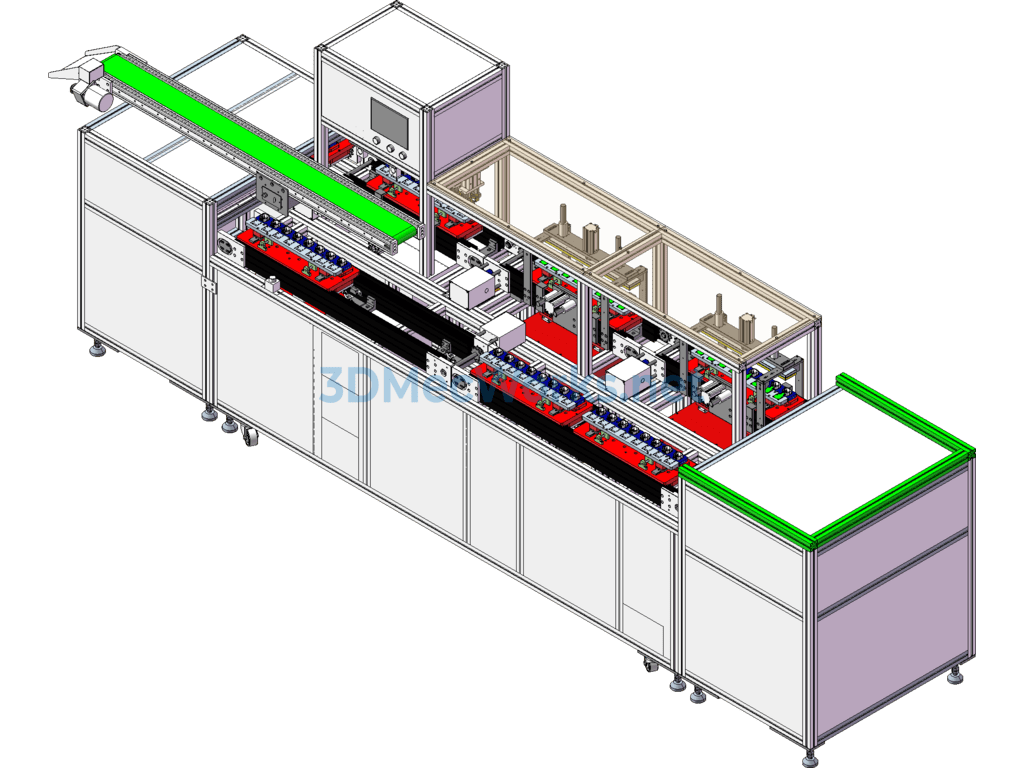

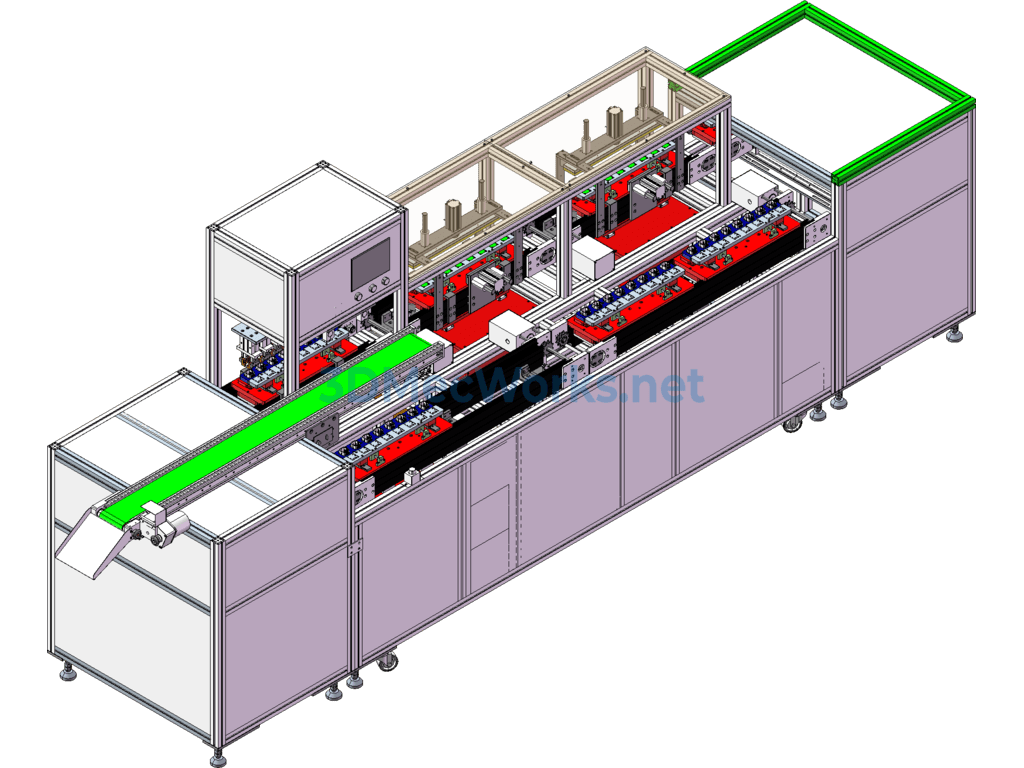

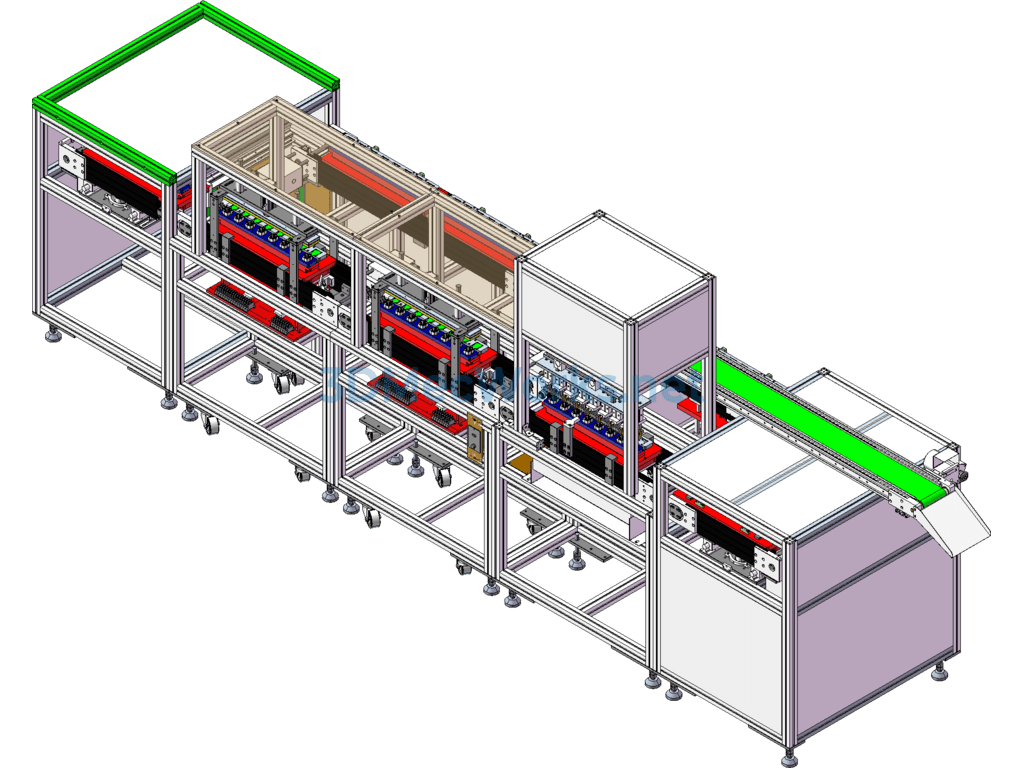

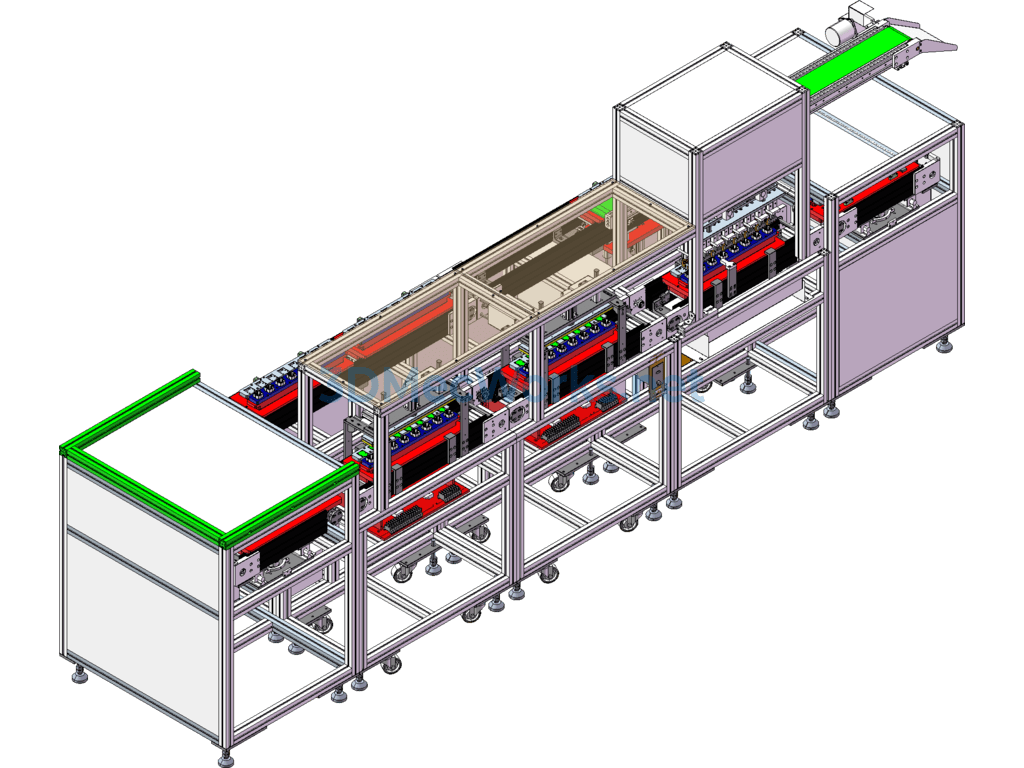

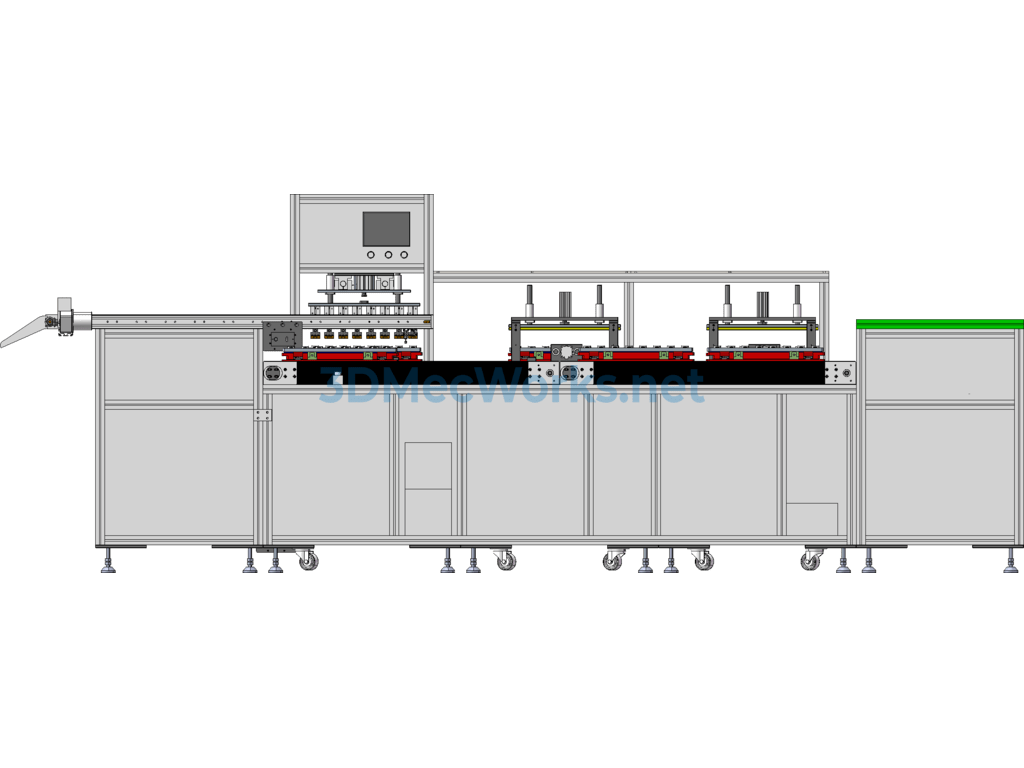

Mobile phone charger self-conductive testing equipment 3D model, this is a fully automated mobile phone charger automatic inspection production line. The electrification test is conducted by point-to-point testing on the charger’s plug using the probe head. This line mainly consists of five major parts: first, you can see the automatic loading at the front end, followed by the pick and place robotic arm, the automatic conveying multiple sprocket, then the 90-degree automatic turning conveyor belt, and finally the conductive test and unloading conveyor belt. In summary, there are many internal structures that are complex and very worth learning from. SW design source files are shared and can be edited!

The mobile phone charger self-conductive testing equipment is mainly divided into seven major parts: feeding station, automatic conveyor belt, handling robotic arm, USB testing station, plug charging testing position, unloading station, and conveyor belt. The entire production process is unmanned operation, making it the most practical equipment in the current automation industry. Therefore, many of the structures in the entire line are very good, and absolutely worth having!

Specification: Automatic Testing Production Line for Mobile Phone Charger Plugs

|

User Reviews

Be the first to review “Automatic Testing Production Line for Mobile Phone Charger Plugs”

You must be logged in to post a review.

There are no reviews yet.