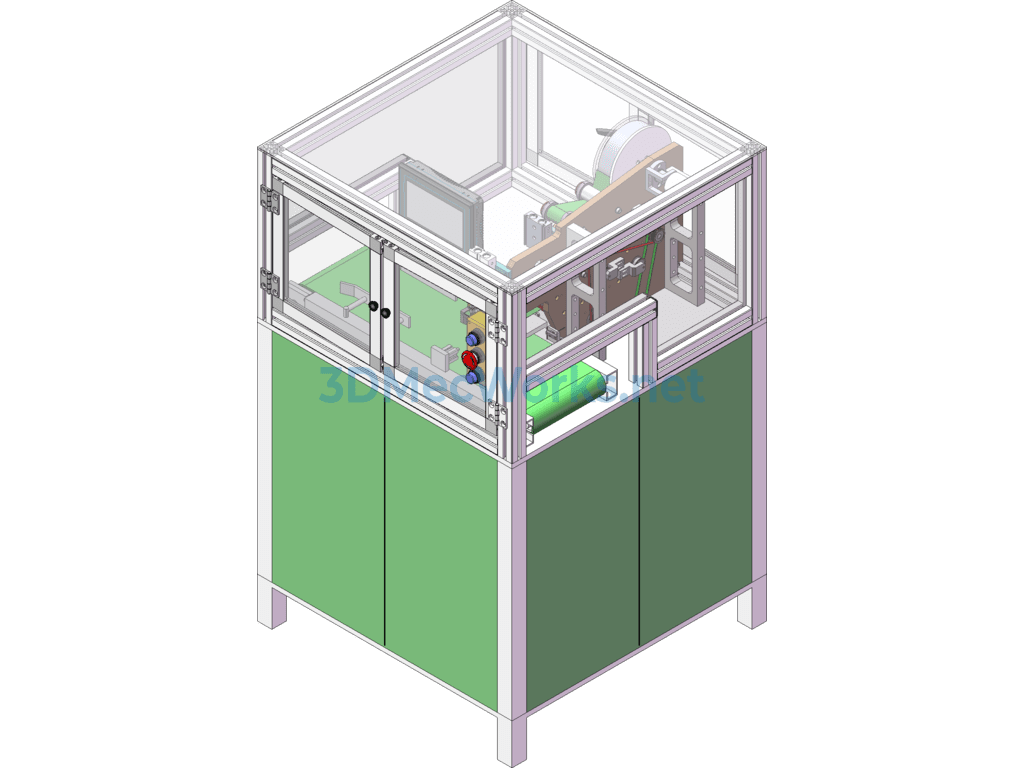

According to the customer’s requirement of placing 10 pieces per minute, with a label size of 20x30x20 (length, width, height), the product sales size can be adjusted appropriately. By modifying existing standard parts and those available in the market, a new machine has been designed to suit the client’s needs.

