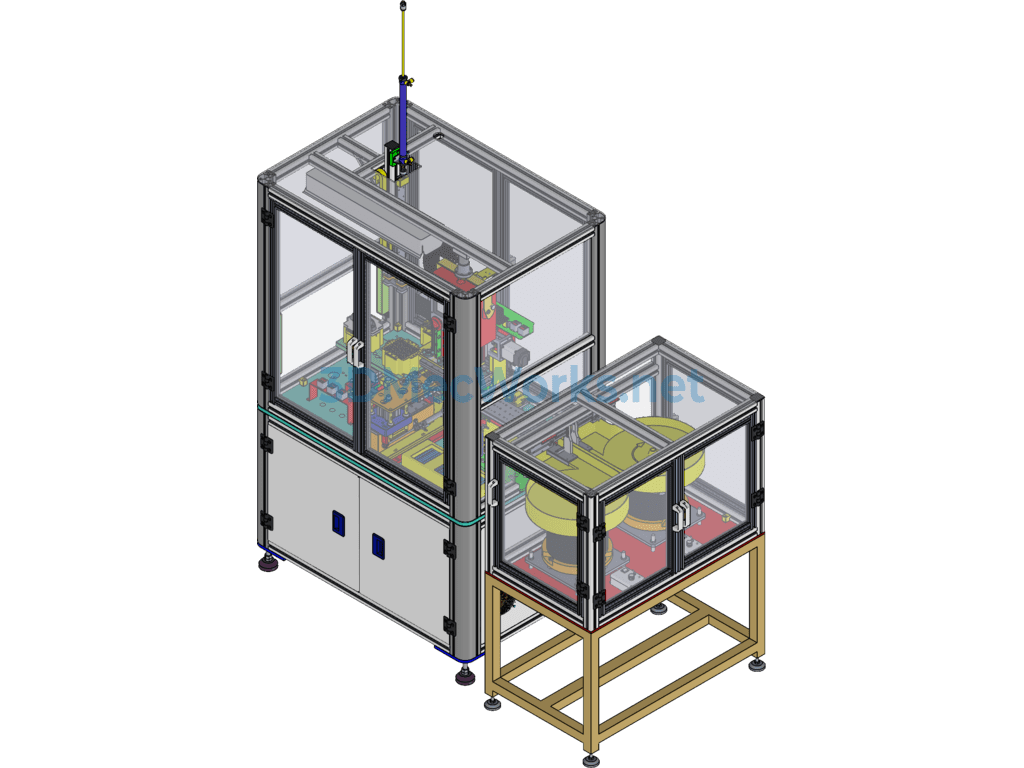

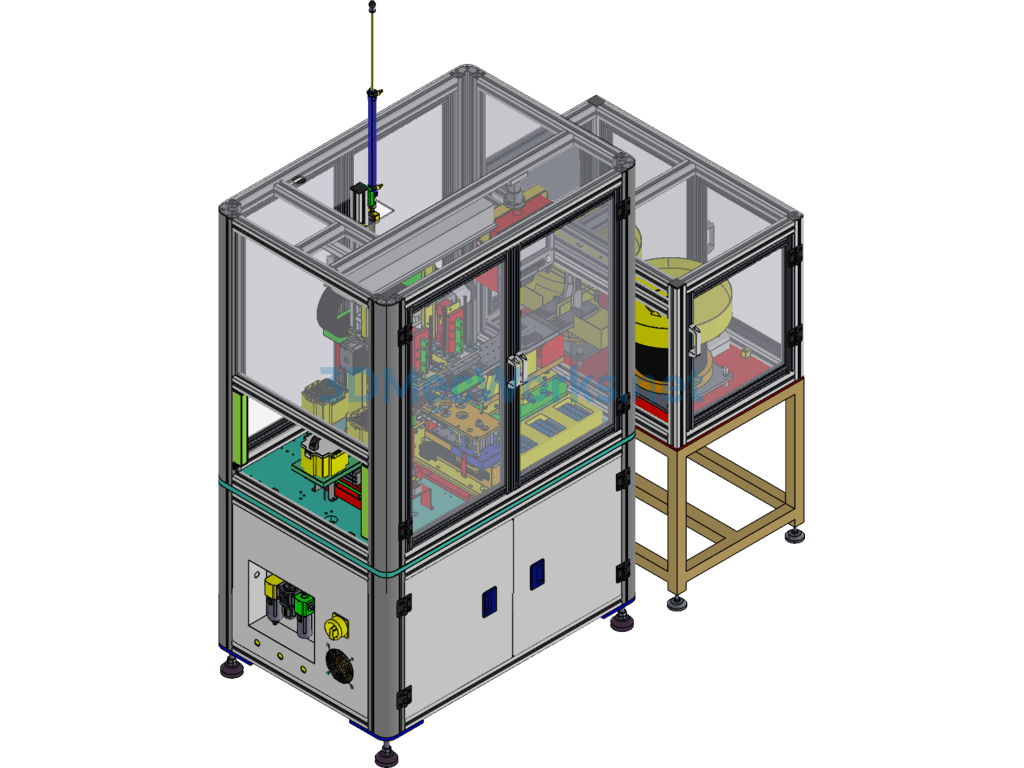

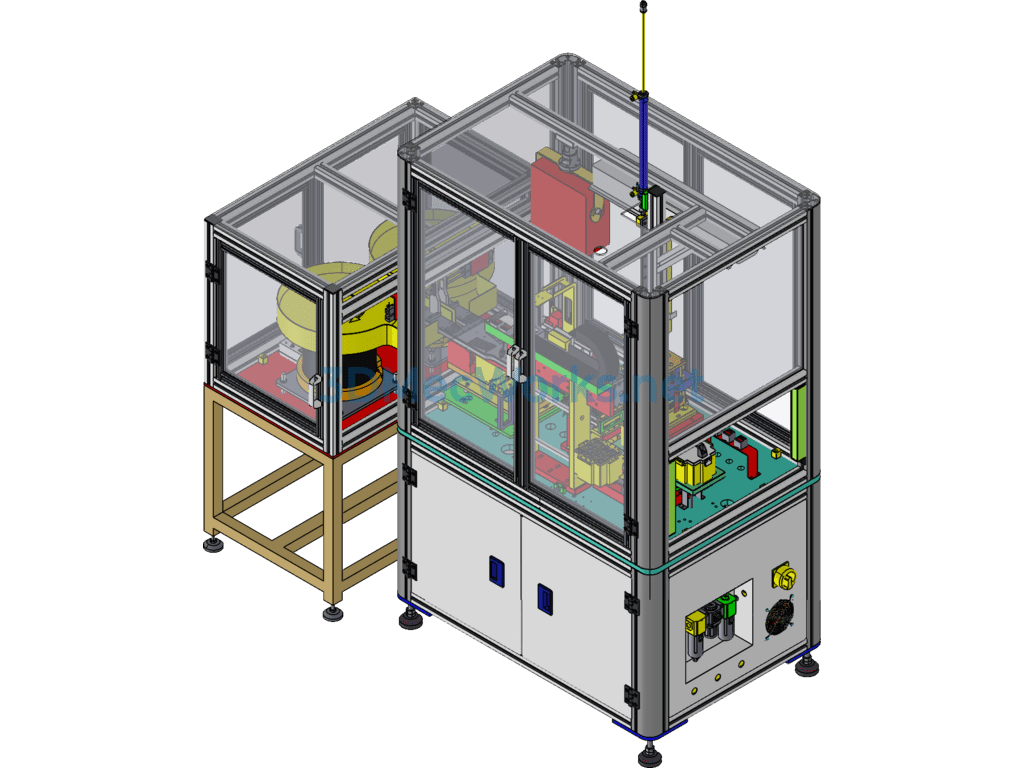

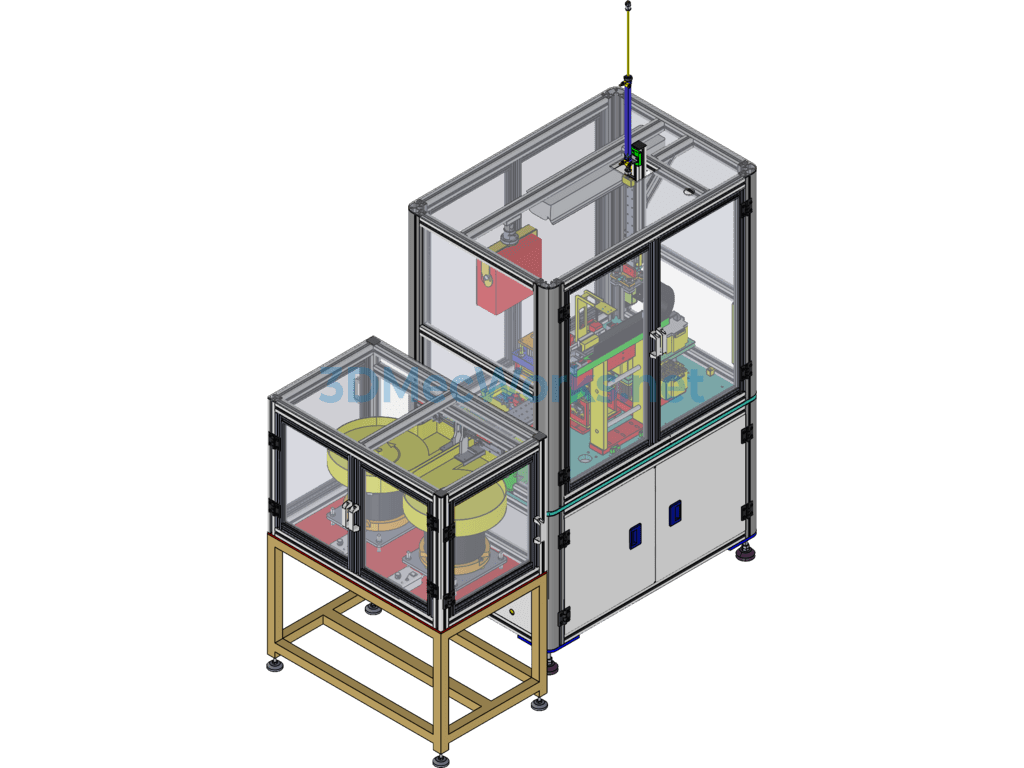

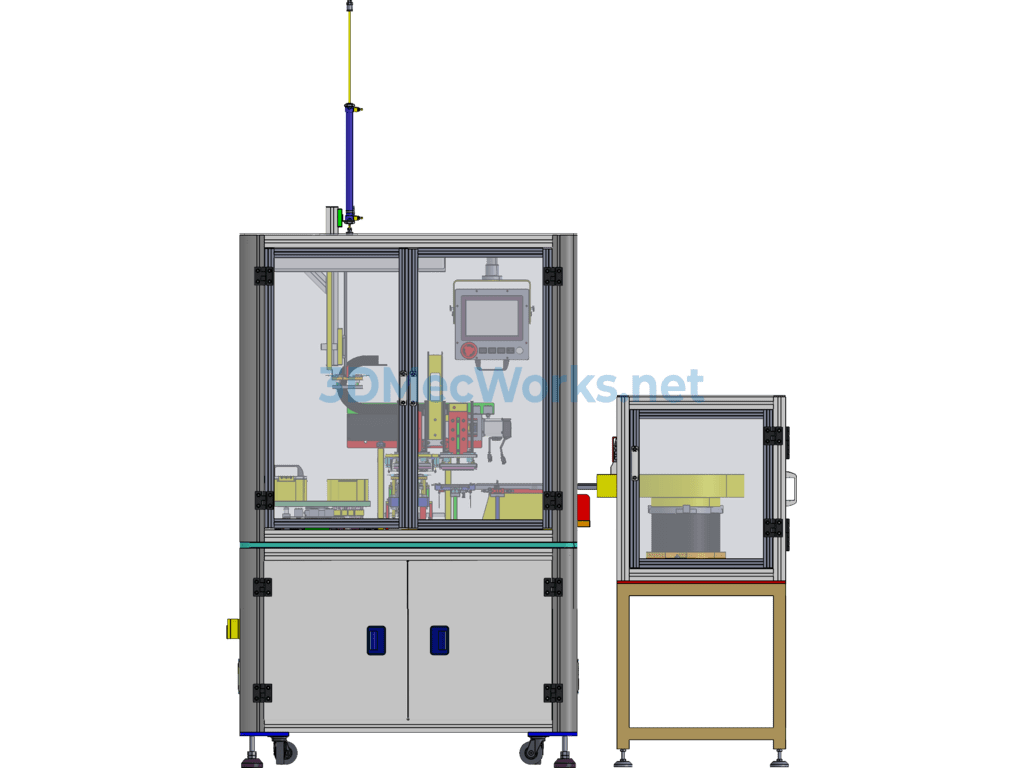

Vibration feeder, product misalignment grabbing through vertical module shifting, coordinated with the misalignment mechanism, achieving product misalignment picking. The vibrating bowl has two 1-out-of-4 channels, significantly improving production efficiency. The equipment realizes automatic feeding, misalignment, and stack unloading, requiring only manual feeder refilling and stacked tooling retrieval, allowing one person to operate multiple devices.

The equipment consists of 6 parts:

1. Feeding mechanism: completes feeding through two 1-out-of-4 vibration bowls and straight vibration.

2. Magnetic steel misalignment and stacking mechanism: completes the action of misplacing and stacking the magnetic steel after feeding.

3. Cover plate mechanism: uses a cylinder to drive the cover plate to close the product position during feeding and move to avoid the suction head during material retrieval.

4. Misdivision and pressing mechanism: achieves the function of misdivision and pressing through the misdivision mechanism and pressing device.

5. Press mechanism: uses pen-type cylinders and compact cylinders to drive the buffering press mechanism to ensure the product is placed in position.

6. Product stacking mechanism: presses in the product stack and drives manual retrieval via a rotary cylinder.

Specification: Automatic Loading and Unloading Stacked Magnetizer

|

User Reviews

Be the first to review “Automatic Loading and Unloading Stacked Magnetizer”

You must be logged in to post a review.

There are no reviews yet.