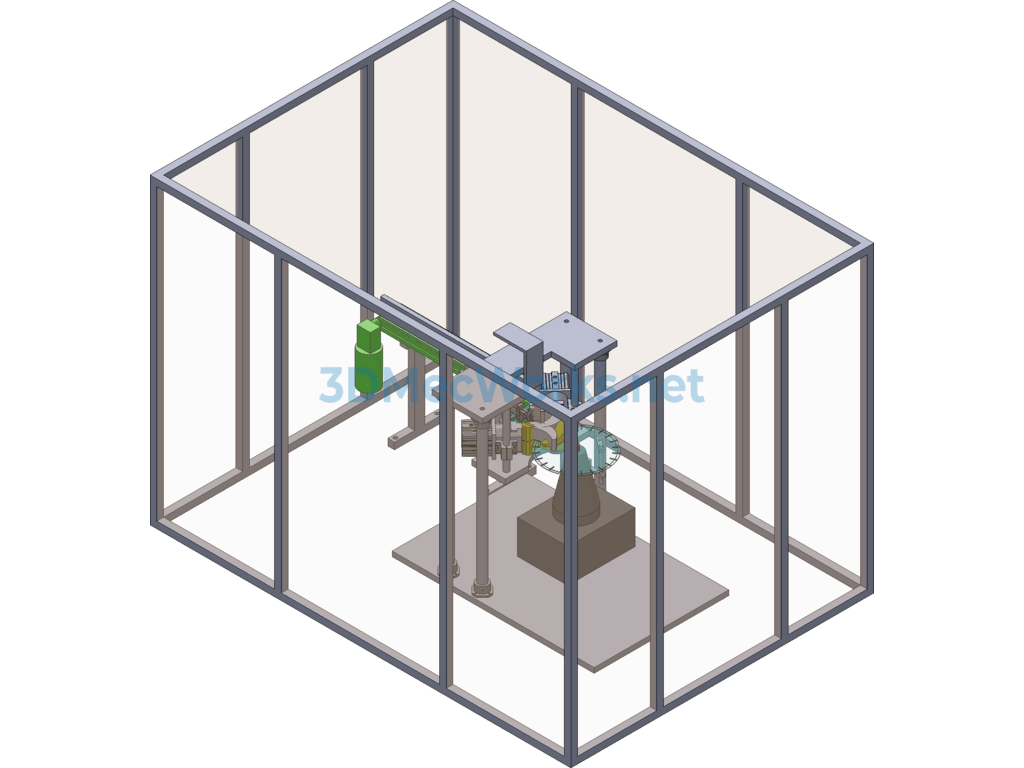

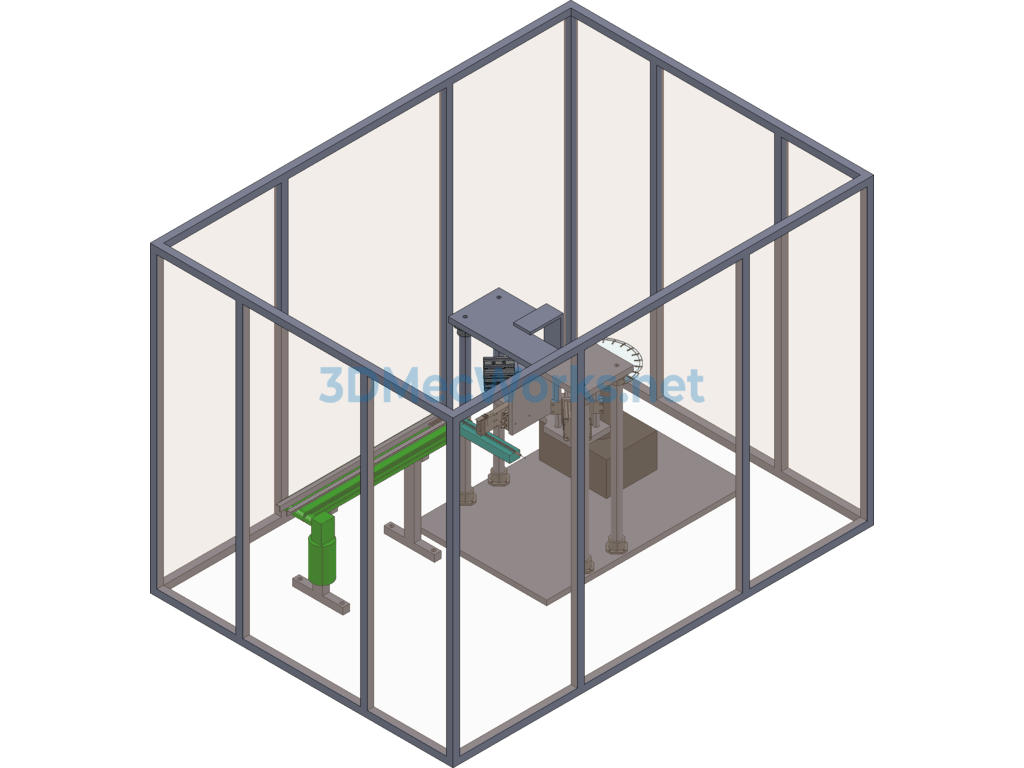

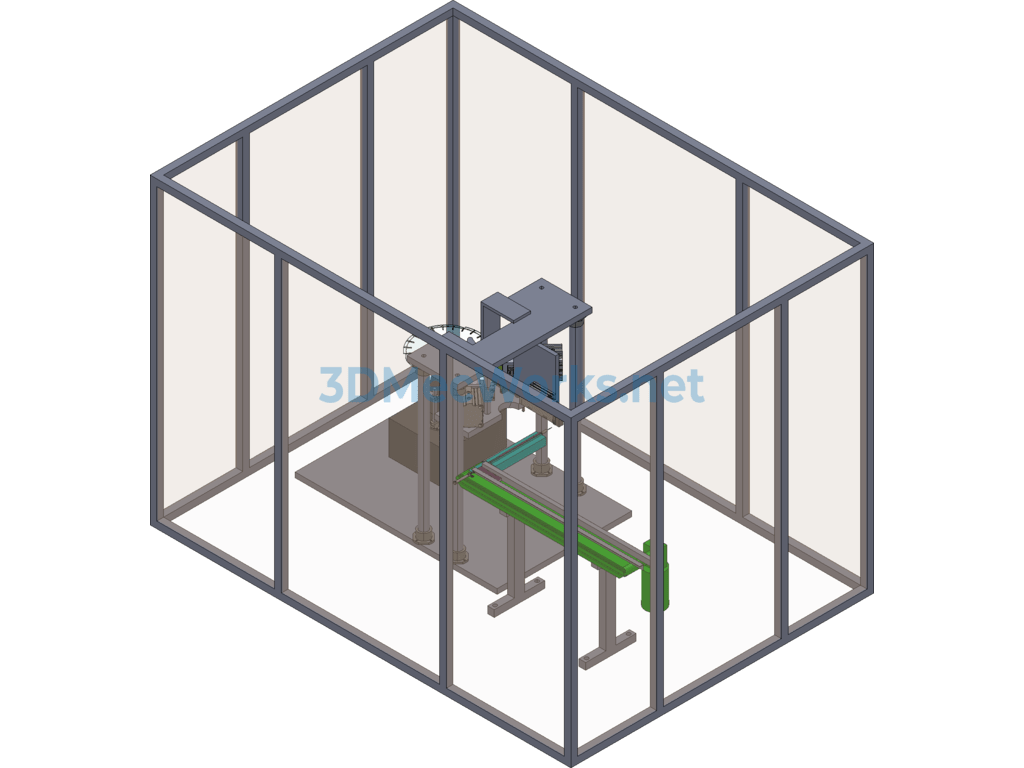

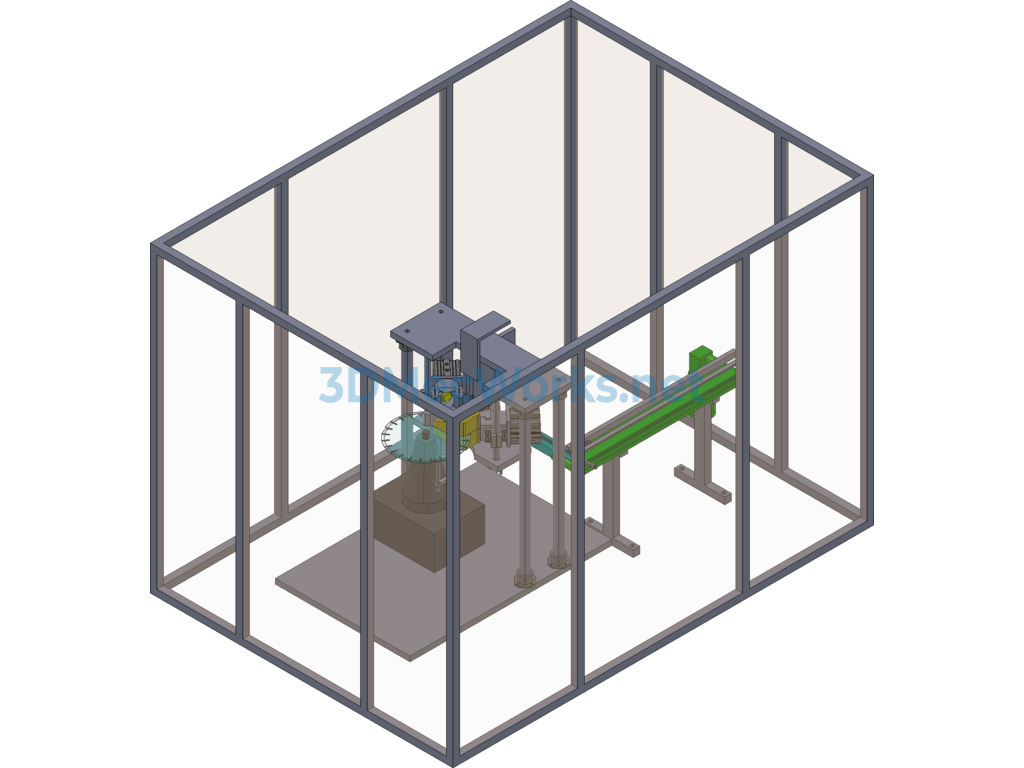

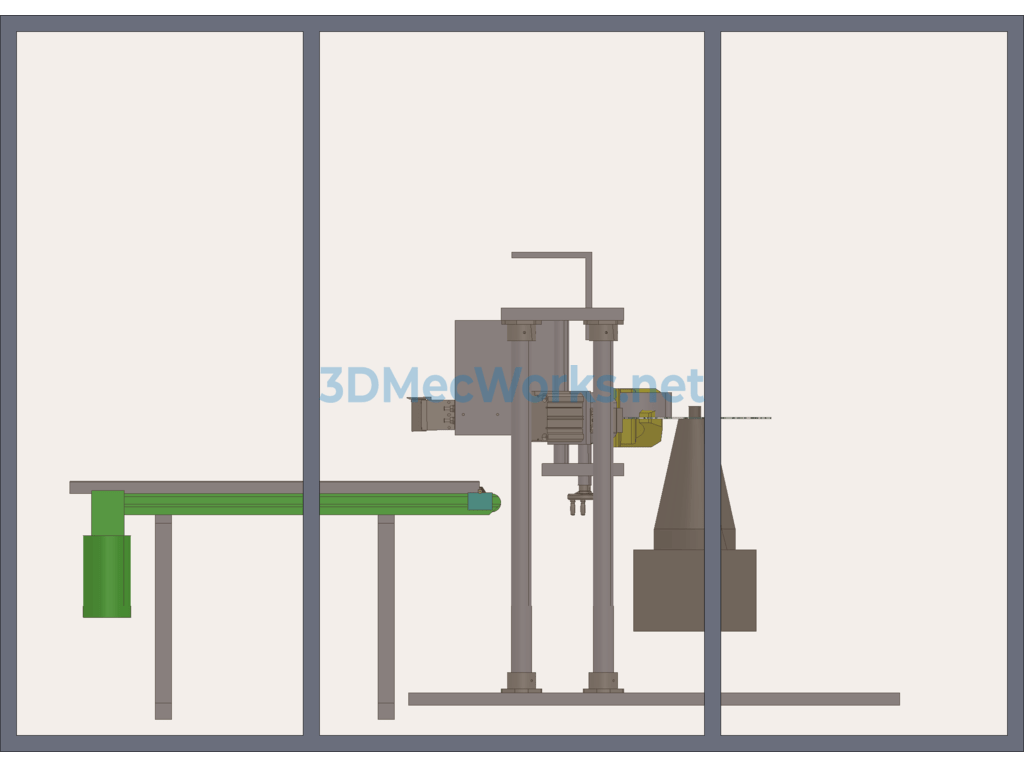

The conveyor module of the line body delivers the cutter head to the gripper, which holds and maintains the position, then moves to the welding station. The two sets of grippers serve for positioning and preventing a certain degree of welding deformation, divided into two welding processes. The first uses low energy and high speed, and the second ensures firm welding (single-sided welding forming on both sides). After welding, the product is manually removed, and the equipment has been running stably in production.

Specification: Automatic Saw Blade Loading and Welding (including Video of Produced Equipment)

|

User Reviews

Be the first to review “Automatic Saw Blade Loading and Welding (including Video of Produced Equipment)”

You must be logged in to post a review.

There are no reviews yet.