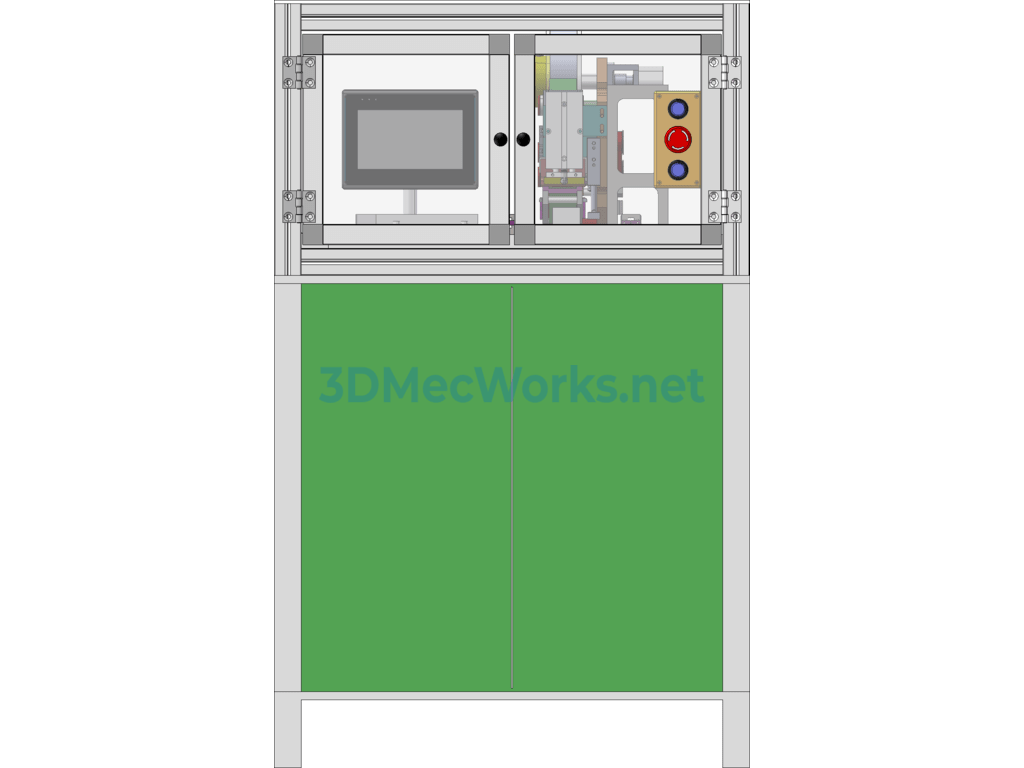

This equipment is a machine that separates labels from roll film through a mold module and then uses a suction cup to attach them to the product.

