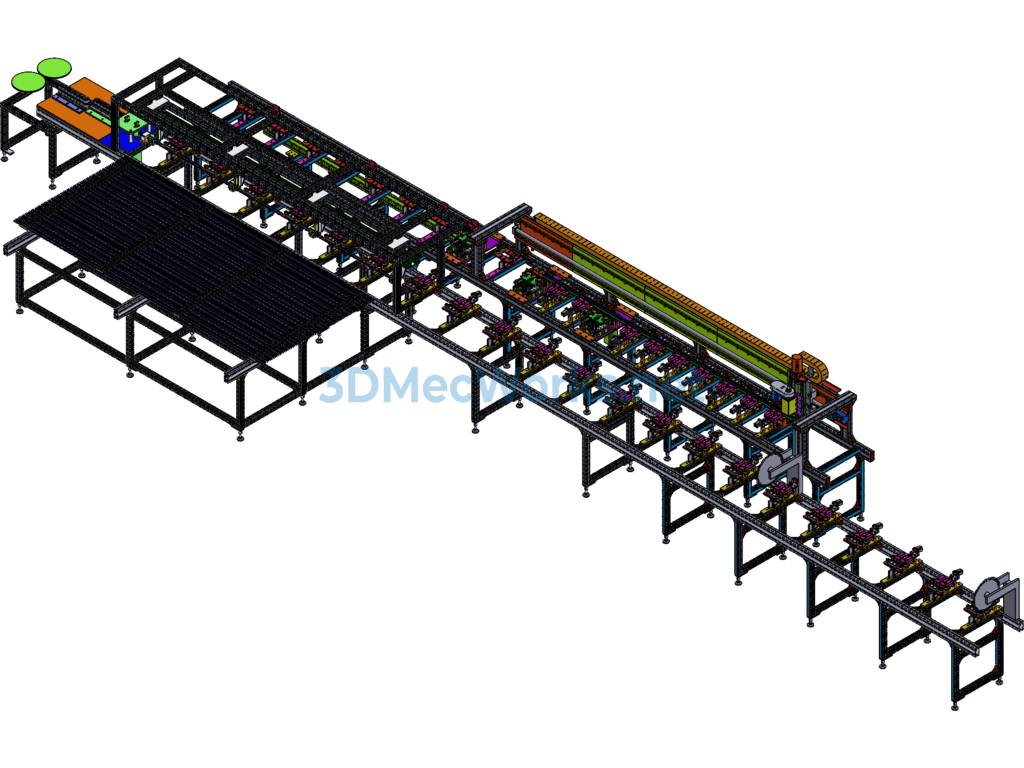

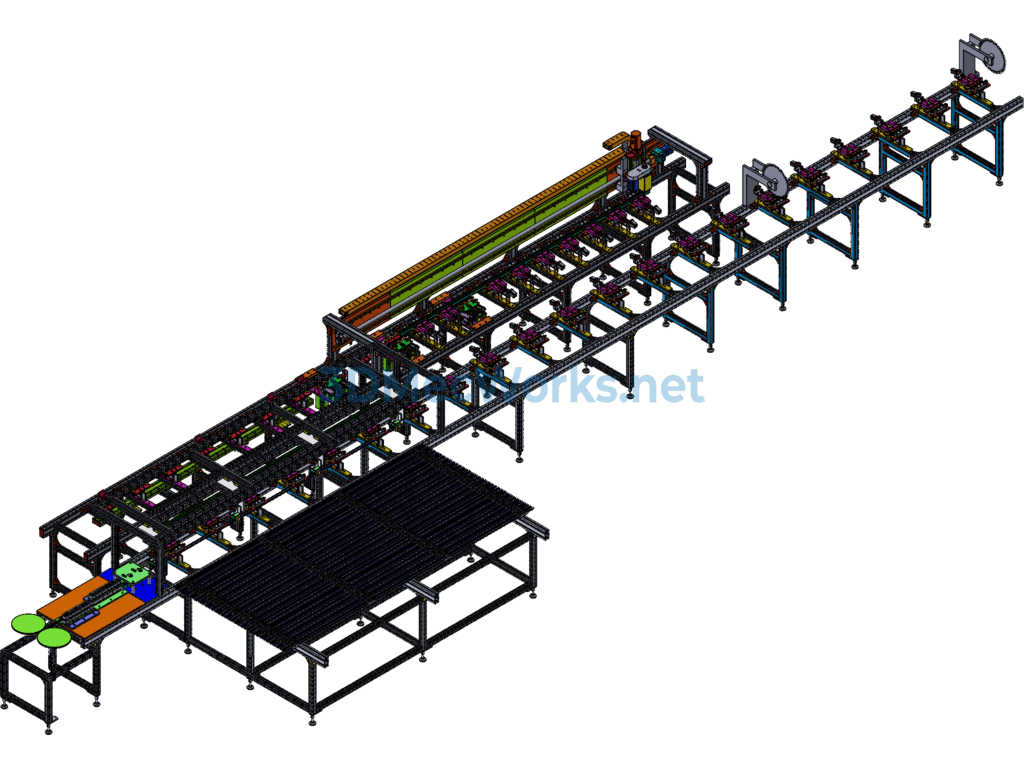

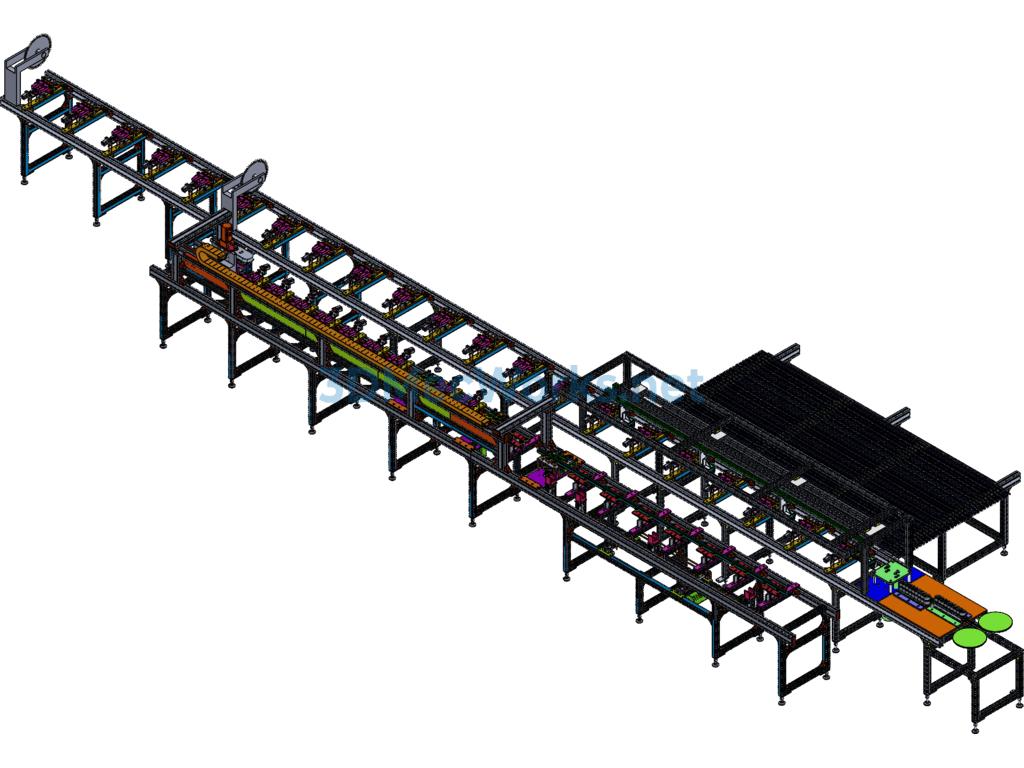

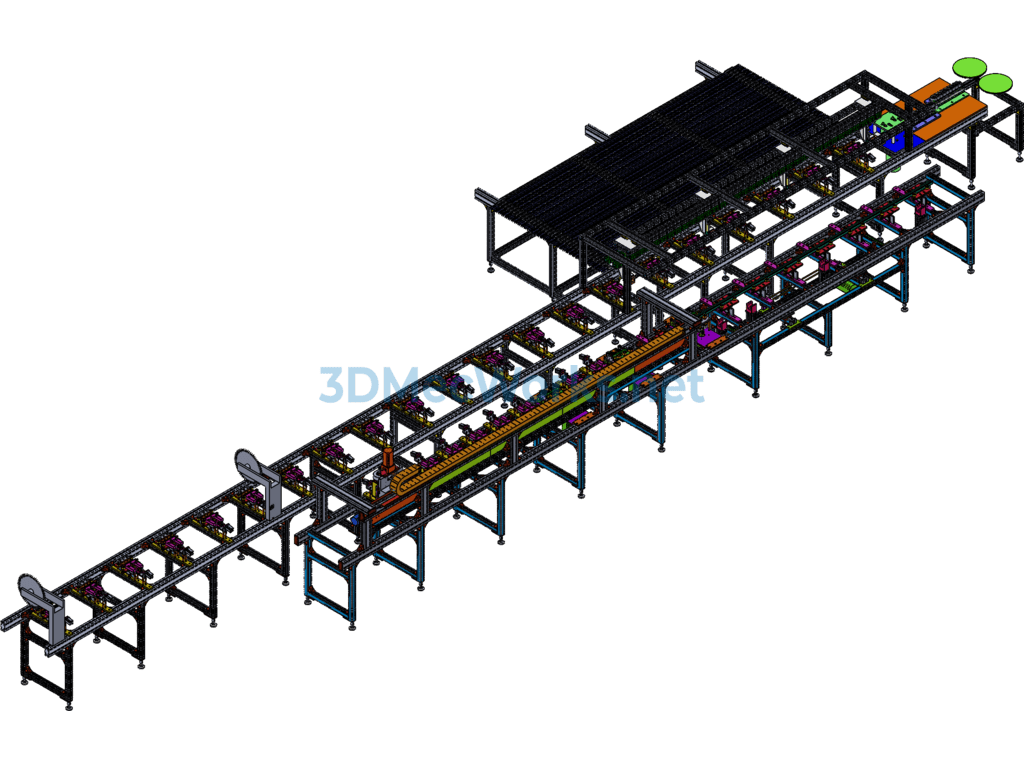

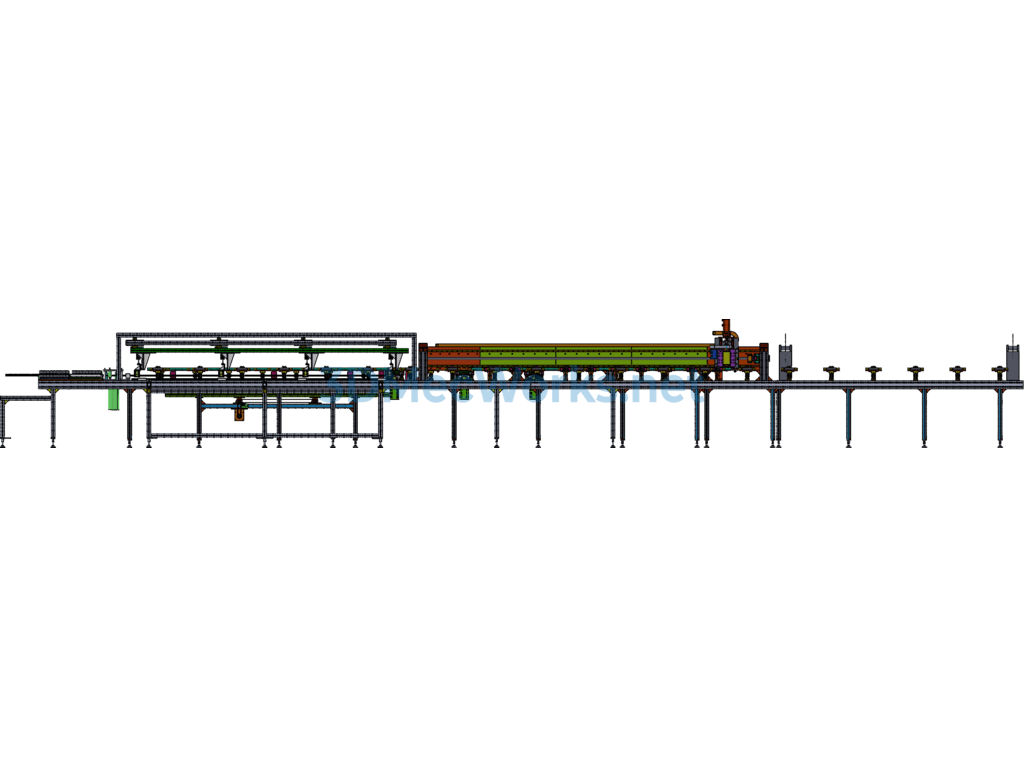

This equipment is a non-standard device specifically designed for LED track lights, replacing traditional manual production. It is suitable for the automatic cutting and assembly of 1~3m tracks, copper bars, and adhesive strips. The entire machine is controlled by a programmable controller and can automatically adjust according to customer product standards (milling, copper bar straightening, copper bar cutting, insertion, pressing, final product cutting at both ends). The machine structure is reasonable, stable, reliable, meticulously manufactured, and easy to operate and maintain. All automatic working systems use high-precision linear modules. All servo motors use products from Panasonic, Japan. This machine operates with an AC220V power supply. Dimensions: 18m*4m*1.5m. The air source uses filtered compressed air, with a pressure of 0.5~0.7Mpa. Production requirement: taking a product length of 3 meters as an example (18 seconds per piece). Scrap rate < 1‰.

There are no reviews yet.