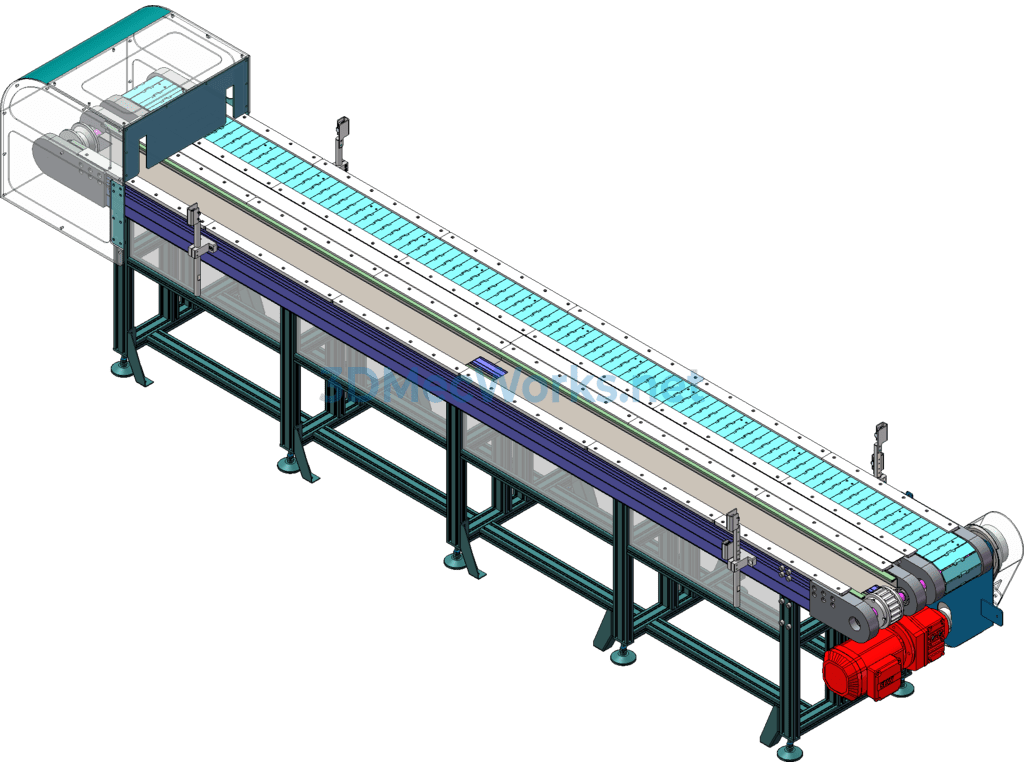

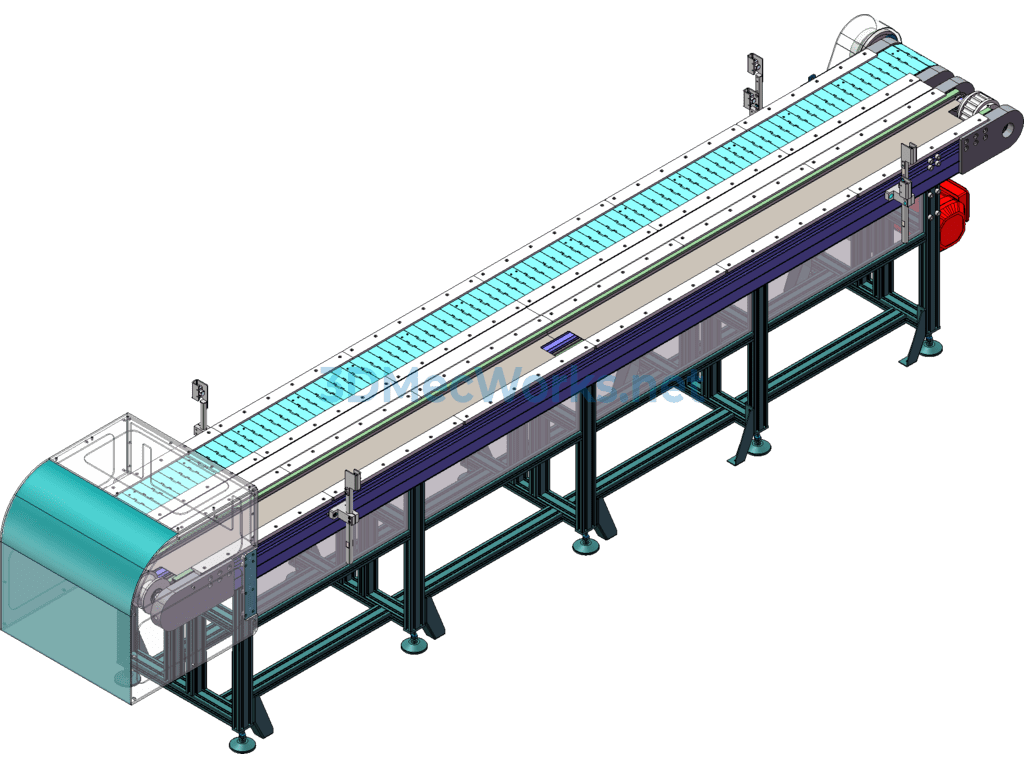

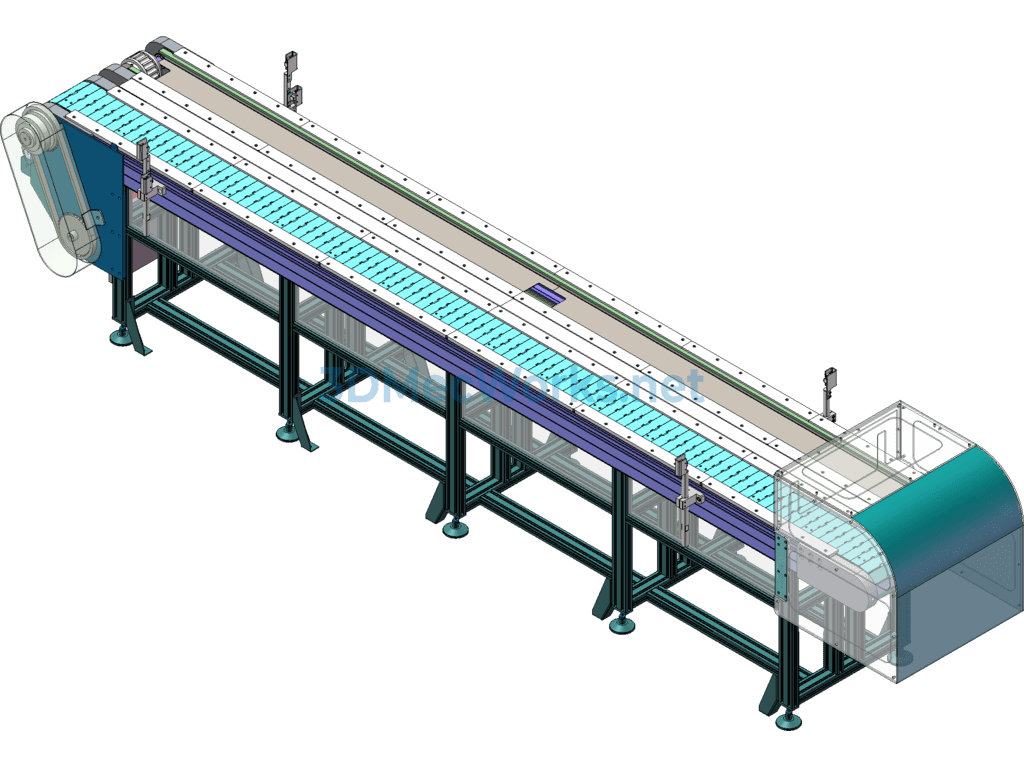

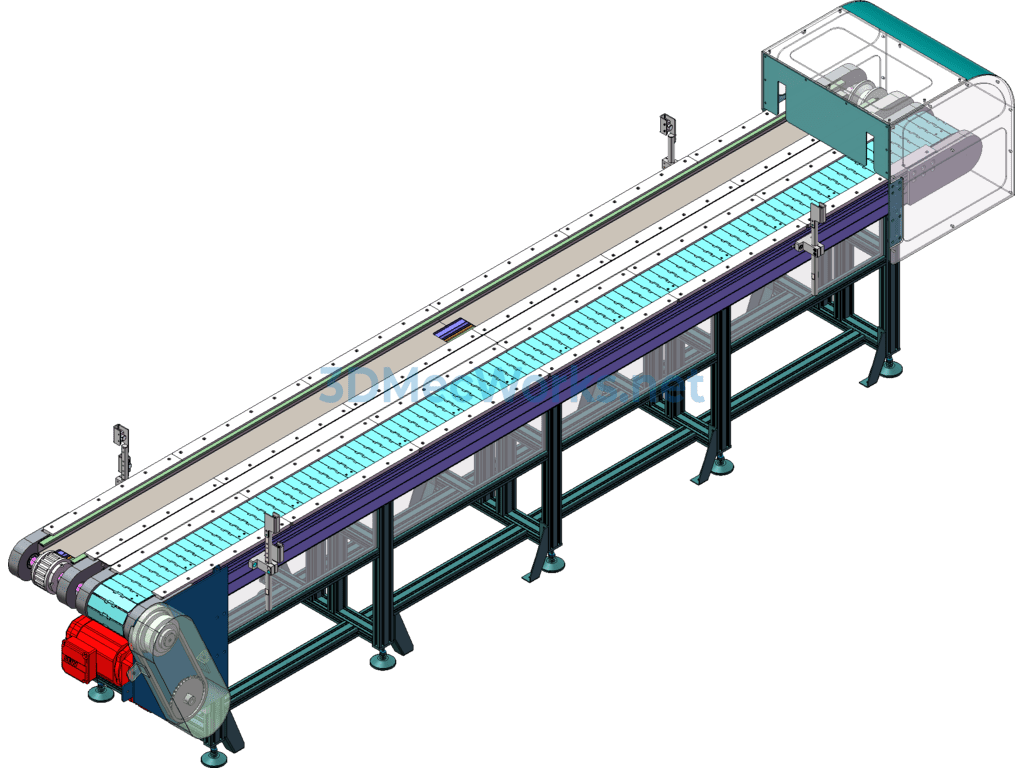

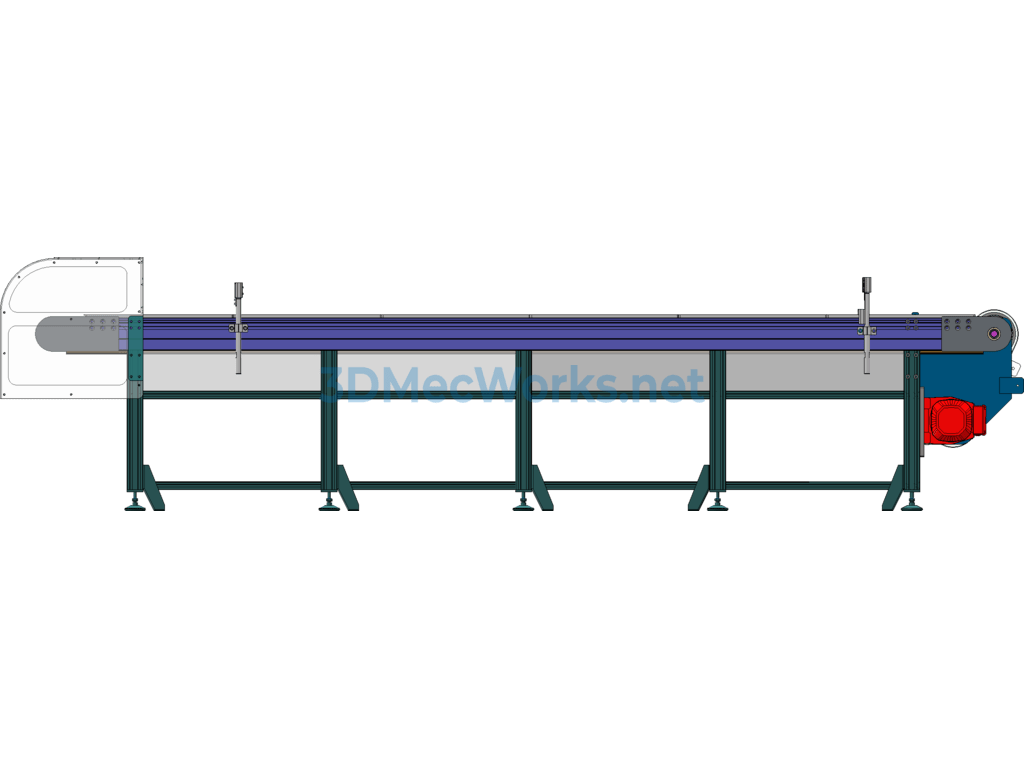

Stainless steel chain plate line hs-0900 crankshaft conveyor is a conveying device that uses a standard chain plate as a bearing surface and a motor reducer as power transmission. The chain plate conveyor consists of a power device (motor), transmission shaft, drum, tensioning device, sprocket, chain, bearing, lubricant, chain plate, etc. The two main parts for carrying materials are: the chain, which provides traction power through its reciprocating motion; and the metal plate, which serves as the carrier during the conveying process. Multiple rows of chain plates can be operated in parallel, making the chain plate conveyor wide and forming a differential speed. The speed difference between multiple rows of chain plates allows multiple rows to convert to single-row conveyance without extrusion, thus meeting the requirements for single-row conveyance in equipment such as beverage labeling, filling, and cleaning. The head and tail of two chain plate conveyors can be made into an overlapping mixed chain to keep the bottle (can) in a dynamic transition state, preventing material retention on the conveyor line. This can satisfy the pressure and non-pressure conveying of empty and full bottles.

Specification: Crankshaft Stainless Steel Plate Chain Line 3d Model + Engineering Drawing

|

User Reviews

Be the first to review “Crankshaft Stainless Steel Plate Chain Line 3d Model + Engineering Drawing”

You must be logged in to post a review.

There are no reviews yet.