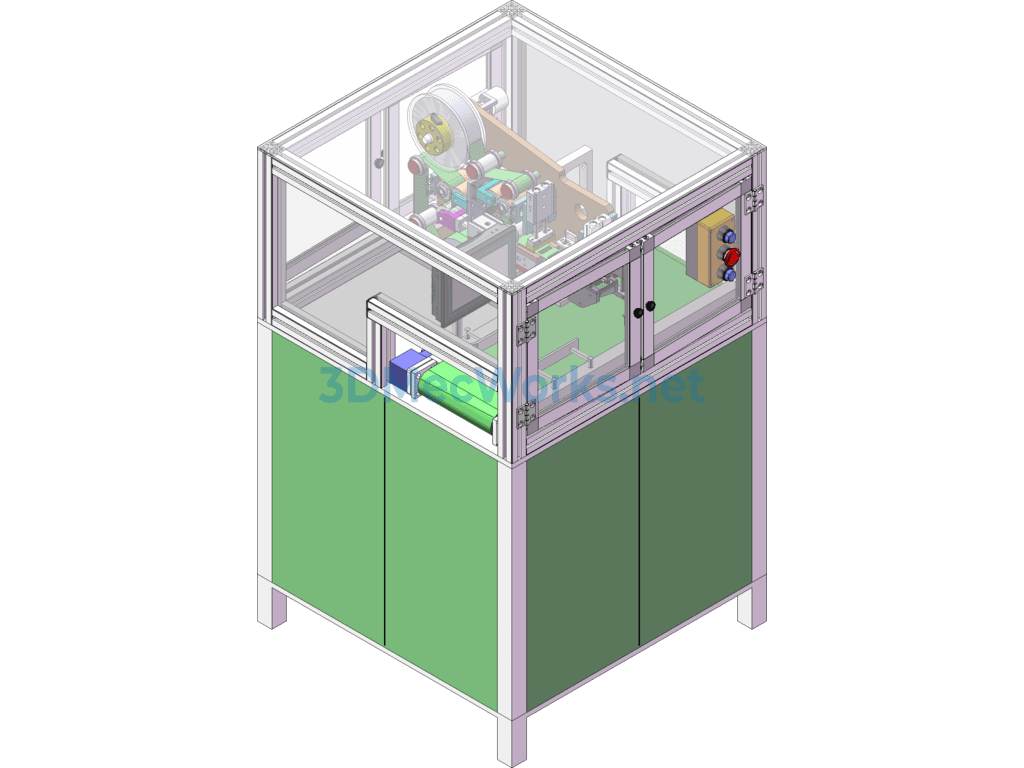

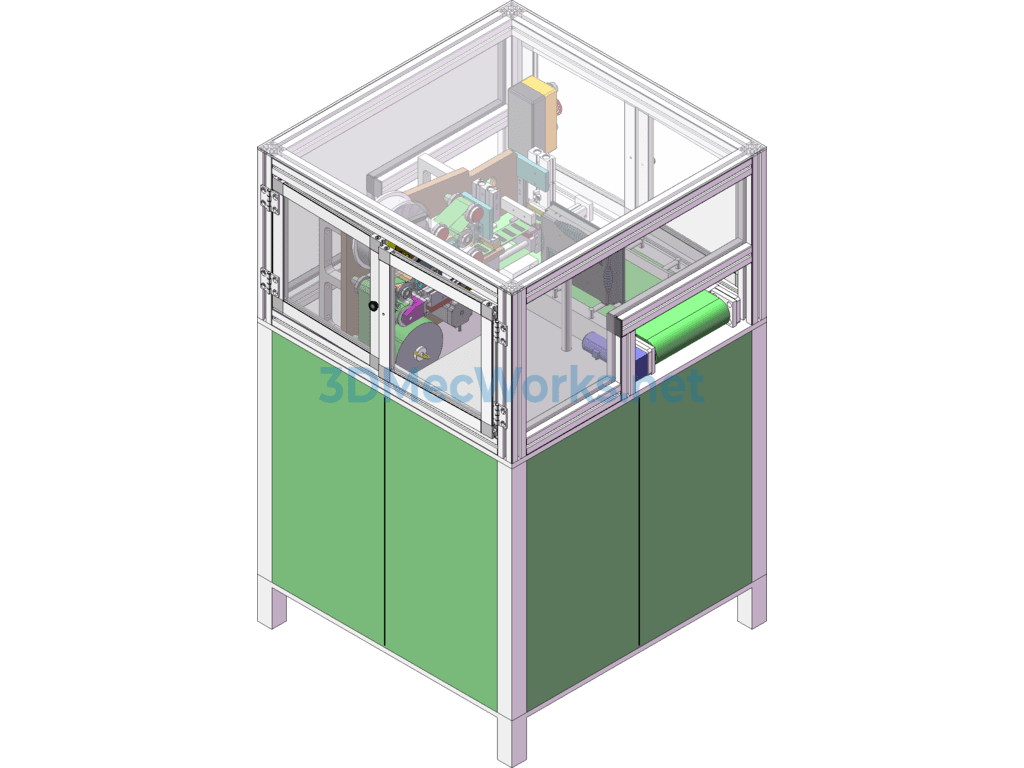

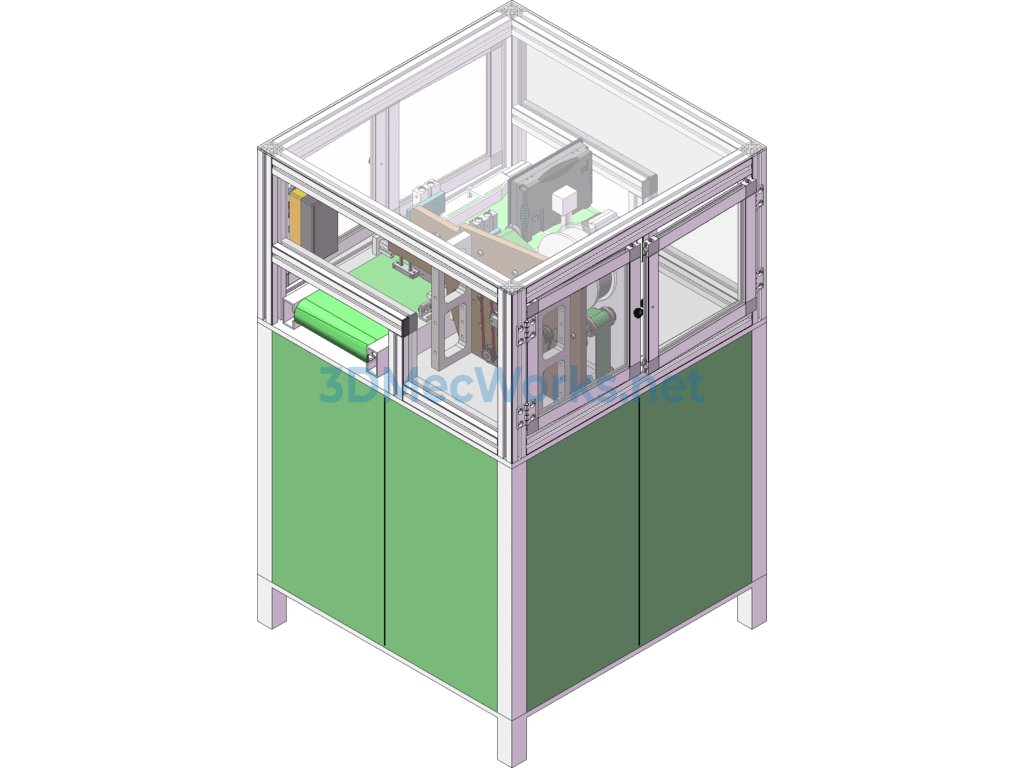

1. The motor drives the reel, and the reel drives the roll film to rotate. This allows for film winding and unwinding, tension control, and quantitative film feeding;

2. The film separation cylinder acts to tear off the label;

3. The suction cup cylinder acts to hold the label, the film separation cylinder retracts, and the suction cup cylinder presses down to label the product;

4. The conveyor line transports the product, with guide plates on both sides for product direction, and the cylinder and adjustable stop block work together for precise positioning to ensure accurate labeling;

Specification: Fixed Mold Stripping Module Fully Automatic Labeling Machine

|

User Reviews

Be the first to review “Fixed Mold Stripping Module Fully Automatic Labeling Machine”

You must be logged in to post a review.

There are no reviews yet.