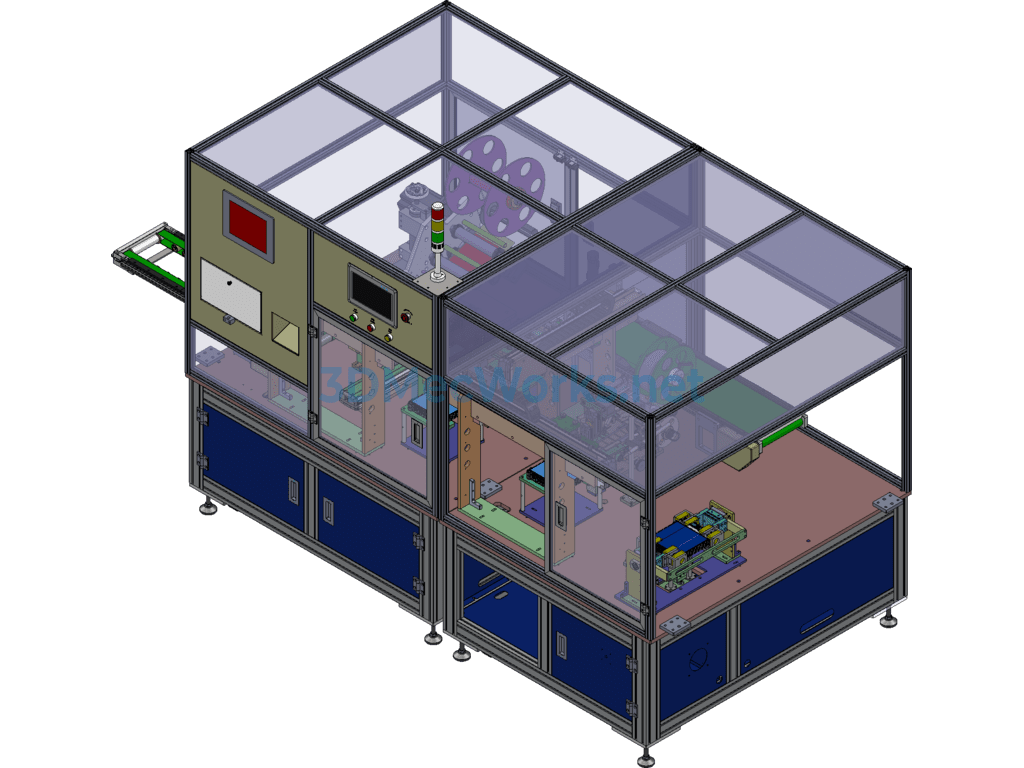

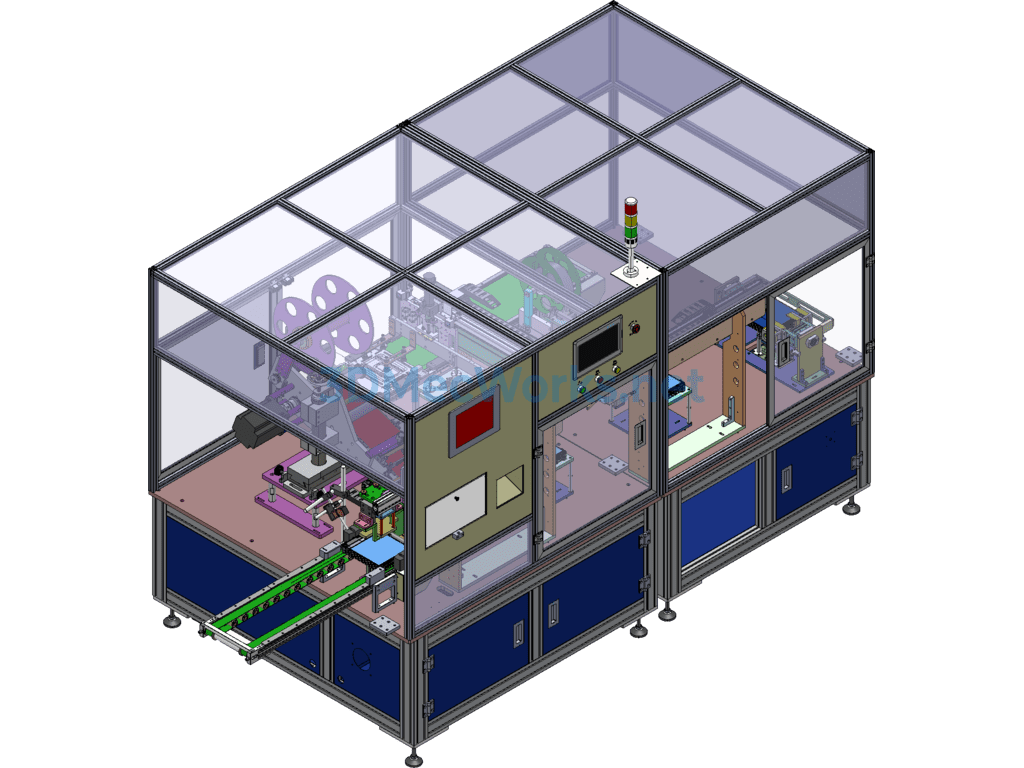

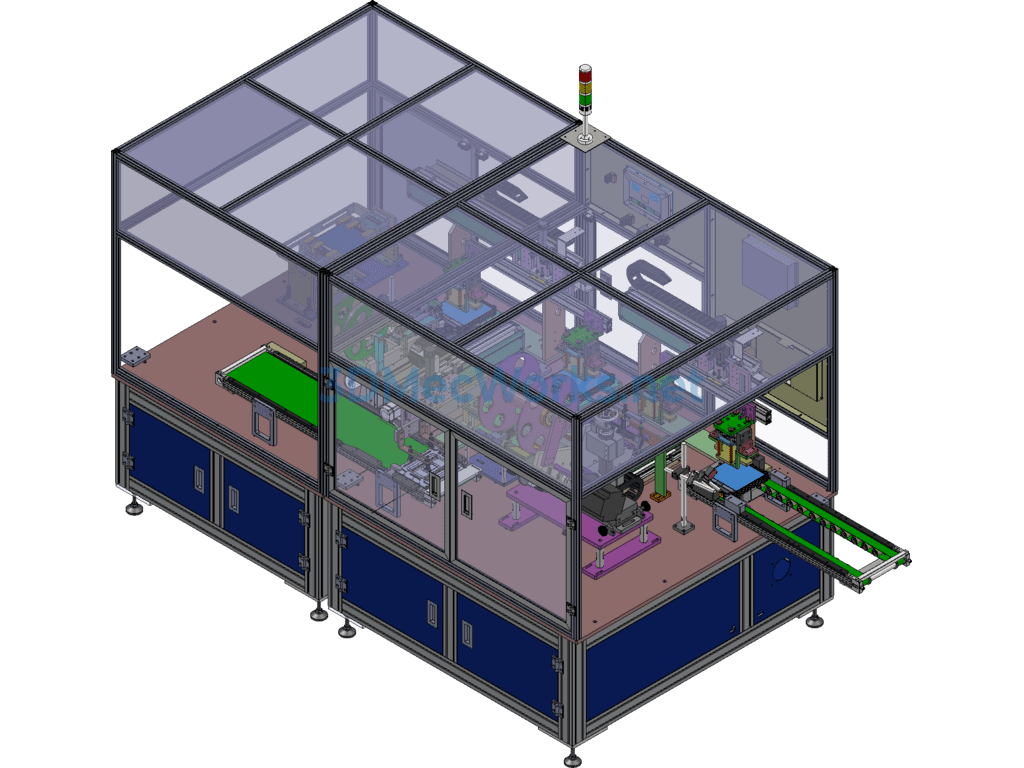

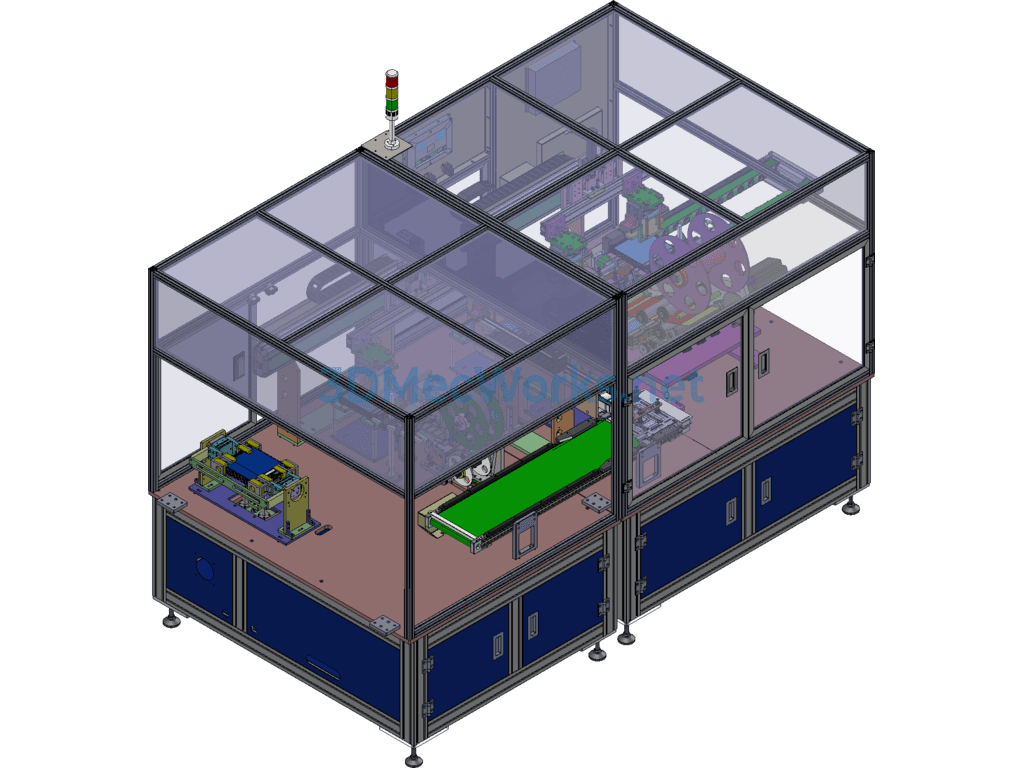

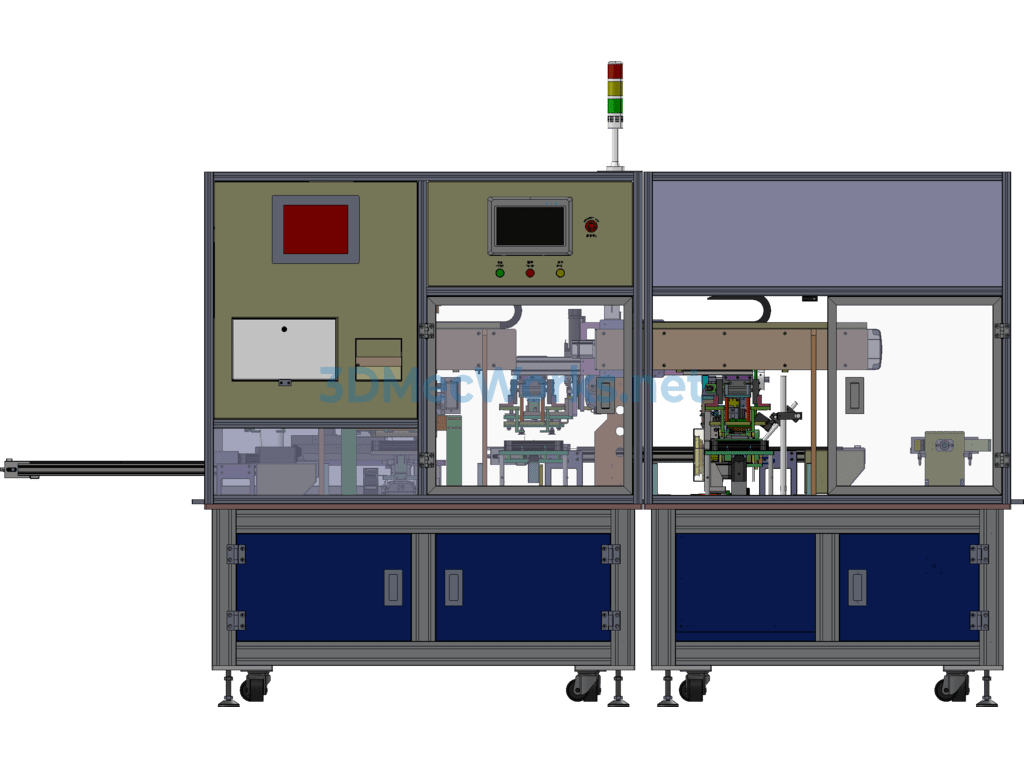

Automatic Insulation Film Labeling and Barcode Equipment/power Battery Pet Protective Film Labeling Machine

Trenton Avery

This equipment is a combined power soft pack battery PET tape pasting and labeling machine. The drawings of this equipment total approximately 400MB, comprising nearly 400 various part drawings. The 3D model of the equipment is designed using SolidWorks 2012 software, and the complete set of drawings are original, complete 3D model design diagrams. This equipment is a non-standard automated power battery PET protective film pasting machine and labeling machine/automatic insulating film pasting and barcode labeling device applicable to products such as lithium