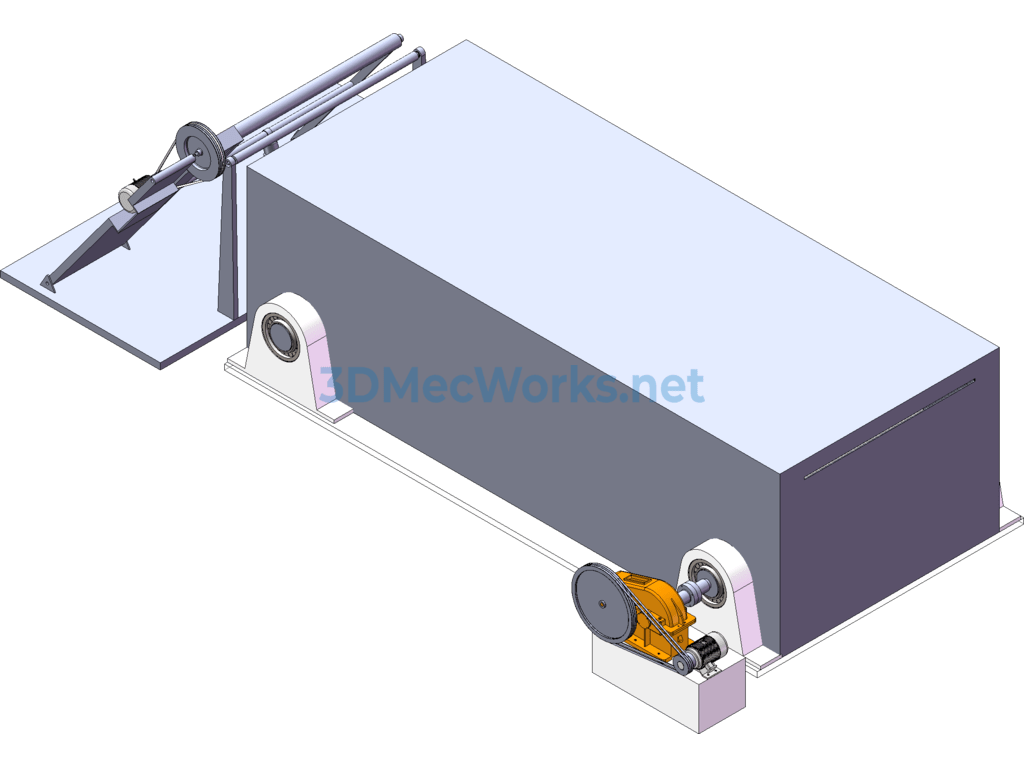

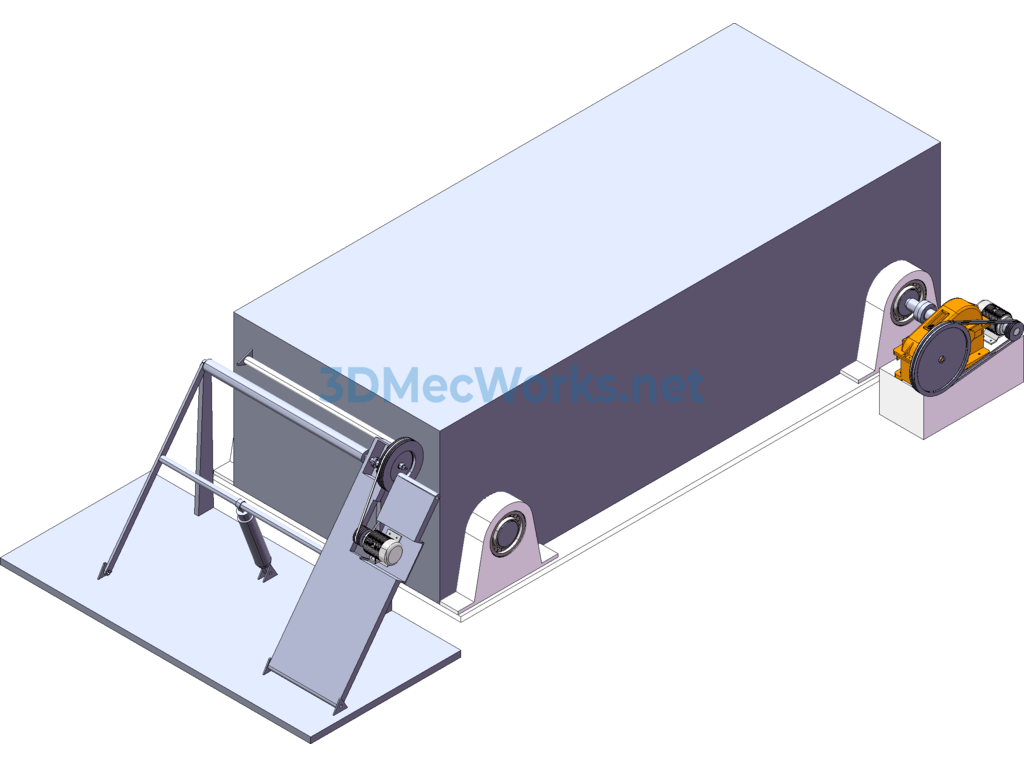

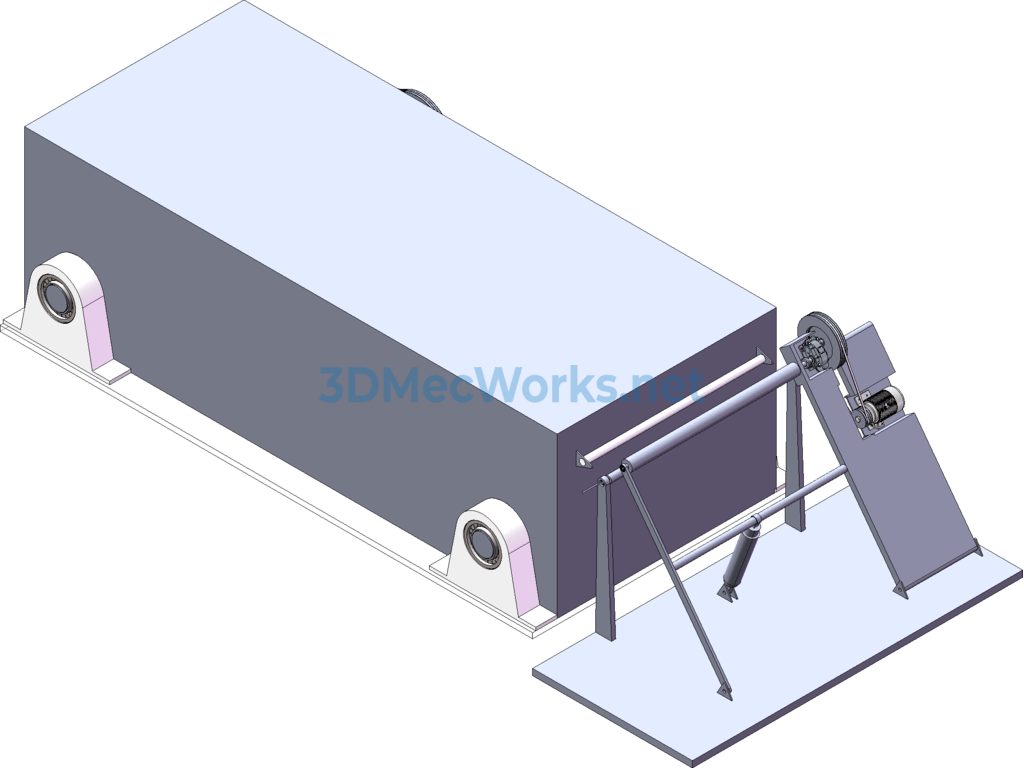

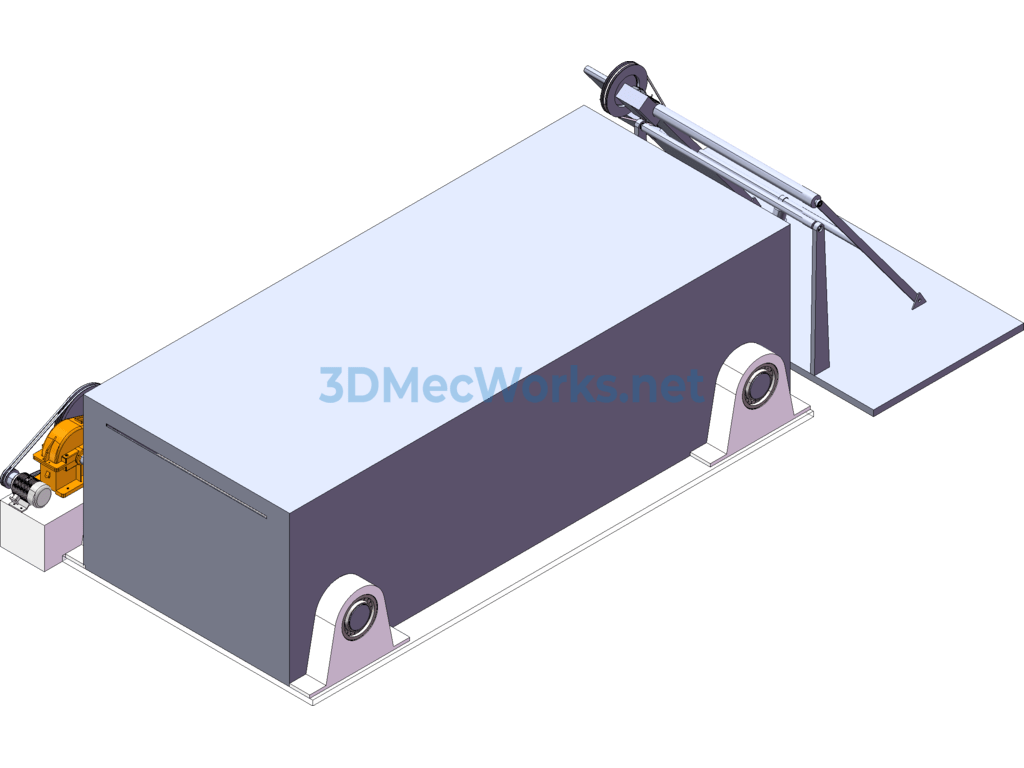

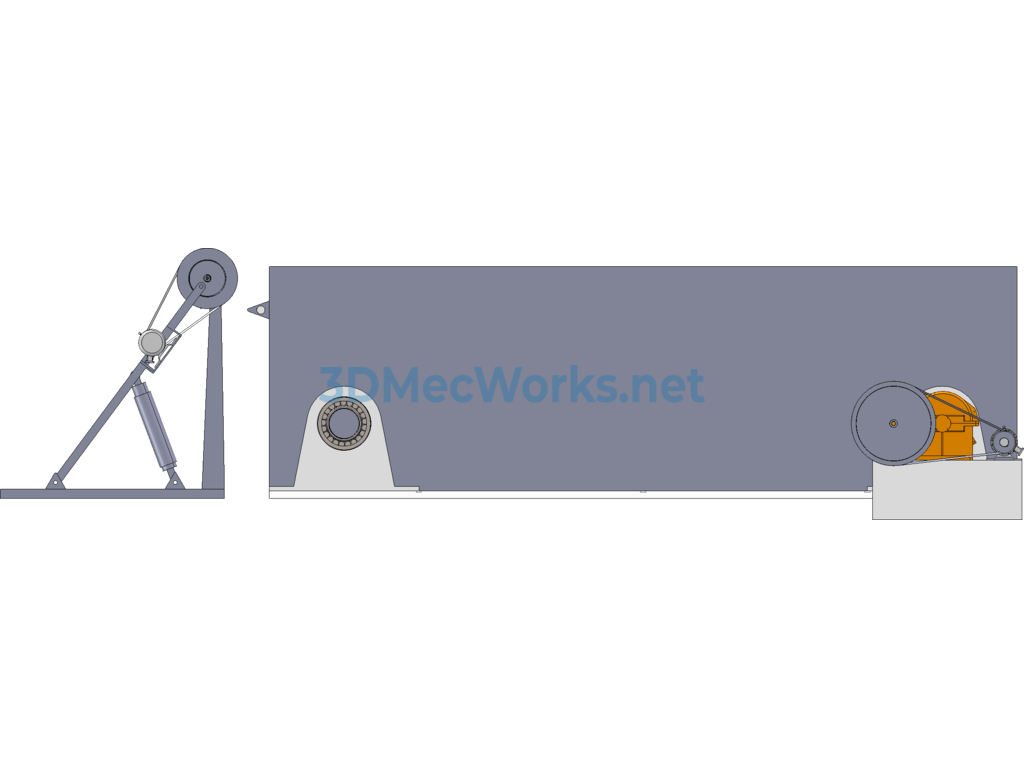

A machine for detecting and cutting damaged spots in cloth, the working process of this product is as follows: First, the non-woven fabric product reaches the non-woven fabric damage spot detection device along the production line. This detection device will automatically check whether there is a damage spot on the product. If there is a damage spot, the device will trigger an alarm, the production line will stop running, and the damaged spot will be cut. Then, the rewinding process of a roll of non-woven fabric will restart. The main innovations of this product are: 1. It can automatically detect whether there is a damaged spot on the product in front of it. 2. It can give an alarm when there is a damaged spot. 3. It can cut the damaged spot again and restart the rewinding of non-woven fabric.

Specification: Fabric Inspection Device (defect Detection)

|

User Reviews

Be the first to review “Fabric Inspection Device (defect Detection)”

You must be logged in to post a review.

There are no reviews yet.