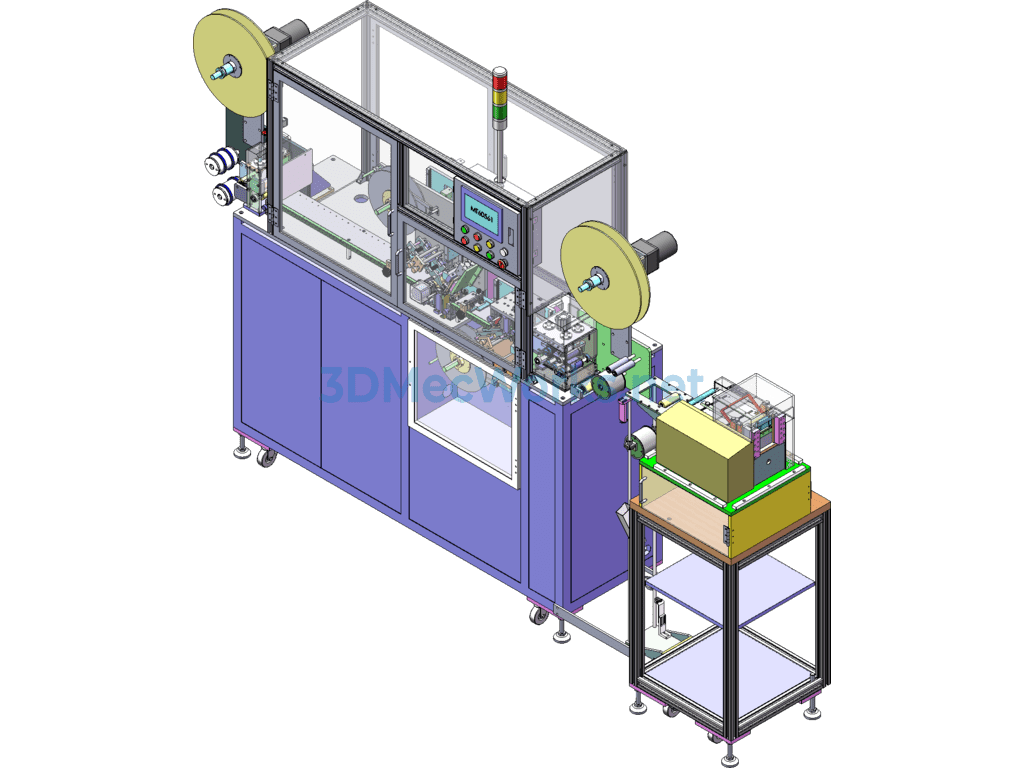

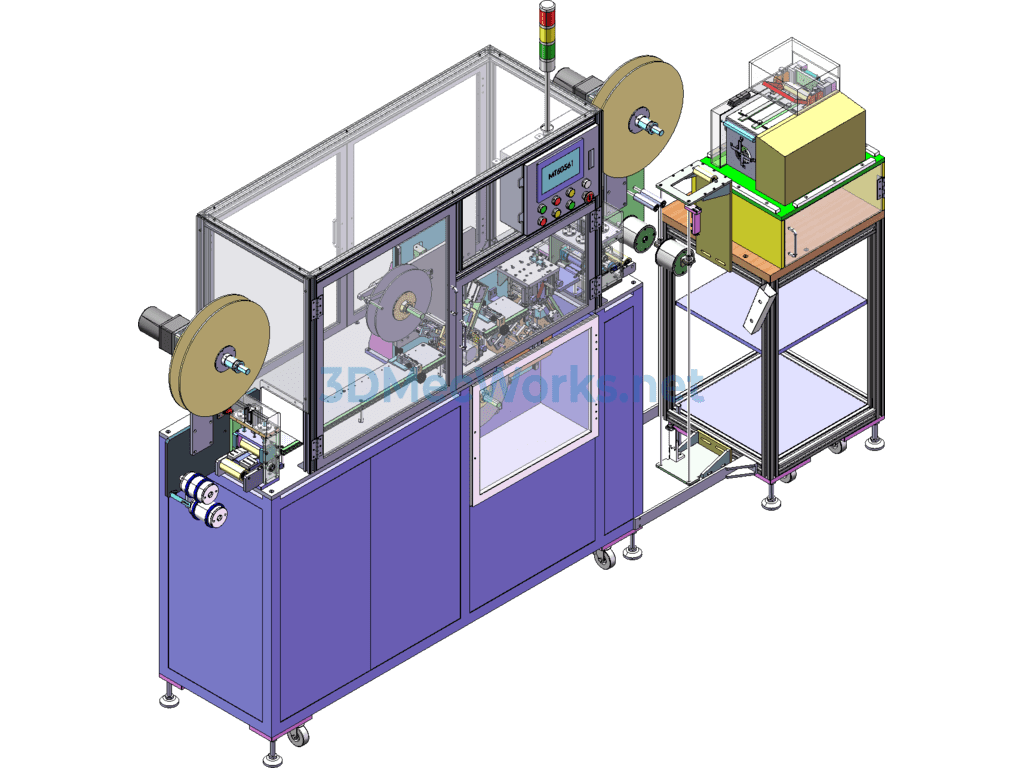

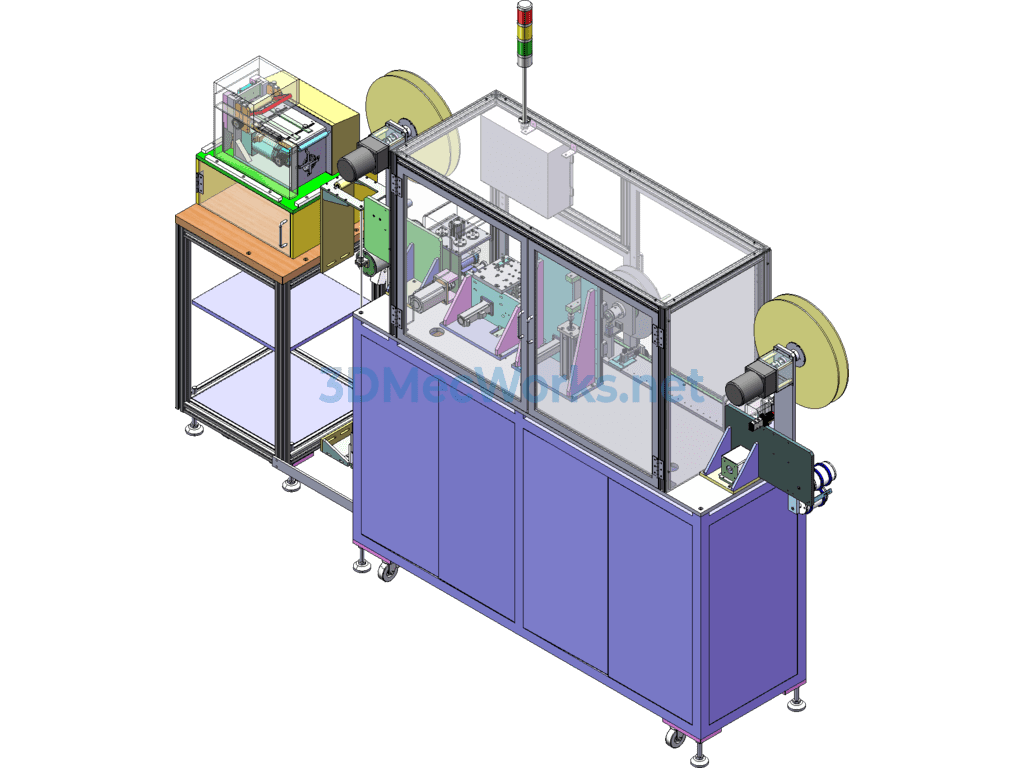

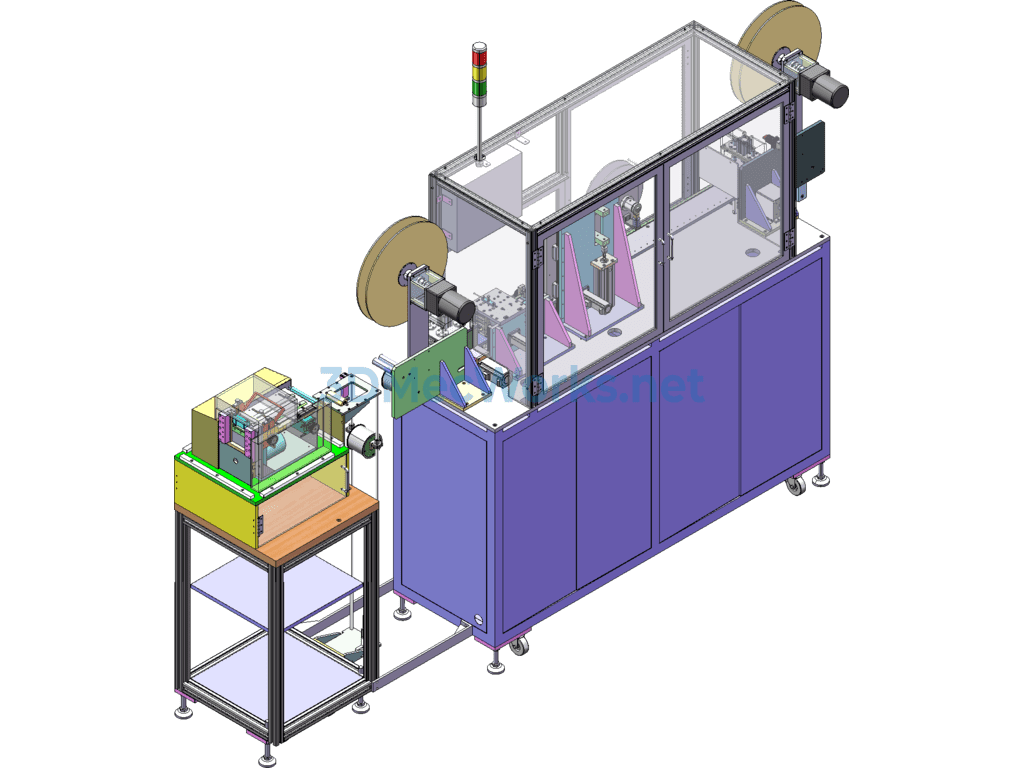

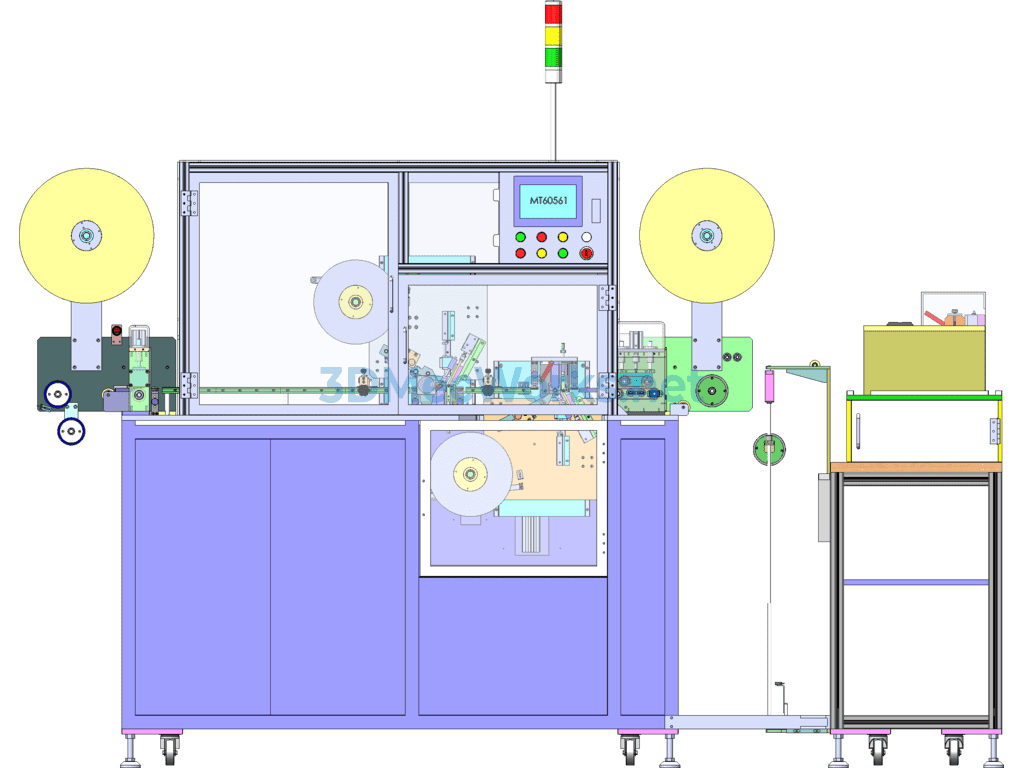

Full-Automatic Double-Sided Adhesive Tape Application Machine for FPC with Complete Line 3D Model. This full-automatic FPC double-sided adhesive application machine can also apply high-temperature and transparent adhesive tapes. The overall design of the device is quite intelligent and highly functional. Starting from the front-end feeding structure, the very front part of the equipment is the feeding section, where the products requiring adhesive tape are made into coil form to enter from the front end. Then, it reaches the adhesive tape application section, where there are a total of two adhesive tape application modules: the front one applies adhesive to the top, while the rear adhesive tape machine is used for applying to the bottom. The adhesive application structure is relatively complex, with principles similar to those of labeling machines, but with an additional cutting function. This means that after the adhesive tape is applied, it needs to be cut, and then the adhesive tape is applied again to the product. Due to the complexity of this adhesive tape application structure, it’s better viewed directly for understanding. Next, let’s introduce the rear-end cutting section. After applying adhesive tapes to both sides in the front section, the product enters a rear-end cutting station, where the products with applied adhesive tape are cut one by one to become finished products. Here, double-sided adhesive tape is applied to FPC flexible flat cables. Those who are interested are welcome to download this FPC line double-sided adhesive application machine and non-standard full-automatic double-sided adhesive mechanical equipment for learning purposes.

Specification: Double-Sided Tape Machine, Non-Standard Fully Automated Double-Sided Tape Applicator for Fpc Line

|

User Reviews

Be the first to review “Double-Sided Tape Machine, Non-Standard Fully Automated Double-Sided Tape Applicator for Fpc Line”

You must be logged in to post a review.

There are no reviews yet.