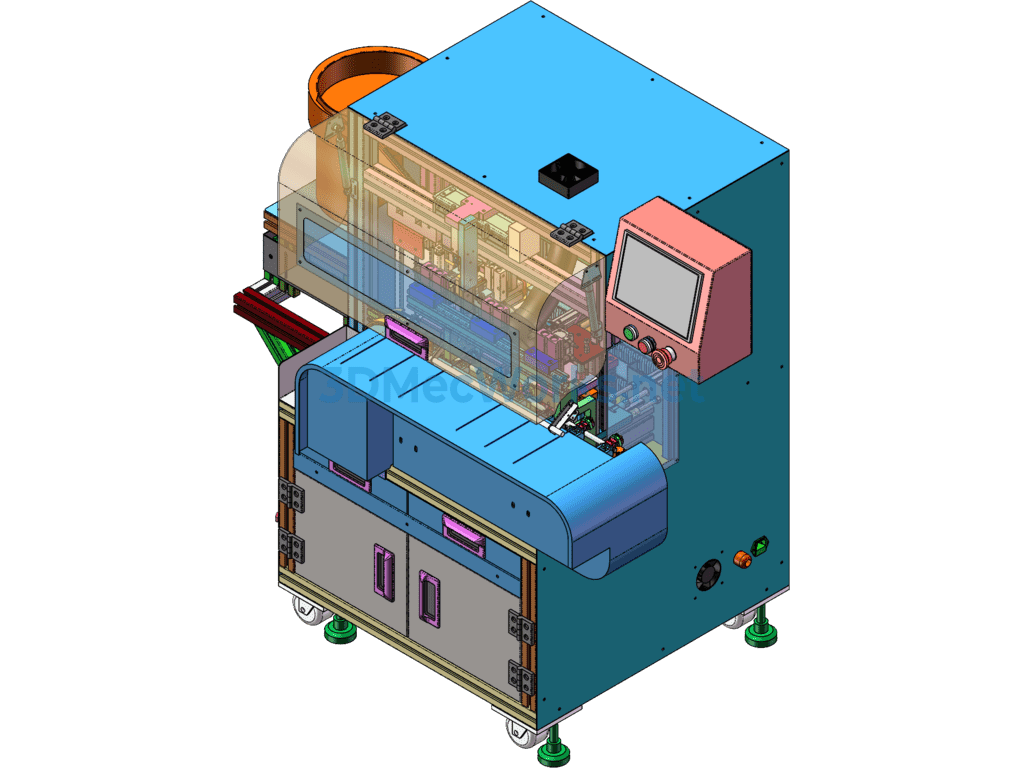

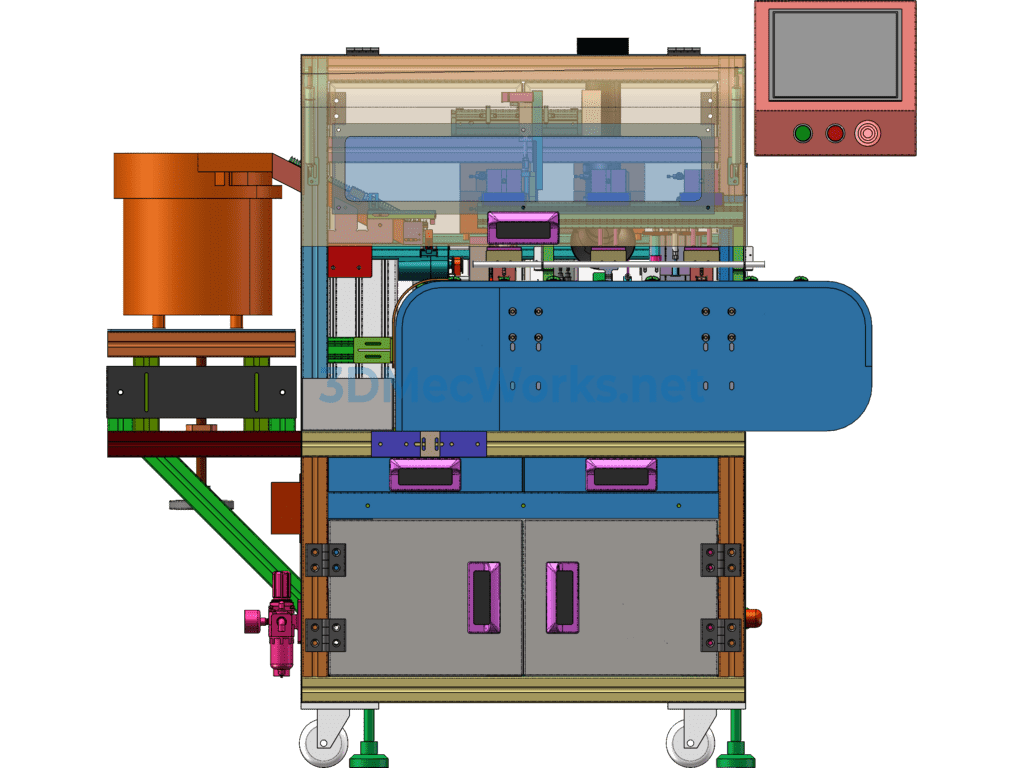

Earphone soldering machine

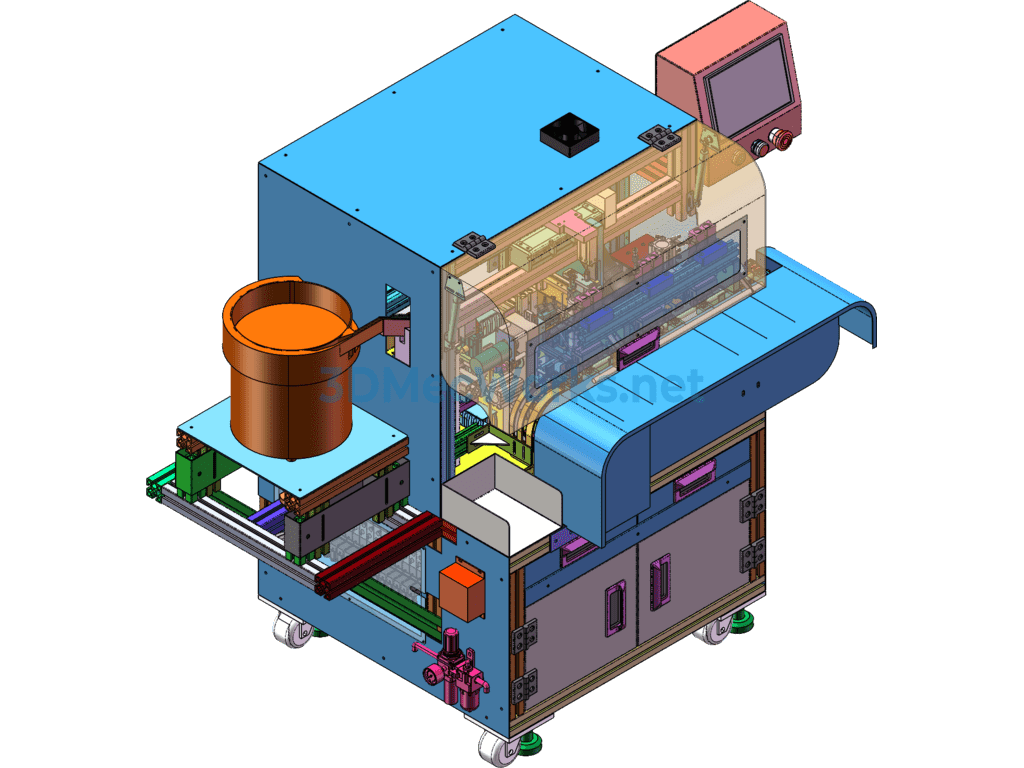

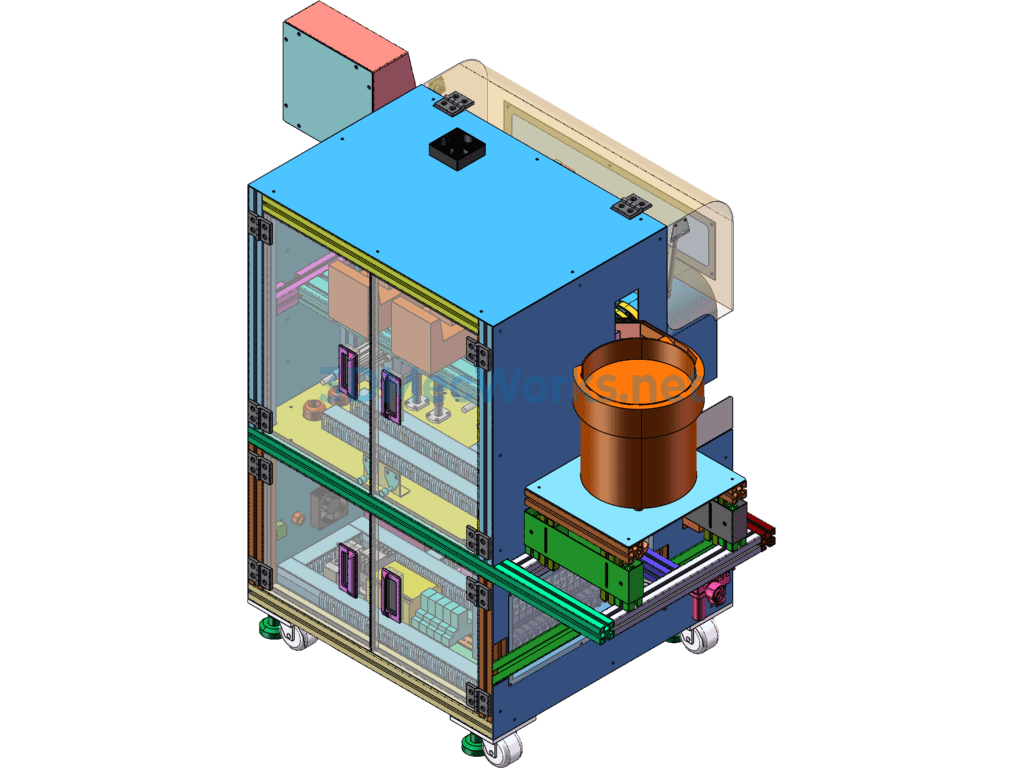

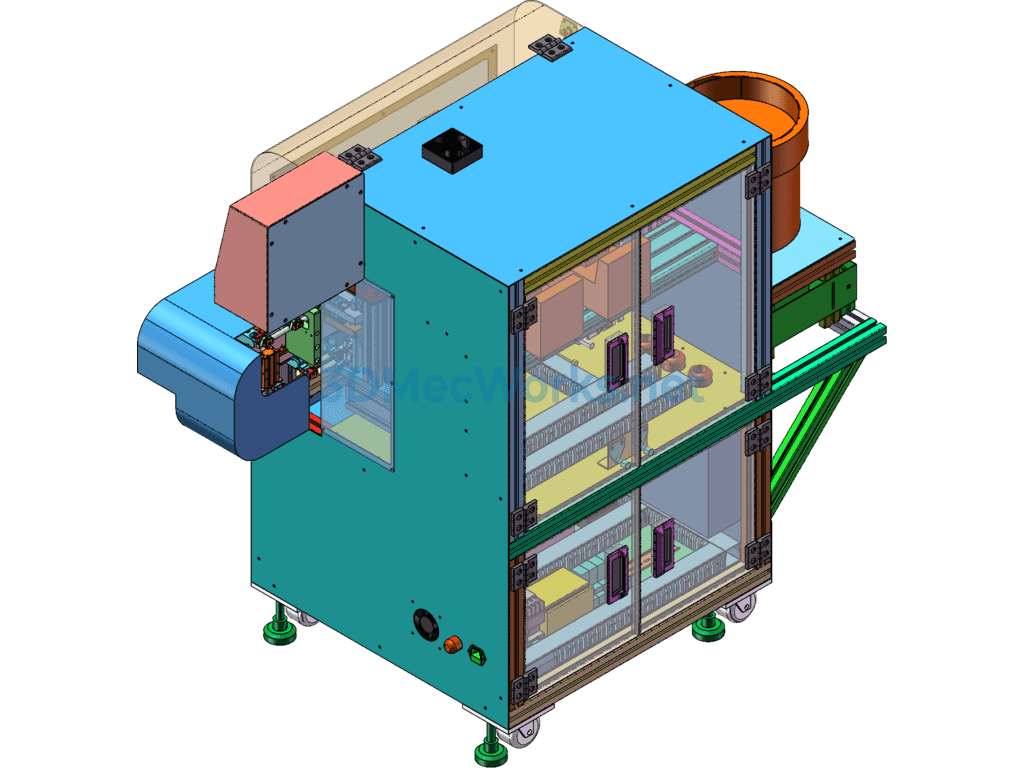

Position relationship: From front to back are LK1 (cam mechanism), (fixture), (robotic arm), (positioning mechanism), (telescopic mechanism), (twisting and cutting mechanism), (tin dipping mechanism), (soldering mechanism), (feeding mechanism), (material picking mechanism).

Connection relationship: Below is a summary of the basic working principle of pin charging connector tin dipping and soldering equipment.

1. In the default state, the (robotic arm) is in a closed state, causing the fixture clamp to open, allowing the earphone cable to be fixed onto the (fixture).

2. After the earphone cable is positioned, the controller controls the (cam mechanism) to move forward one station while the (robotic arm) opens. After moving