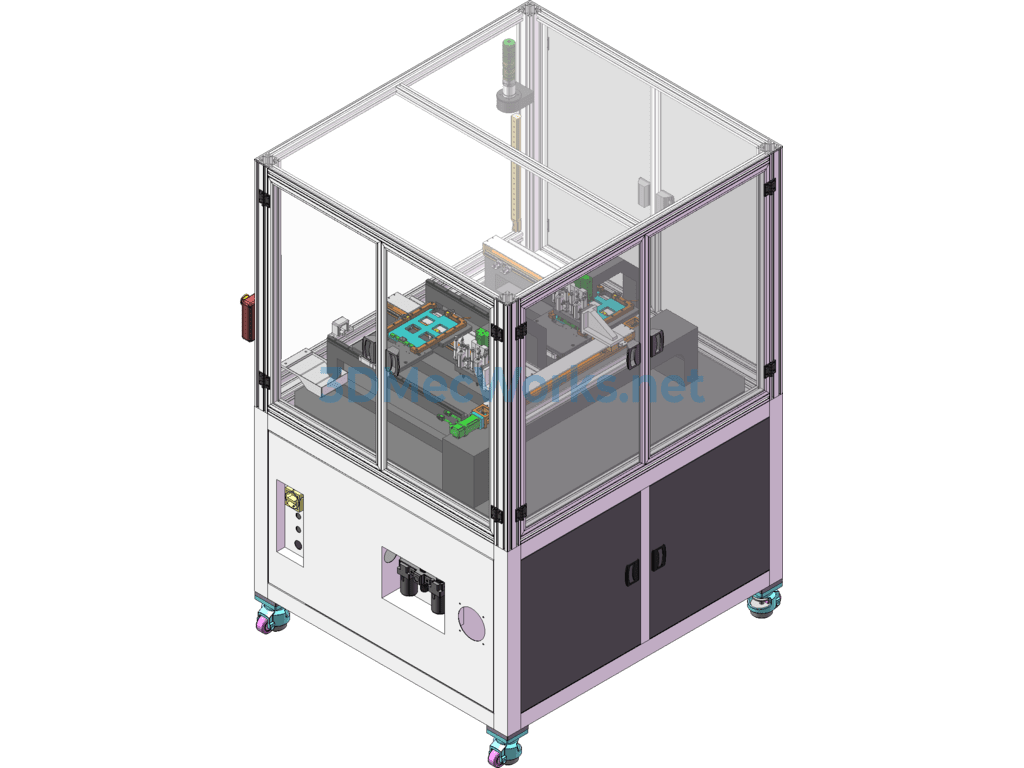

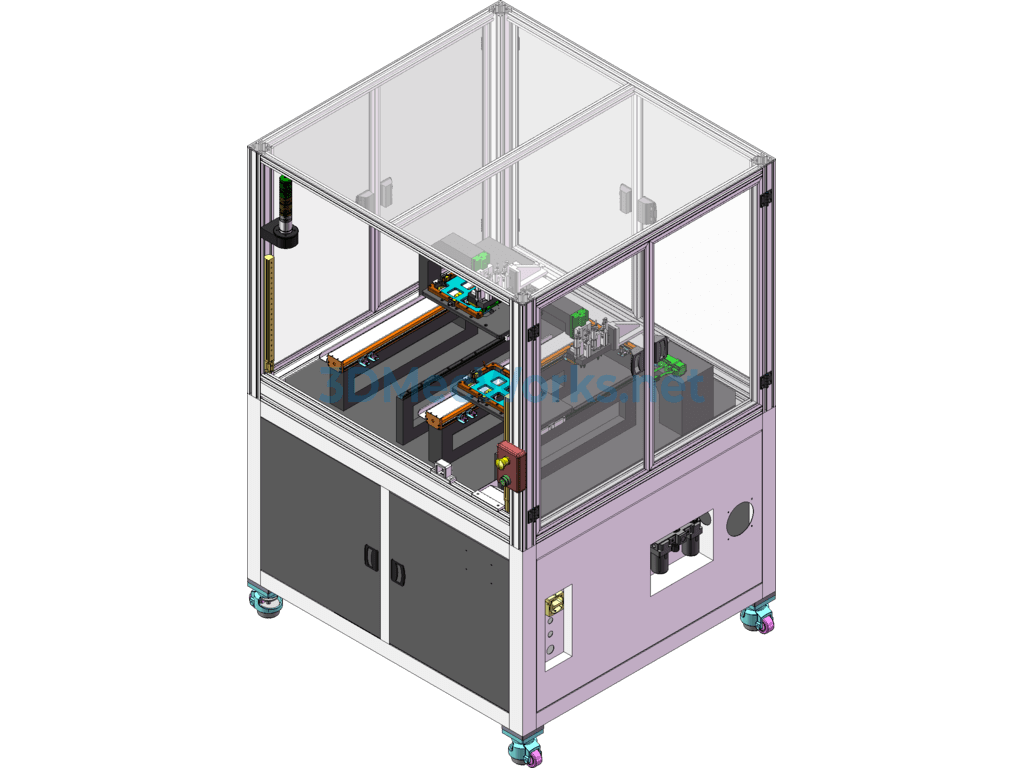

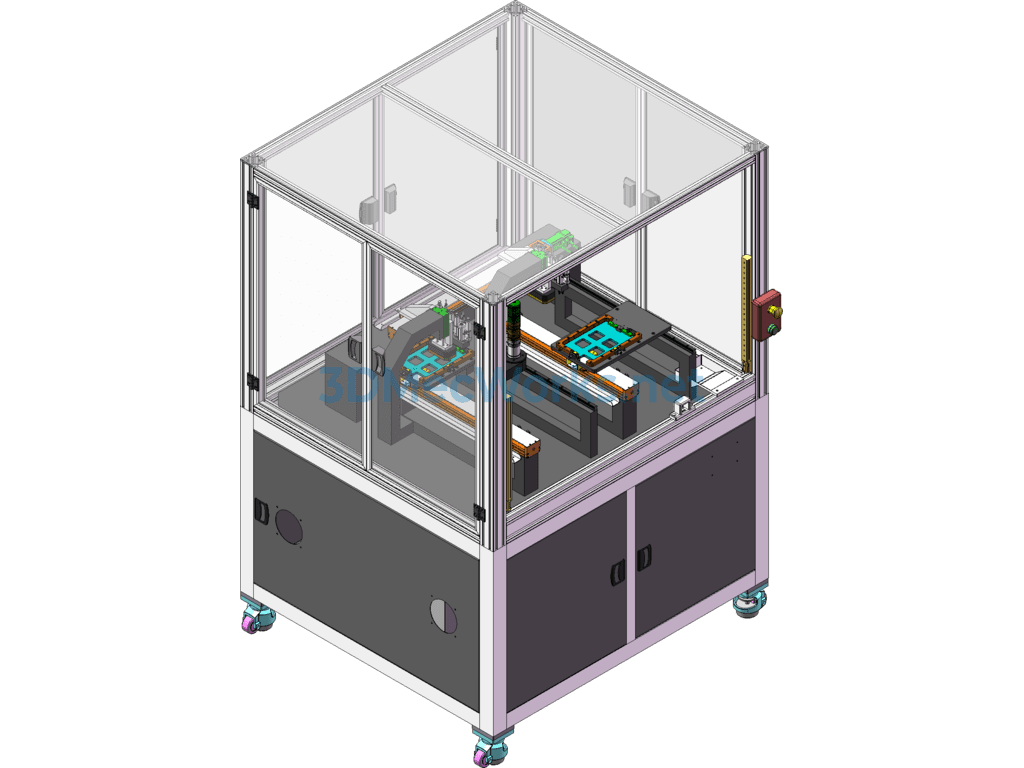

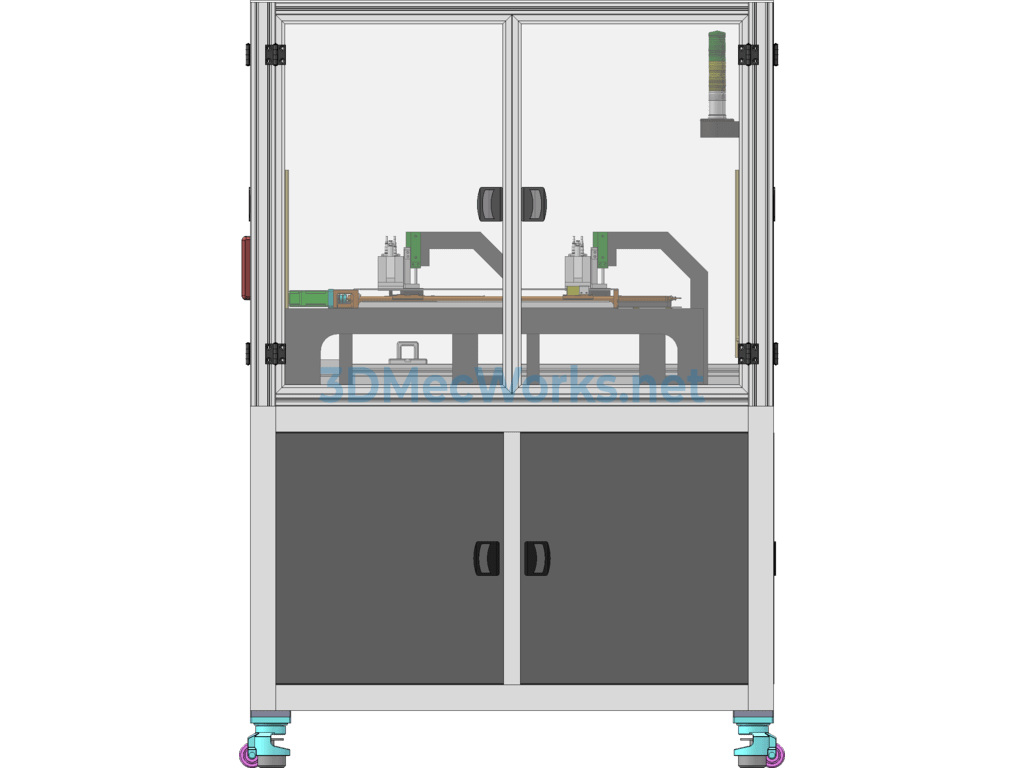

Flat Panel Step Difference Testing Equipment Operation Process:

1. Test the internal height of the flat panel product, divided into left and right fixture groups for material switching, saving device CT and providing productivity;

2. Manually place the product into the fixture for positioning and side clamping fixing.

3. The Y-axis enters the testing area, and the Z-axis cylinder presses down to fix the product in place for movement.

4. The GT test cylinder drives the GT test head to test the product height.

Specification: Flat Plate Step Difference Detection Equipment (including Dfm, Bom)

|

User Reviews

Be the first to review “Flat Plate Step Difference Detection Equipment (including Dfm, Bom)”

You must be logged in to post a review.

There are no reviews yet.