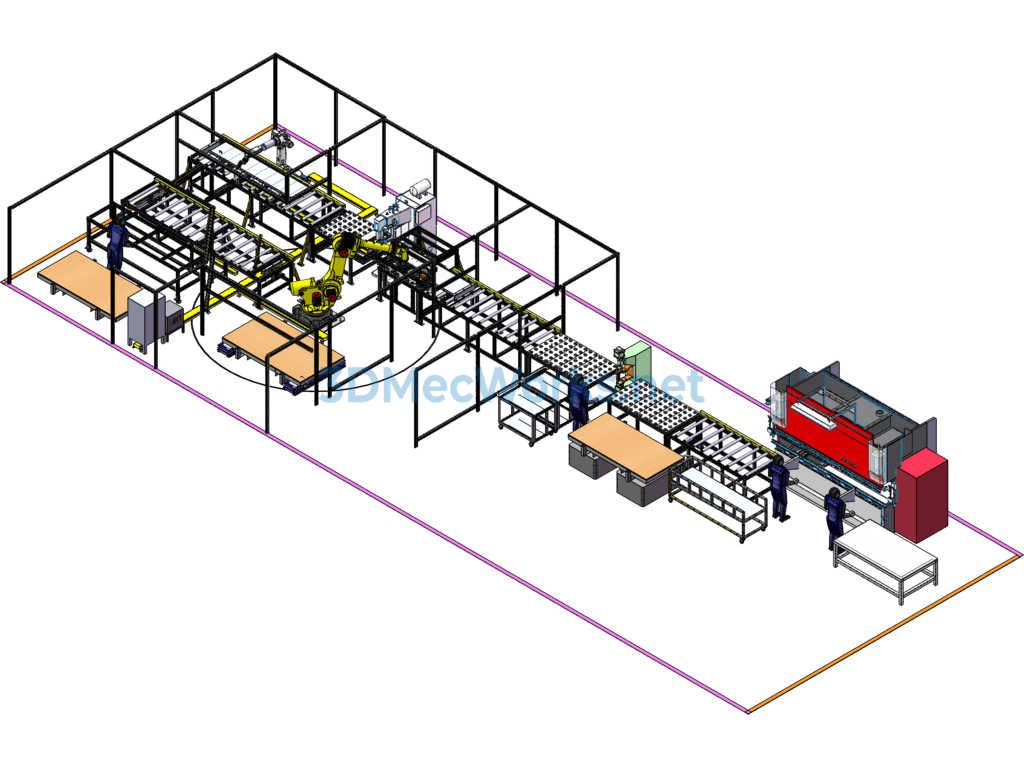

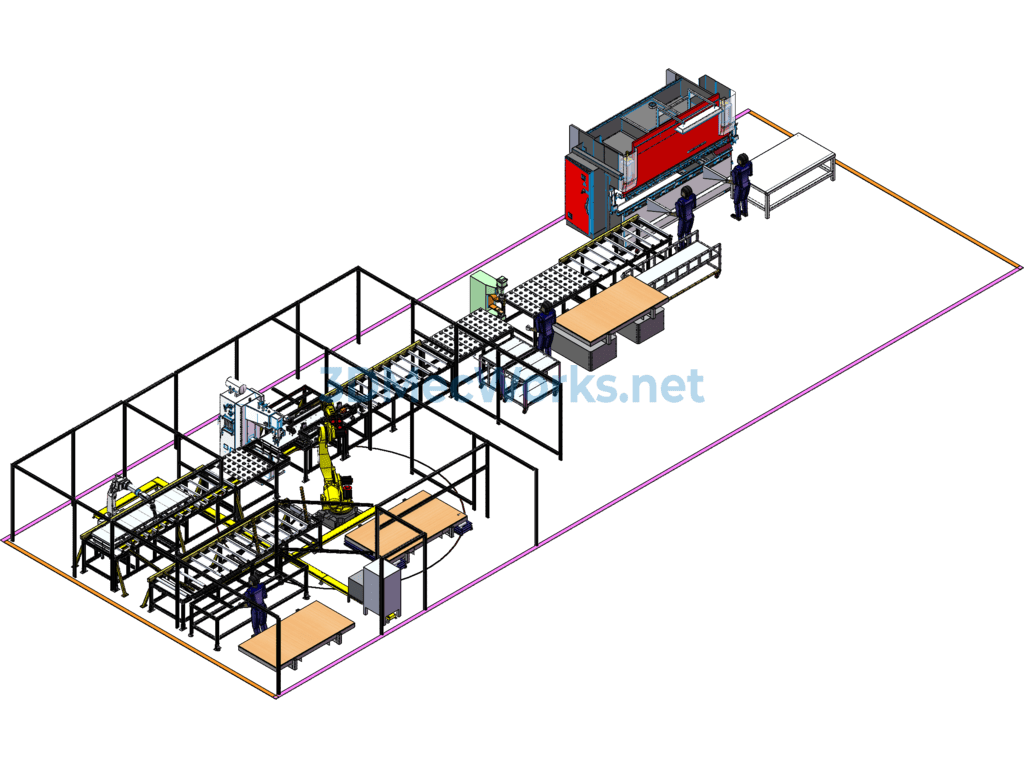

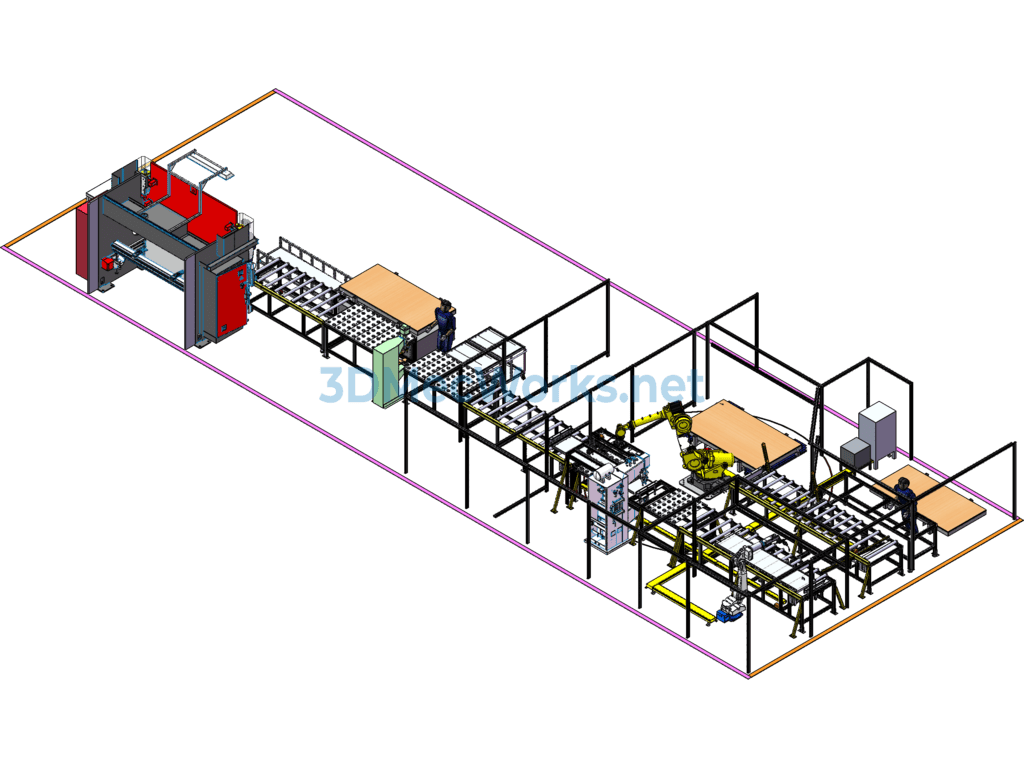

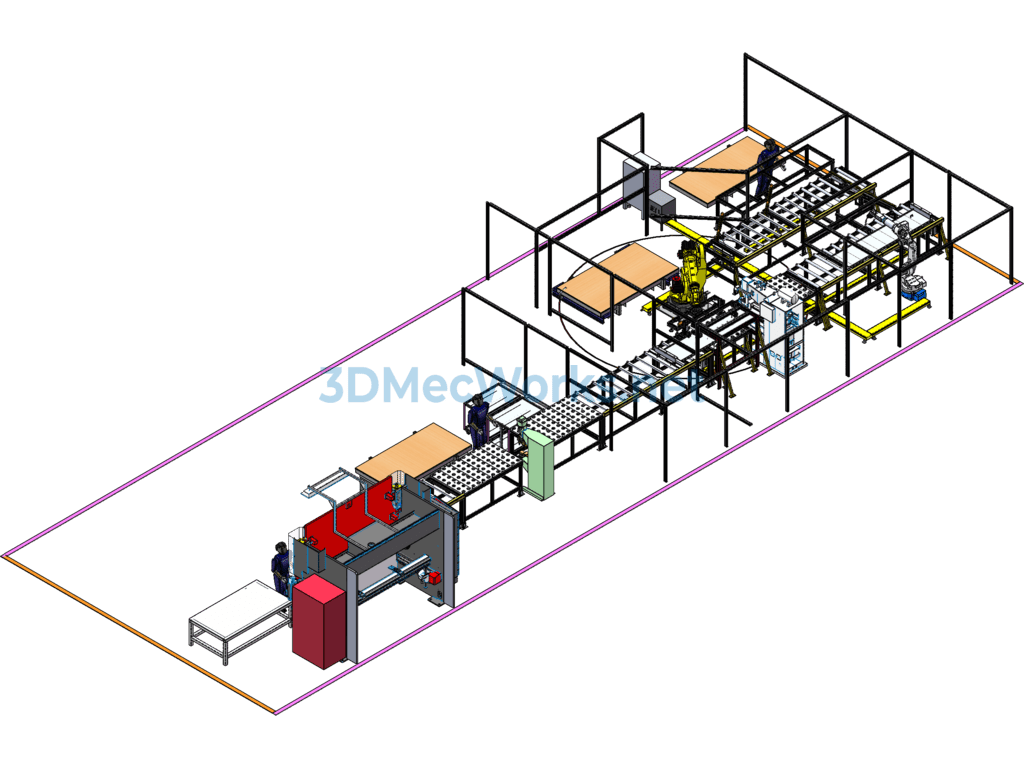

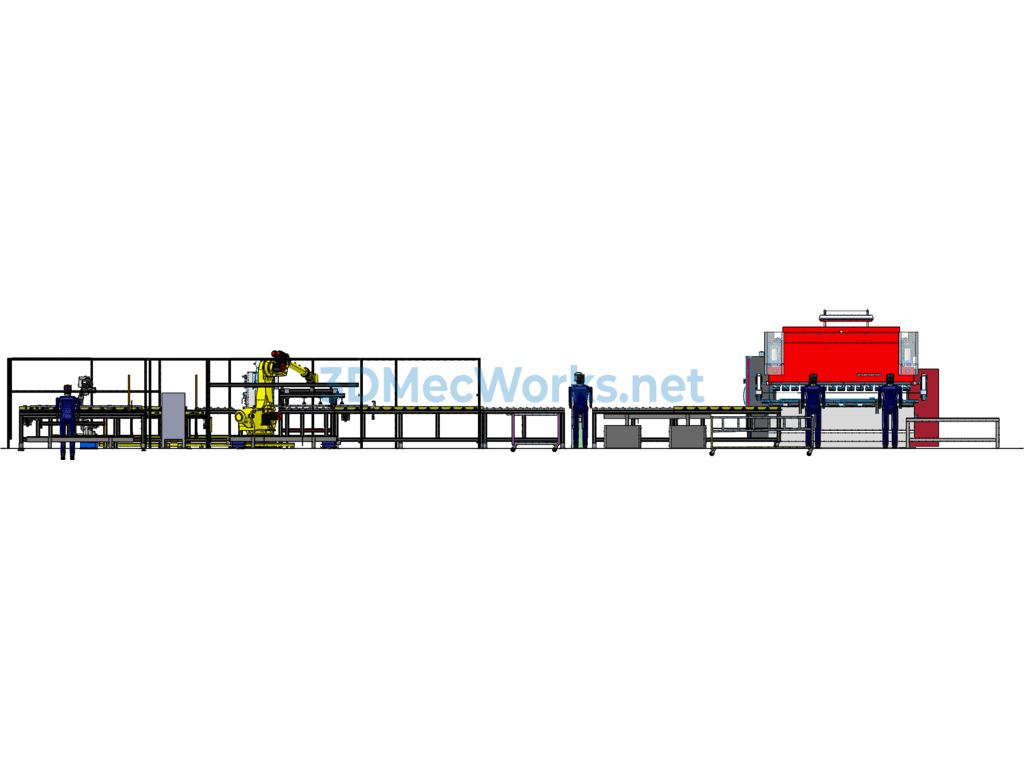

Instructions: 1. This system involves the automatic positioning of elevator door panels for bending – end cap welding – reinforcement ribs, robot-guided door panel welding of reinforcement ribs, robot CO2 welding & weld point grinding, manual grinding (with special powder as backup), and robot palletizing of door panels. 2. This system employs 4 people, with 1 person specifically assigned when using special powder, as detailed below: (1) 2 people for door panel bending; (2) 1 person for end cap welding + reinforcement rib loading; (3) 1 person for special powder grinding (when necessary); 3. The design production cycle for this system is 38 seconds per piece. This system has been implemented in the elevator factory.

Specification: Automatic Welding, Polishing, and Stacking Production Line for Door Panels

|

User Reviews

Be the first to review “Automatic Welding, Polishing, and Stacking Production Line for Door Panels”

You must be logged in to post a review.

There are no reviews yet.