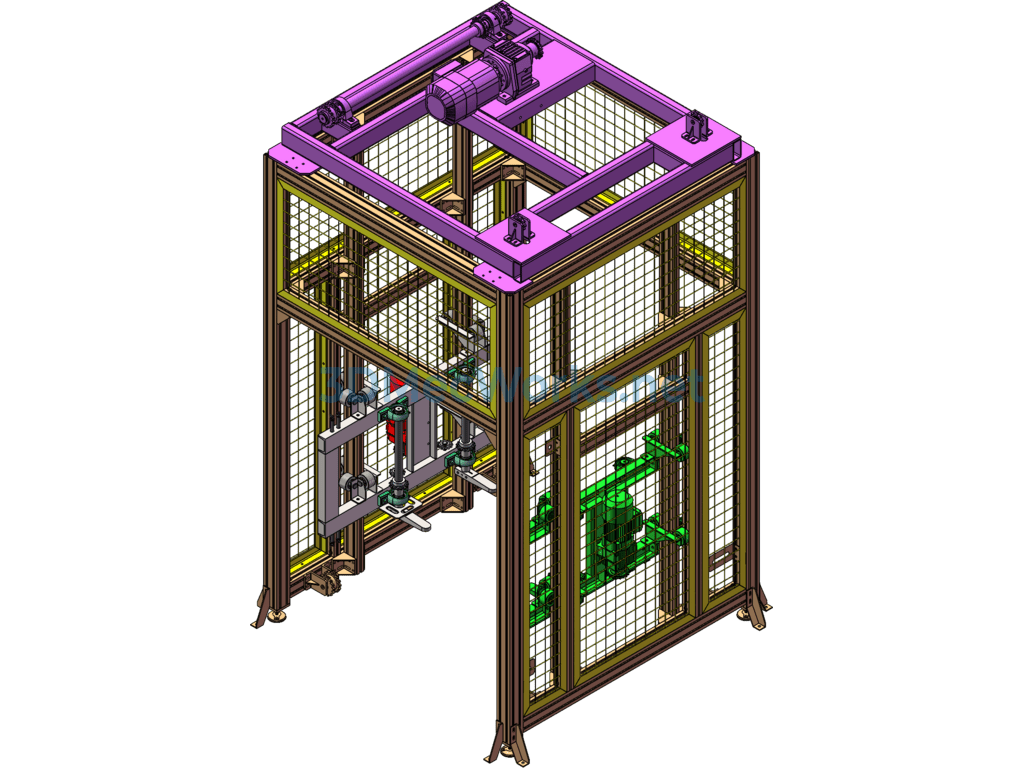

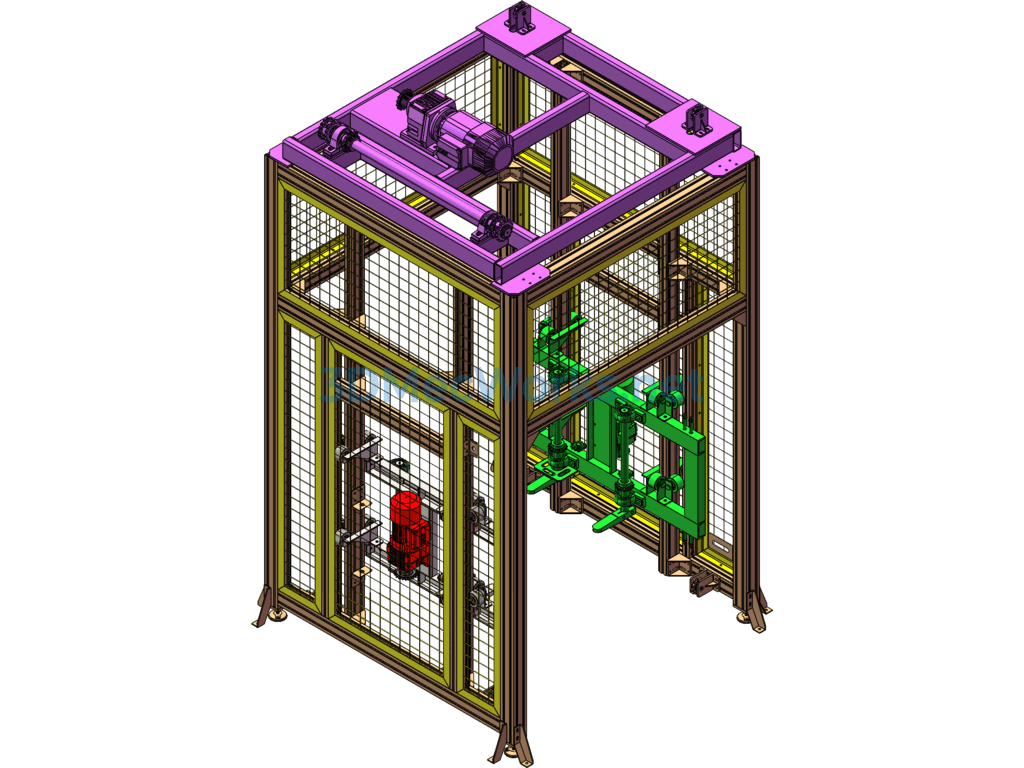

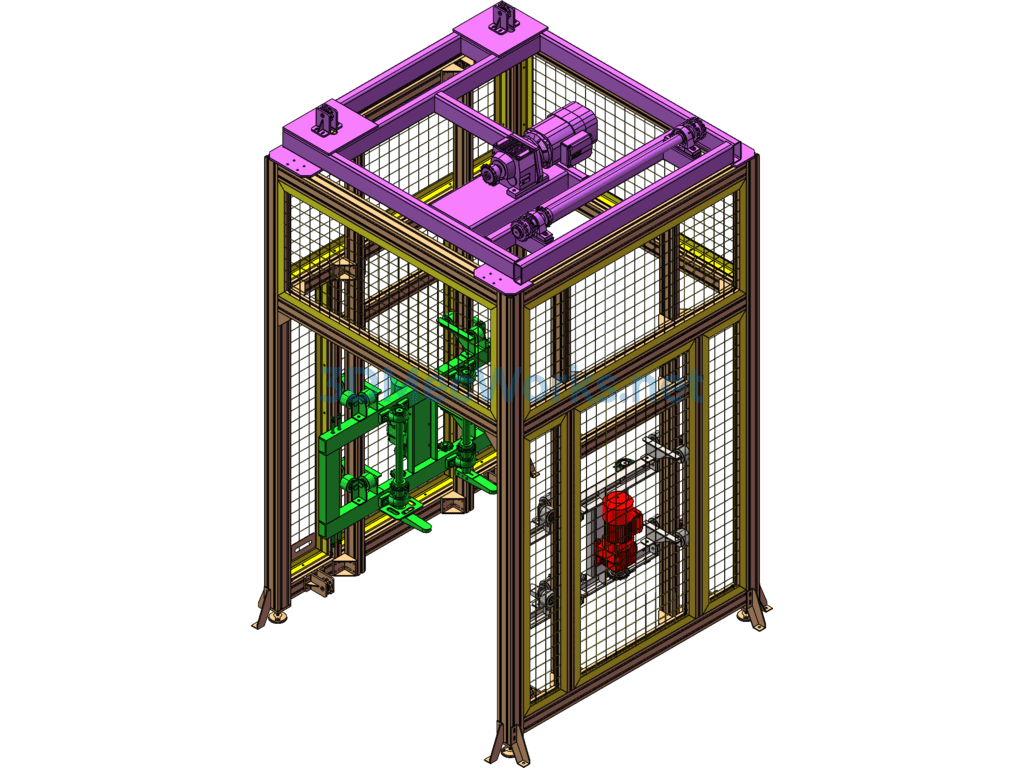

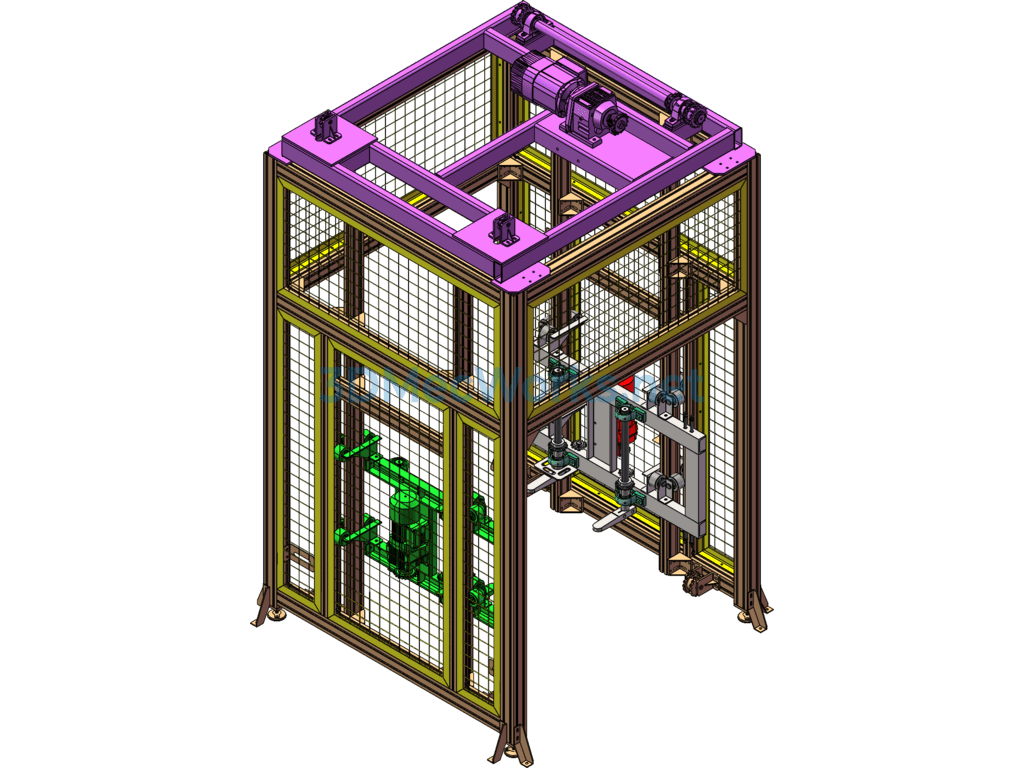

Disc stackers and de-stackers are used in pallet conveying systems. They work in combination with various conveyors to either collect empty pallets from the conveying line or distribute empty pallets to it.

Disc Stacker: Also known as a pallet collector, this machine automatically stacks empty pallets, which have had their goods removed