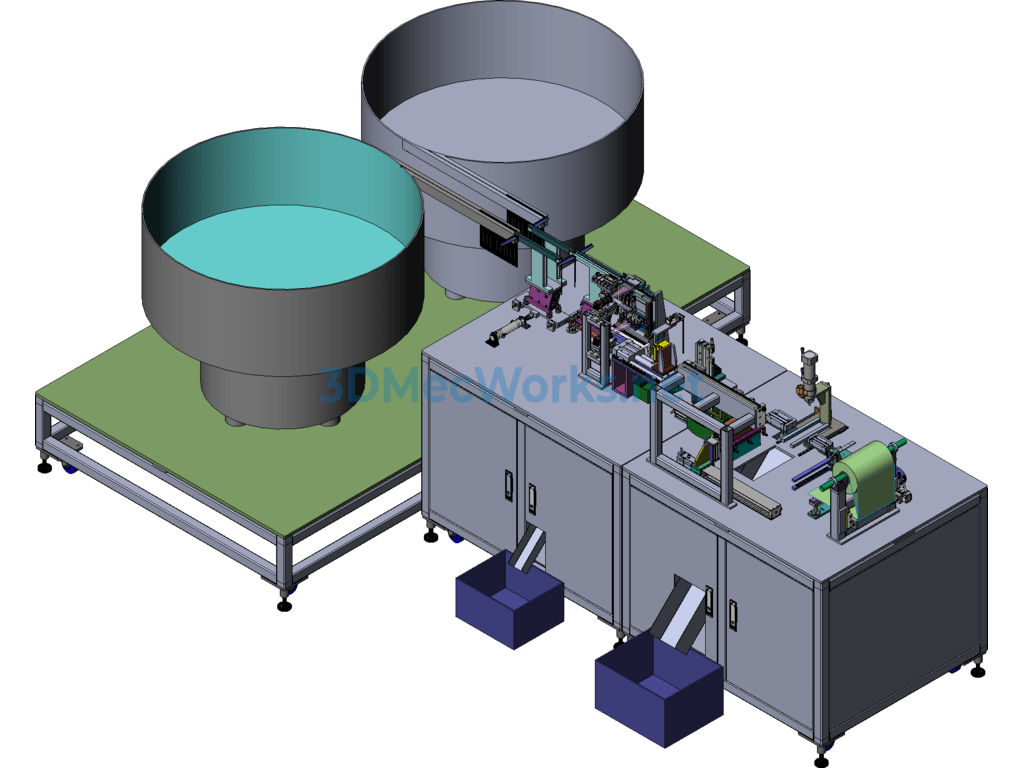

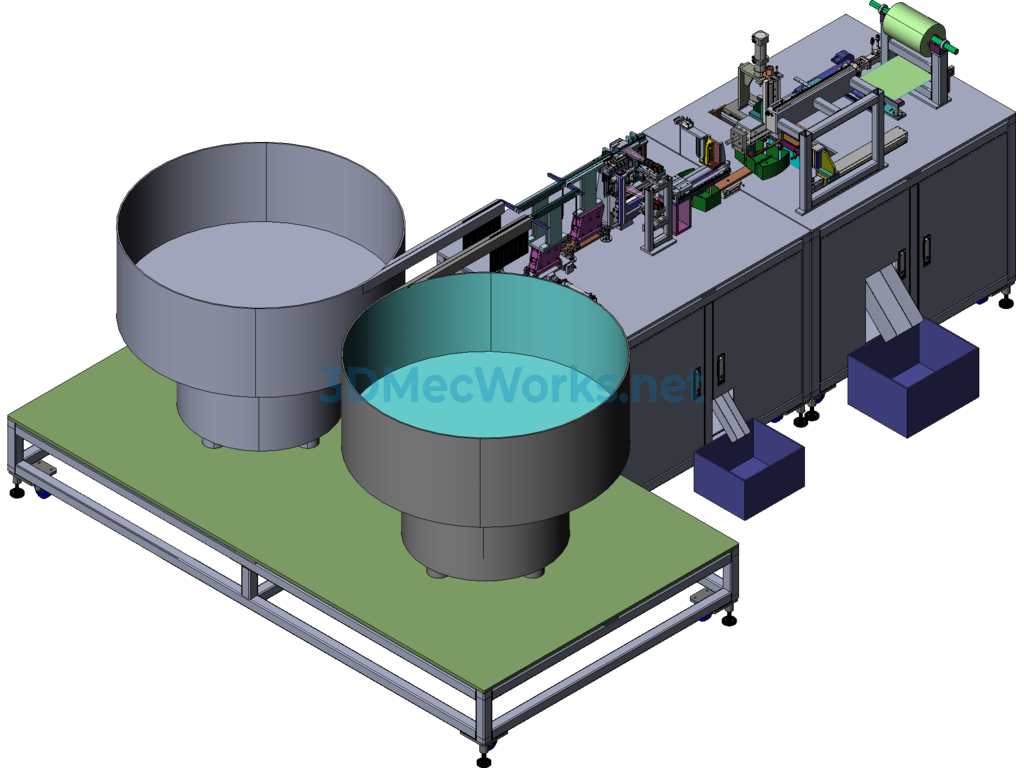

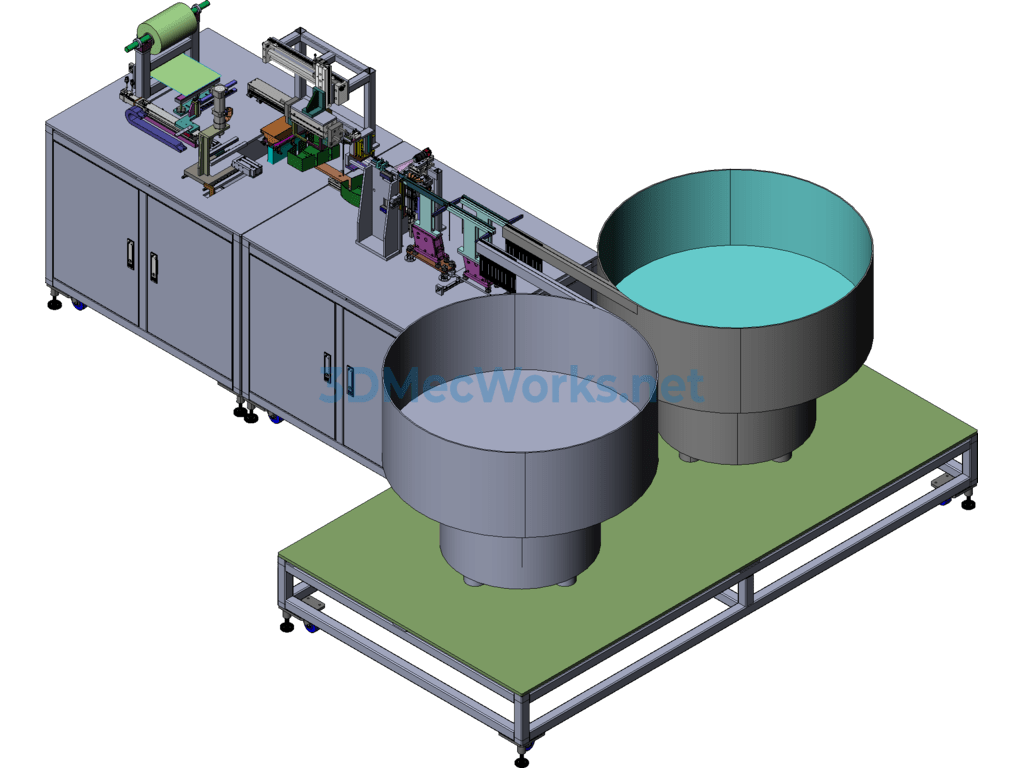

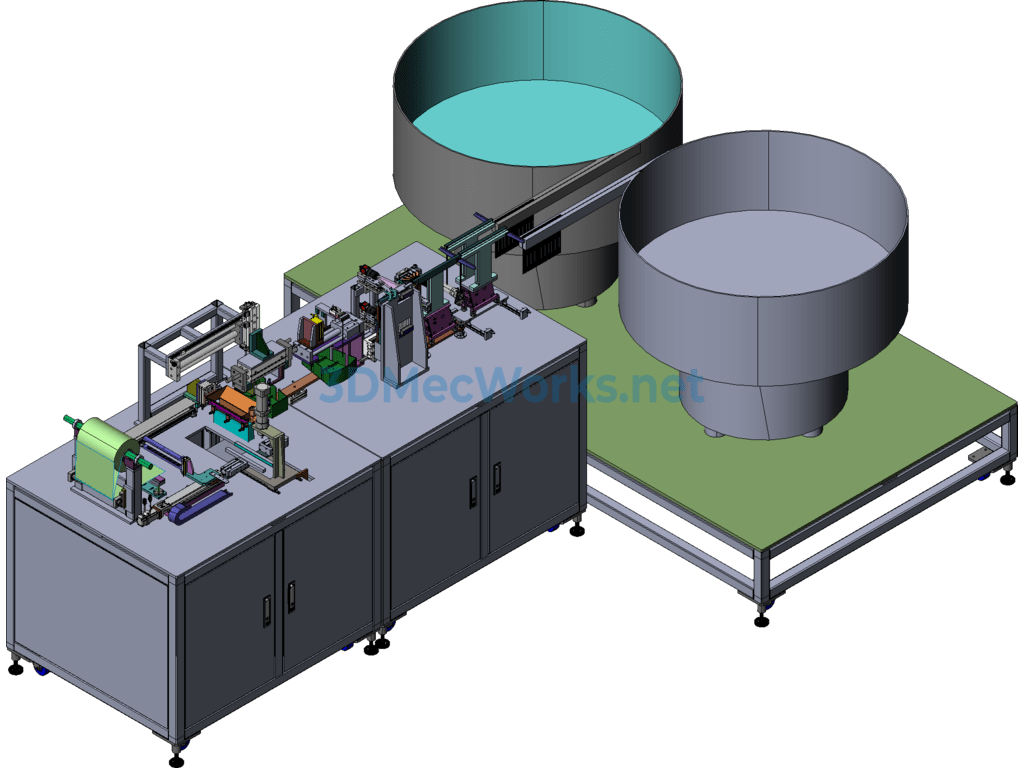

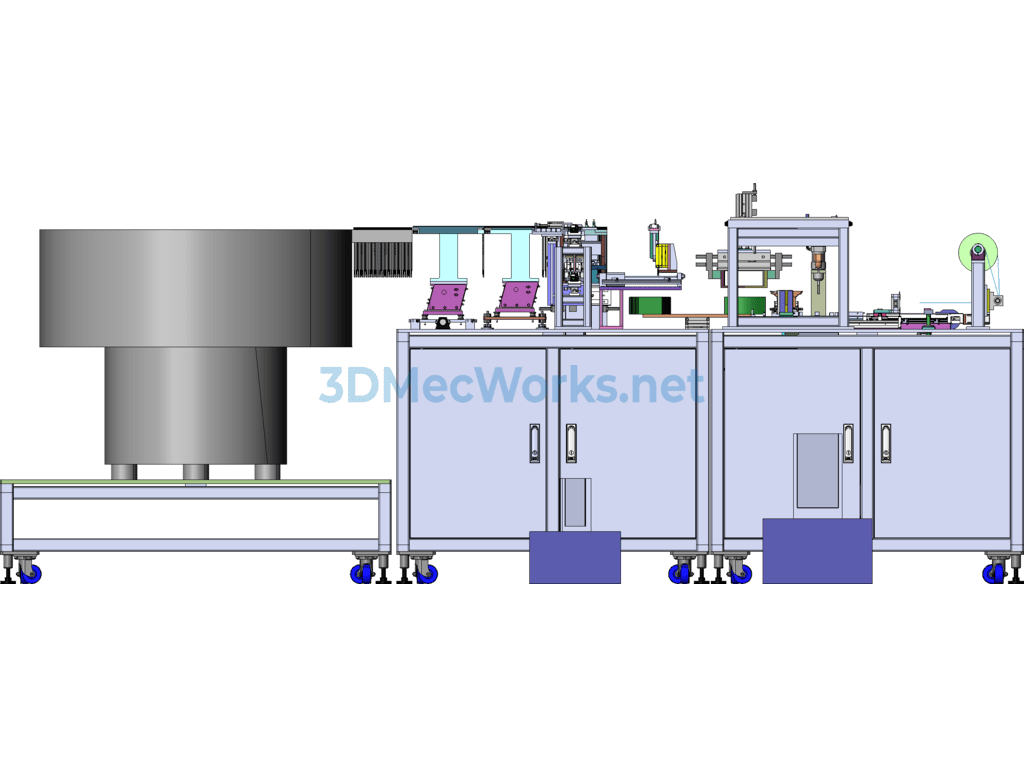

Automated cable tie inspection and packaging machine

Two sets of vibrators alternately supply materials, count and distribute materials while the CCD checks for insufficient injection molding heads inside the cable tie’s leading end, and the CCD checks for insufficiencies at the trailing end of the cable tie, counting and packaging.

Introduction to the operation of the cable tie inspection automatic packaging machine:

1. Manually place the circuit board in the guiding and positioning of the inner cavity;

2. Manually place two sets of chip trays;

3. After the photoelectric detection of material feeding is in place, the device prepares and waits, and the manual button starts the device;

4. The material release platen moves out of the way, and the suction nozzle moves to the tray to pick up materials, compressing them into the circuit board after moving;

5. Prompt for unloading and material change;

6. Remove the empty tray, place a new material tray, and the equipment remembers the number position for the other disk;

7. The feeding position allows selecting every two rows separately;

Specification: Cable Tie Detection and Automatic Packaging (detailed Action Flow in Ppt)

|

User Reviews

Be the first to review “Cable Tie Detection and Automatic Packaging (detailed Action Flow in Ppt)”

You must be logged in to post a review.

There are no reviews yet.