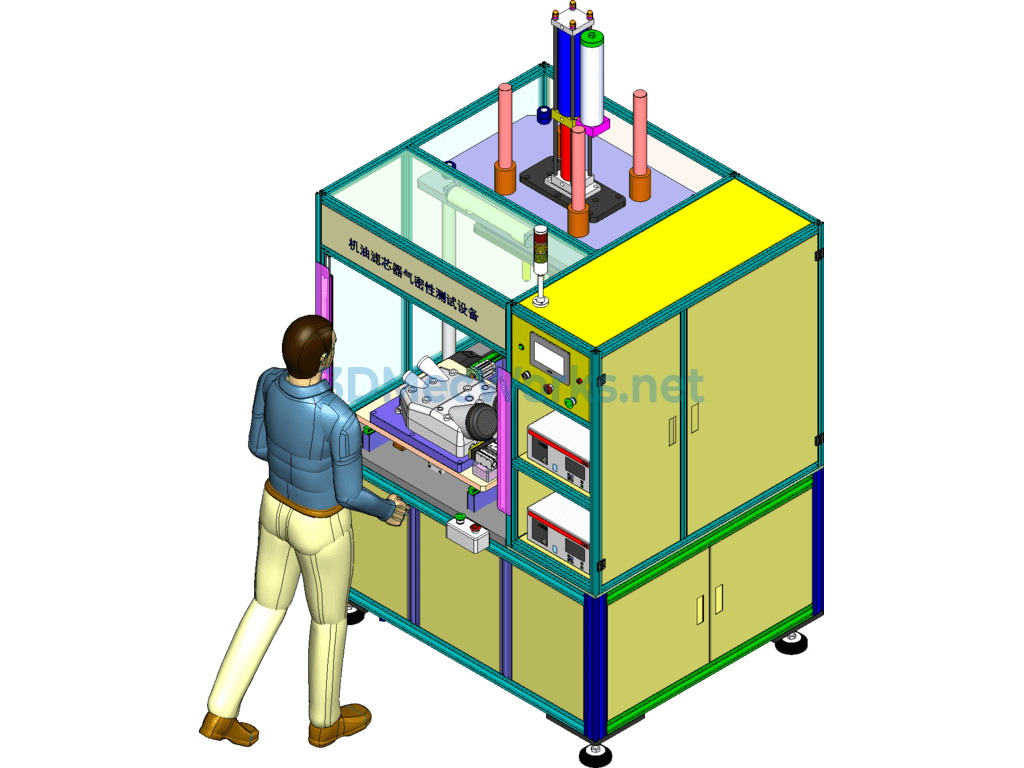

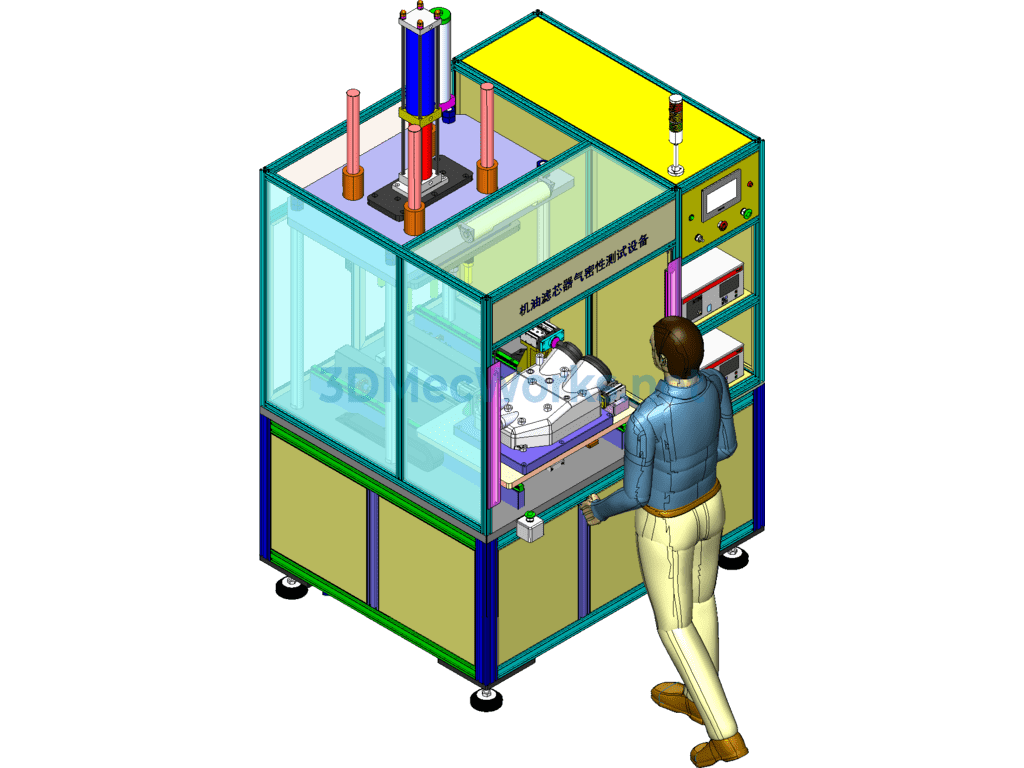

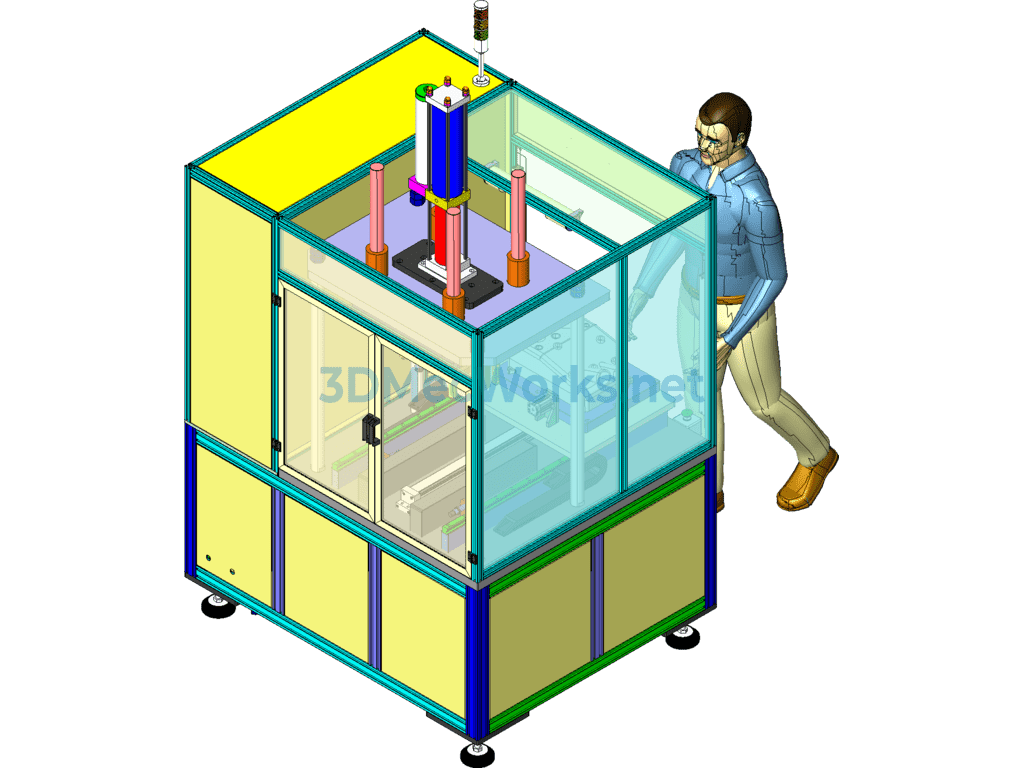

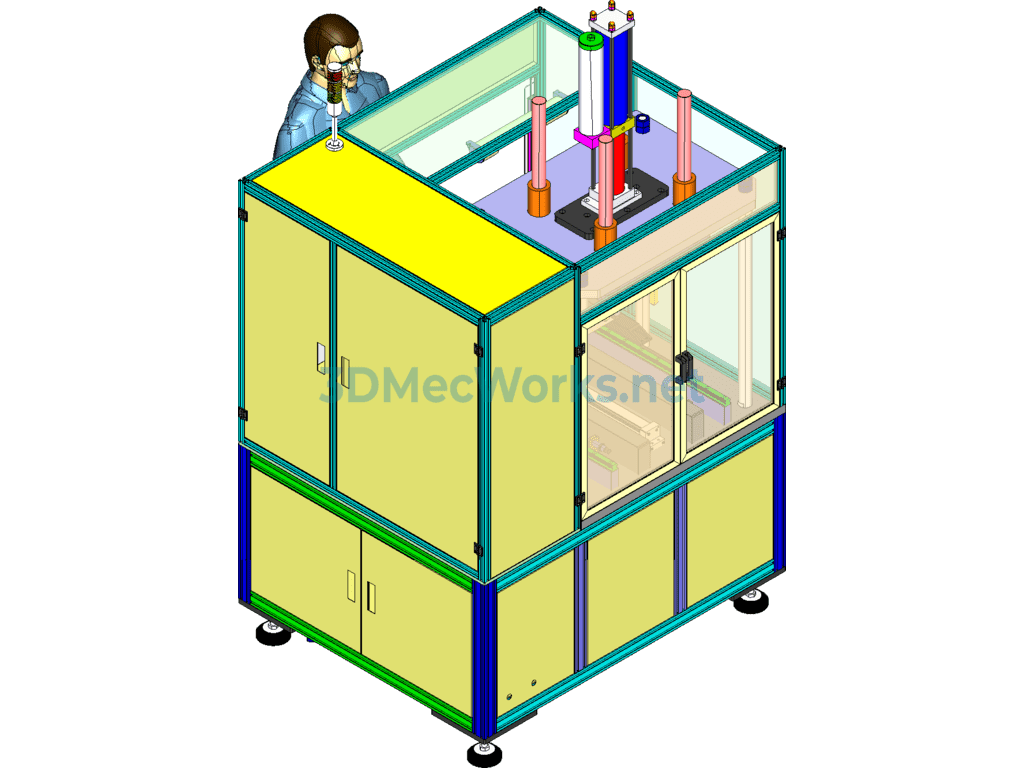

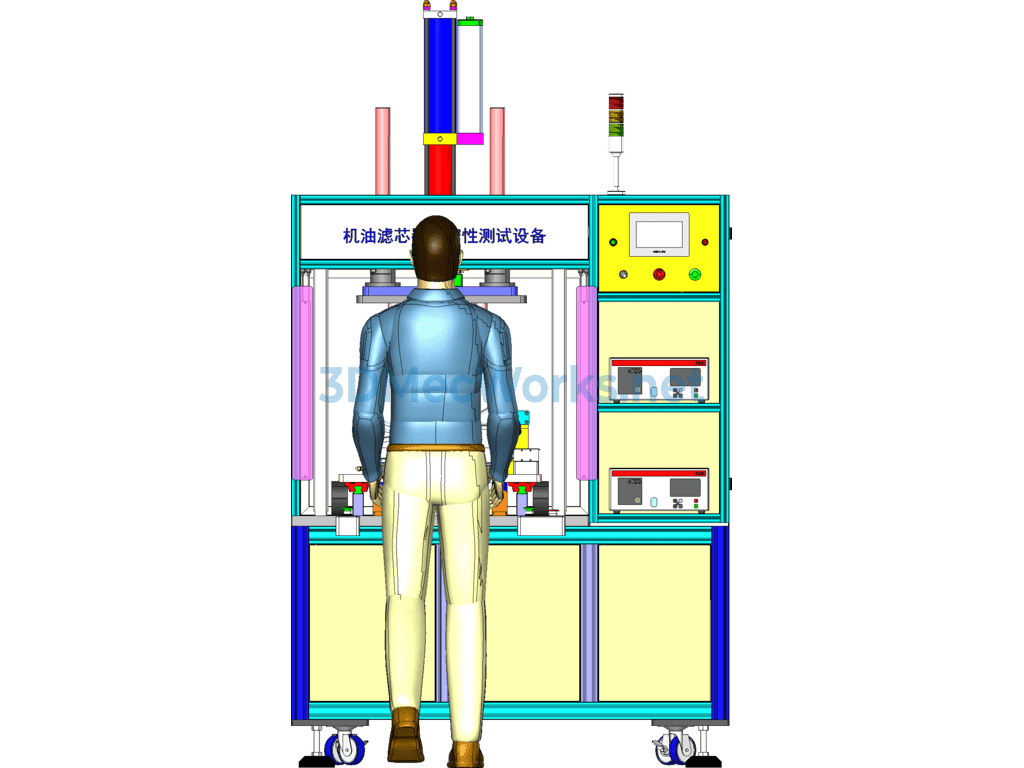

Automobile Engine Oil Filter Air Tightness Testing Equipment Includes 3D Model + Engineering Drawings + PDF Working Principle Description + Detail Description

Equipment Working Principle & Step Description:

1. Place the product to be tested into the equipment holder (positioned by round pin and diamond pin);

2. After the photoelectric sensor on the holder detects the product, the operator starts the button with both hands (the holder & product are automatically driven into the pressing position through a rodless cylinder);

3. After the holder & product reach the pressing position, the press head (spring press head & sealing head) automatically presses down;

4. After the press head presses down in place, the back sealing & side sealing cylinder extends; No. 1 & No. 2 air tightness leak testers respectively start testing; after the test is completed, the sealing cylinder retracts, and the press head (spring press head & sealing head) automatically rises;

5. After the press head rises in place, the holder & product are automatically pushed out of the original position by the rodless cylinder drive;

6. The operator takes out the product that tested OK; (cycle operation continues)

Specification: Automobile Oil Filter Airtightness Testing Equipment (including 3d Model + Detailed Description)

|

User Reviews

Be the first to review “Automobile Oil Filter Airtightness Testing Equipment (including 3d Model + Detailed Description)”

You must be logged in to post a review.

There are no reviews yet.