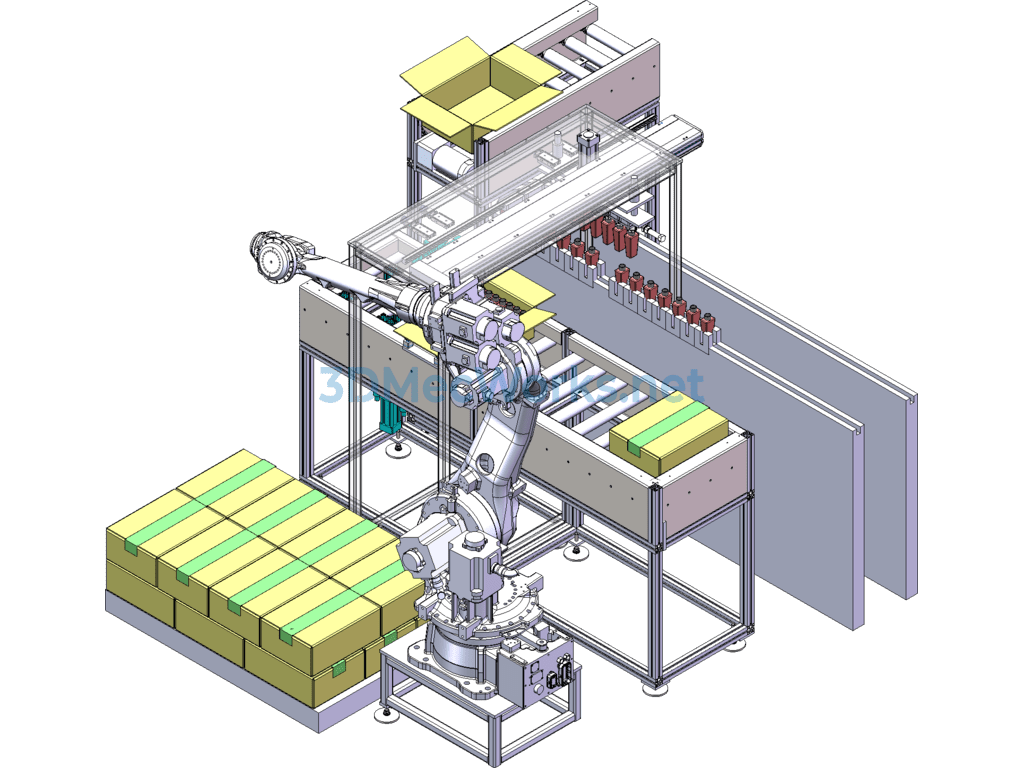

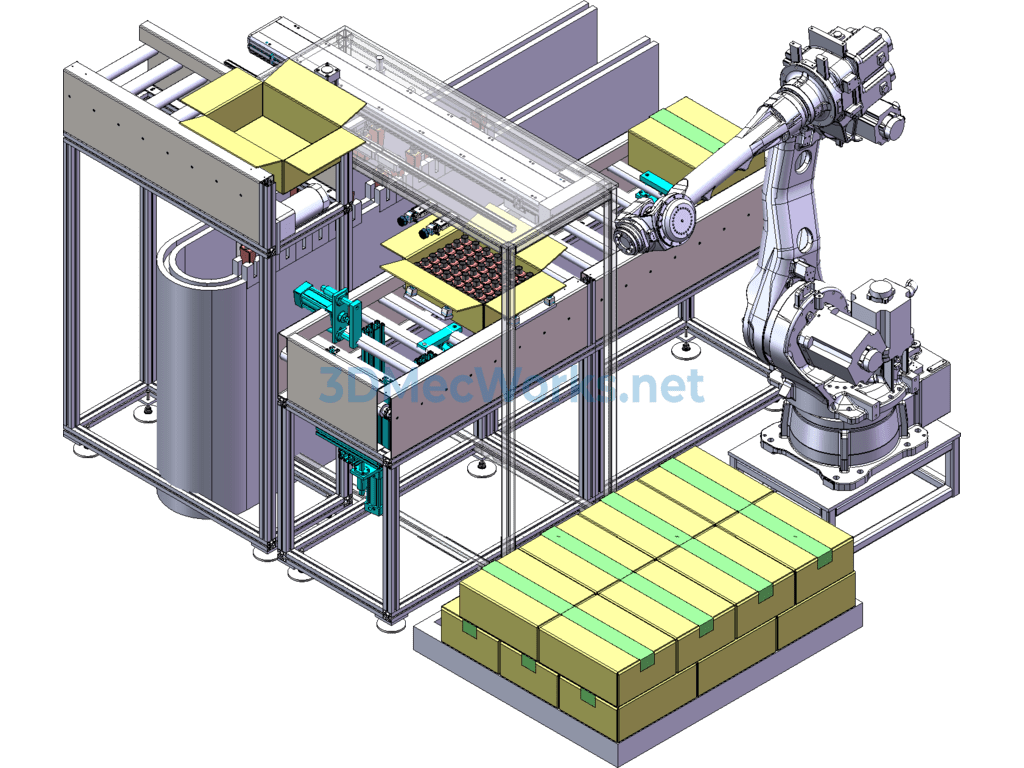

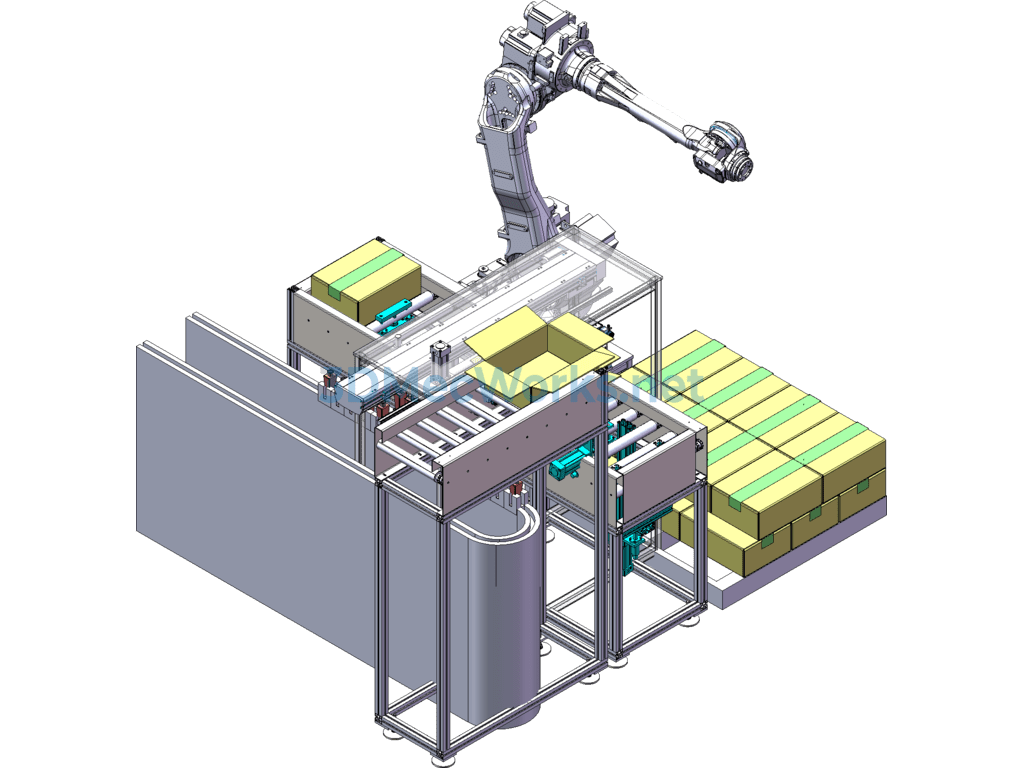

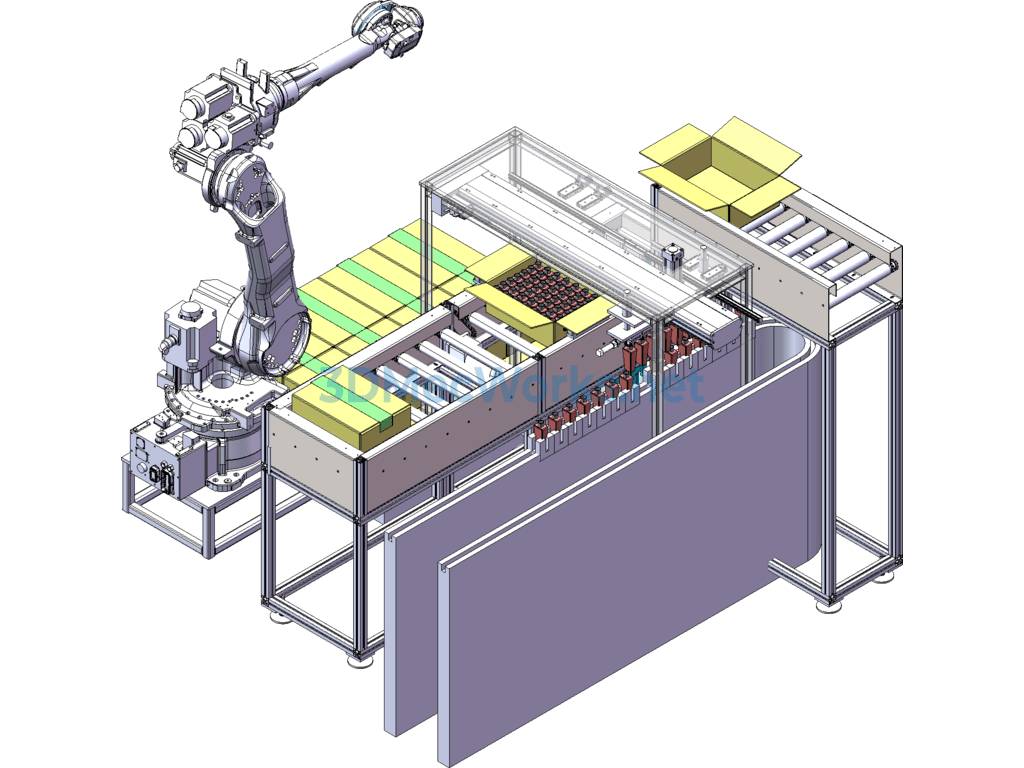

Automated Unboxing, Feeding and Conveying Assembly-DFM

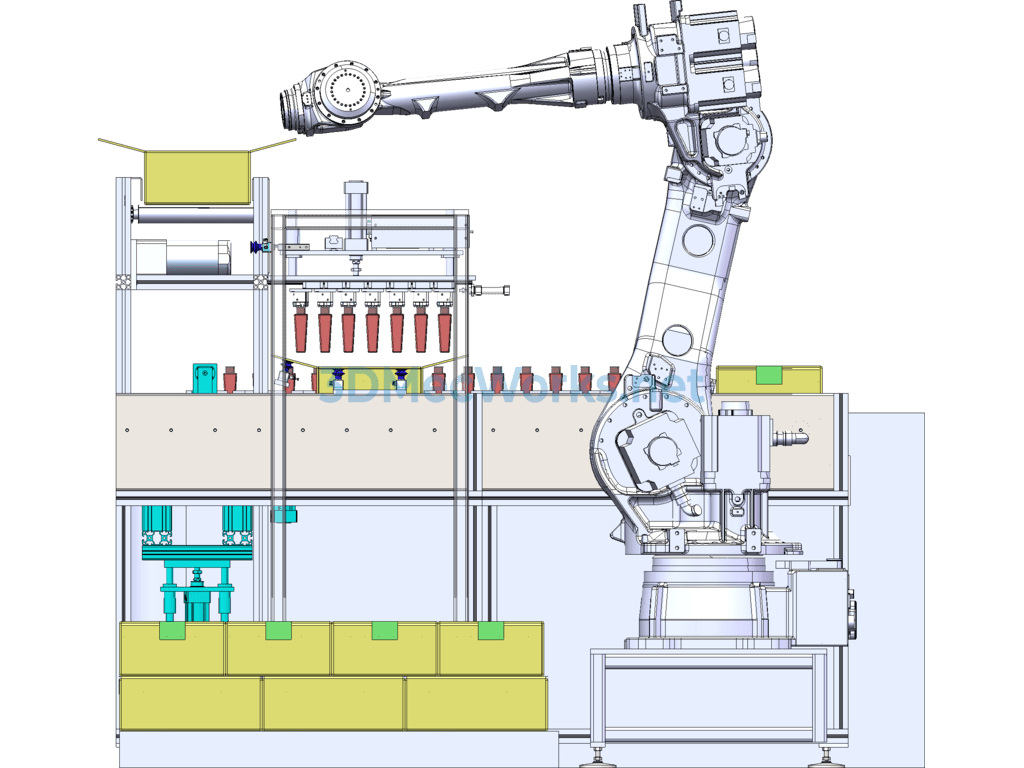

Automated unboxing and feeding conveyance, with robotic positioning and gripping of boxes for unboxing, modular bottles are conveyed to the main station.

The camera on the robot takes pictures of the pallets to identify the box opening direction. Suction cups pick and place the box onto the roller conveyor line. Blades cut the tape on the box. When the box reaches the feeding point, a positioning mechanism positions the box, the suction cups open the box flaps. A servo picking manipulator picks and places glass bottles onto the fixture assembly line. After picking, the empty box flows out.

Requirement: To achieve automation in picking and placing incoming boxes, picking and placing glass bottles, and automatic collection of empty boxes.

Process: Photographic identification of box direction, positioning, automatic picking and placing of glass bottles, expelling of empty boxes. Incoming material is a 7×7 uniform distribution, each batch is 7×1.

Samples: Pallet size is 1200*1000, box size is 390*290*143mm, glass bottle 50*126*20.

Specification: Automatic Unboxing and Feeding Conveyor Assembly (includes Detailed Ppt Instructions)

|

User Reviews

Be the first to review “Automatic Unboxing and Feeding Conveyor Assembly (includes Detailed Ppt Instructions)”

You must be logged in to post a review.

There are no reviews yet.