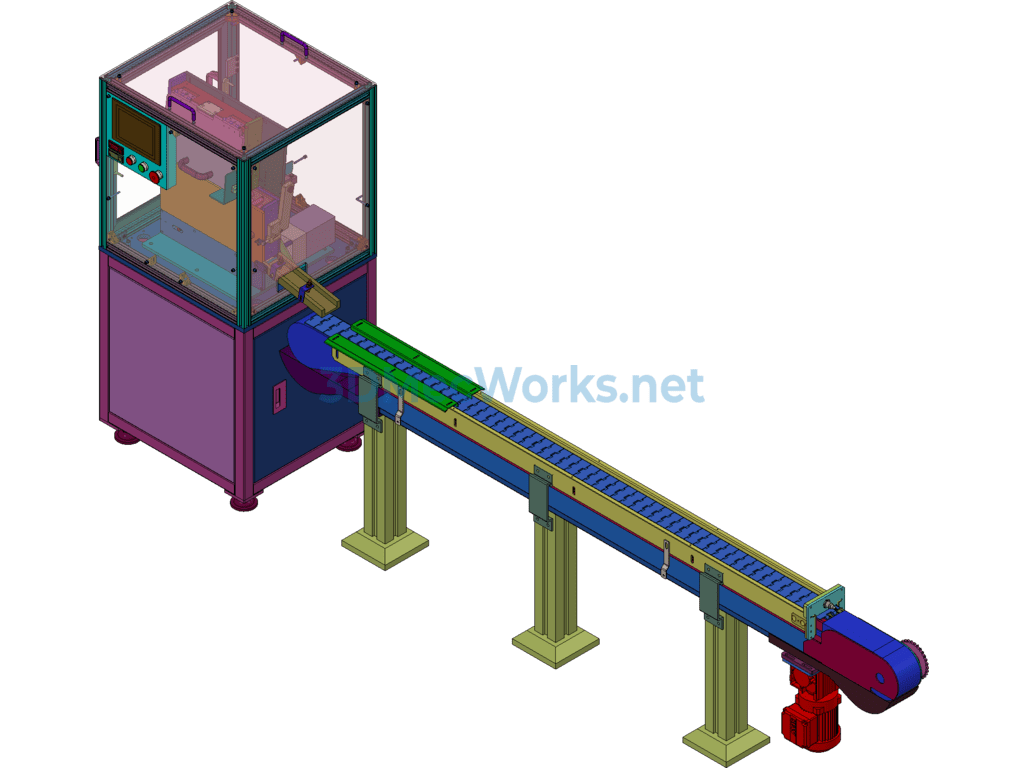

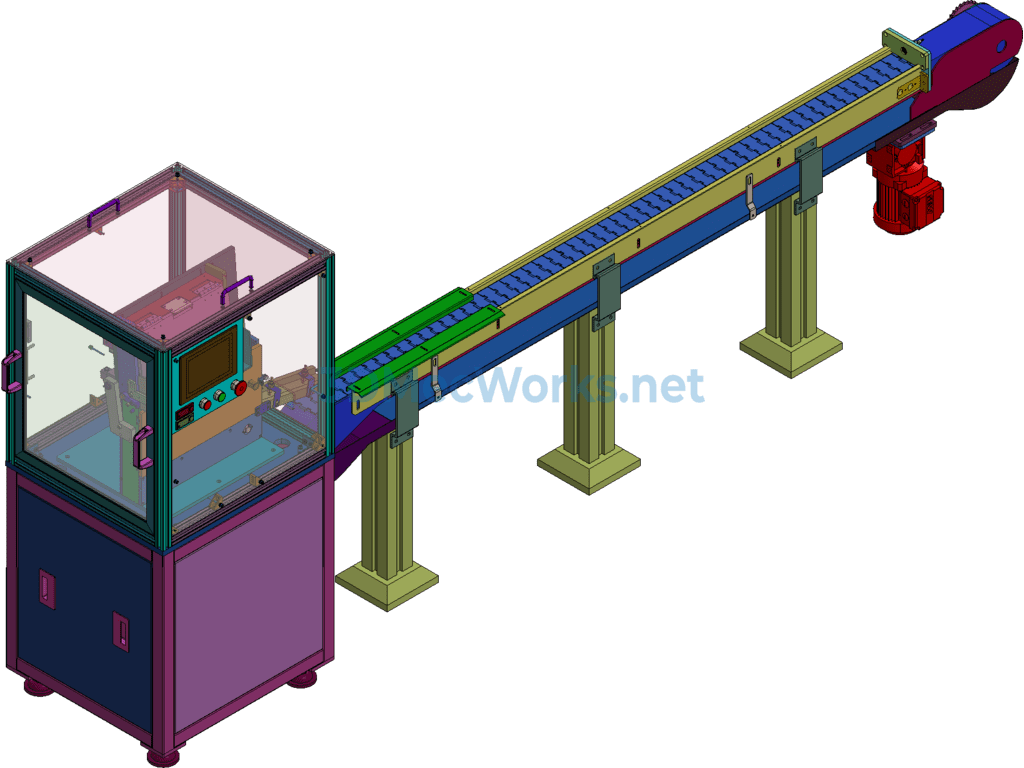

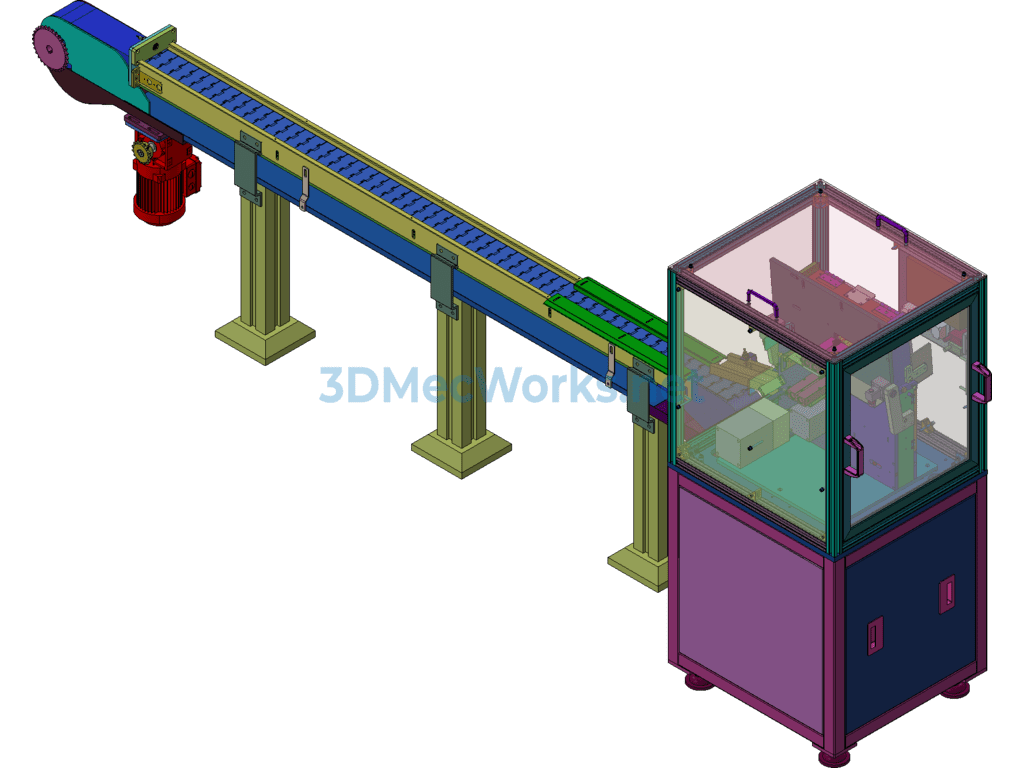

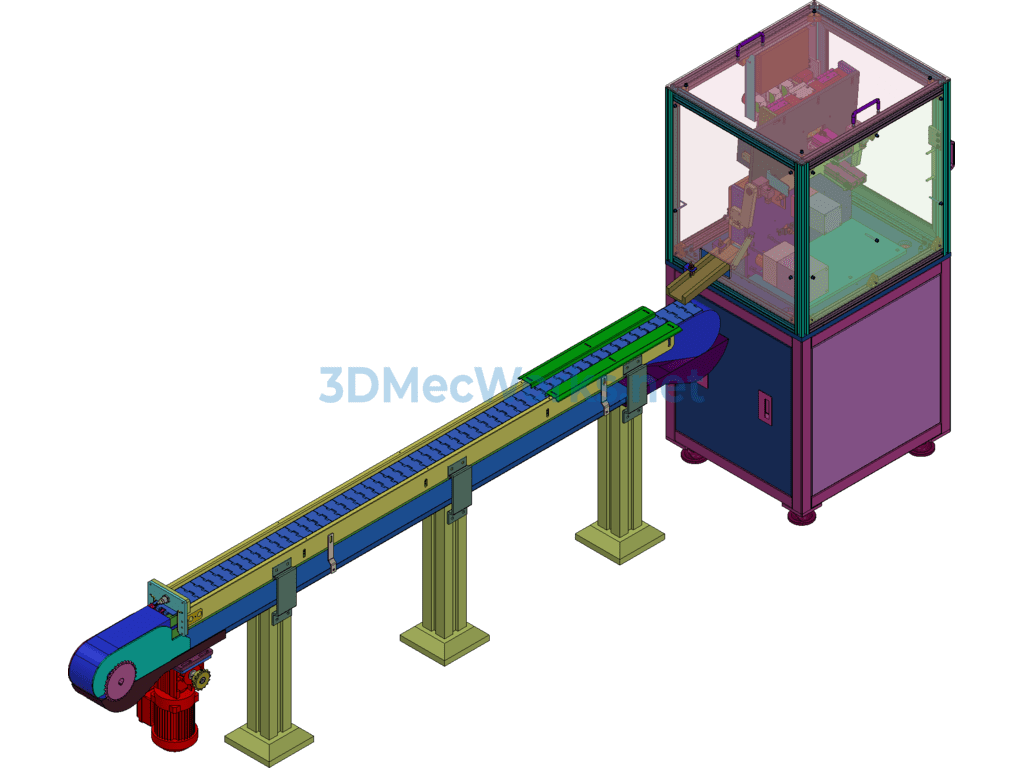

The mechanism of this equipment is designed using SW2016 to include editable part features. This equipment adopts an automatic lifting and arranging feeding method and is equipped with advanced sensors that prevent assembly without materials. After the cylinder action, the line box nut is re-inspected to maximally prevent the occurrence of finished line boxes without nuts (the workpiece is too small, making it easy for line