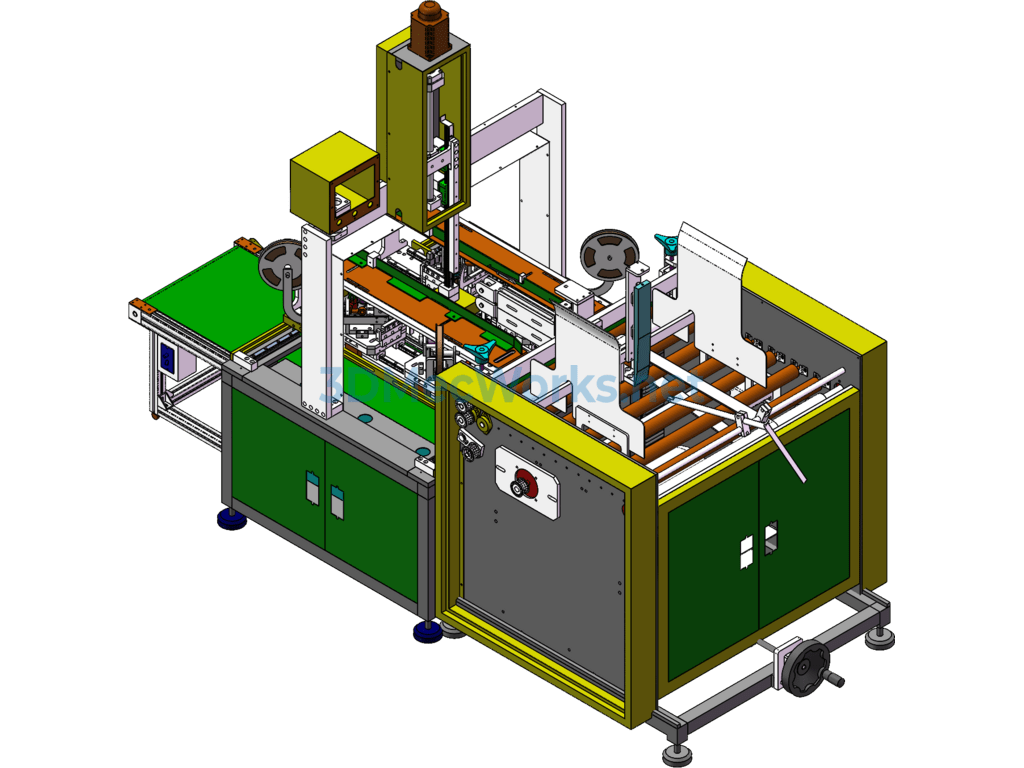

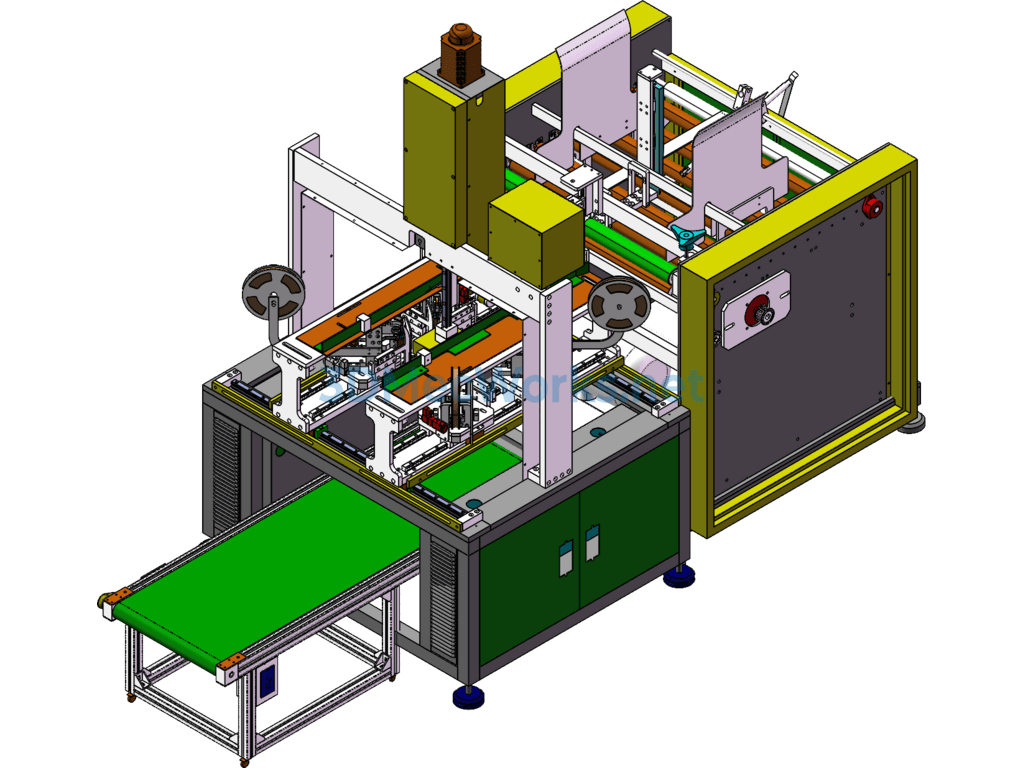

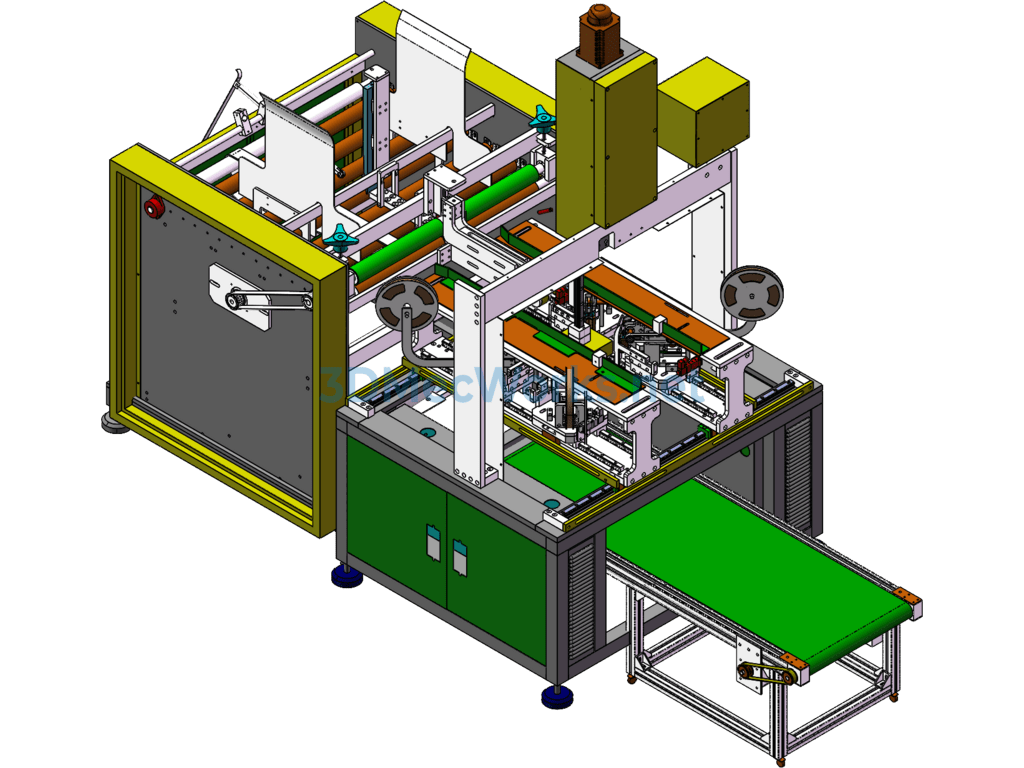

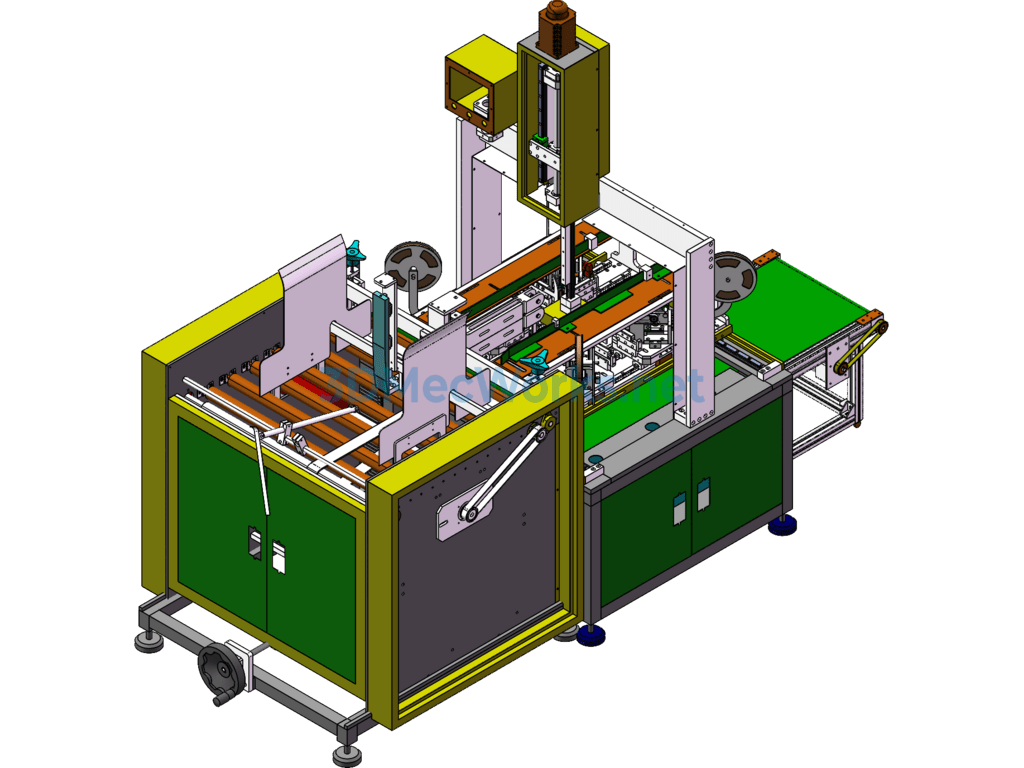

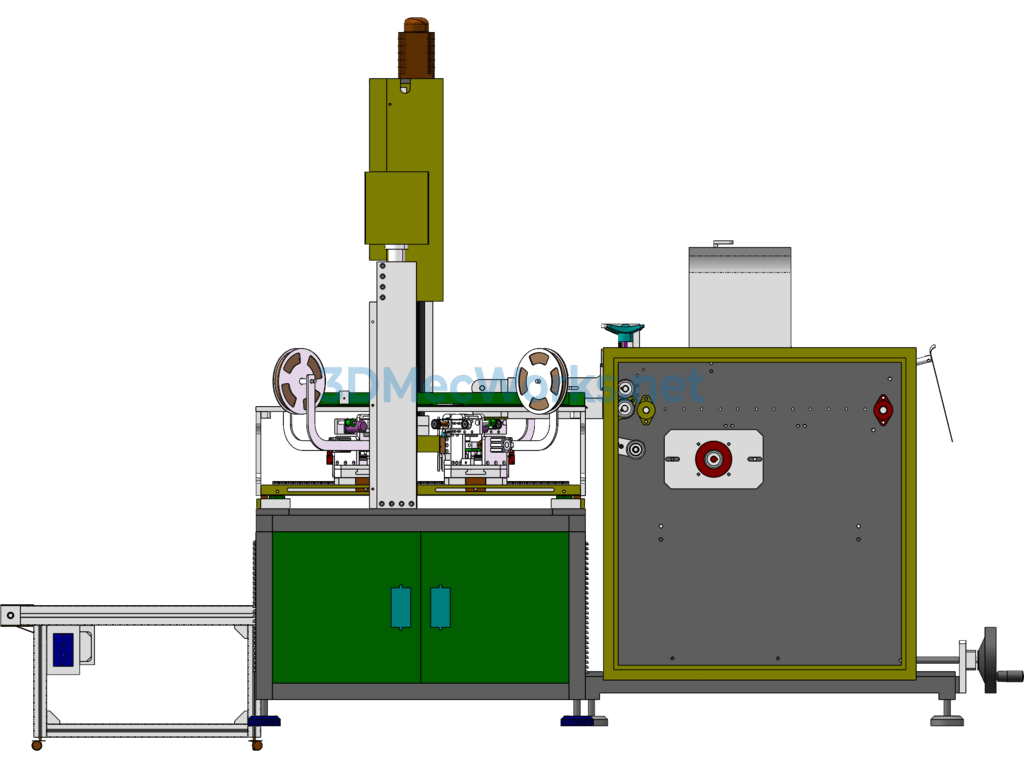

Fully automatic carton corner pasting machine, utilizing mold forming, mold size can be changed, with thermal cutting and motor lead screw to form the carton corner pasting. Fully automatic carton corner pasting machine, carton corner pasting machine, gift box corner pasting machine drawings, corner pasting equipment drawings, carton corner pasting machine 3D model. The fully automatic four-corner high-speed pasting machine is reasonably designed and widely used for forming and pasting four corners of products such as folders, albums, hardcover book jackets, decorative boxes, and shoe boxes. It is popular. The corner pasting machine can produce independently or be combined with machinery such as the feeder pasting machine, V-grooving machine, forming and folding machine to form an assembly line operation. It