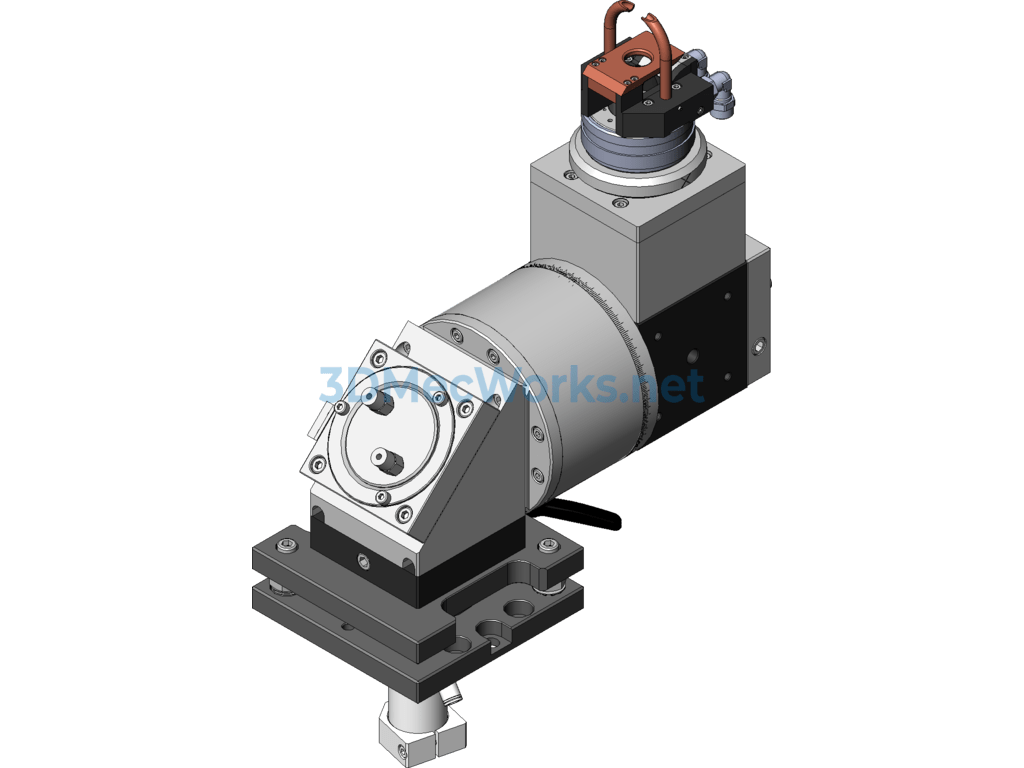

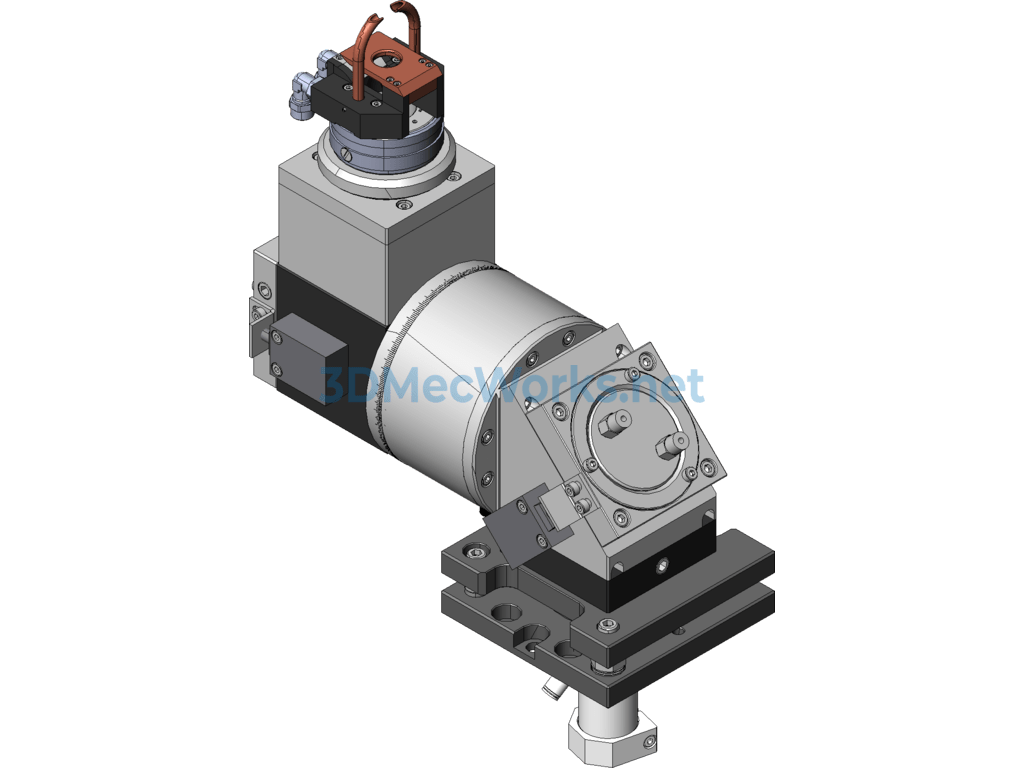

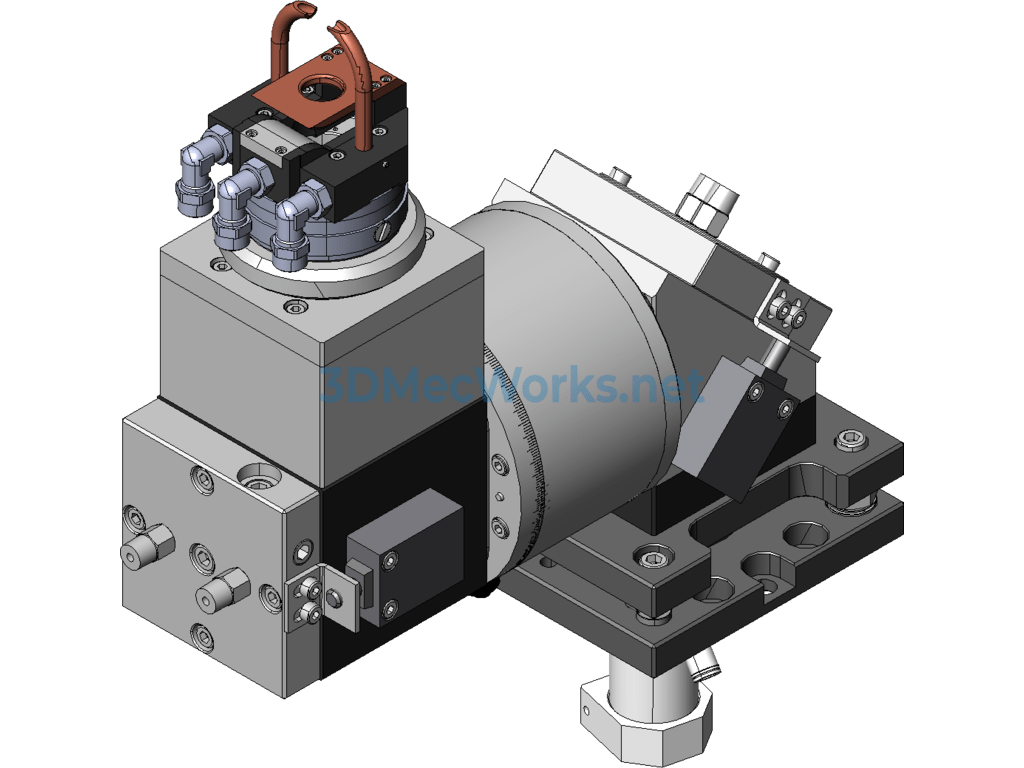

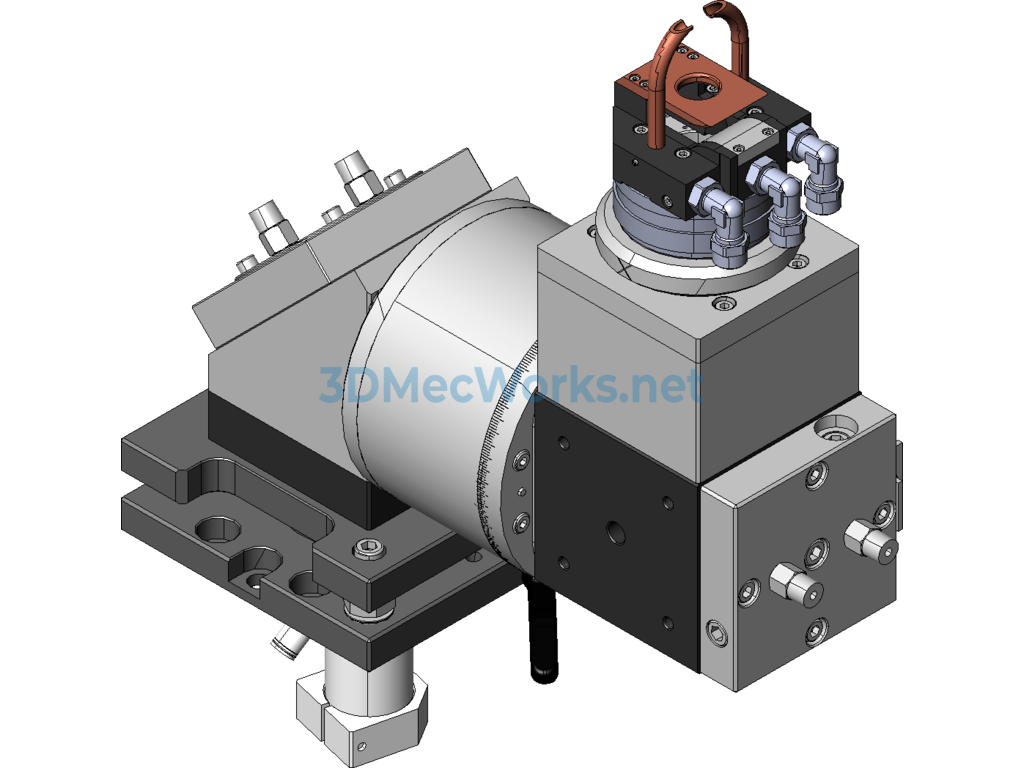

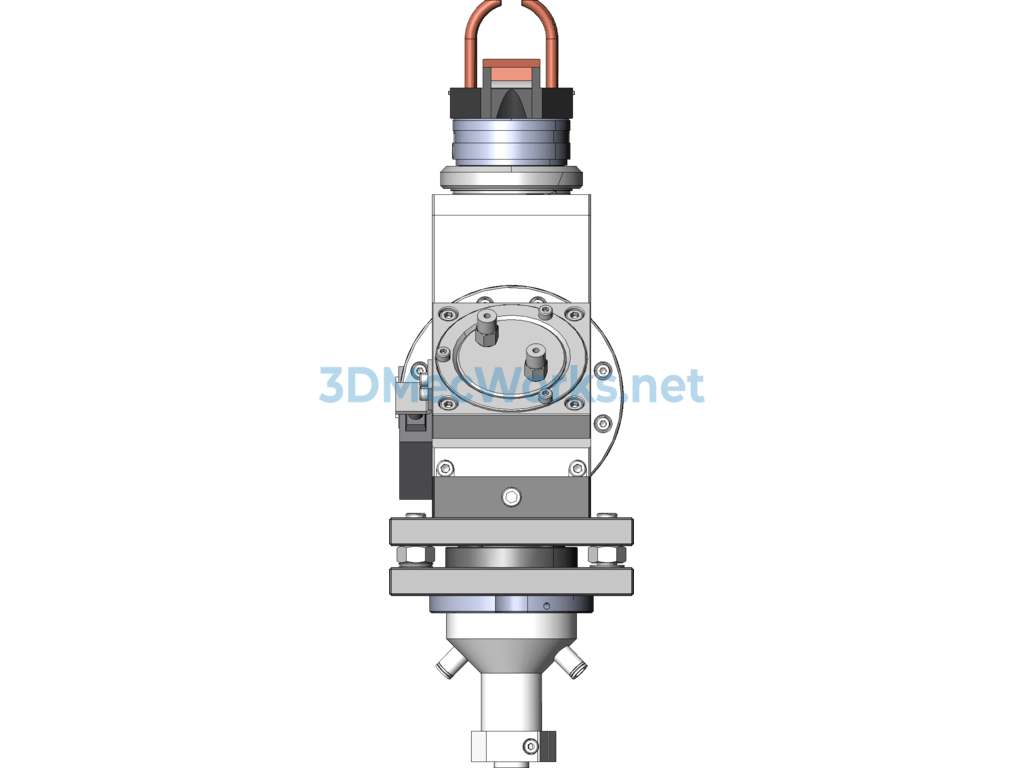

This is a 3D model original file of a fiber laser welding head, fully editable. Laser welding technology has significant advantages. The advantages primarily include: greater penetration depth/larger gap welding capability; better toughness of welds, with the ability to influence weld lattice structure through the addition of auxiliary materials; no sagging on the back of the weld when there is no burn-through; wider applicability; less investment with laser substitution technology. For laser MIG inert gas shielded welding hybrid, the advantages mainly include: higher welding speed; greater welding depth; less heat generated during welding; high strength of the welds; narrow weld width; small weld protrusion. This ensures the entire system’s production process is stable, equipment availability is good; minimal weld preparation and post-welding treatment; short welding production time, low cost, and high production efficiency; excellent optical equipment configuration performance. The fiber welding head file is in SolidWorks 2016 version format. Feel free to download for reference.

Specification: Fiber Laser Welding Head

|

User Reviews

Be the first to review “Fiber Laser Welding Head”

You must be logged in to post a review.

There are no reviews yet.