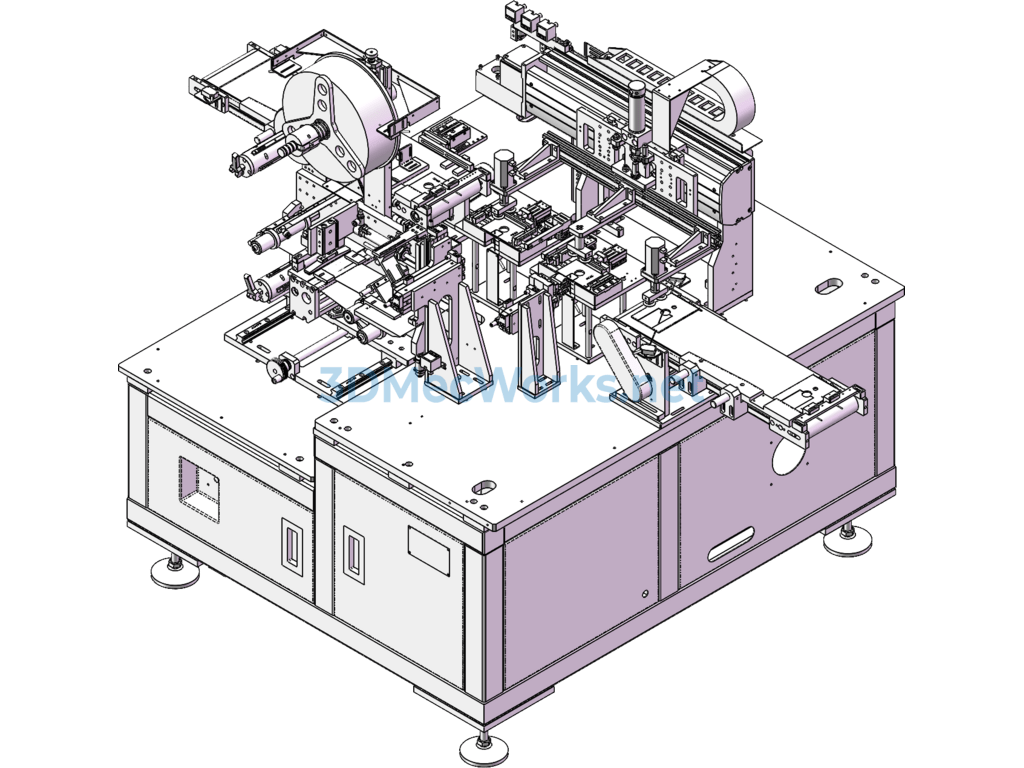

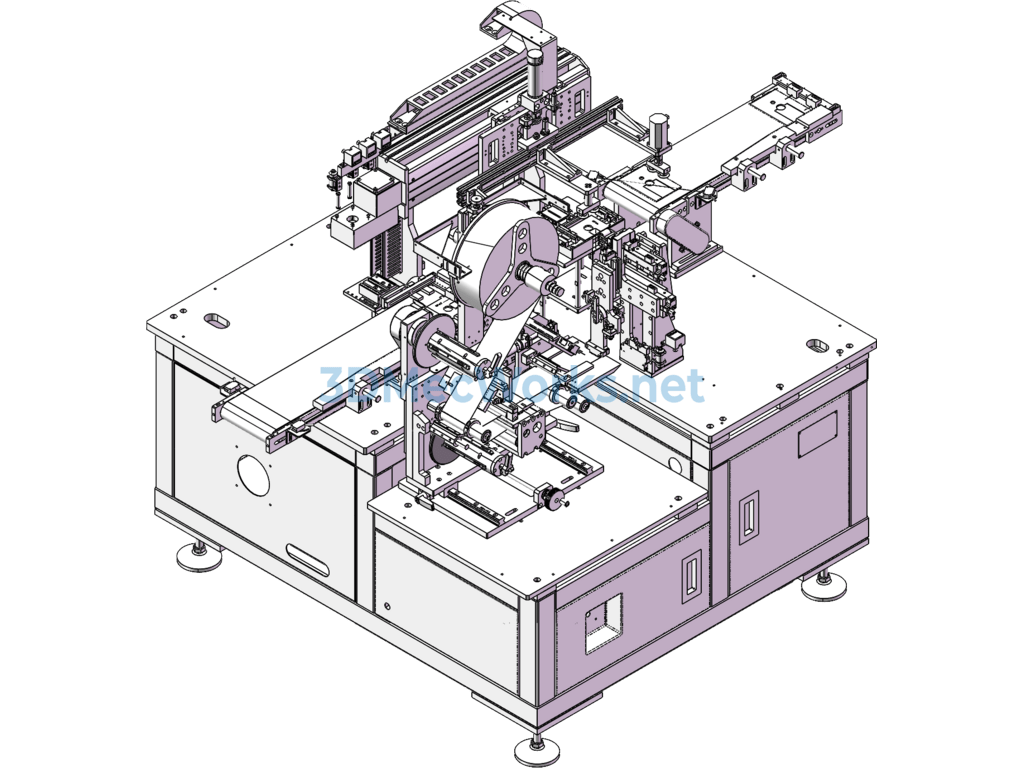

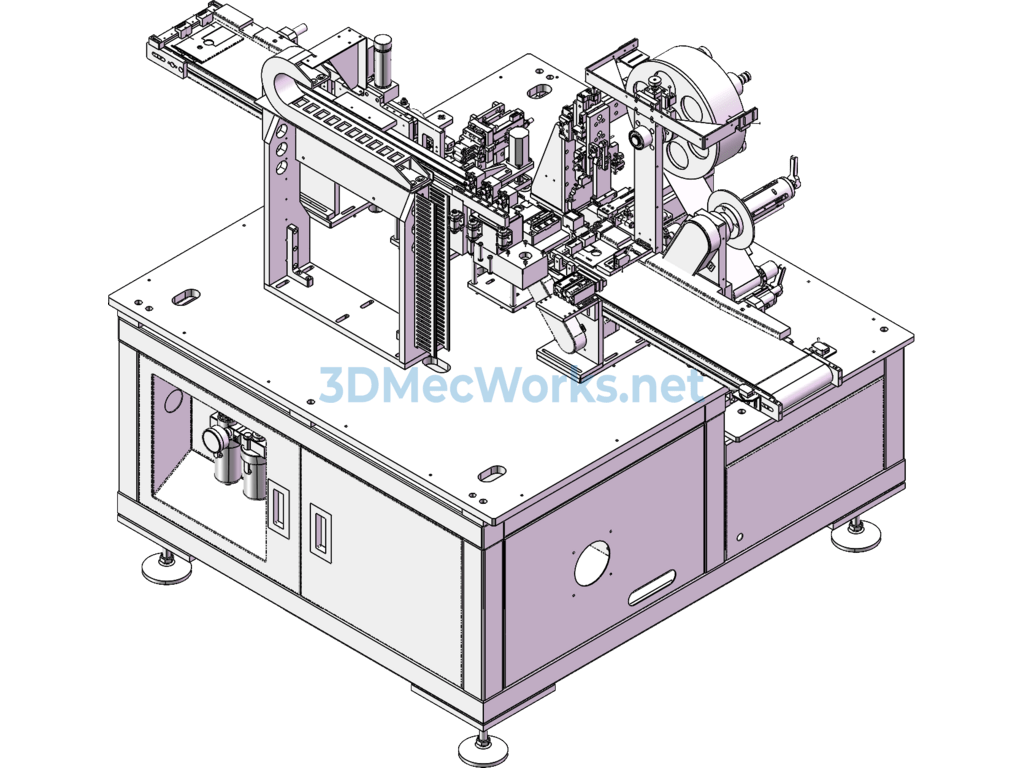

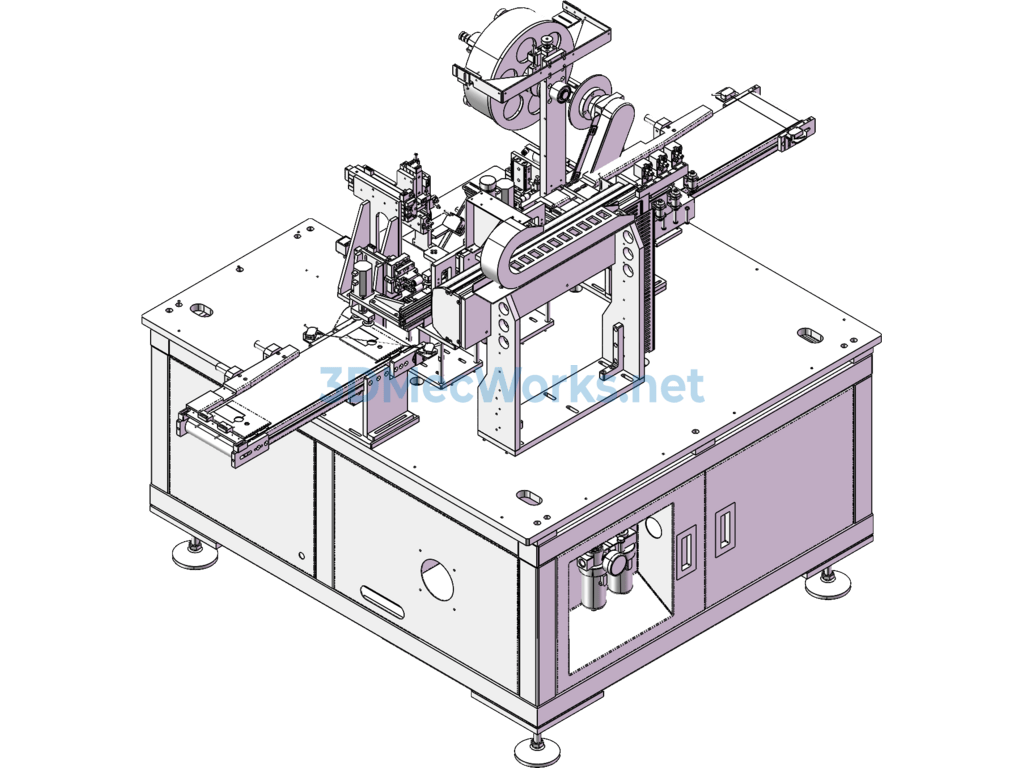

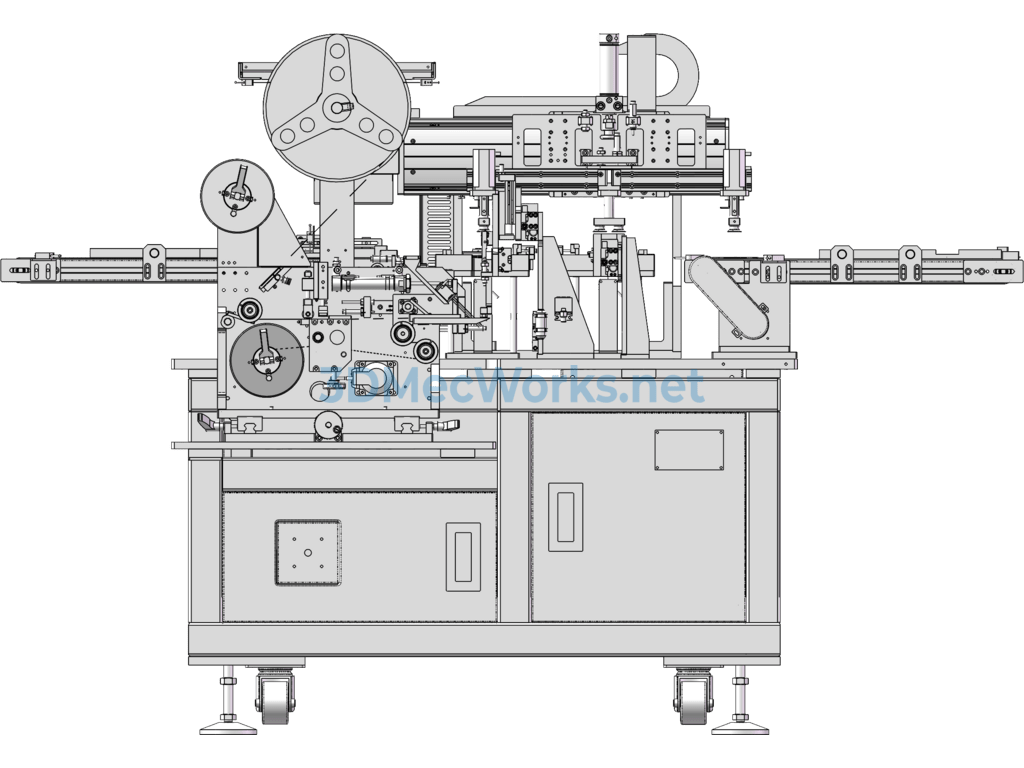

This equipment is used in the side adhesive process of the mobile phone battery production line, a fully automatic side adhesive tape applicator. The battery cell is fed from the left end of the equipment and positioned at the pick-up location through belt transmission. The linked robotic arm, using a suction cup, transports the mobile phone battery to the adhesive positioning platform and wrapping positioning platform. The adhesive dispensing module, which consists of a set of laser sensors and a servo motor, automatically peels and dispenses the material. The tape module removes the adhesive tape and applies it to the side of the battery. Subsequently, the wrapping module wraps the adhesive tape on the front and back of the battery, completing the taping action. After completing the taping, the linked transport robotic arm conveys the battery to the discharge belt to move to the next process. The equipment is designed with a capacity of 1000 PCS/h, equipment dimensions are 1200X1100X1900mm, module details are clear, and structural design is well-defined, for reference use.

Specification: Automatic Side Lifting Adhesive Tape Applicator Machine

|

User Reviews

Be the first to review “Automatic Side Lifting Adhesive Tape Applicator Machine”

You must be logged in to post a review.

There are no reviews yet.