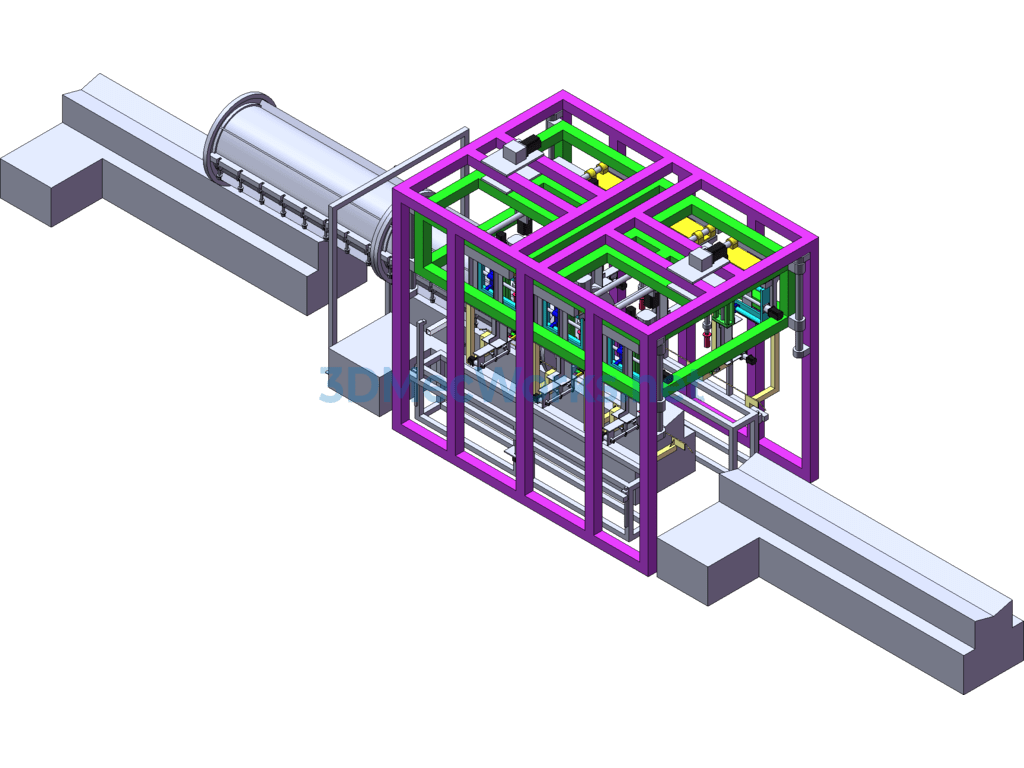

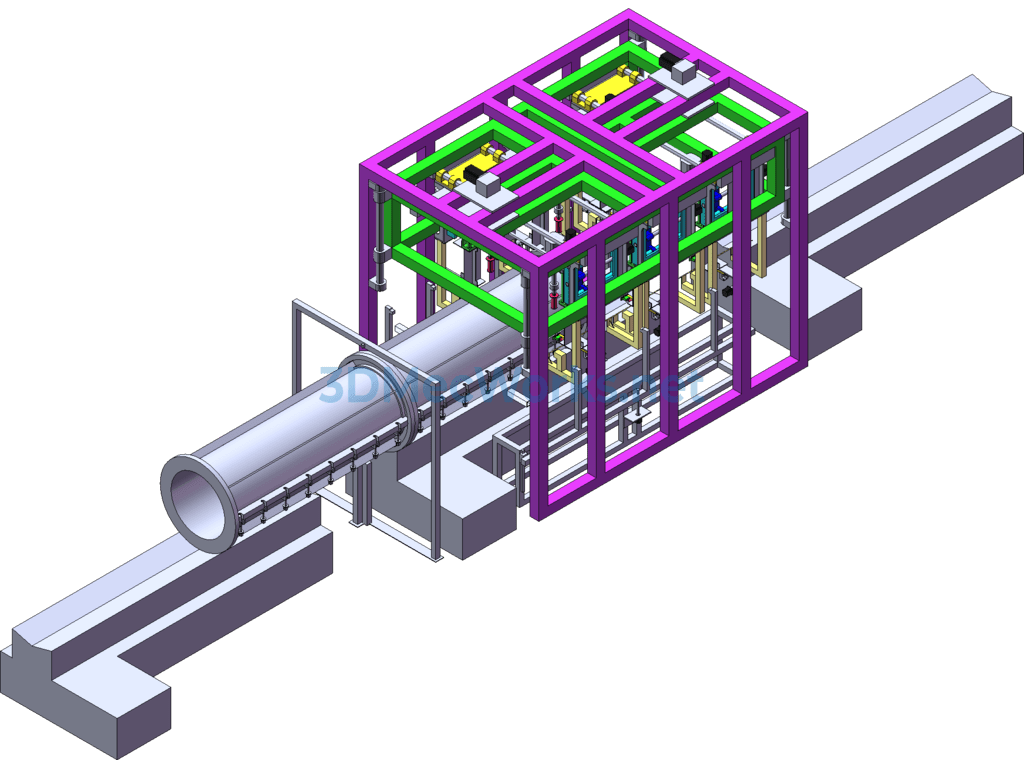

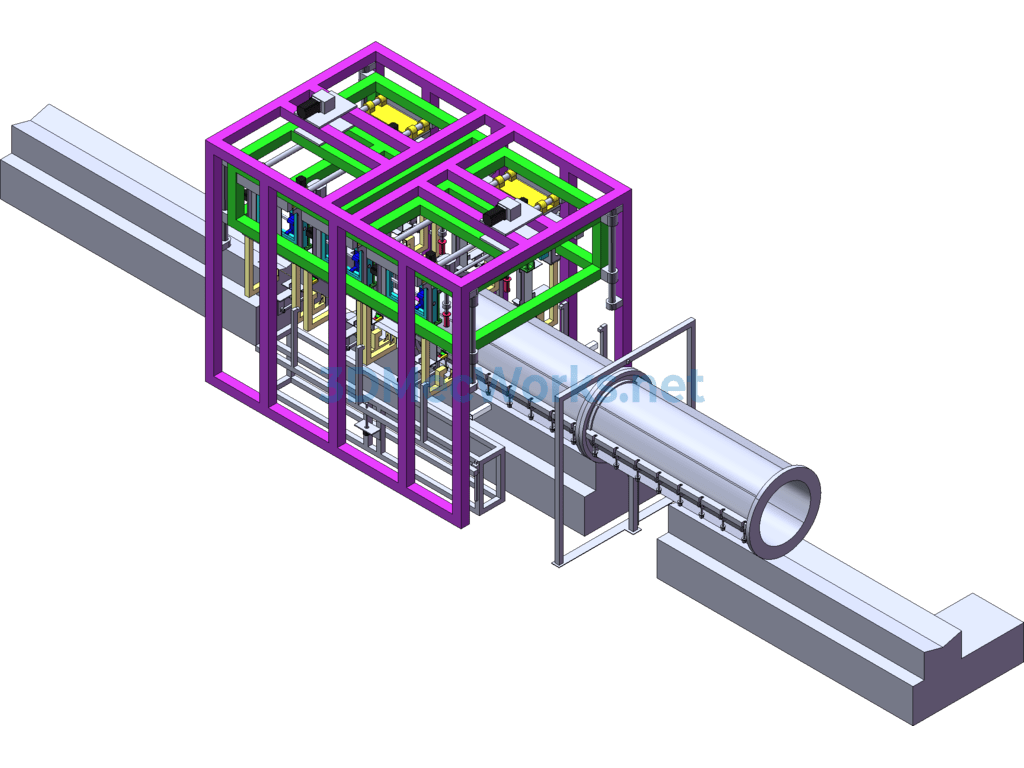

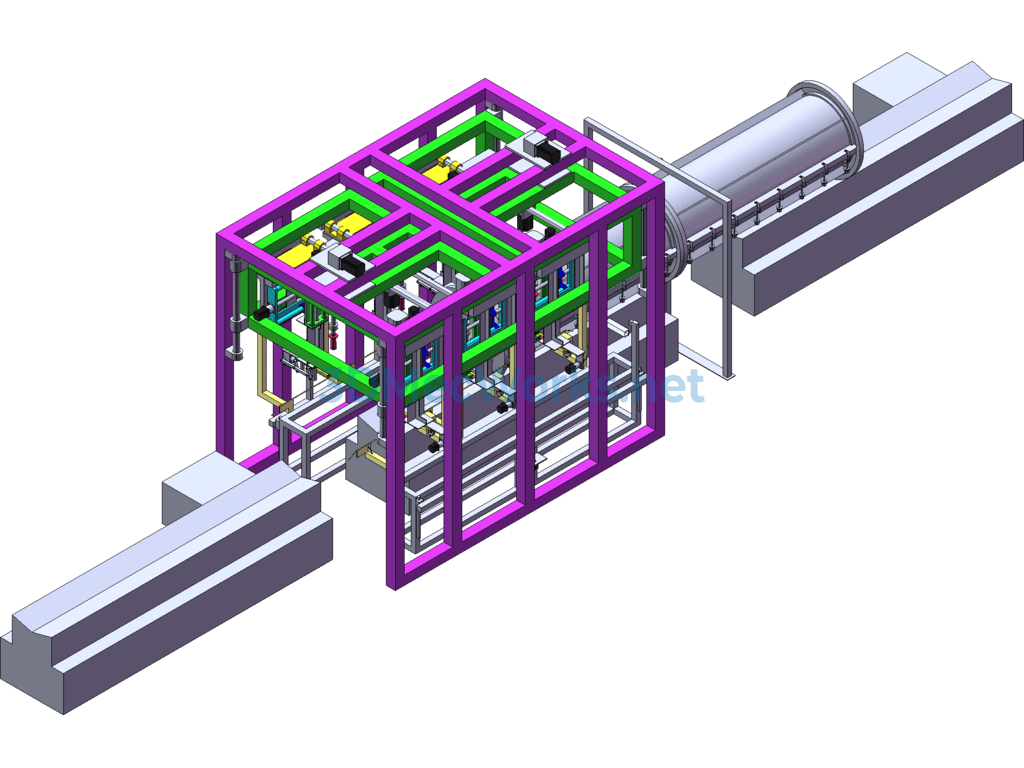

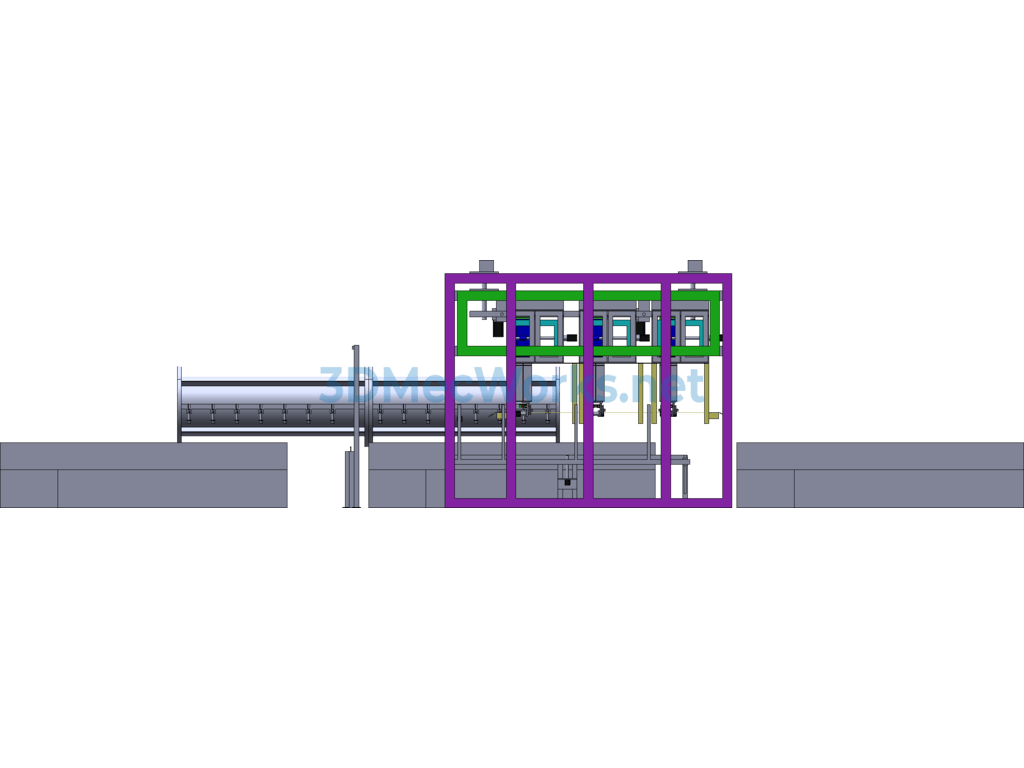

Multi-Specification Pipe Pile Mold Automatic Mold Locking Device, including a pipe pile mold conveying device, outer frame, inner frame, detection device, bolt support guide rail, as well as an air gun device, bolt leveling mechanism, and bolt alignment positioning mechanism installed on the air gun installation rod. The detection device is used to detect the diameter of the pipe pile mold. Then, the lifting mechanism adjusts the height of the inner frame and detection device. The translation mechanism adjusts the distance between the two air gun installation rods to adapt to the diameter of the pipe pile mold. Subsequently, the bolt is leveled using a four-bar linkage mechanism with an electromagnet. The horizontal bolt is placed on the bolt support guide rail to advance, and then a four-bar linkage mechanism of the bolt alignment positioning mechanism flips the bolt, and a telescopic push rod moves it to the slot for positioning. Finally, the air gun device descends to complete the tightening work. The multi-specification pipe pile mold automatic mold locking device can automatically detect and adapt to different pipe diameters, pipe lengths, and different bolt spacing specifications for the pipe pile mold. The bolts are tightened accurately and efficiently during mold locking.

Specification: Automatic Clamping and Locking Machine for Piles of Various Specifications (in Mass Production, Includes Real-World Images)

|

User Reviews

Be the first to review “Automatic Clamping and Locking Machine for Piles of Various Specifications (in Mass Production, Includes Real-World Images)”

You must be logged in to post a review.

There are no reviews yet.