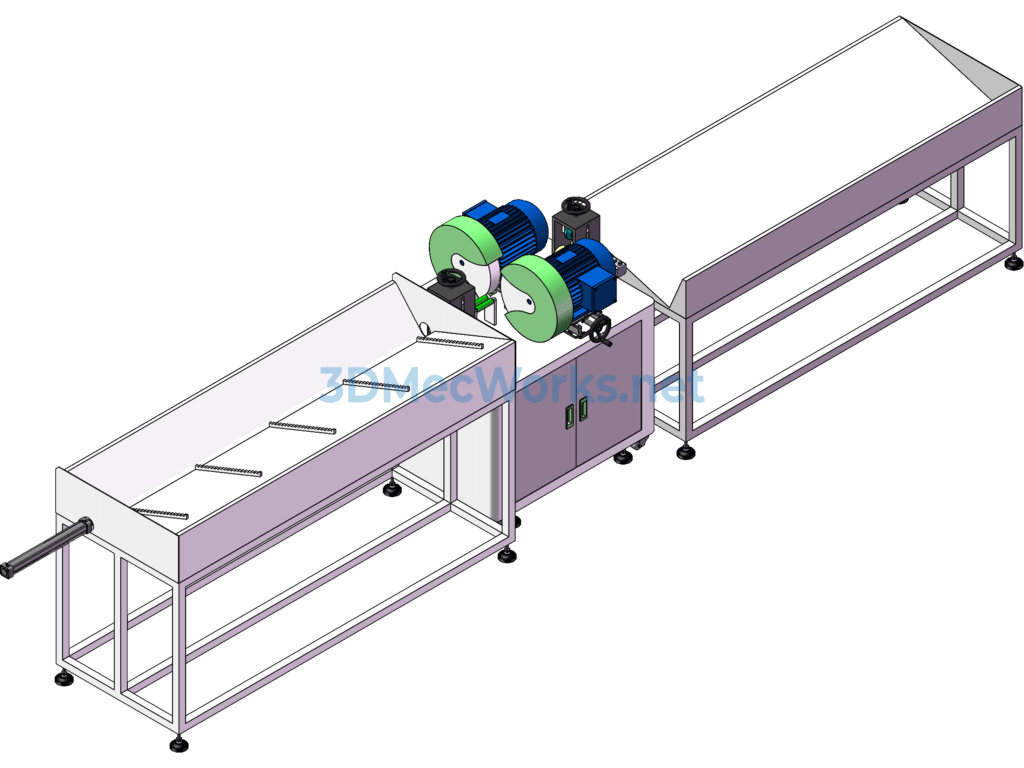

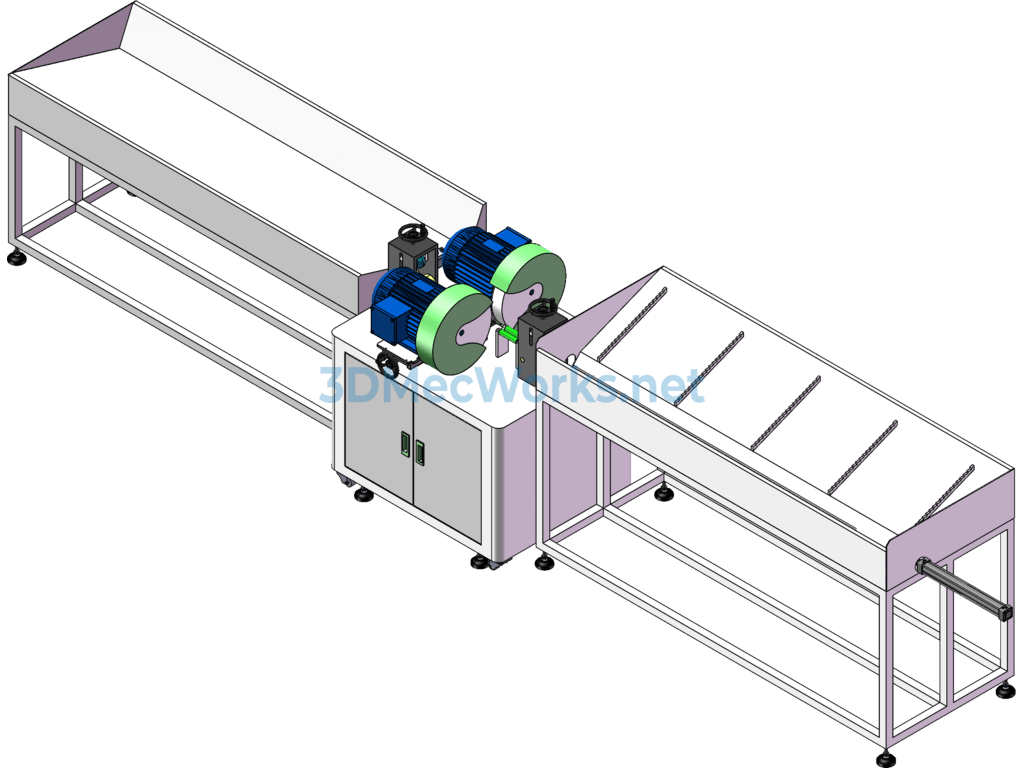

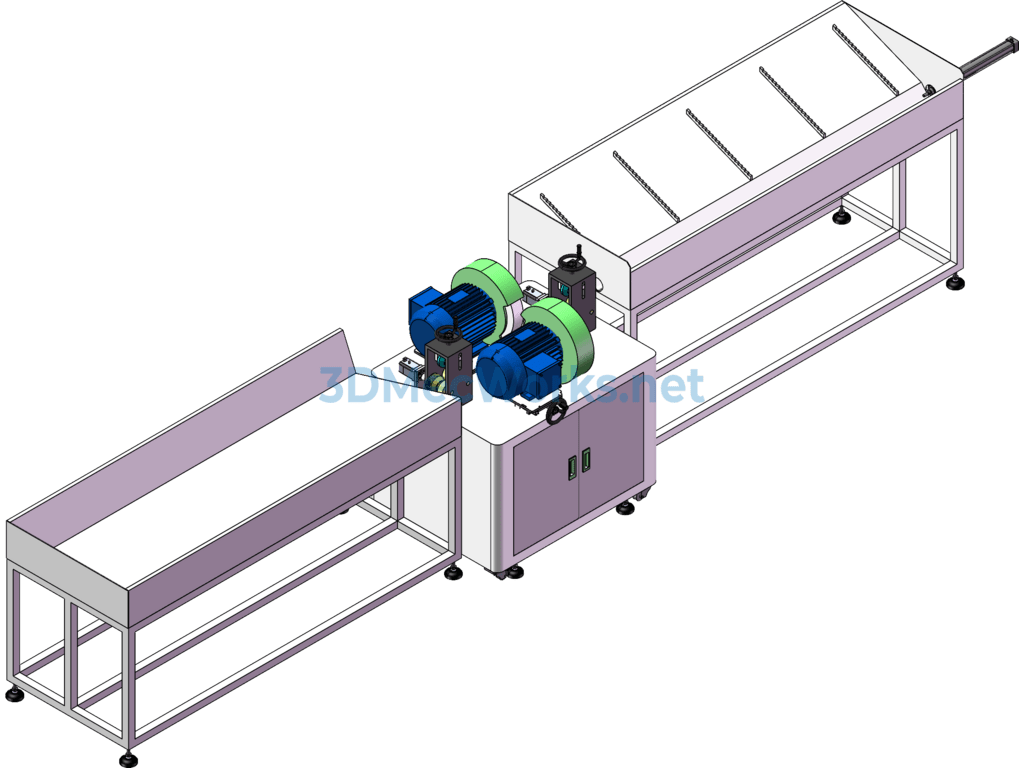

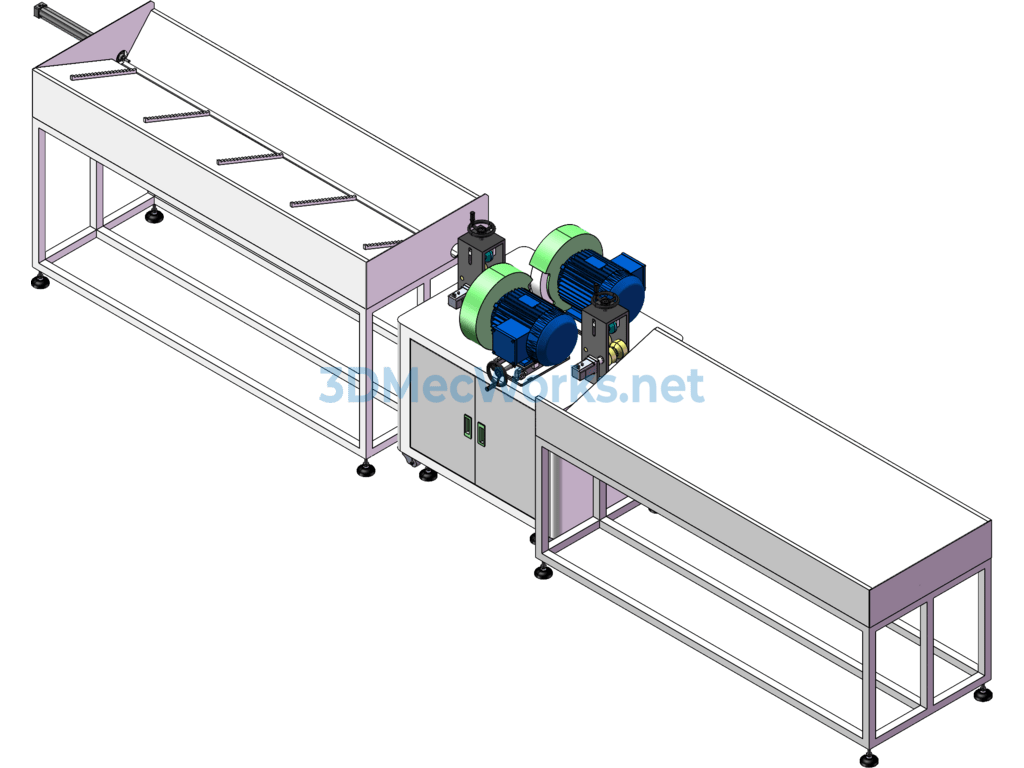

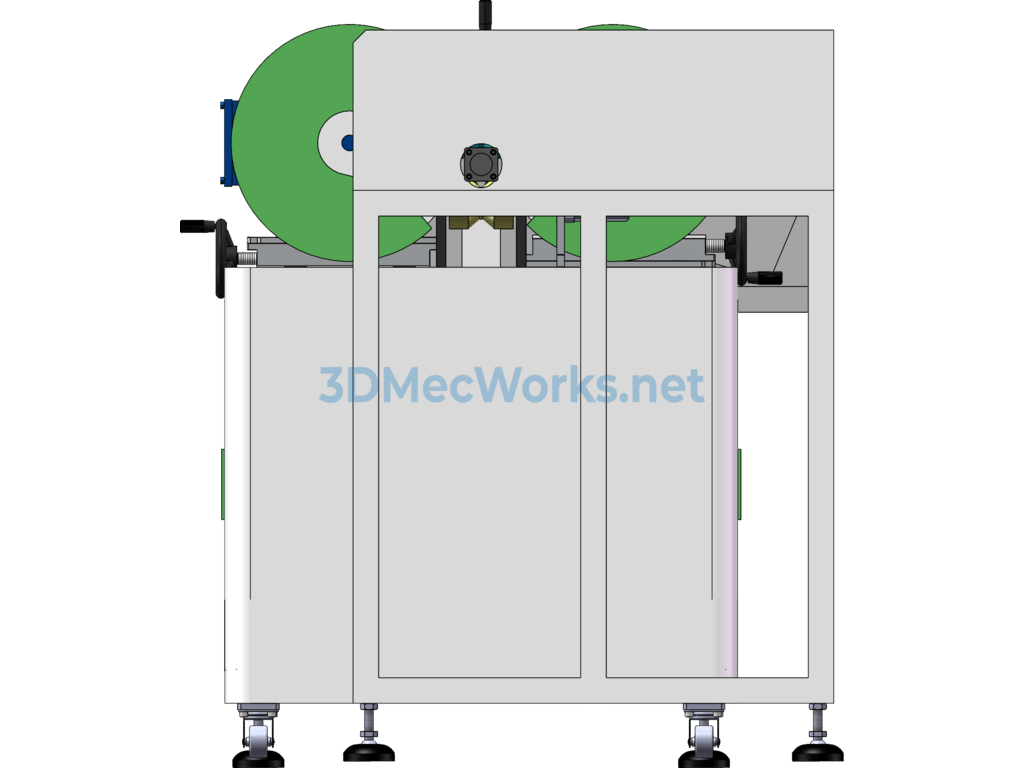

This equipment is an automatic tube polishing machine, which performs surface brushing or mirror polishing on tubes after they have been cut from long tubes into short tubes and both ends have been welded shut. This equipment is used to complete product polishing, making it one of the automated devices to improve processing efficiency and reduce manpower. The current automation goals are: post-processing surface finish of 0.8, a cycle time of approximately 60 seconds per piece, and a capacity of over 60 pieces per hour. It can adapt to the production of tubes of different lengths. Other specifications follow general industry standards. Main structure:

1. High-rigidity frame: square tubes & white sheet metal with baked paint, transparent observation window;

2. Tube dividing & push-type feeding conveyor: cylinder, stepper motor & reduction mechanism, adaptable feeding rollers of different diameters, tube lifting and positioning mechanism;

3. Inclined twin-link polishing mechanism: polishing wheel position & angle adjustment mechanism, slide rail, lead screw & front-back adjustment mechanism;

4. Adjustable fixtures: precision adjustment of fixture cavity size, anti-static;

5. Control system: includes main control units such as PLC, HMI, electric box, and hardware and software systems for detection, safety alarms, counting, etc.

(The diagram is for reference only; the actual design diagram will be based on the final review and approval by both parties.)

Specification: Automatic Pipe (steel Pipe) Polishing Machine

|

User Reviews

Be the first to review “Automatic Pipe (steel Pipe) Polishing Machine”

You must be logged in to post a review.

There are no reviews yet.