can paste various high-end paper products such as folders, loose-leaf binders, albums, writing materials, advertising game boards, gift boxes, mooncake boxes, refined boxes, and hard boxes.

Feeding Section: Circulating feeding device: Can quickly replenish material, saving a lot of time: Feeder feeding device: Thin plates, thick plates, die-cut plates, grooved plates can be fed in quickly and smoothly, avoiding damage to gray boards, material jamming, double feeding, and other phenomena.

Feeding Belt: Adopts a fully automatic heaven and earth cover type slide rail telescopic device, cooperating with the slidable feeder part. Size is easy to adjust; The material bearing rod can automatically stretch: A touch screen can be used to enable or disable with one click, suitable for special specification boxes, preventing carton falling off.

Corner pasting section: Corner pasting times: One-button switch: Corner pasting times can be chosen; Tape length: Four stepper motors sending tape, corner pasting tape length can be saved with one button; Air blow protection: When turned on, air will be automatically blown during standby to prevent the tape from overheating and melting causing blockage.

Other: The frame adopts thickened 45# steel plate, baking paint treatment, precisely processed parts, all hard chrome plating treatment; Uses multiple sets of linear guide rail sliders for guidance, making plate adjustment more precise.

1. Feeding Section: a. Circulating feeding device: Can quickly replenish material, saving a lot of time;

b. Feeder feeding device: Thin plates, thick plates, die-cut plates, grooved plates can be quickly and smoothly fed in, avoiding damage to gray boards, material jamming, double feeding, and other phenomena;

c. Feeding Belt: Adopts fully automatic heaven and earth cover type slide rail telescopic device, cooperating with the slidable feeder part, size is easy to adjust;

d. Material bearing rod can automatically stretch: A touch screen can enable or disable with one click, suitable for special specification boxes, preventing carton falling off.

2. Corner Pasting Section:

a. Corner pasting times: One-button switch: Corner pasting times can be chosen;

b. Tape length: Four stepper motors send tape, corner pasting tape length can be saved with one button;

c. Air blow protection: When turned on, air will be automatically blown during standby to prevent tape from overheating and melting, causing blockage.

3. Others:

a. The frame adopts thickened 45# steel plate, baking paint treatment, precisely processed components, all hard chrome plating treatment;

b. Uses multiple sets of linear guide rail sliders for guidance, making plate adjustment more precise;

c. Main shaft transmission: Uses high-power servo drive, combined with imported guide rail double slider precision guidance, improving efficiency and lifespan.

Specification: Automatic Gift Box Corner Pasting Machine

|

User Reviews

Be the first to review “Automatic Gift Box Corner Pasting Machine”

You must be logged in to post a review.

There are no reviews yet.