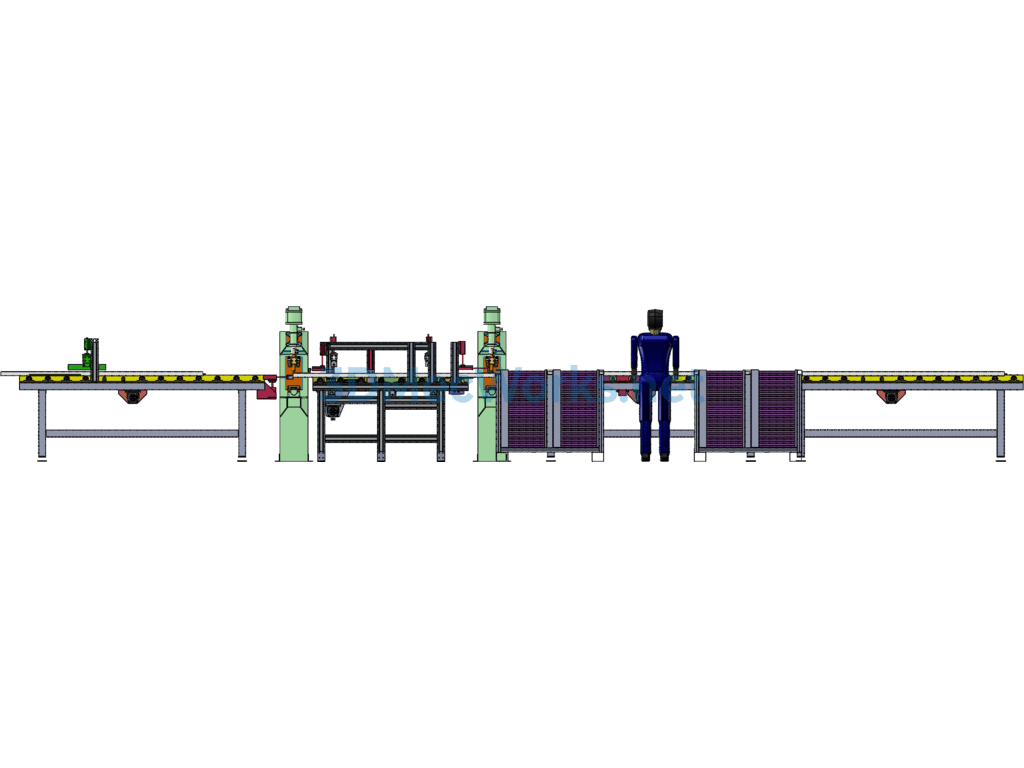

1. Project Content (1) Door panel conveying line; (2) Stiffener centering positioning mechanism; (3) Door panel centering positioning mechanism; (4) Upper end cap positioning mechanism; (5) Lower end cap positioning mechanism; (6) Door panel welding pushing mechanism; (7) Electrical control system; 2. Project Overview This project utilizes positioning mechanisms for door panels, stiffeners, and end cap plates, as well as receives and outputs door panels from previous and subsequent processes to achieve automatic resistance welding of the door panel and end cap plate. 3. Product Specifications: Double-sided bending door, DW800-DW900 DH2100-DH2200 4. Production Line Cycle Time: ≤28 seconds/piece. This workstation is currently applied in a German-funded elevator end cap plate welding.

Specification: Automatic Welding Workstation for Elevator Door Panel End Plates

|

User Reviews

Be the first to review “Automatic Welding Workstation for Elevator Door Panel End Plates”

You must be logged in to post a review.

There are no reviews yet.