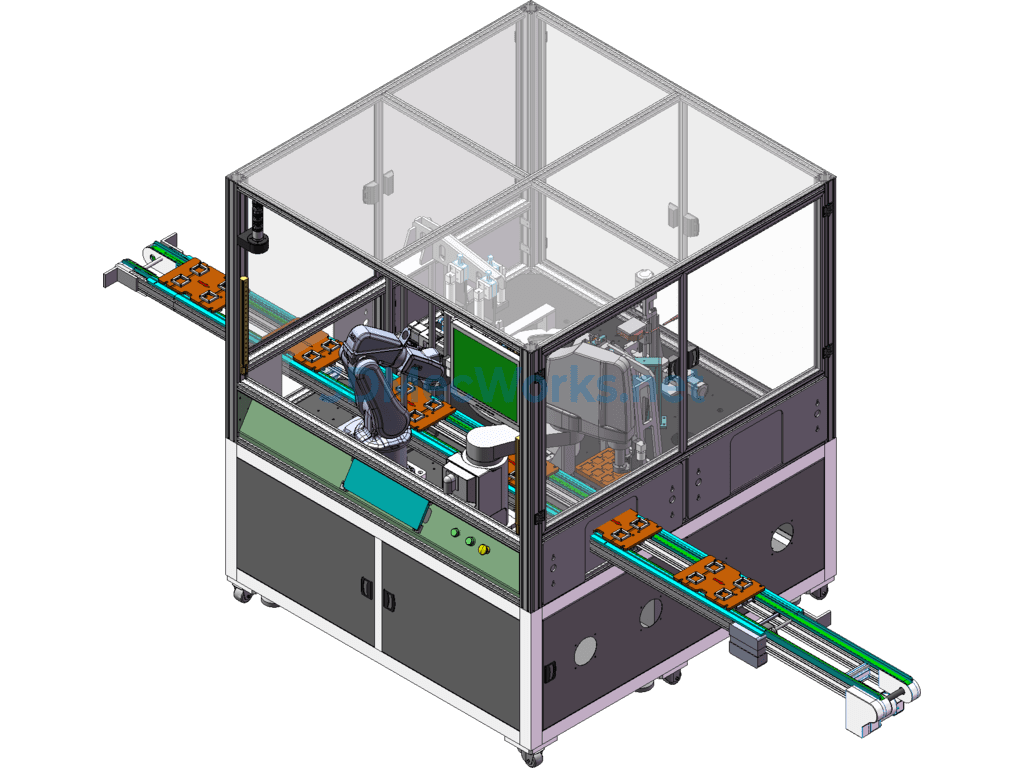

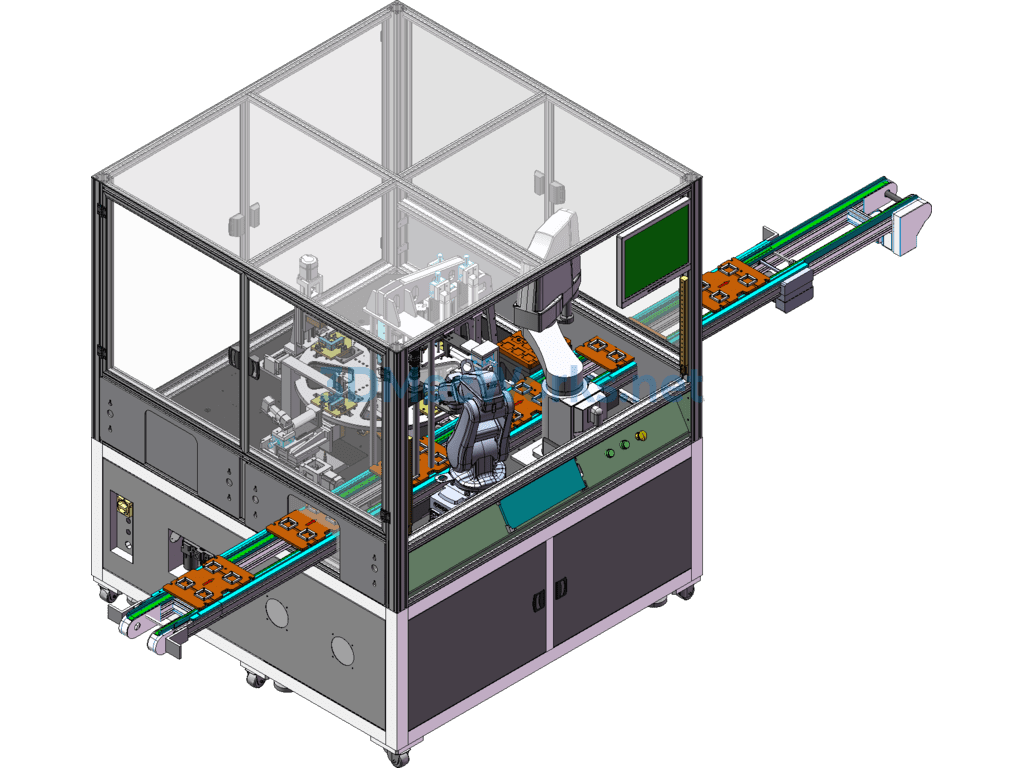

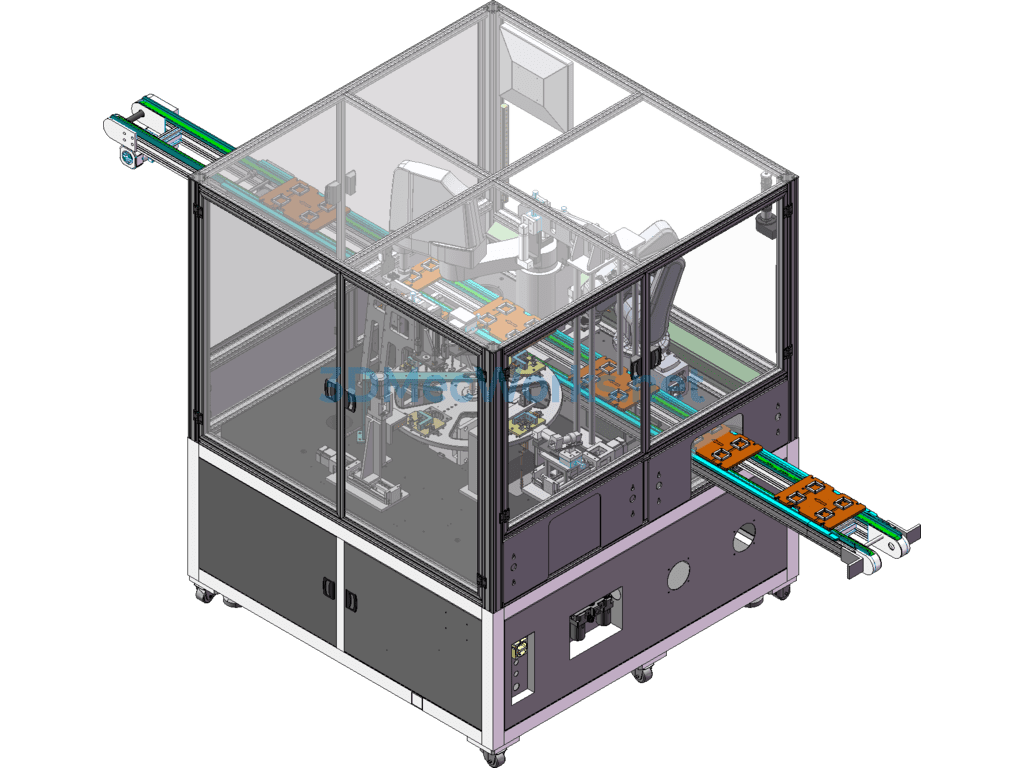

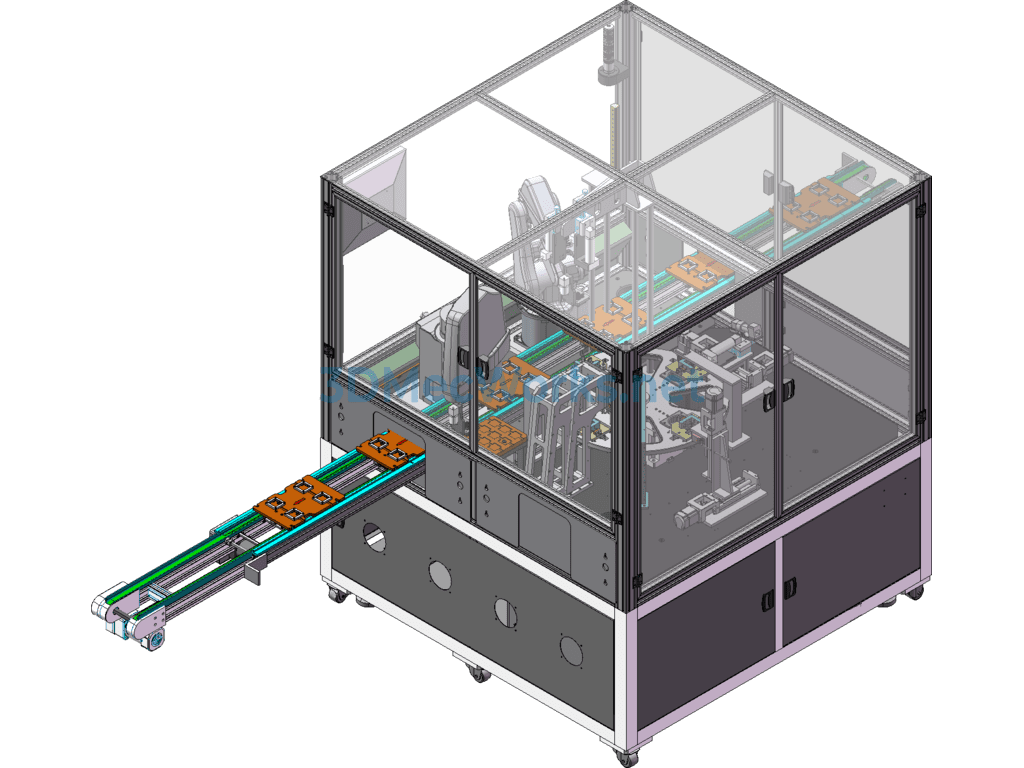

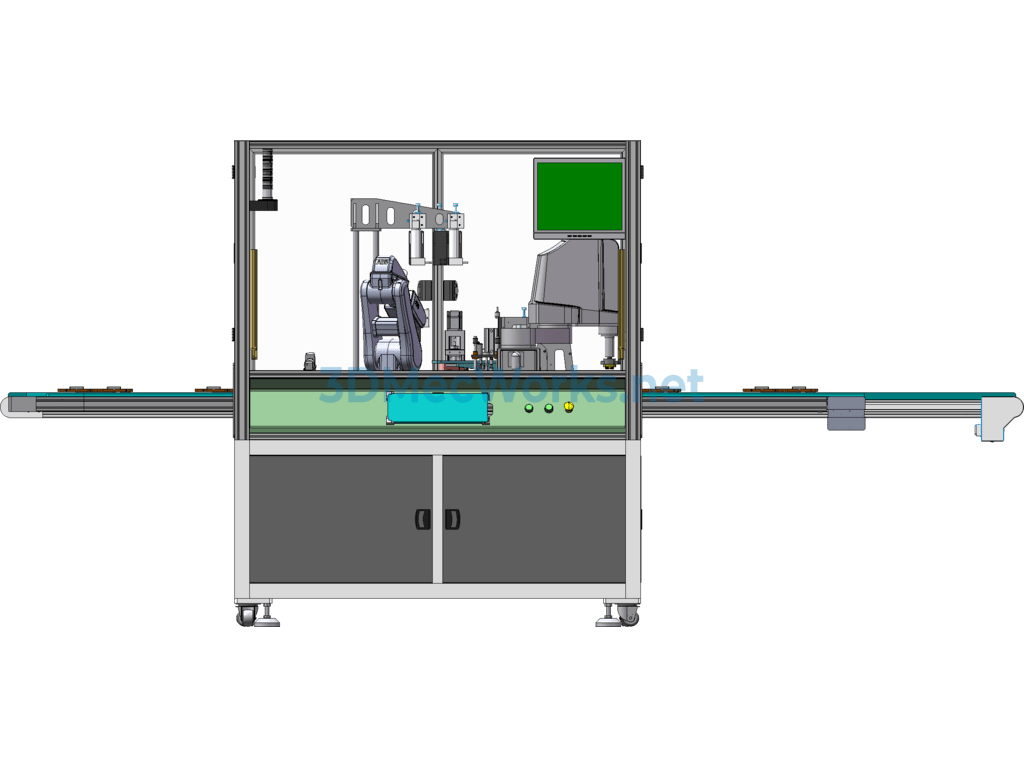

General Equipment for Battery Capacitor Size Detection (Generated with BOM.DFM)

1. The tray is loaded manually or enters the equipment through a line-transfer method;

2. A four-axis robot with visual positioning grabs the product within the fixture;

3. Product height is detected by a GT module, line-scan laser detects the product’s flatness dimensions, CCD captures and detects contour dimensions, and a six-axis robot grabs and unloads the internal structure dimensions;

4. Adopts a four-station turntable model for circular feeding and detection.

Specification: Battery Capacitor Size Detection General Equipment (bom.dfm Included)

|

User Reviews

Be the first to review “Battery Capacitor Size Detection General Equipment (bom.dfm Included)”

You must be logged in to post a review.

There are no reviews yet.