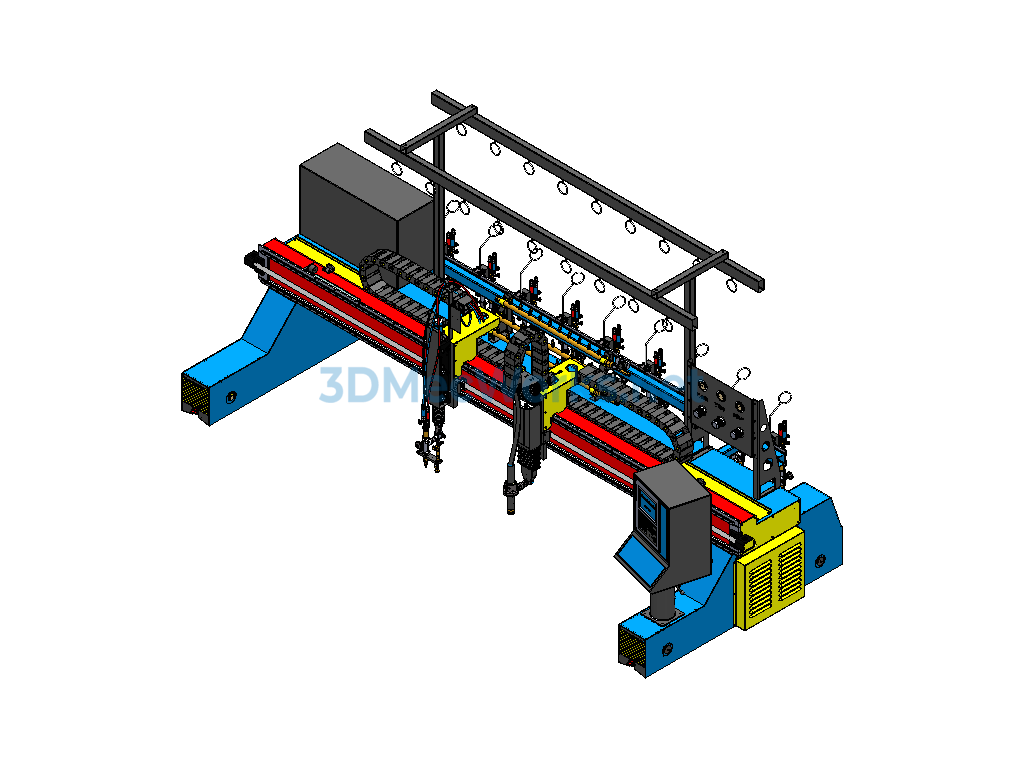

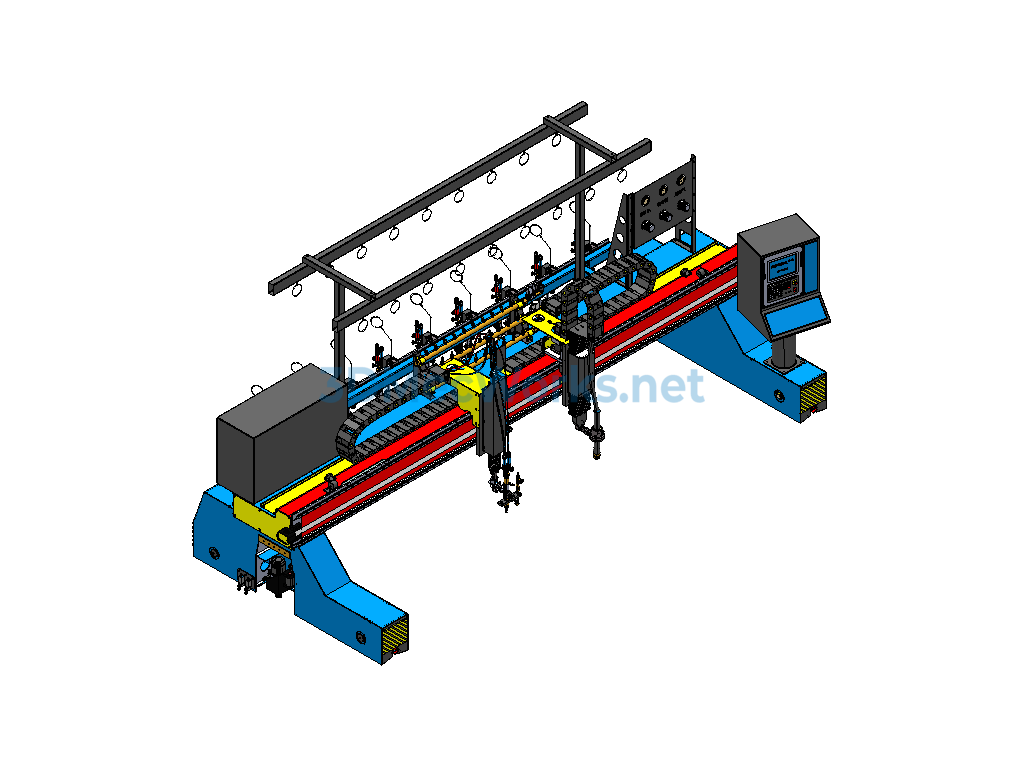

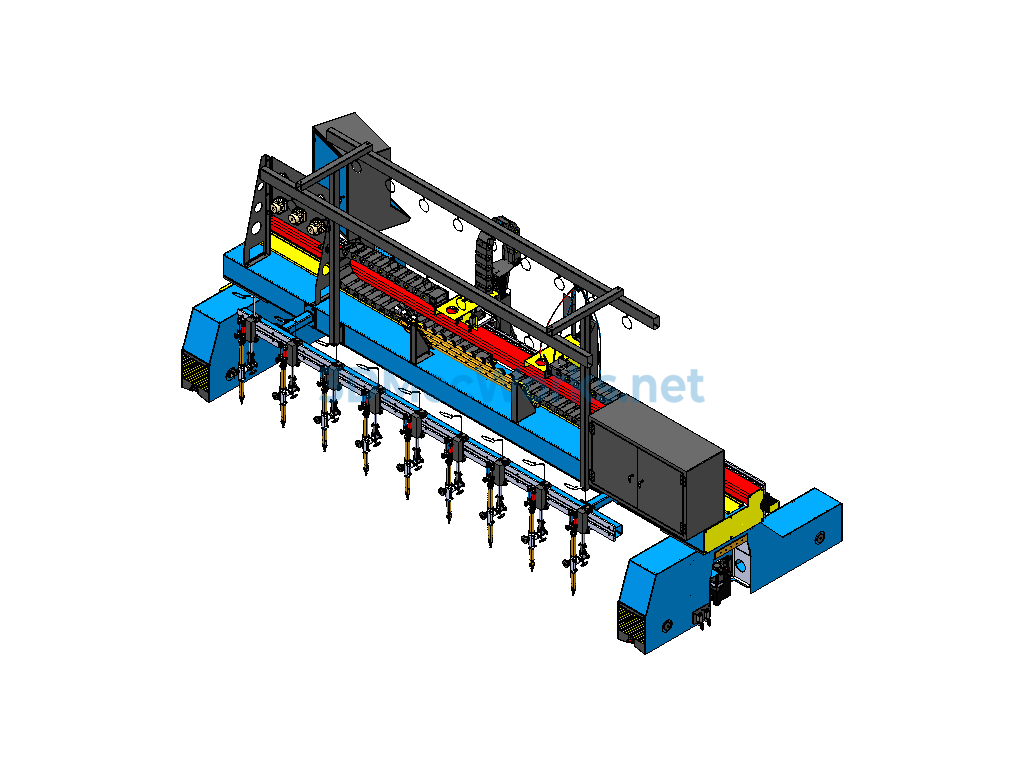

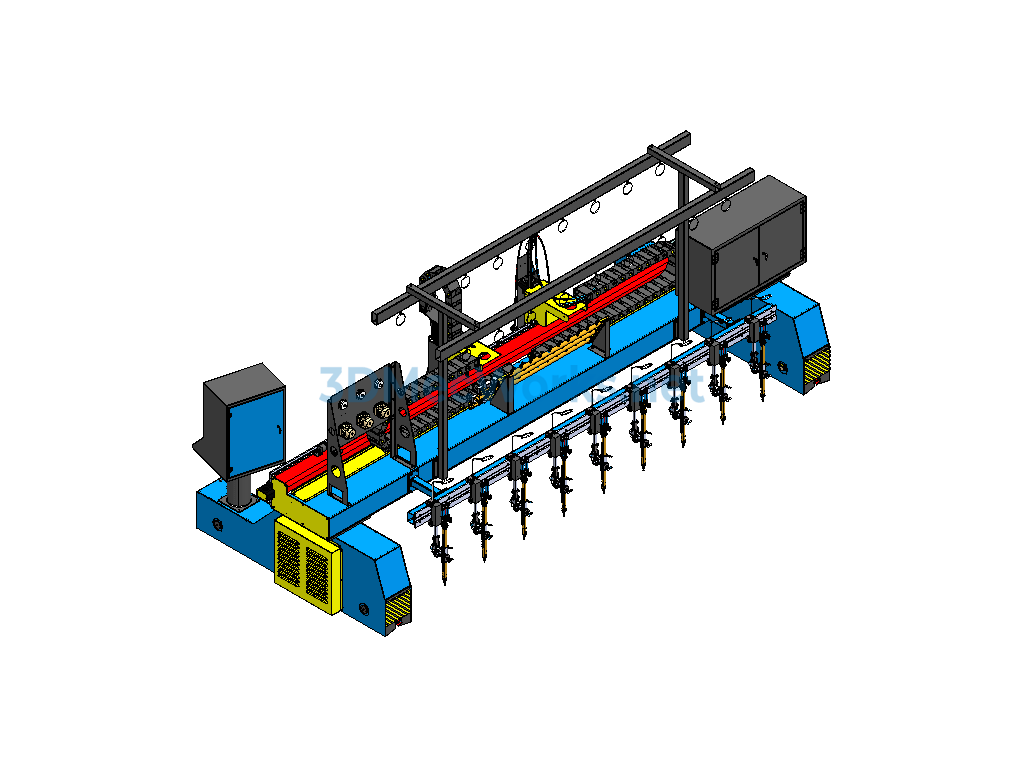

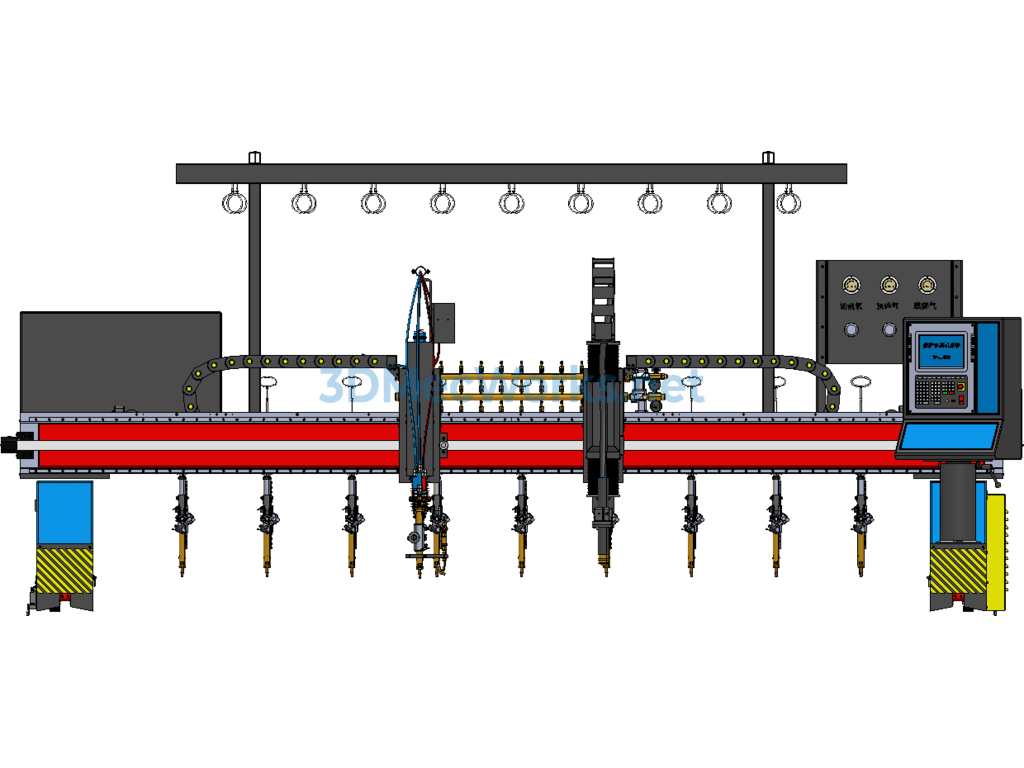

The frame of the CNC 4-meter plasma cutting machine adopts a fully welded structure, with a vibration processor to eliminate internal stress, thereby improving frame stability and reducing deformation. The X-axis uses a high-precision linear circular guide rail, and the Y-axis uses a high-precision linear guide rail, both exhibiting low resistance during operation. Multifunctional instruments are installed for testing on the X-axis and Y-axis, ensuring the straightness error of the X-axis is less than ±0.05mm, and the vertical error between the X-axis and Y-axis does not exceed ±0.05mm. The operation trolley adopts a lightweight structure, facilitating plasma cutting quality assurance. The industrial computer operating system is based on a stable DOS system, offering a good human-machine interface and allowing for free switching between Chinese and English languages. The maximum running speed of the X-axis and Y-axis can reach 8 meters per minute. The industrial control computer can interface with ISO standard CNC languages, display cutting graphics, simulate cutting, and supports manual programming functions. The main control system of the plasma cutting machine features a drive transmission system utilizing Mitsubishi Electric’s digital AC servo system from Japan. The motor uses high-magnetism rare earth materials, providing good magnetic conductivity and heat dissipation. Its encoding resolution is four times that of ordinary types, thereby ensuring higher control precision. The cutting software introduces special European duct drawing software, with a large library, simple learning curve, flexible operation, and high cutting accuracy.

Specification: Cnc Plasma Cutting Machine

|

User Reviews

Be the first to review “Cnc Plasma Cutting Machine”

You must be logged in to post a review.

There are no reviews yet.