batteries, polymer batteries, and various soft pack power batteries for film pasting, labeling, and barcode pasting. The equipment mainly uses a film pasting feeder to adhere the needed film onto the battery surface. This set of film pasting feeders can also be used in the packaging industry because it is a standard mechanism and very stable. When the battery enters through the conveyor belt, the cell manipulator grabs the product and places it onto a secondary positioning sliding table at the film pasting station. Then, the bottom sliding table module moves, driving the cell to the film pasting position, where it starts peeling and pasting the film as the sliding table module moves outward, pasting and rolling out tightly. This film pasting machine produces films without air bubbles and provides excellent pasting effectiveness and speed. This pasting position utilizes rolling-type pasting, whereby the product is fixed on the positioning base, moved by the module manipulator to the film pasting position. The film is pasted onto the battery surface as the module moves outward, a method known as rolling film pasting. Thus, the surface of the pasted film will not have bubbles. After the film pasting completes, the transport manipulator grabs the battery to another station for labeling and barcode pasting. Prior to labeling, an aluminum shell is installed in the middle of the battery, and this is likewise grabbed and installed by the manipulator. Subsequently, the manipulator grabs the battery module for labeling, then rotates and flips for battery module assembly and other processing flows. This equipment can also be used in different industries for film pasting. The main technical parameters of the power battery PET protective labeling machine are as follows: Type, Specification Parameters, Overall machine dimensions: 3850*1720*1700MM (L*W*H). Input voltage: AC—220V 50Hz or AC—380V 50Hz (optional). Maximum power of the machine: 0.5KW (at 220V). Input air pressure: 0.4-0.6 Mpa. Air consumption: 1.5 L/min. Production efficiency (C/T): ≤3.0 S/piece. Equipment utilization rate: ≥95%. Processing method: Automatic detection, automatic pressing, automatic discharging. Material change method: Manual replacement. Programming method: Touch screen parameter modification. The drawings contain detailed structures and considerable details for learning.

Specification: Automatic Insulation Film Labeling and Barcode Equipment/power Battery Pet Protective Film Labeling Machine

|

User Reviews

Be the first to review “Automatic Insulation Film Labeling and Barcode Equipment/power Battery Pet Protective Film Labeling Machine” Cancel reply

You must be logged in to post a review.

There are no reviews yet.