two stations with the same steps, when the earphone cable reaches the (twisting and cutting mechanism) workstation, the (positioning mechanism) comes into play.

3. The (positioning mechanism) performs a secondary positioning of the (fixture) using the correction block and clamp. The twisting branch of the (twisting and cutting mechanism) begins to work. The uneven earphone core wires reach the same horizontal plane after the twisting step, providing favorable conditions for subsequent mechanisms.

4. After completing the twisting, the (cam mechanism) moves forward one more station one second before the (positioning mechanism) returns to its original position. The earphone wires reach another cutting workstation of the (twisting and cutting mechanism) where they are completely trimmed under the action of the cutting agency, facilitating subsequent tin dipping. Every time it moves forward one station, all actions above are repeated.

5. When the (cam mechanism) reaches the tin dipping station and the (tin dipping mechanism) reaches the predetermined position, the (telescopic mechanism) extends and rotates the fixture a certain angle, completing the tin dipping of the earphone wires. The tin dipping mechanism and telescopic mechanism return to their original positions, and the fixture is restored to its pre-rotation state under the action of the tension spring.

6. Then the cam mechanism moves two stations sequentially to the (soldering mechanism) workstation. The (material picking mechanism) robotic arm picks the connector pin head and transfers the connector pin to the robotic arm of the (feeding mechanism) via the rotating component. After the connector pin is delivered to the designated position, some components in the feeding mechanism correct the connector pin. Once the connector pin finds the correct position, it will slip. After several rotations, the rotating body stops, and the product is sorted correctly. At this point, the robotic arm grabs the connector pin, and after multiple layers of delivery, the connector pin is brought in front of the (soldering mechanism).

7. While the (soldering mechanism) is working, the positioning mechanism before the soldering station repositions the (fixture) again to ensure soldering accuracy. After soldering is completed, the (cam mechanism) moves two stations forward, and the earphone wires naturally slide into the material pickup tray under the action of the top plate, completing the soldering step with the connector pin. Every time it moves forward one station, all actions above are repeated.

Software: SolidWorks2016

Attachments include: drawings, engineering drawings, 3D, assembly drawings, part drawings, BOM table.

Specification: Earphone Cable Soldering Machine

|

User Reviews

Be the first to review “Earphone Cable Soldering Machine”

You must be logged in to post a review.

There are no reviews yet.