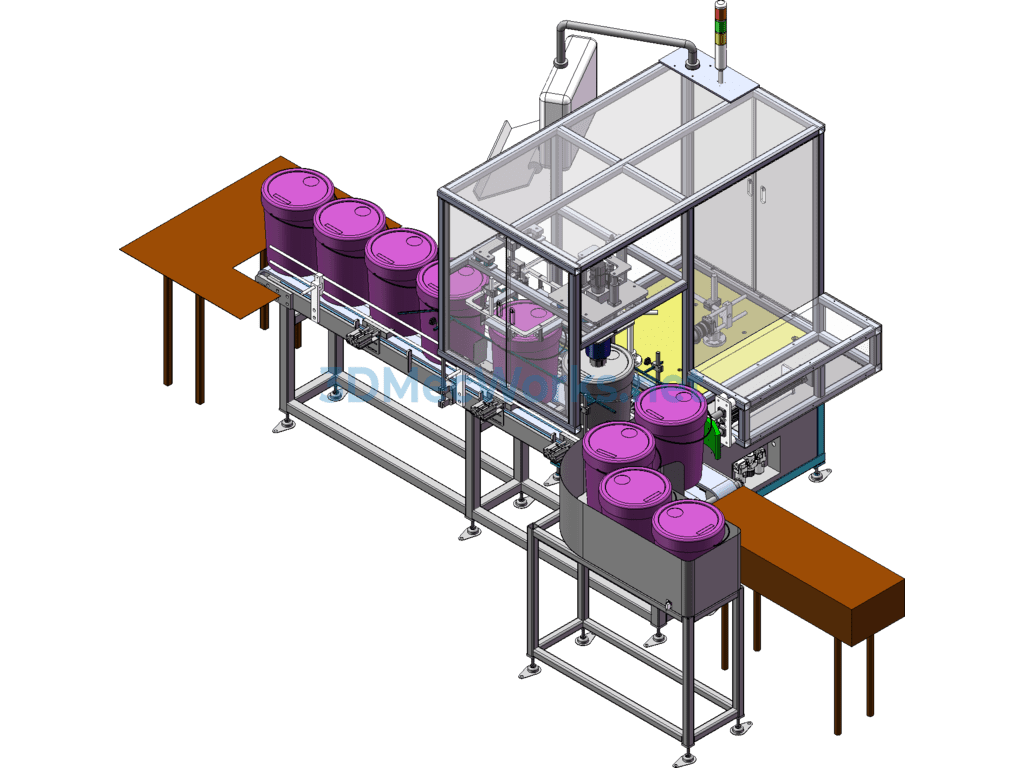

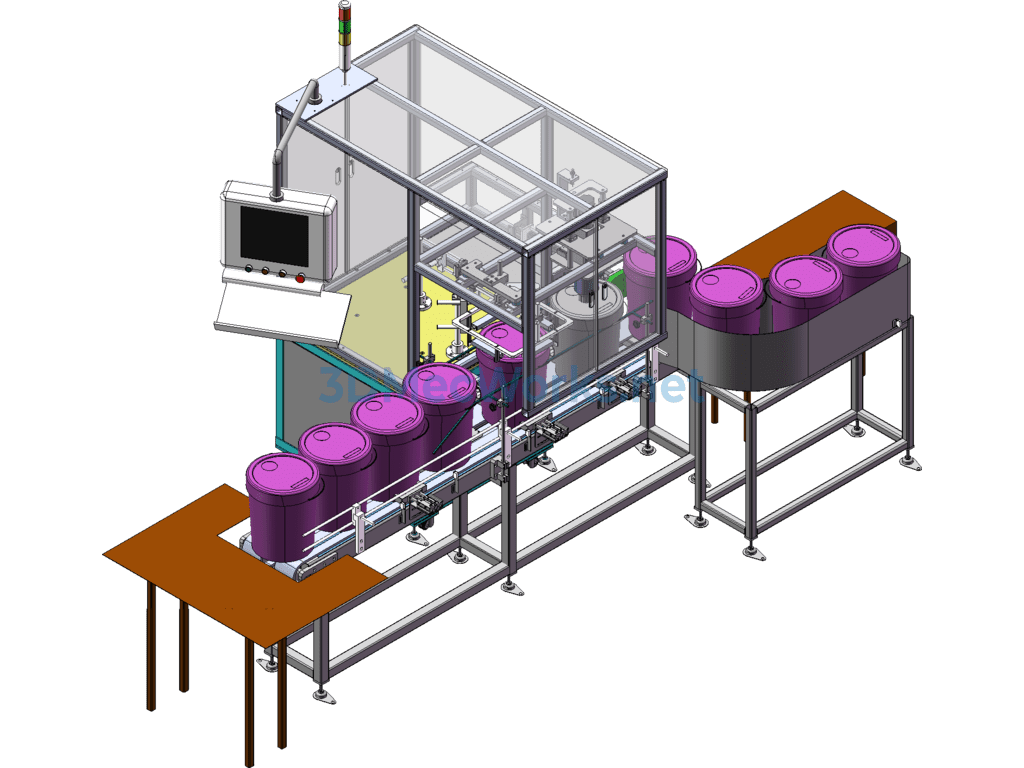

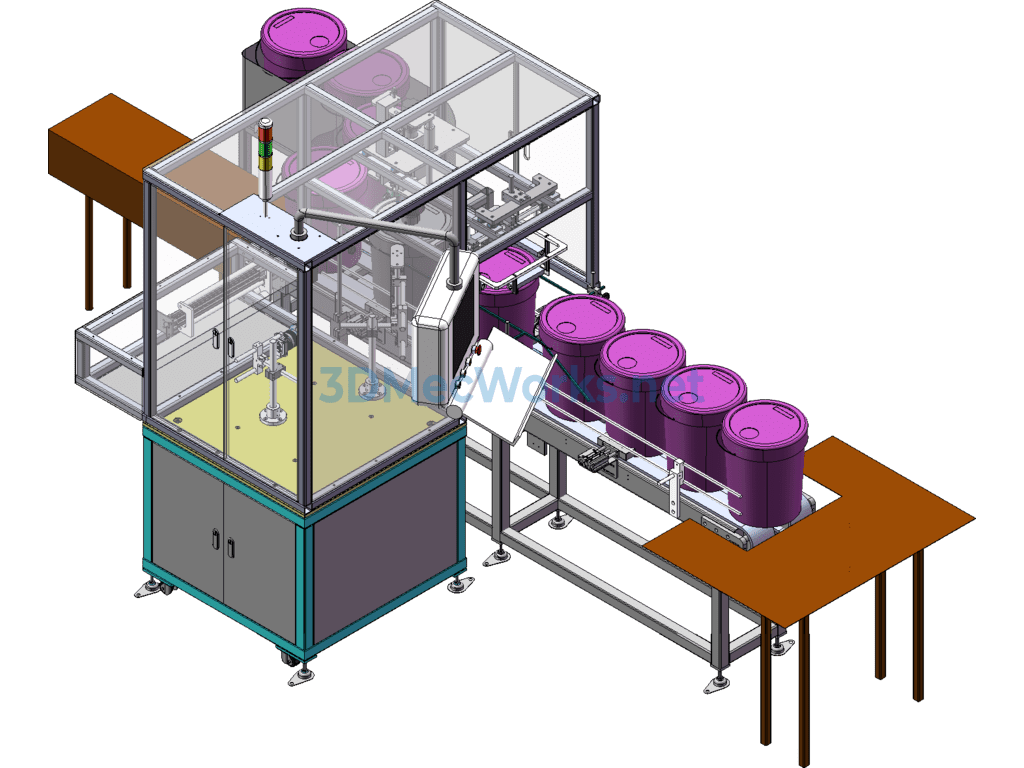

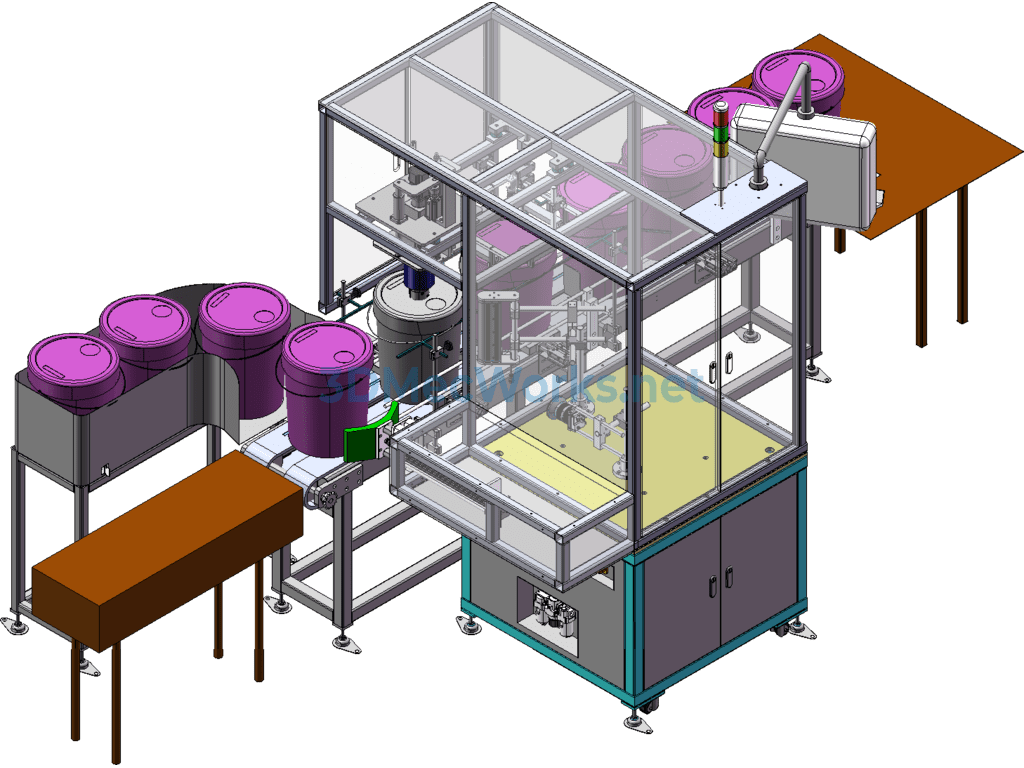

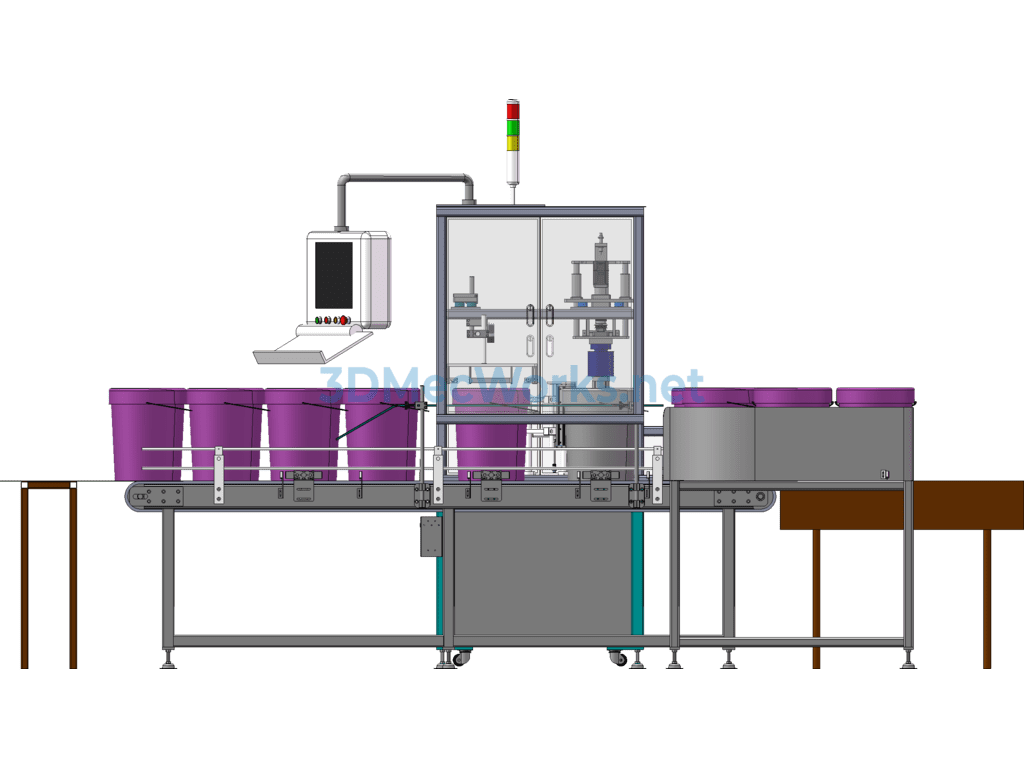

BP industrial oil drum inspection equipment production line achieves the following functions through the system:

Applicable product: 20L industrial oil drum inspection

1. Foreign object inspection:

a) Cloth, toilet paper, sleeve, film inside the drum,

b) Size to be determined greater than 2mm

c) Current size of drums held by XM used for largest inspection, diameter 265mm

d) Field of view: 400*300mm

2. Label inspection:

a) Whether labels are incorrectly applied, shape, color, many types of patterns, 20-30 types, 2-3 new products added each year,

b) Number of labels, currently 1, 2, or 3 labels

c) Types of labels include thermal transfer and printed labels

d) Manual application, certain amount of error allowed above/below; less than +/-2.5mm

e) Similar font size, images or samples provided by the client

f) Current size of drums held by XM and labels used for largest inspection, 226mm*193mm

g) Field of view: 240mm

3. For new products, software provides a window, allowing customers to automatically select models!

4. Foreign objects are only at the bottom, drum specification is uniform, many colors currently in white, black, green, yellow

5. Speed: 800P/H

6. Equipment modification needed; independent from customer’s own equipment;

7. Software interface bilingual, NG images need to be saved, new product addition function

8. Tolerance of flow channel 10mm,

File contains 3D models, engineering drawings, BOM table. Design specifications, operation manuals, and other materials

Specification: Bp Industrial Oil Drum 20l Automated Inspection Line 3d + Engineering Drawings + Bom + Manual

|

User Reviews

Be the first to review “Bp Industrial Oil Drum 20l Automated Inspection Line 3d + Engineering Drawings + Bom + Manual”

You must be logged in to post a review.

There are no reviews yet.