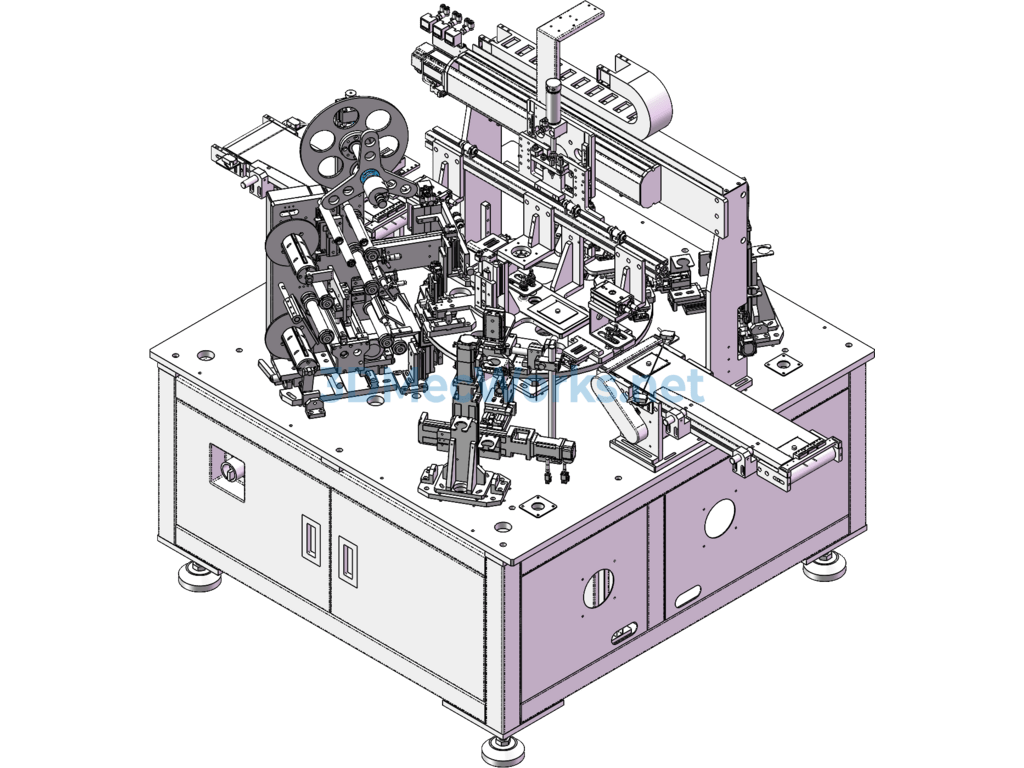

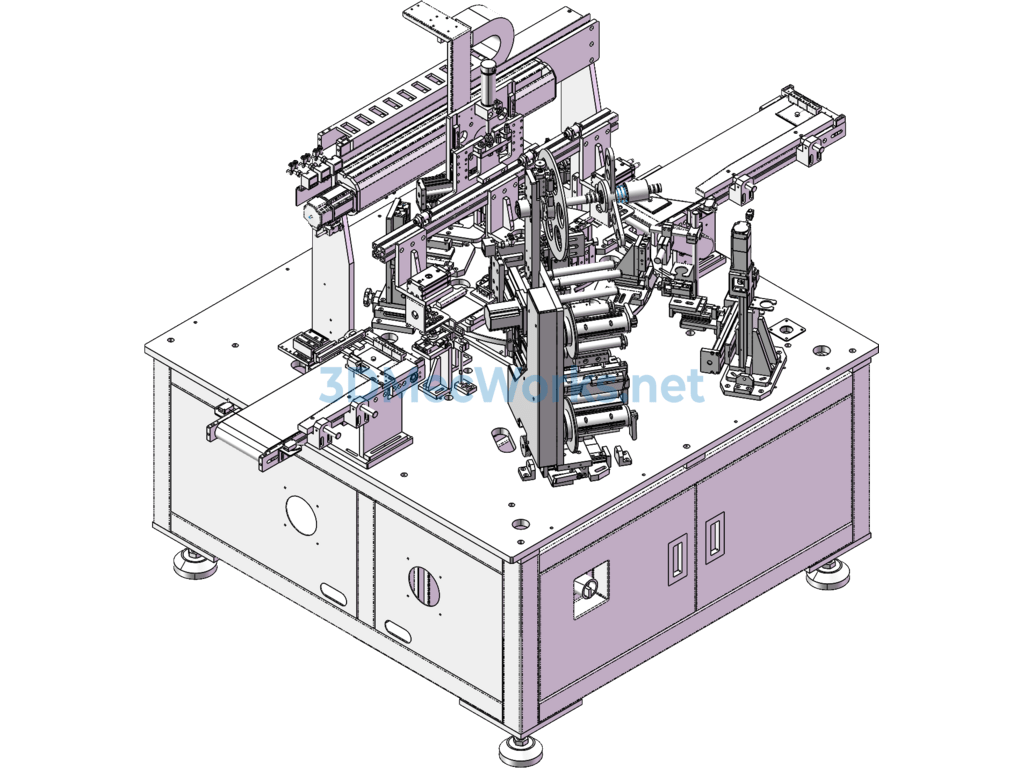

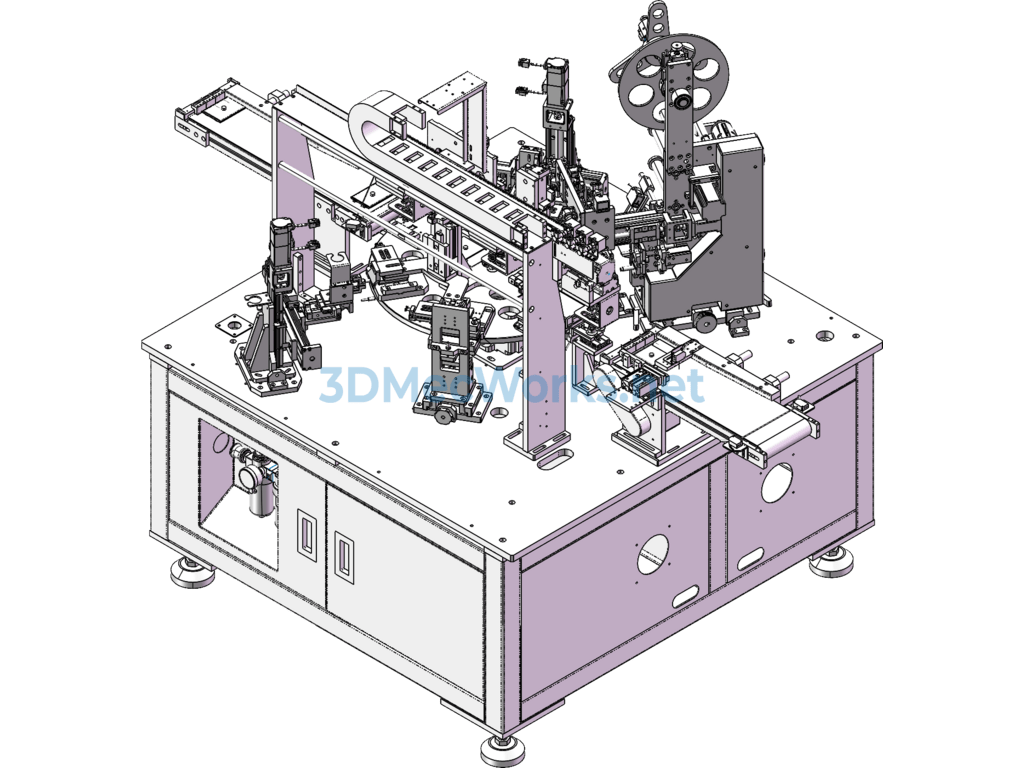

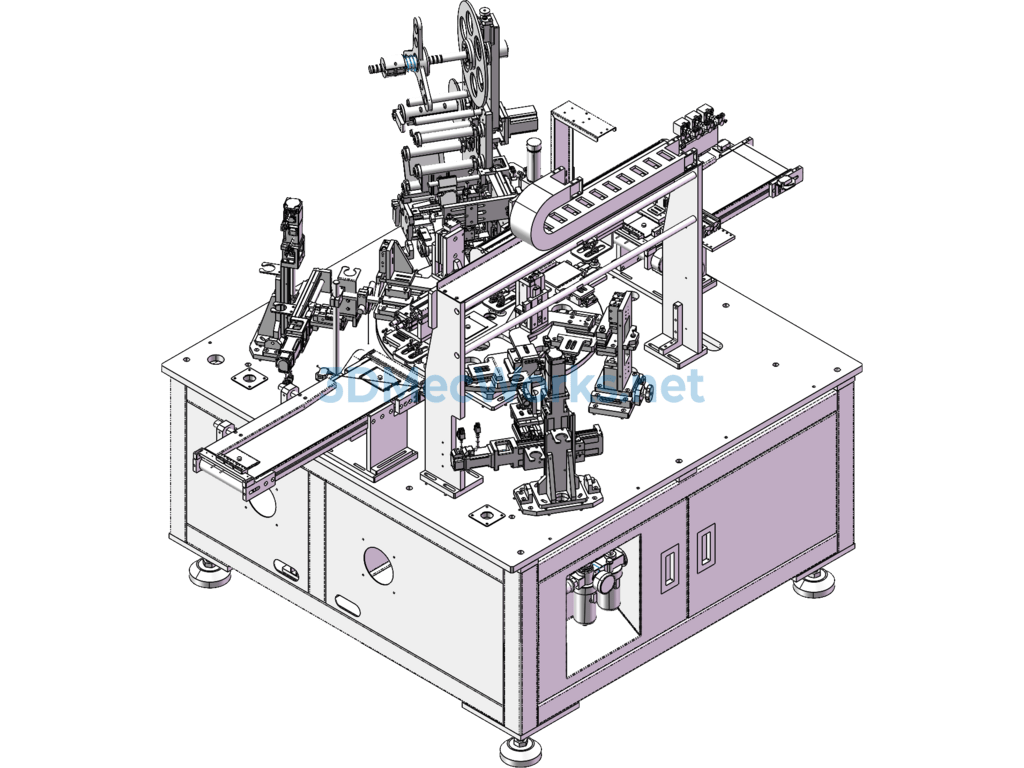

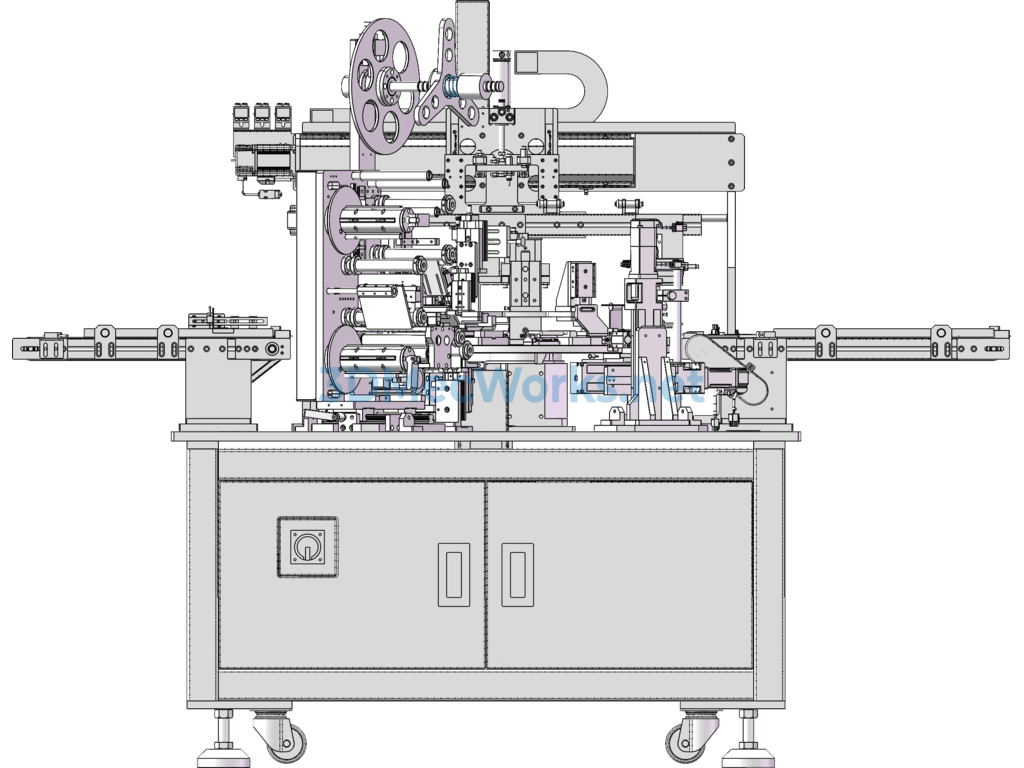

This device is used in the process of applying peripheral adhesive tape on a mobile phone battery production line. The peripheral adhesive tape is a strip-shaped adhesive tape used to protect the circuit board after the FPC has been bent. The device features automatic loading and unloading, a belt transmission structure, and a linked manipulator that picks the battery from the belt after positioning and places it onto the adhesive platform. The suction head then applies the adhesive tape to the top front of the battery case. Since the adhesive tape is longer than the battery’s width, it also needs to wrap around the sides. This is done using a finger cylinder that grabs the adhesive tape, wrapping it securely around the external surface covering the battery’s width. The adhesive tape clamp is made of non-sticky material, and the X and Y-axis servo motors control the wrapping path. Each station is connected by a turntable for automatic transfer. After wrapping, the battery undergoes shaping and compaction. Finally, a linked manipulator grabs it for transfer to the next process. The device is designed with a production capacity of 1000 PCS/h and dimensions of 1200X1200X1900mm. The structural design is clear and straightforward.

Specification: Automatic Peripheral Tape Applicator Machine

|

User Reviews

Be the first to review “Automatic Peripheral Tape Applicator Machine”

You must be logged in to post a review.

There are no reviews yet.