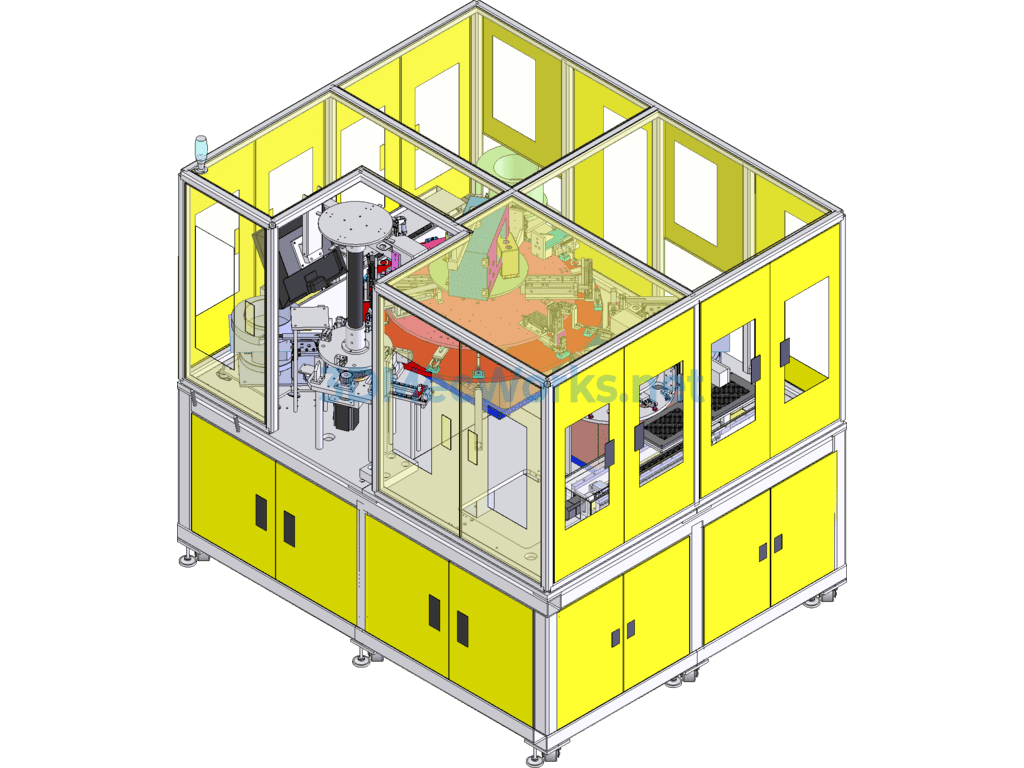

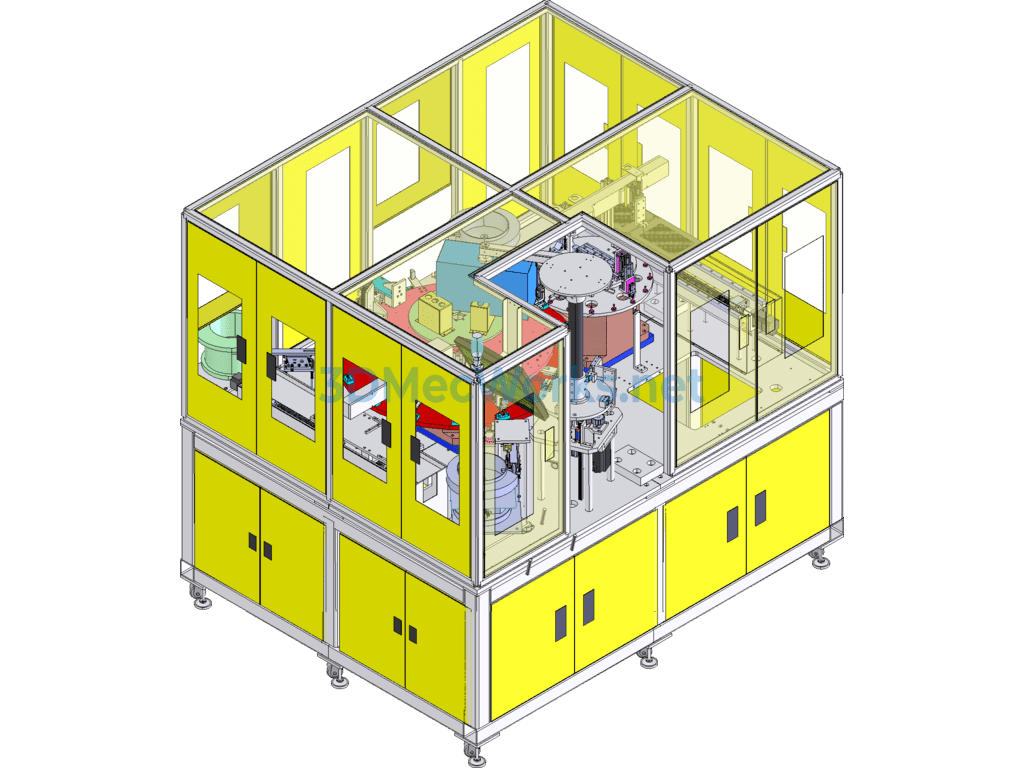

