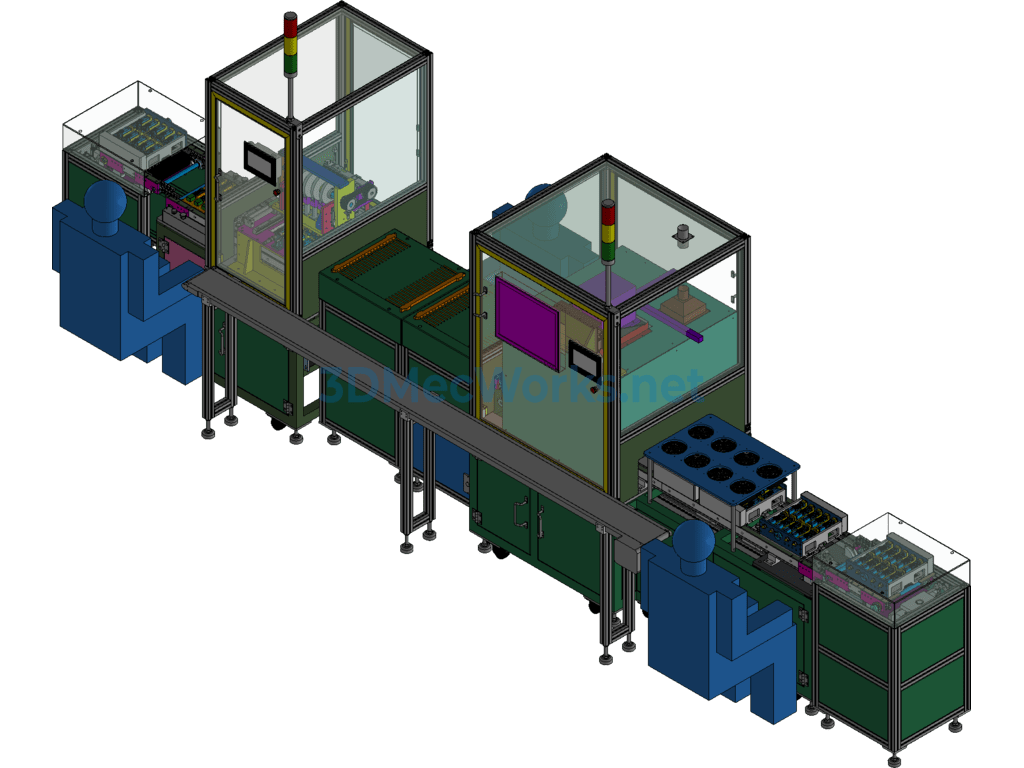

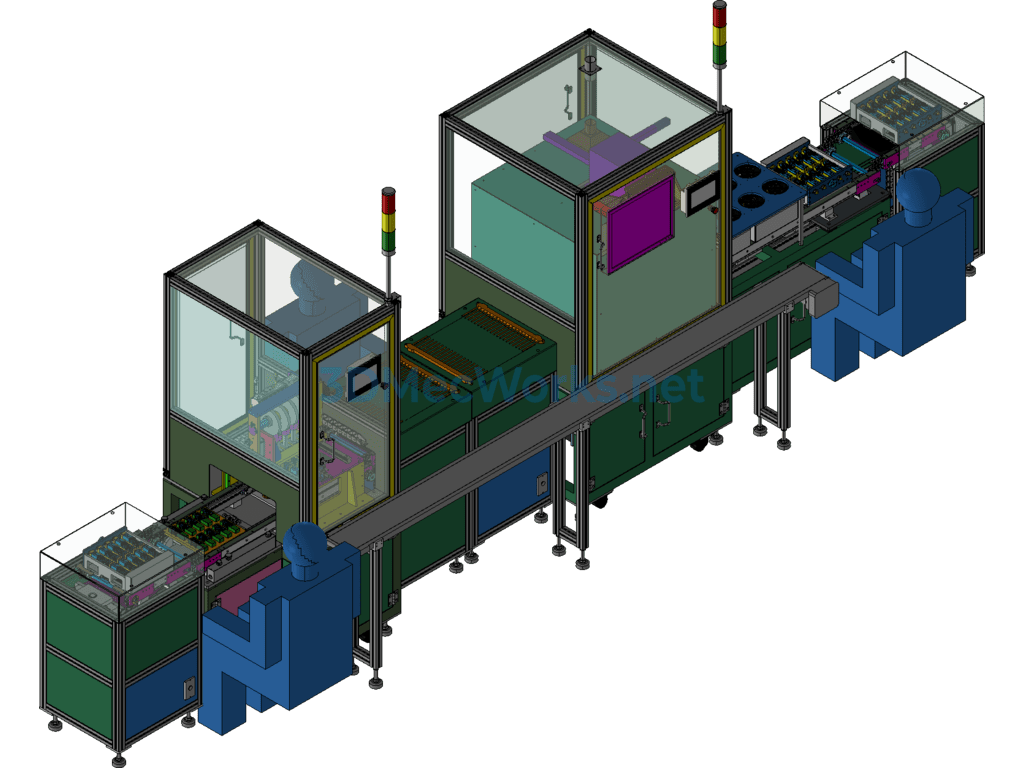

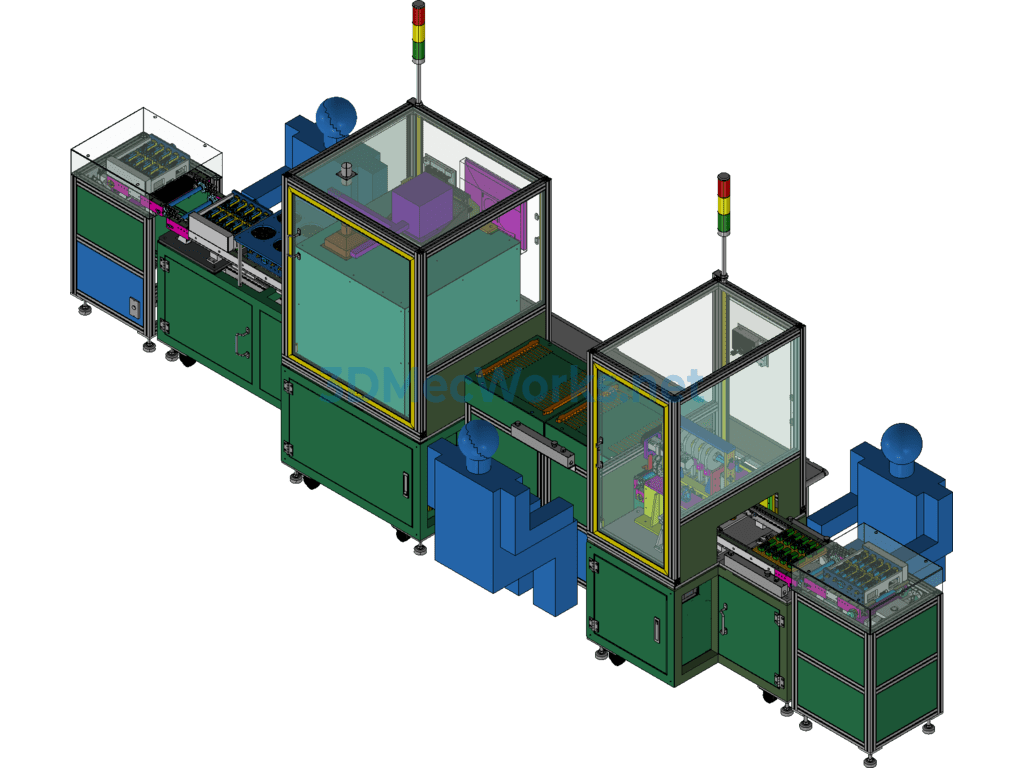

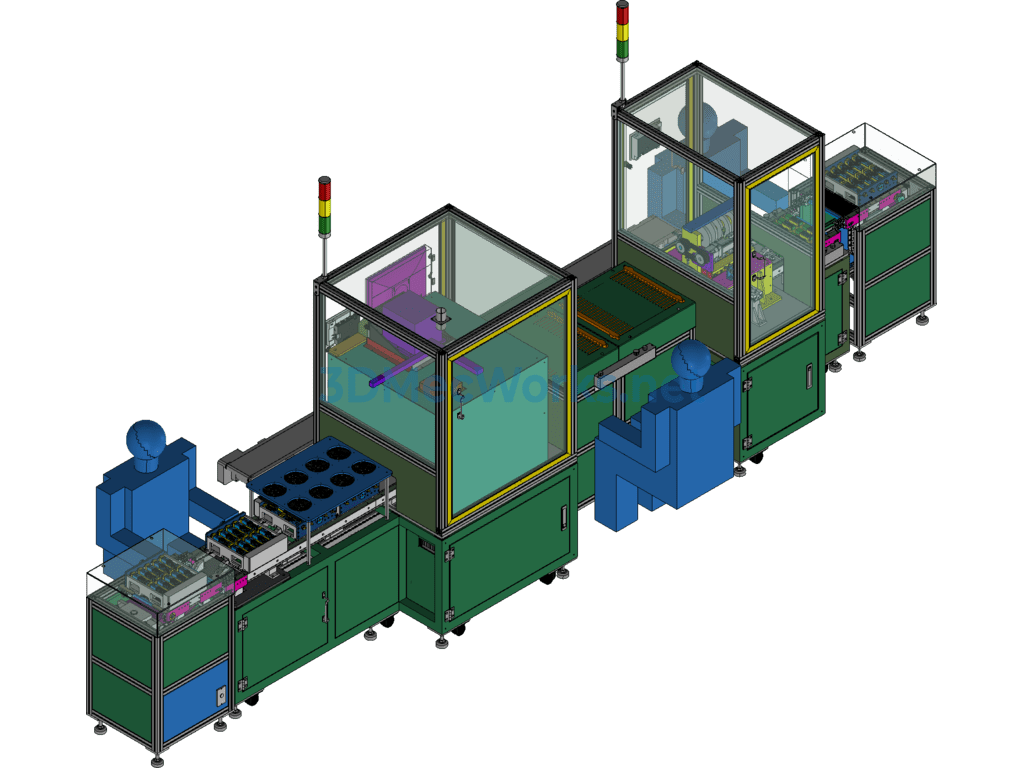

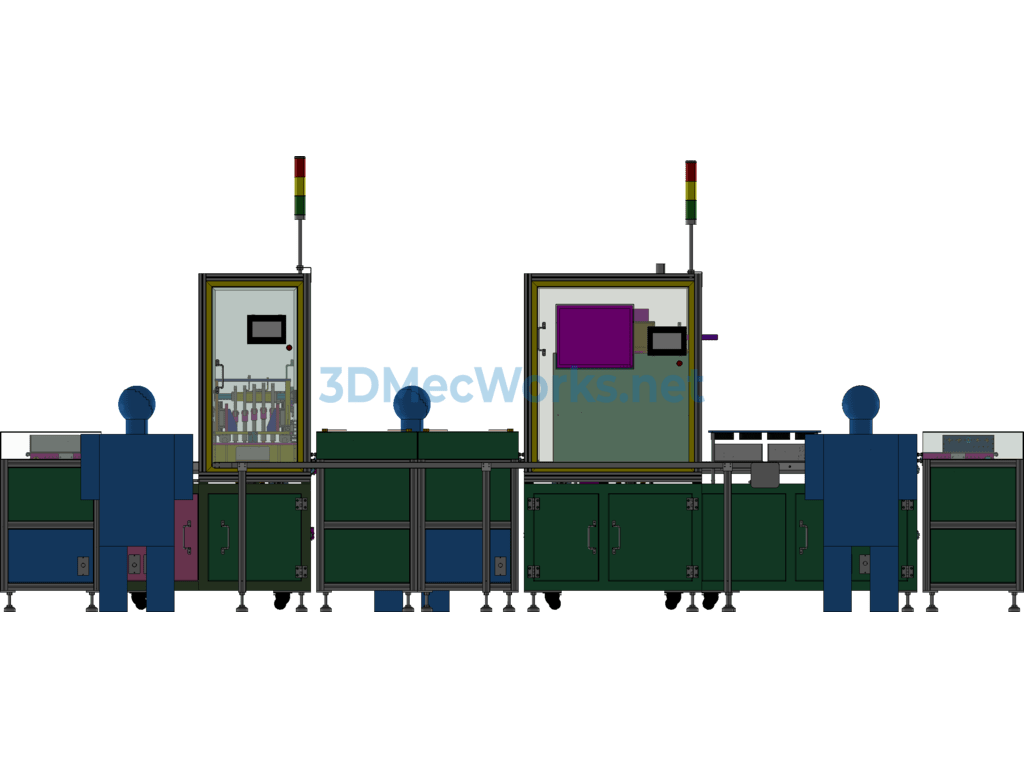

Silicon Steel Welding Machine 3D Model,

Due to the complex process, narrow process window, and high production difficulty, the production of silicon steel sheets is honored as an artwork among steel products, especially oriented silicon steel sheets. Therefore, welding silicon steel sheets also poses a significant challenge. Traditional argon arc welding easily burns tungsten needles, and frequently changing them consumes a lot of time, making mass production impossible.

However, using laser welding technology for silicon steel sheets results in narrow weld seams, deep penetration, parallel sides on both sides of the weld seam, and a small heat-affected zone.

The laser welding machine uses a laser as the welding power source, employing high-energy laser pulses for localized heating of the material area. The energy of the laser radiation spreads internally through the material by heat conduction, melting the material and forming a specific molten pool.

It is a new type of welding method, primarily targeting the welding of thin-walled materials and precision parts.

Specification: Automatic Silicon Steel Sheet Press-Fitting and Welding Machine

|

User Reviews

Be the first to review “Automatic Silicon Steel Sheet Press-Fitting and Welding Machine”

You must be logged in to post a review.

There are no reviews yet.