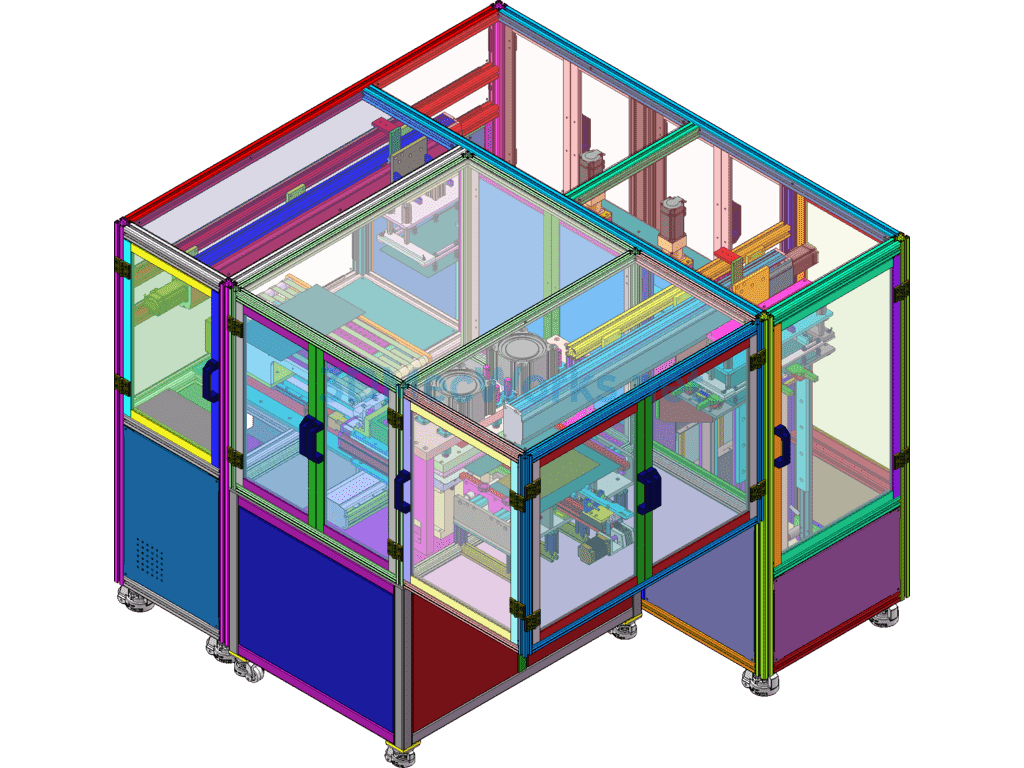

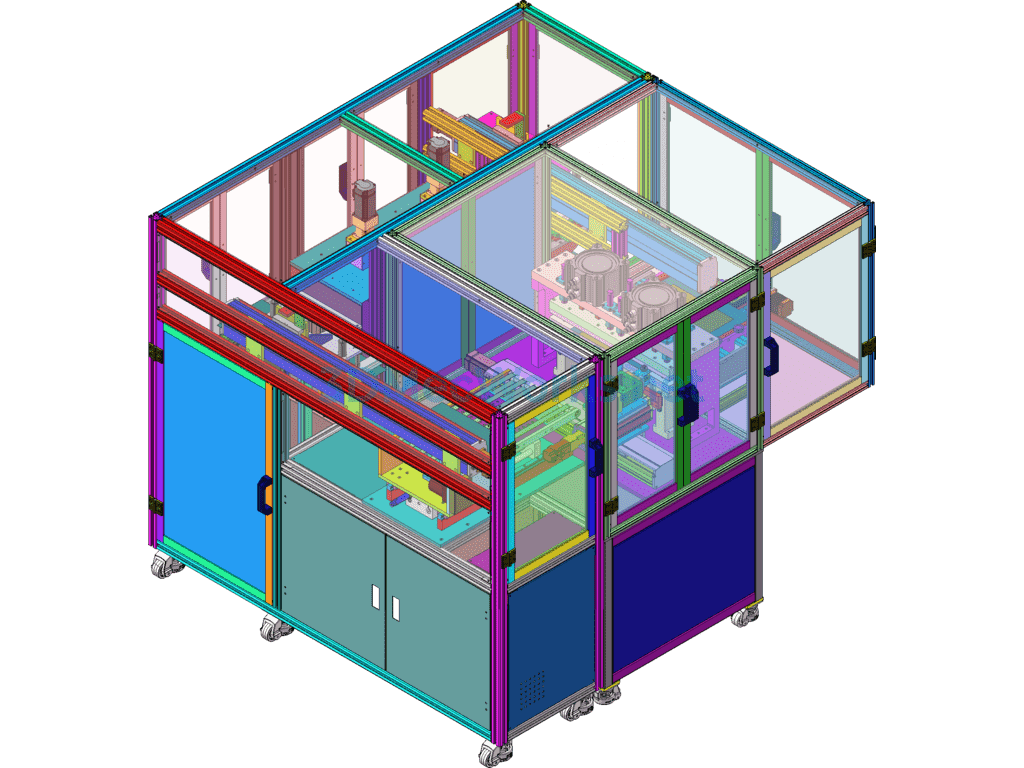

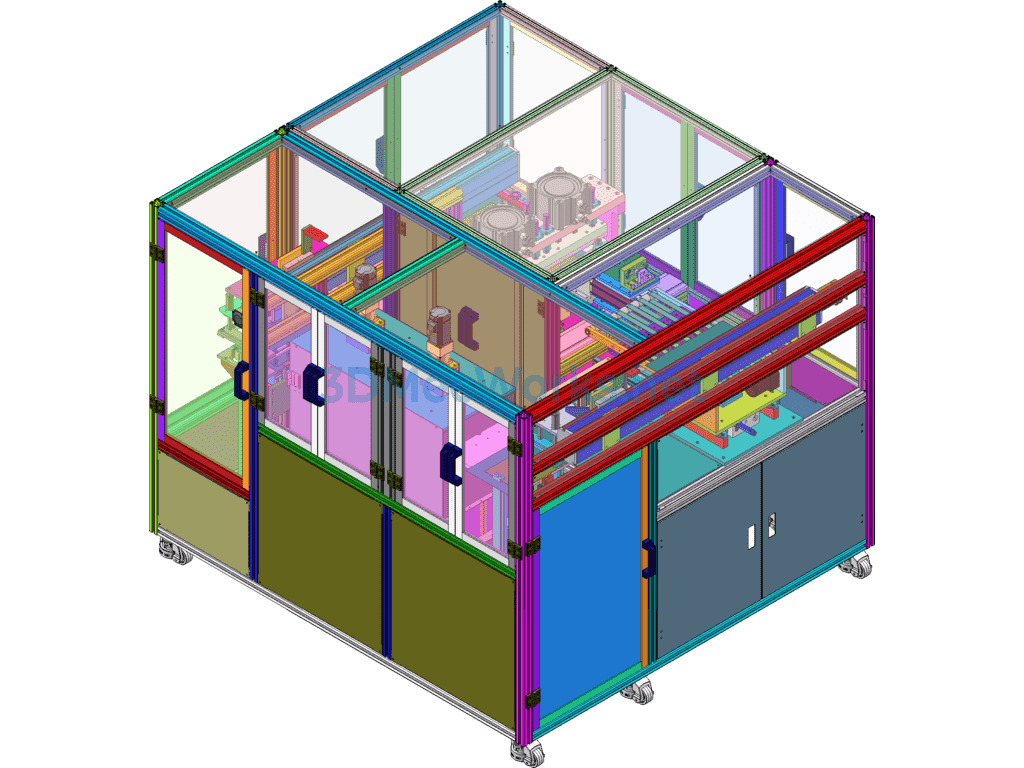

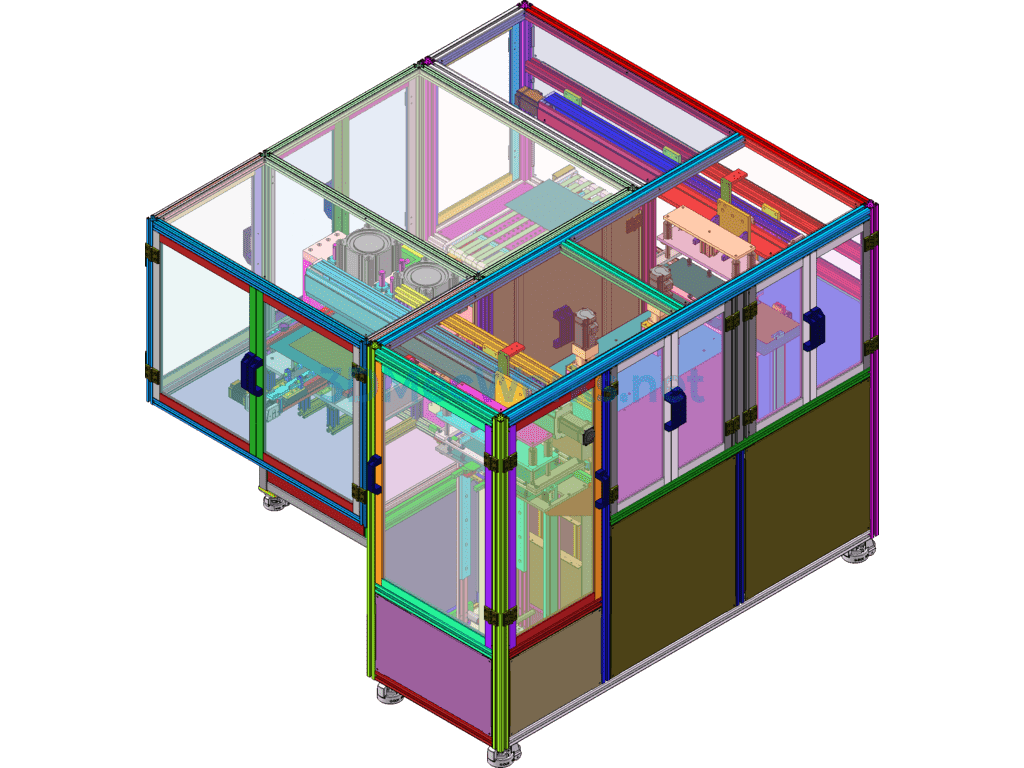

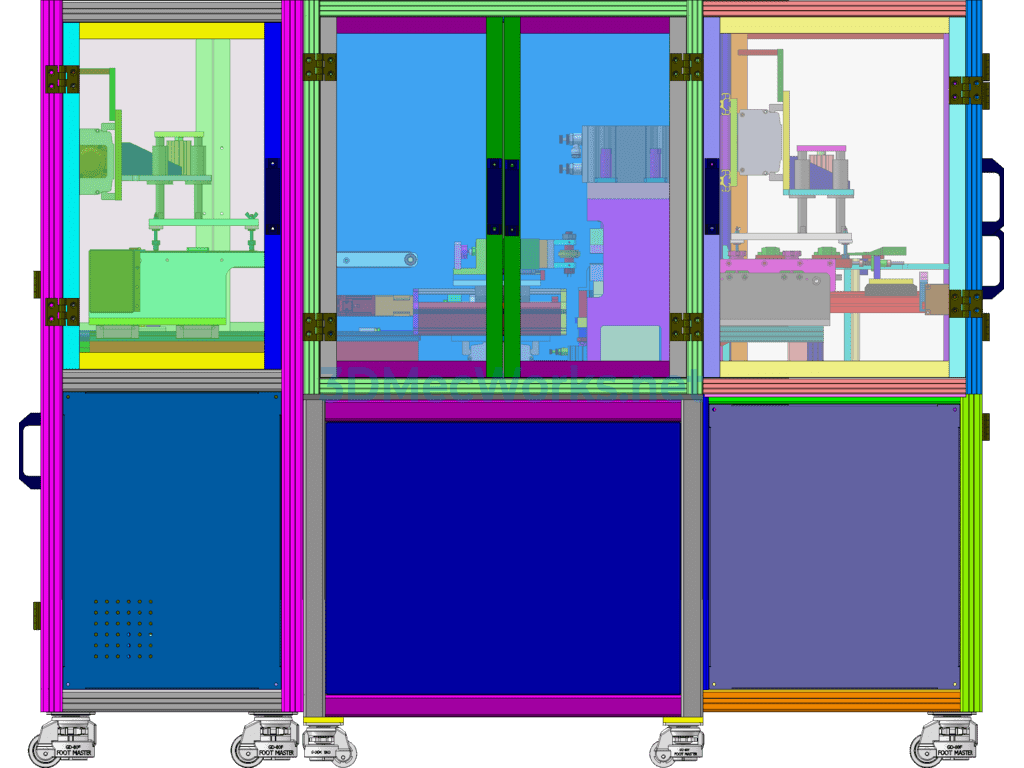

The automatic feeding equipment for pressing is directly connected to the equipment through an assembly line interface. A servo motor coupled with a lead screw is used to transfer products in motion, and the presser uses a cylinder-driven up-and-down motion. After automatic feeding and pressing detection, the materials are automatically unloaded. The entire machine is controlled by a PLC to reduce frequent manual operations and save costs. The file contains the x-t universal format, and mechanical designers are welcome to download and exchange ideas.

Specification: Automatic Lamination Feeding Equipment Includes Engineering Drawings, Bom, and Dfm

|

User Reviews

Be the first to review “Automatic Lamination Feeding Equipment Includes Engineering Drawings, Bom, and Dfm”

You must be logged in to post a review.

There are no reviews yet.