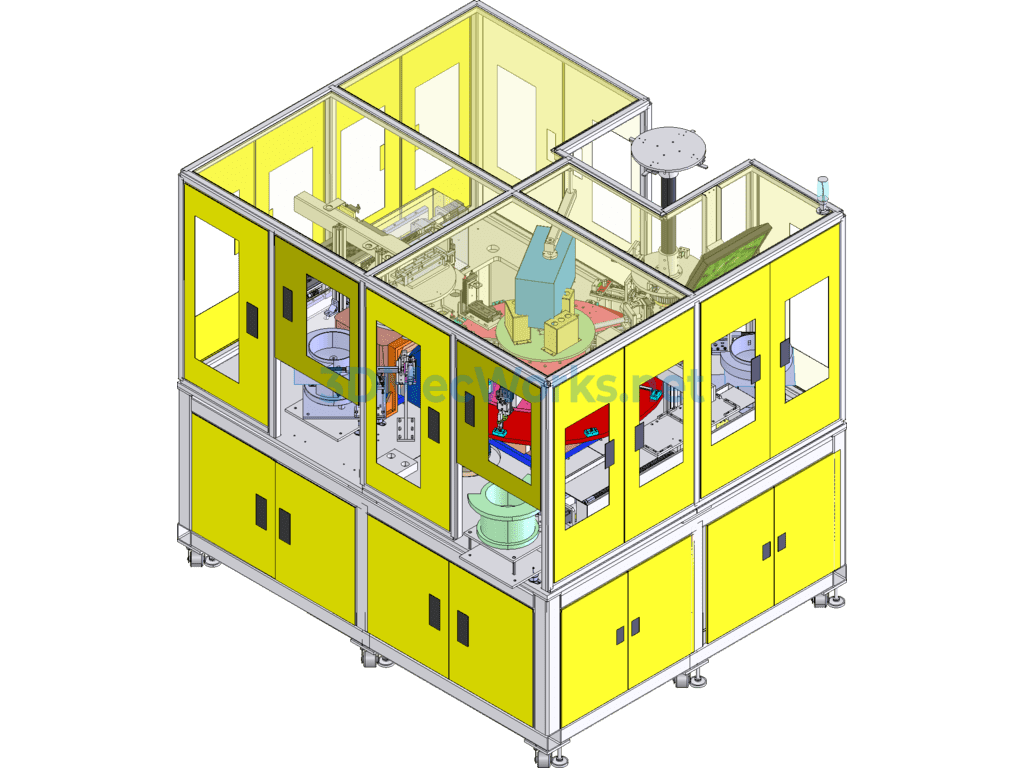

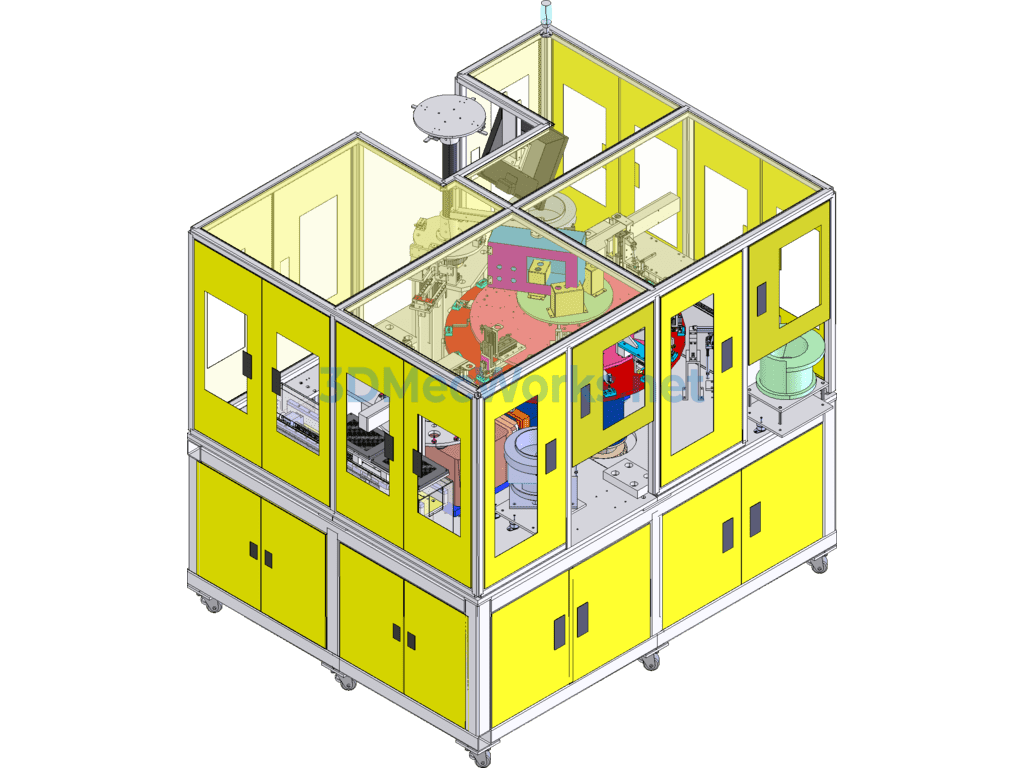

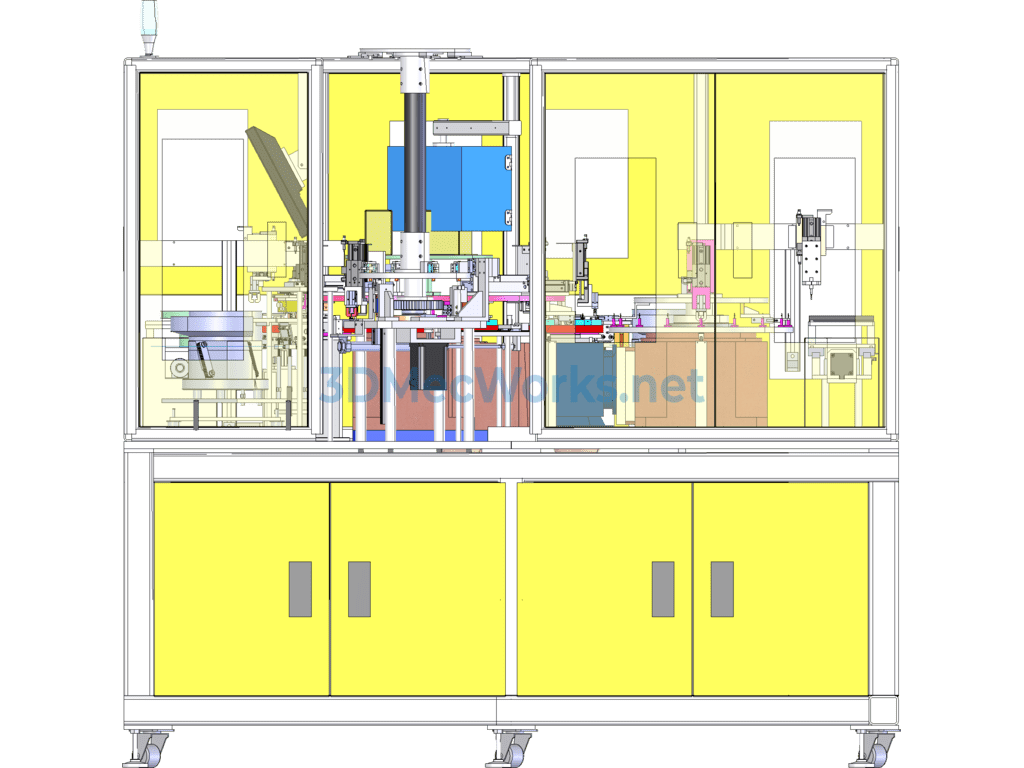

Fiber Optic Head Assembly Machine Network Signal Plug Non-standard Assembly Equipment