via the conveyor line, into a pile (usually 6-10 pallets) when sent one by one to the stacker. The stacked pallet pile is then stored or redistributed for use.

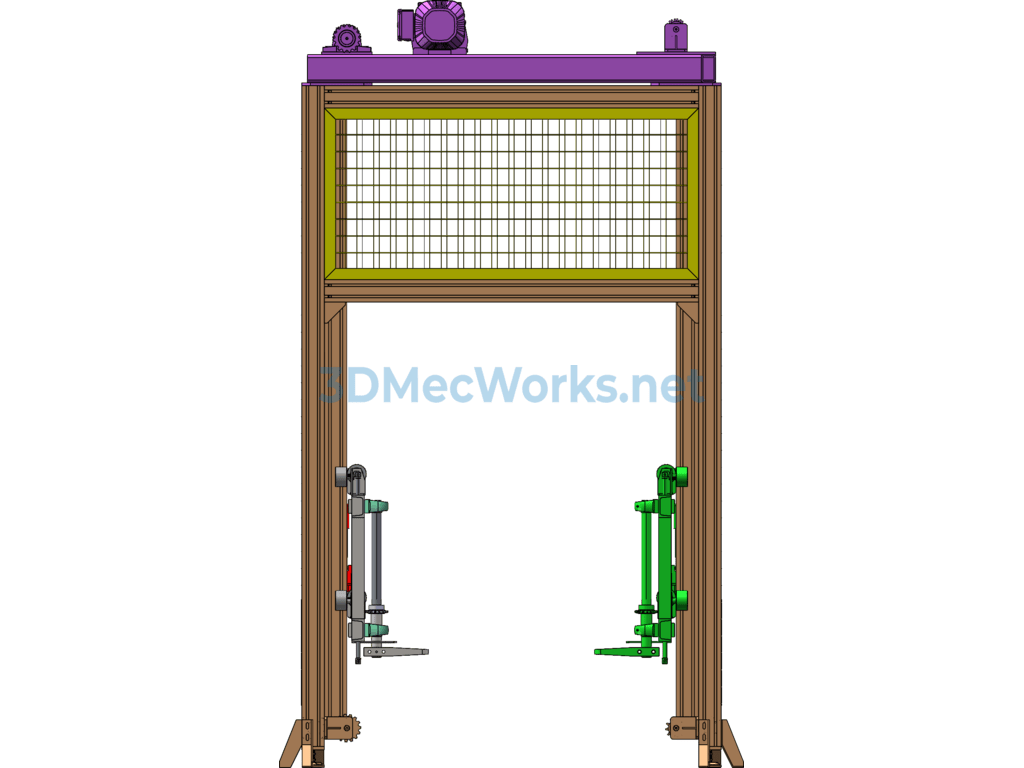

De-stacker: This machine functions in the opposite way to a stacker. It separates and sends out stacked pallets one by one as needed.

The external structures of stackers and de-stackers are essentially the same. Besides possessing all the structures and functions of a stacker, a de-stacker is equipped with an additional independent top fork drive mechanism.

Stackers and de-stackers generally cannot be used alone. They need to be integrated into the conveying system. They either stack single empty pallets delivered via the conveying line or de-stack the pallet piles sent in and then redistribute them via the conveying line.

Specification: Disk Disassembly Machine

|

User Reviews

Be the first to review “Disk Disassembly Machine”

You must be logged in to post a review.

There are no reviews yet.