Simone Hawkins

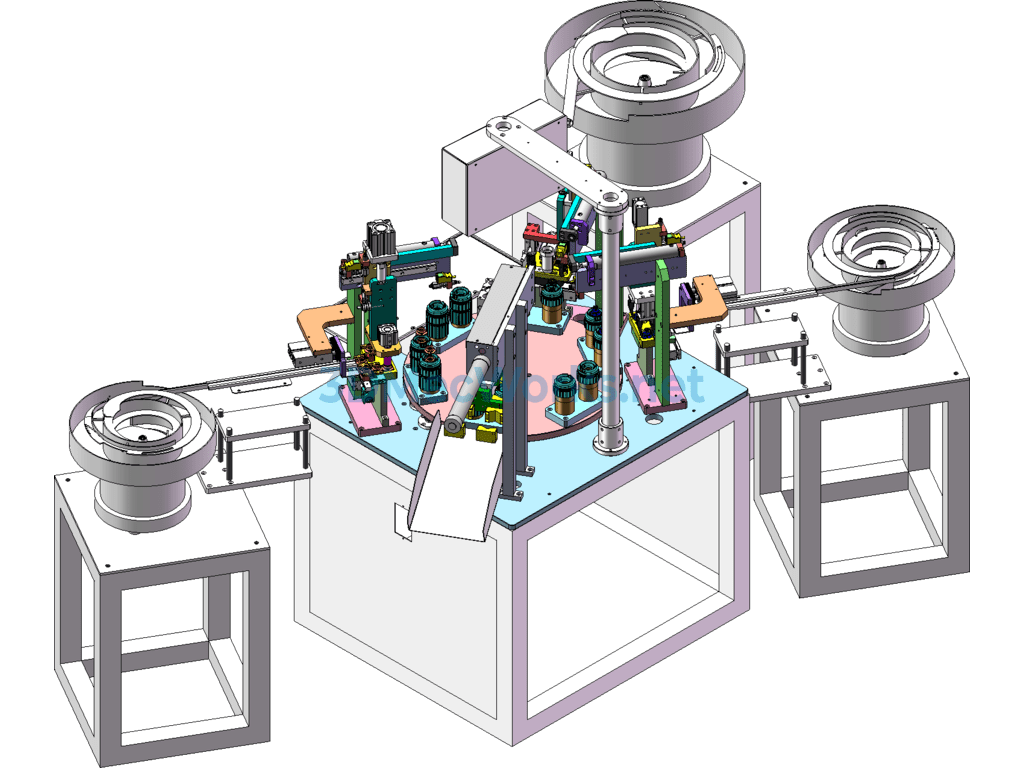

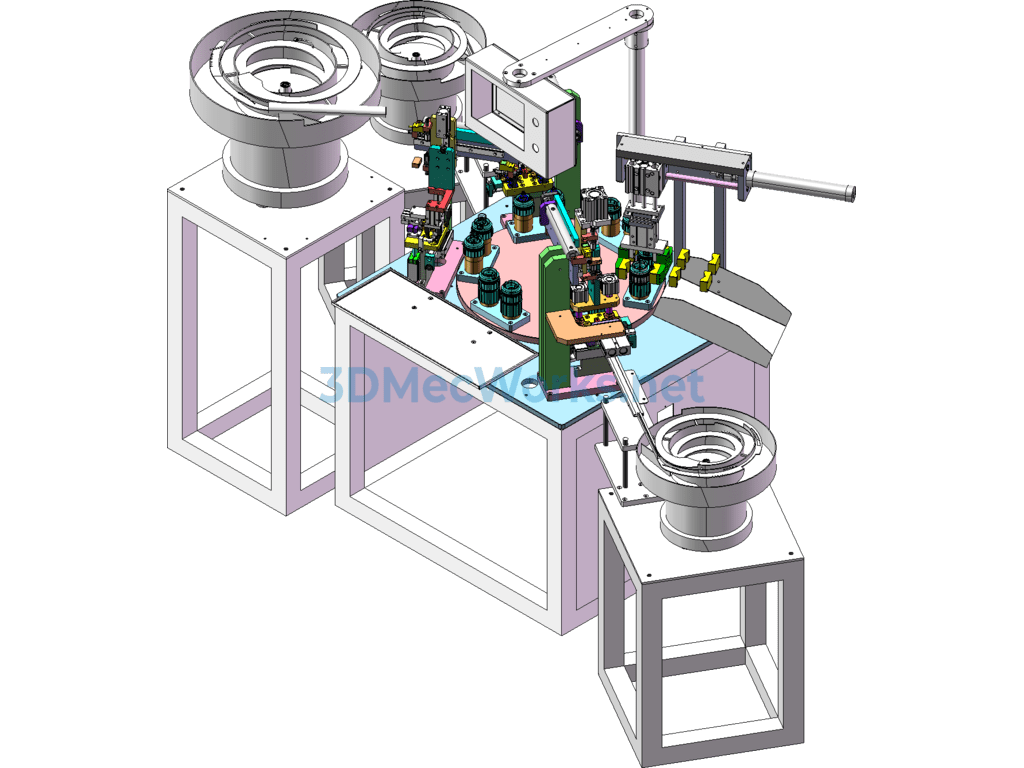

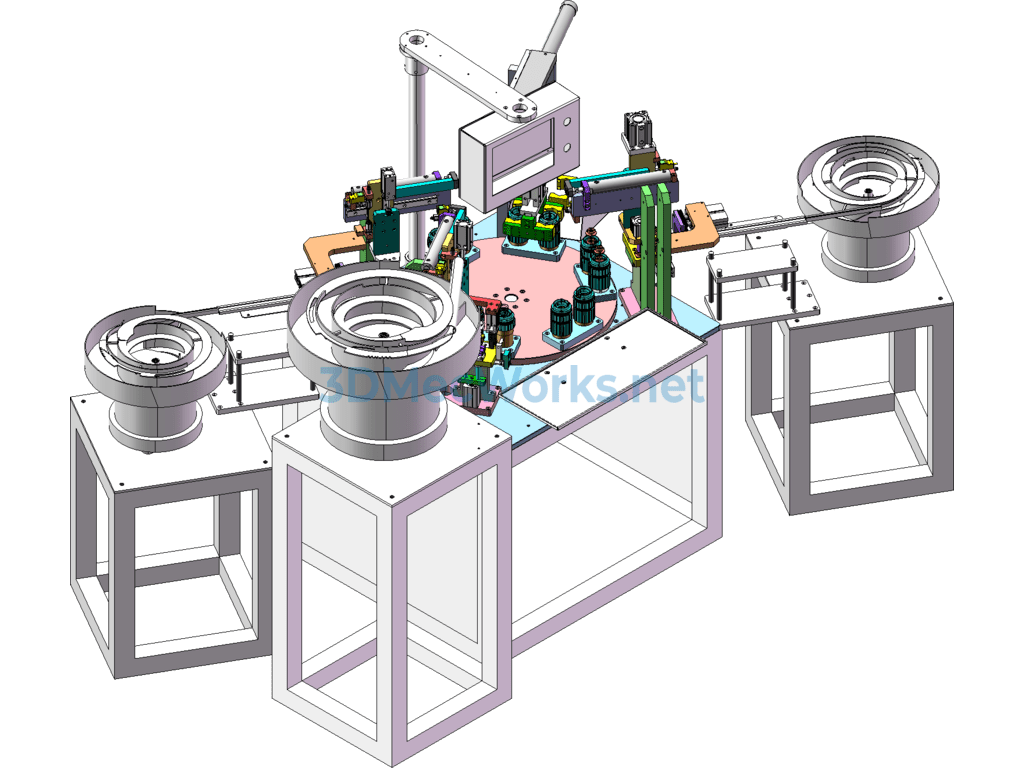

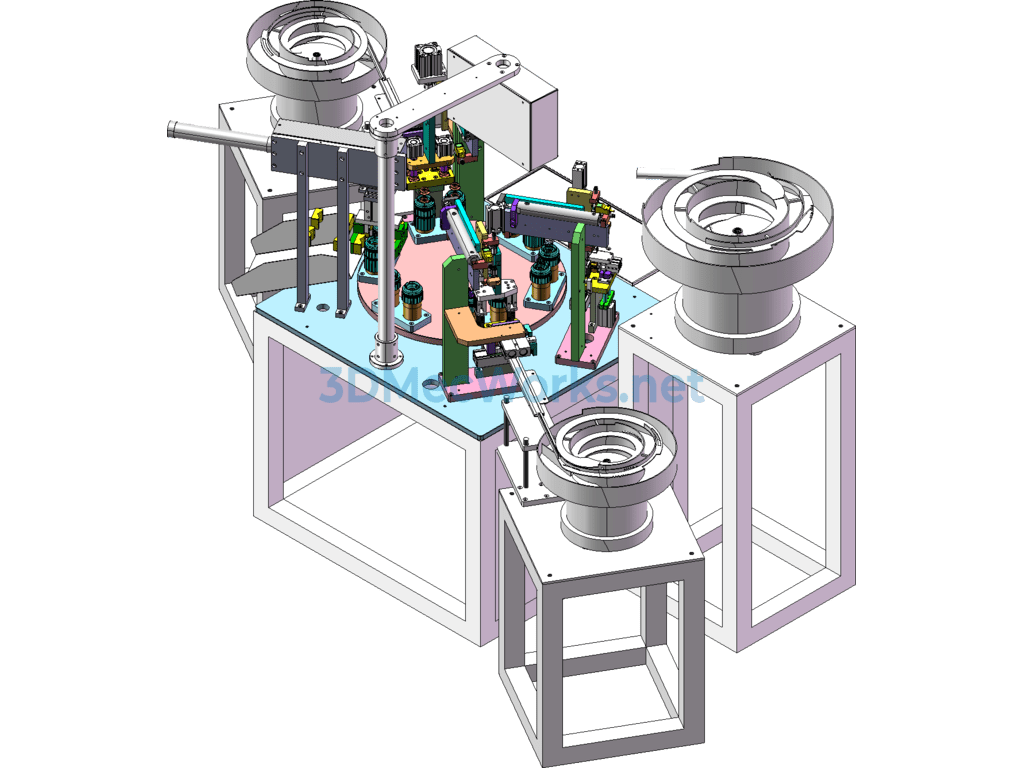

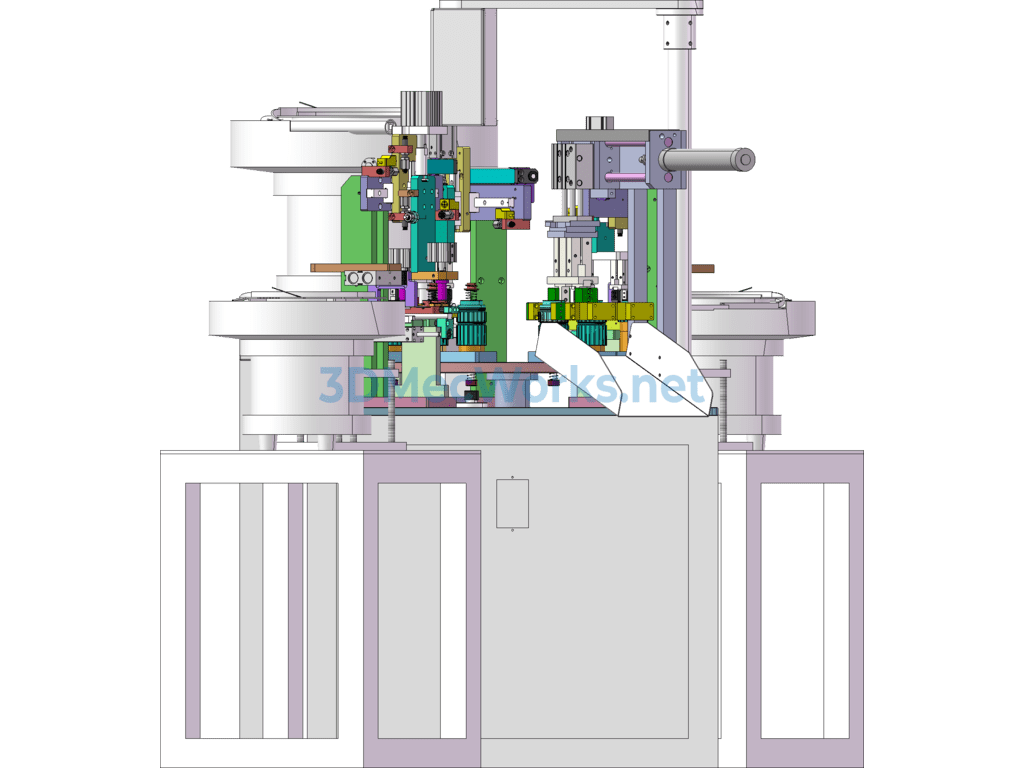

This equipment is primarily developed for the cannon barrel ejection of player figures by player factories. Due to the limitations of product size, manual assembly is restricted and relatively slow, prompting the development of automated machinery to improve production efficiency. As the base is relatively large, vibratory bowl feeding would be costly, so manual feeding is used instead, while other components adopt automatic feeding. The production cycle is 1.5 seconds per piece. The equipment mainly consists of a 6-position indexing table forming six workstations. The first workstation is for base loading, done manually, with a universal fixture for three types of products. The second workstation involves loading male fasteners, with feeding from a vibratory bowl, distributed by a distribution mechanism, and robotic arms placing the fasteners into the base. The third workstation involves spring loading, with the method identical to the second workstation. The fourth workstation involves loading female fasteners, using the same method as the second workstation, and at the same time, the bottom assembly mechanism pushes the male fastener into the female fastener. The fifth workstation is for product unloading; the unloading robot arm grips the product and places it into the unloading chute. The sixth workstation checks whether the fixture is empty for the next cycle.

Specification: Automatic Player Cannon Barrel Assembly Machine

|

User Reviews

Be the first to review “Automatic Player Cannon Barrel Assembly Machine” Cancel reply

You must be logged in to post a review.

There are no reviews yet.