1. Equipment Description

This equipment is suitable for products such as: fiber optic heads, signal plugs, communication connectors, and various types of fiber optic connectors. This device is a state-of-the-art fully automatic fiber optic head assembly machine: it is mainly used for assembling fiber optic network communication ports and signal interface products. The equipment operates in a turntable manner with three vibrating plates and one material tray for feeding, assembling four fiber optic head parts together to form the common fiber optic head. The assembly parts include: fiber optic shell, fiber optic plastic parts, fiber optic metal parts, and the fiber core, also known as the needle of the fiber optic head. This equipment uses one large turntable and two small turntables to accomplish assembly and feeding. The largest turntable in the middle is designed as a 16-position divider, while the small turntable for the fiber core also features 16 positions. The manipulator takes the fiber core from the loading tray and places it accurately in the jig on the turntable to assemble it into the fiber glue part. The overall action principle of the equipment is: the loading manipulator takes the material to the small turntable. As the turntable rotates to the docking position with the large turntable, the cylinder in the large turntable grips the product to assemble it into the fiber optic head on the large turntable. When the large turntable rotates to the next position, the stepper motor drives the small turntable to feed the plastic components. Another vibrating plate serves as the feeding vibrating plate for the fiber optic shell; similarly, a pneumatic manipulator grips it onto the large turntable for assembly. When the assembled fiber optic head rotates to the discharging position, the manipulator grips the finished product and places it neatly into the receiving tray. Once the receiving tray is full, the device alerts for manual collection. The above describes the fully automatic working principle of this equipment.

2. The main assembly parts of the equipment include the follows:

1. Fiber Core Feeding: The product is placed in a plastic box. The feed manipulator extracts the product from the box and places it into the rotating tray, minimizing changeover time, with a material shortage alarm function.

2. Fiber Plastic Parts Feeding: Plastic parts are fed automatically with the cooperation of a vibrating plate and a linear vibrator, including a material shortage alarm function.

3. Fiber Metal Parts Feeding: Metal parts are fed automatically in the same manner as plastic parts with a vibrating plate and a linear vibrator, including a material shortage alarm function.

4. Fiber Shell Parts Feeding: Similarly to the other parts, the fiber shell parts are fed automatically with a vibrating plate and a linear vibrator, including a material shortage alarm function.

5. Divider Turntable: A 16-position rotating disc, with the large turntable divided into three layers. The bottom layer is for rotating discs and fixed jigs for operational use, the middle layer secures various cylinder gripping mechanisms, and the top layer manages wiring of terminal boxes and pneumatic lines.

6. Loading and Unloading Manipulators: They extract products from the index tray, automatically switching materials according to the attributes designated by the software.

There is much more to the functionality and principles of this equipment that is not detailed here. Those interested can download and study it further. There are many ingenious design structures for everyone to take their time to learn and research after downloading. This is a very good set of fiber optic head automatic assembly equipment diagrams. You are welcome to learn and study further, thank you.

3. Main Technical Parameters:

Category Specification Parameters

Complete Machine Dimensions: 2100*1700*2000MM (L*W*H)

Input Voltage: AC-220V 50Hz or AC-380V 50Hz optional

Maximum Machine Power: 2.2 KW (220V)

Input Air Source Pressure: 0.4-0.6 Mpa

Air Consumption: 1.5 L/min

Production Efficiency (C/T): ≤4.0 S/piece

Device Utilization Rate: ≥95%

Processing Method: Automatic Loading, Feeding, Automatic Assembly, Automatic Collection

Manipulator Motion Resolution: 0.005 mm

Manipulator Repeat Positioning Accuracy: ≤±0.02 mm

Control Communication Method: Manual disc placement

Programming Method: Touchscreen Parameter Modification

Specification: Fiber Optic Connector Assembly Machine Network Signal Plug Assembly Machine Non-Standard Assembly Equipment

|

User Reviews

Be the first to review “Fiber Optic Connector Assembly Machine Network Signal Plug Assembly Machine Non-Standard Assembly Equipment”

You must be logged in to post a review.

There are no reviews yet.