boxes to be assembled without nuts, which leads to a large number of defective products, and employees cannot inspect each one individually), ensuring the product’s quality rate. This machine assembles only one component at a time, with a speed of 50-70 units per minute. The control method uses PLC control with touch screen display and operation, making it simple and easy to learn. Every action of this equipment can be operated individually on the touch screen, and if a functional fault occurs, the problem will be displayed directly on the touch screen in text form, making troubleshooting easy for the user. The line box nut and iron piece are synchronously assembled, and before assembly, the nut is checked again for proper placement. If there is no nut or a lack of nuts, the equipment will not assemble the iron piece, avoiding the situation where the iron piece is installed without a nut. It includes editable STP and UG universal formats.

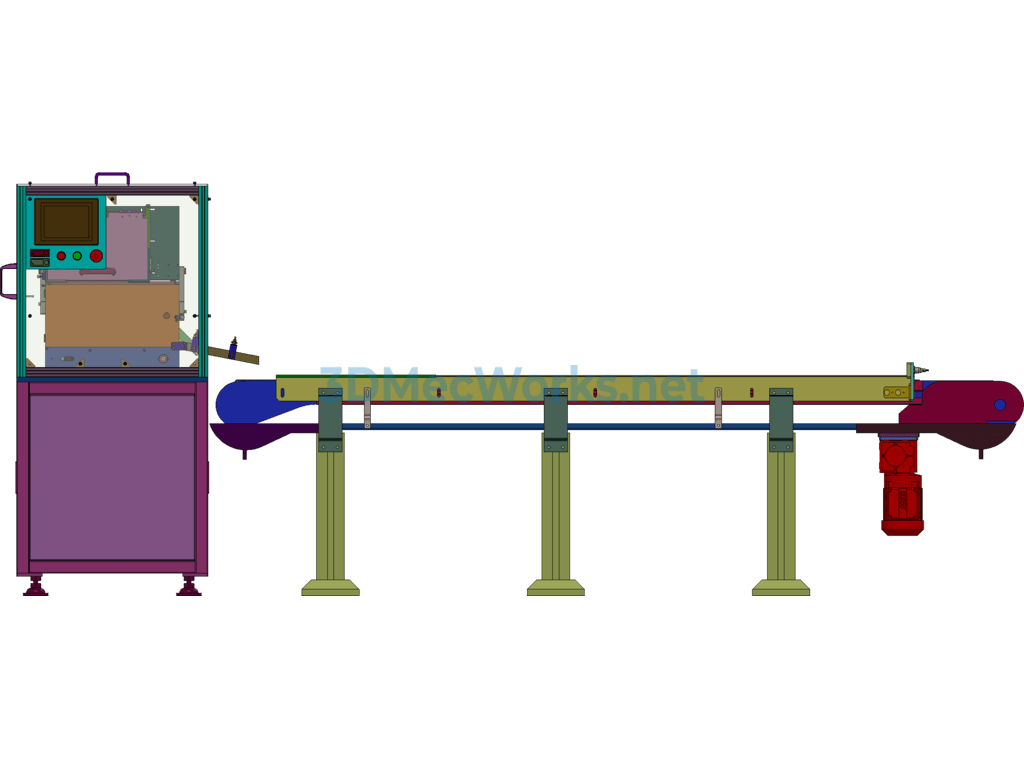

Specification: Automatic Line Box Loading Equipment

|

User Reviews

Be the first to review “Automatic Line Box Loading Equipment”

You must be logged in to post a review.

There are no reviews yet.