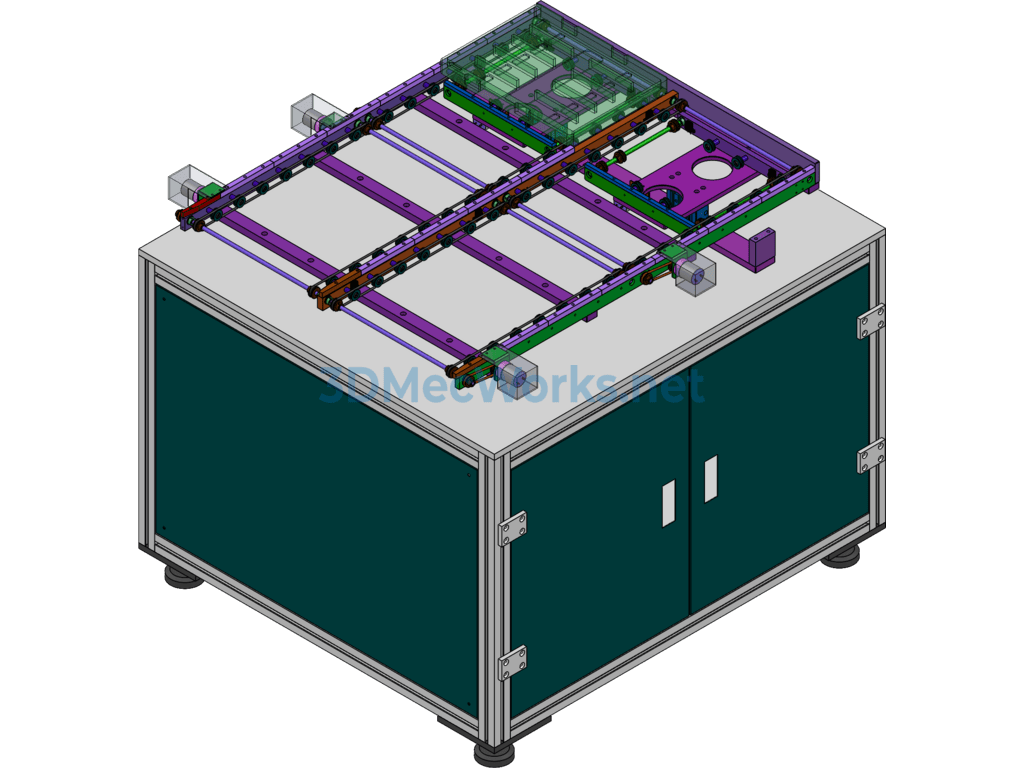

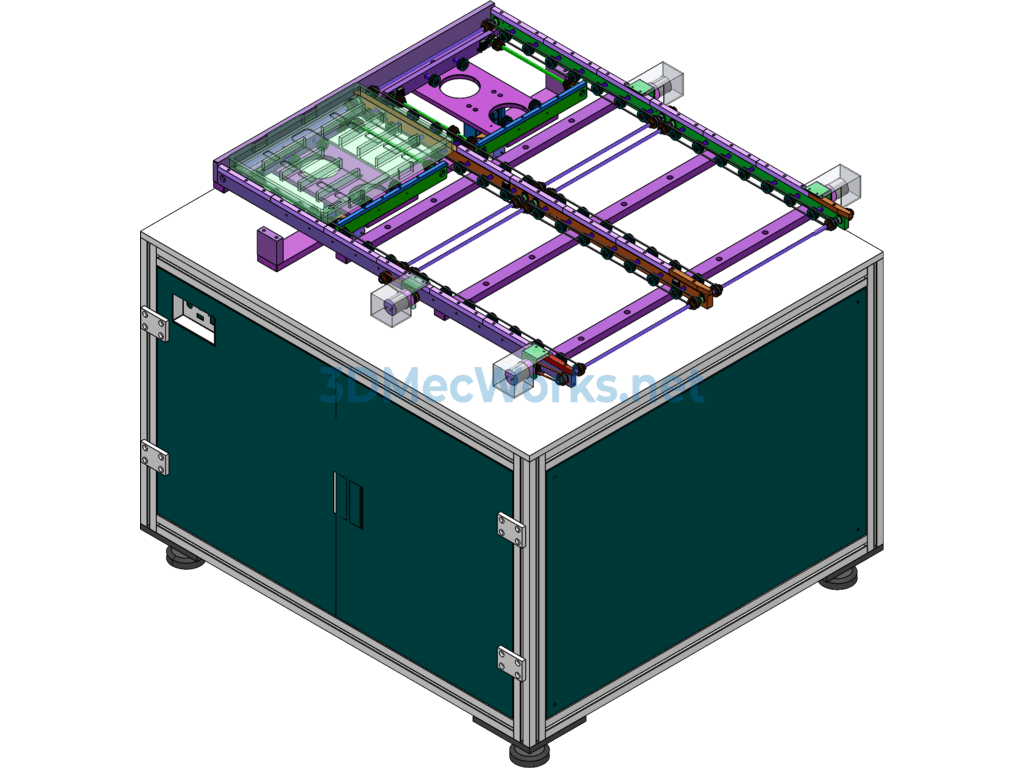

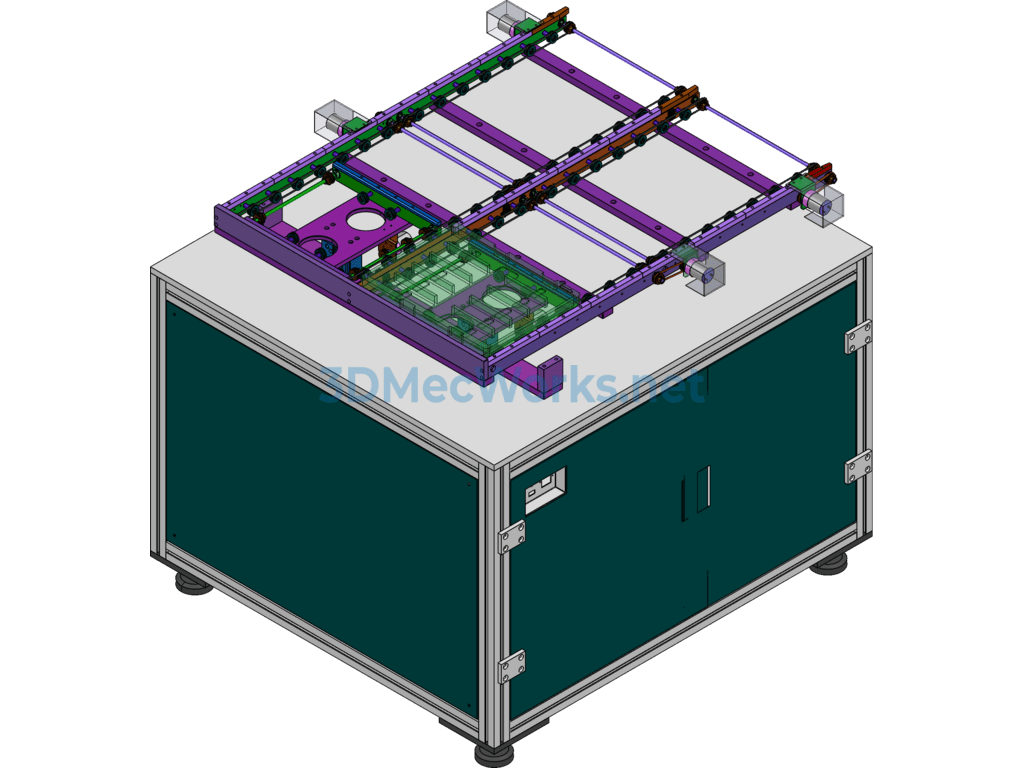

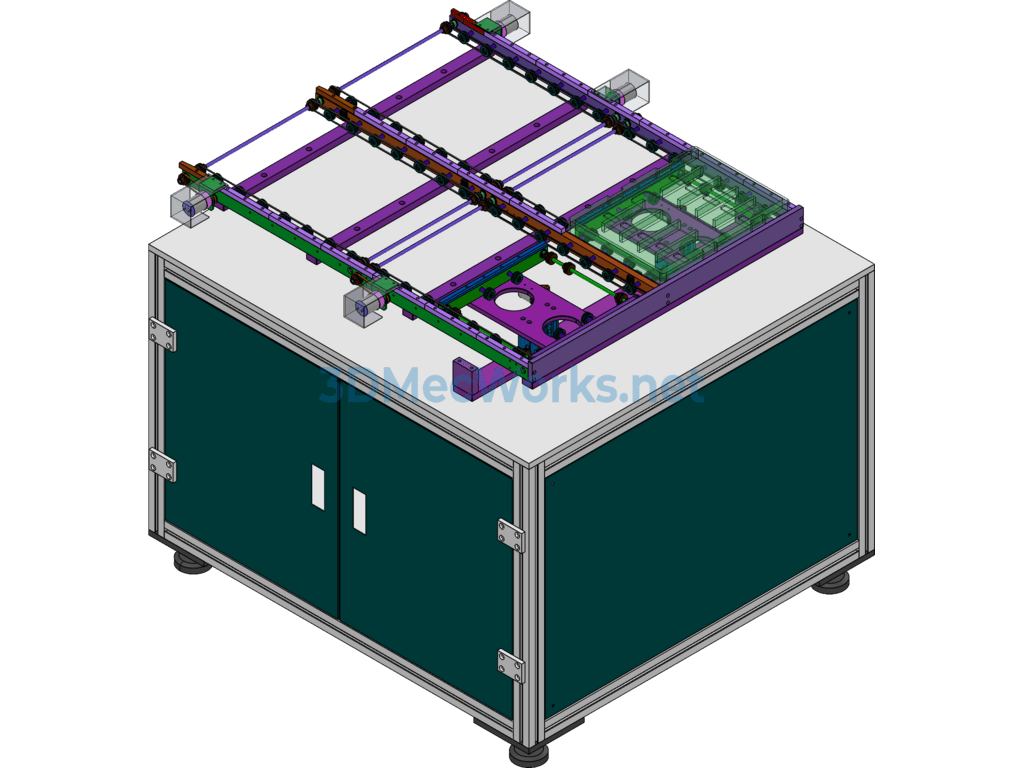

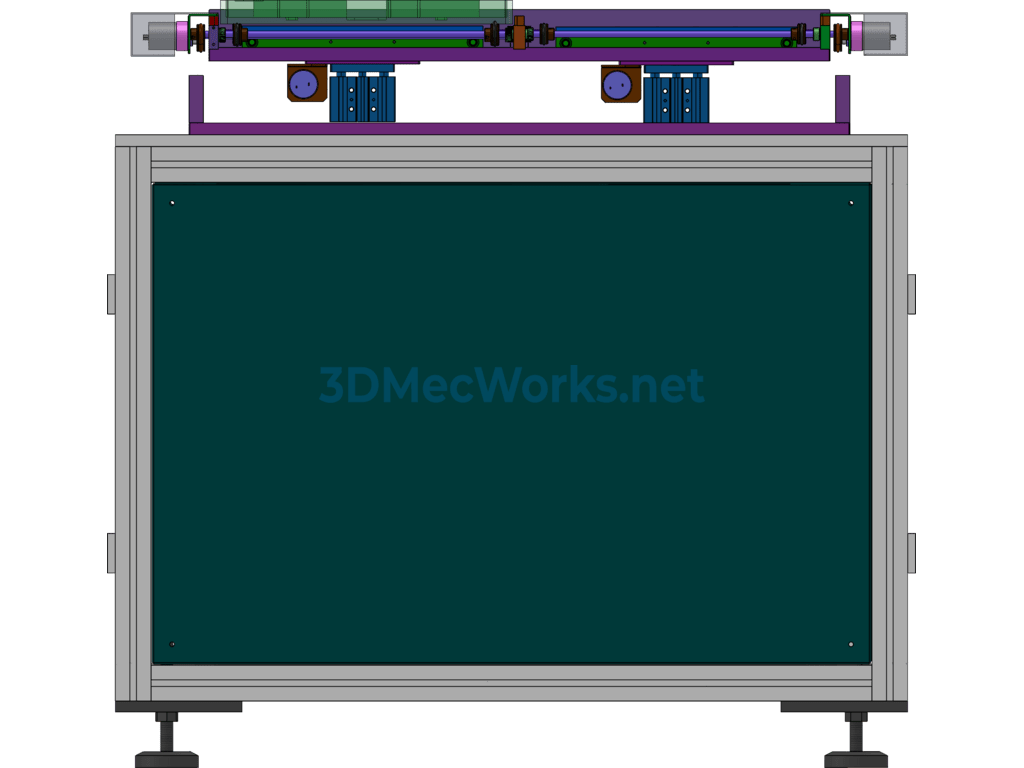

Circular Belt Conveyor Line Return Line Transfer Machine

1. Equipment Description

This equipment is a return line designed with a circular belt. The conveyor has a total of 6 small motors driving it: 2 for the first section of the conveyor, 2 for the second section, and 2 for the lifting transfer units. These components, along with one input and one output plus a lifting and lateral movement system, complete the cyclic use of carriers and vacuum trays. The conveyor system is divided into an input and an output; the input conveyor is on the left, and the output is on the right. The carriers on the left input conveyor are loaded with products, and once the products are consumed, the lifting transfer conveyor moves the empty carrier trays or vacuum trays, elevates and transfers them to the right-side empty conveyor for recycling. This conveyor system uses motors with relatively low power and transports relatively light products, hence the use of a circular belt design. This belt design is quite convenient for installation and debugging, and circular belts are relatively wear-resistant and easy to replace if needed. In the automation industry, this type of belt is increasingly used in conveyor designs for light industrial applications. The above describes the functionality and principle of this conveyor. It is a highly effective conveyor return line. Feel free to download.

Specification: Belt Conveyor Return Line Lifting Transfer Machine

|

User Reviews

Be the first to review “Belt Conveyor Return Line Lifting Transfer Machine”

You must be logged in to post a review.

There are no reviews yet.