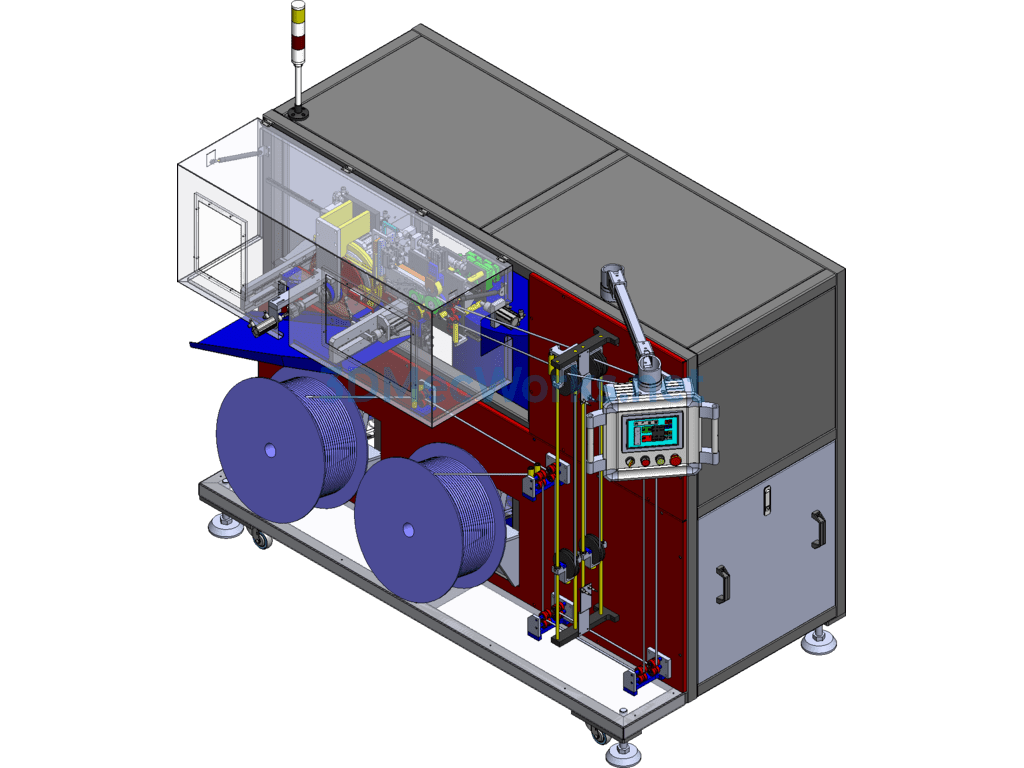

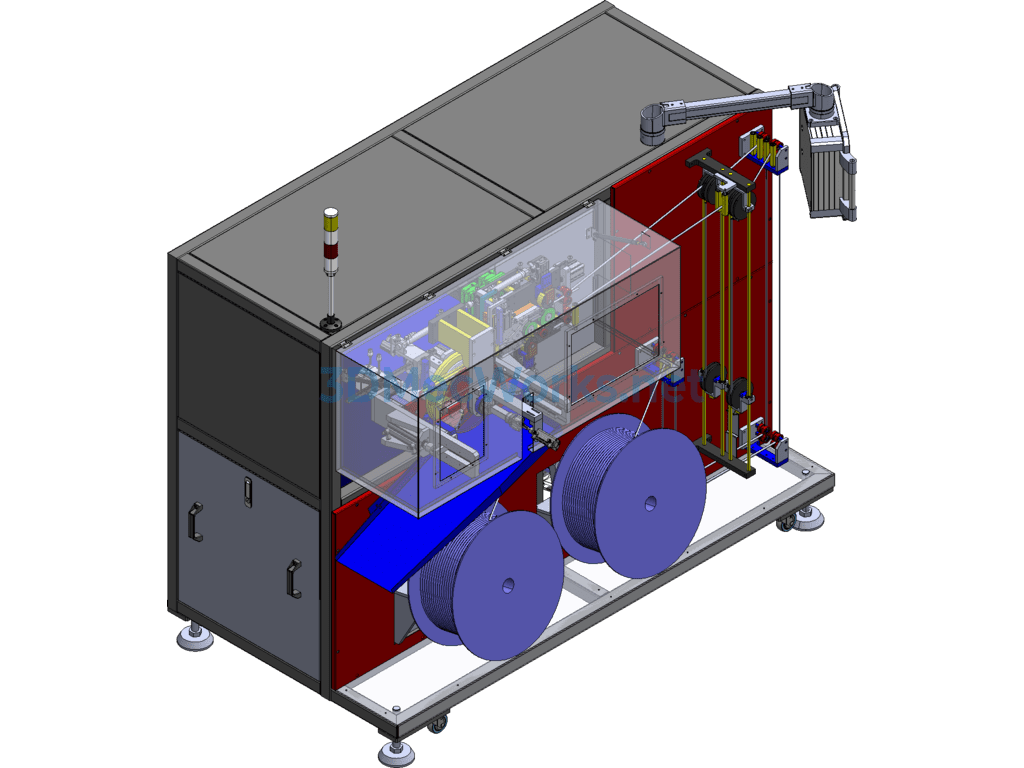

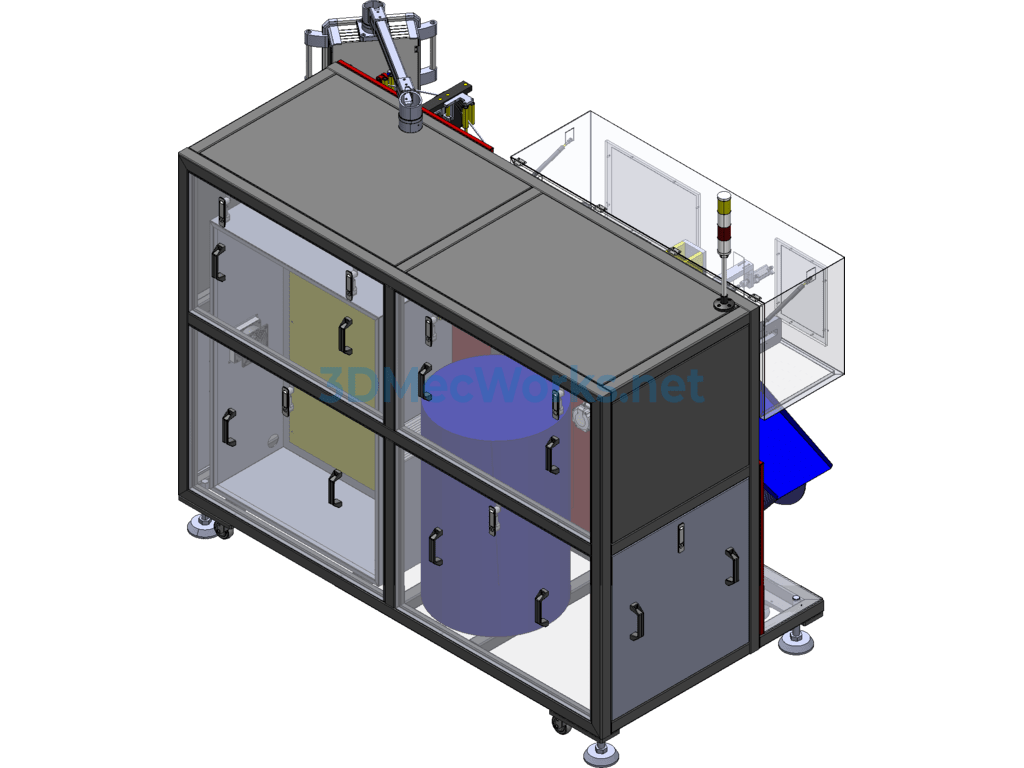

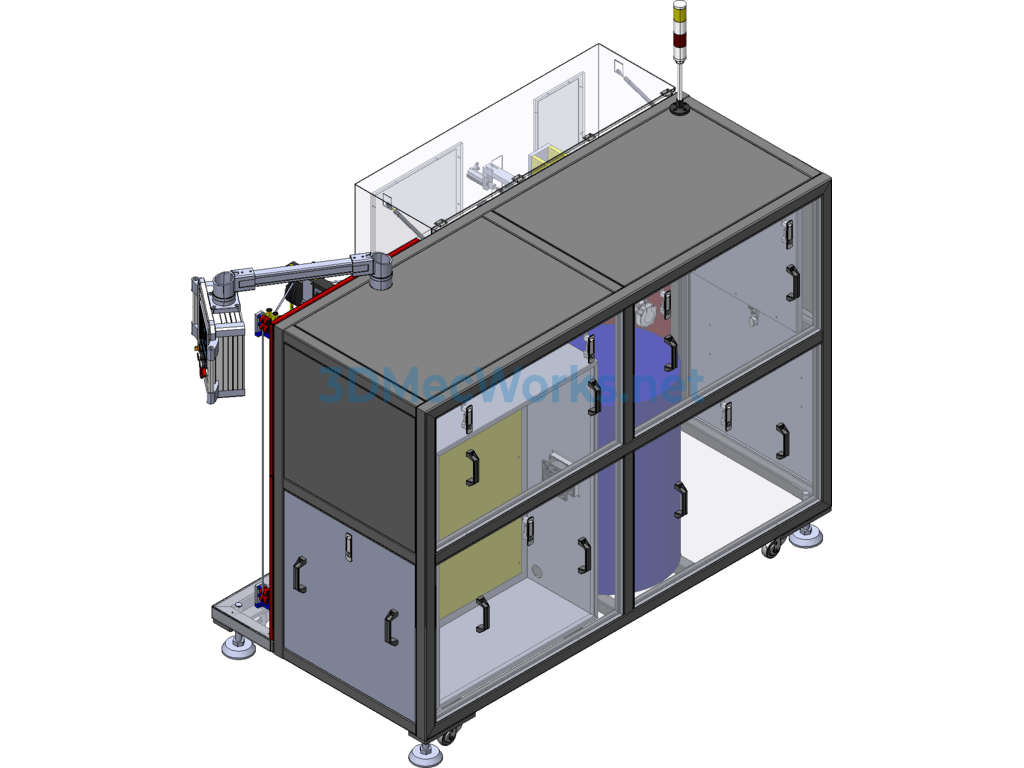

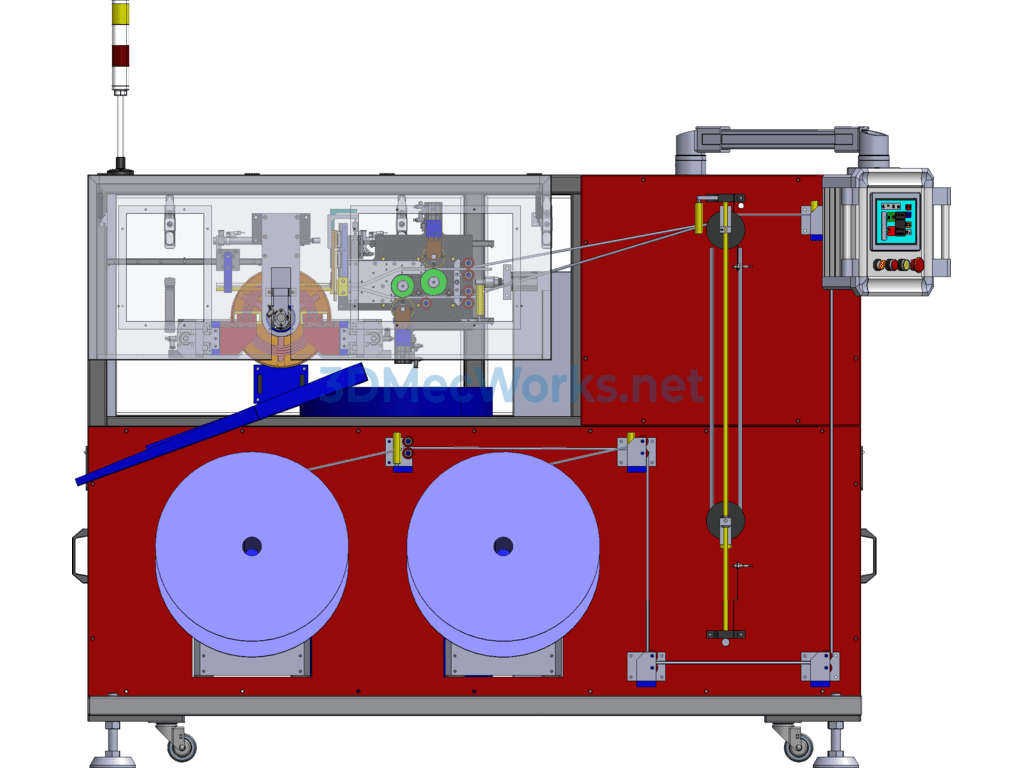

The automatic conduit coiling welding machine is used for automatic conduit coiling and welding. A long tube and a short tube, as mentioned above, are taken and coiled side by side. When coiling the tubes side by side, one end is aligned, showing the difference in length at the other end. During coiling, the tubes are wound side by side in a plane, forming a flat shape. After coiling, two points on the entire coil are spot-welded using high-frequency waves to fix the entire coil in place. The bonded part ensures it doesn’t come apart but can be torn open by hand.

Specification: Automatic Catheter Coiling Welding Machine

|

User Reviews

Be the first to review “Automatic Catheter Coiling Welding Machine”

You must be logged in to post a review.

There are no reviews yet.