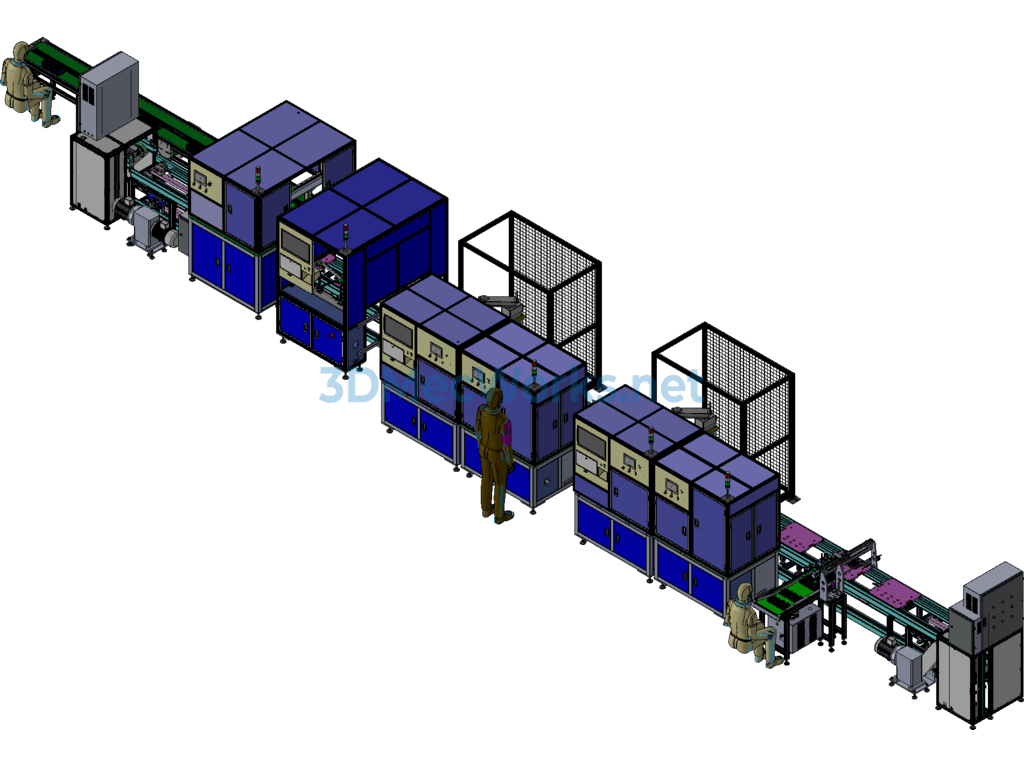

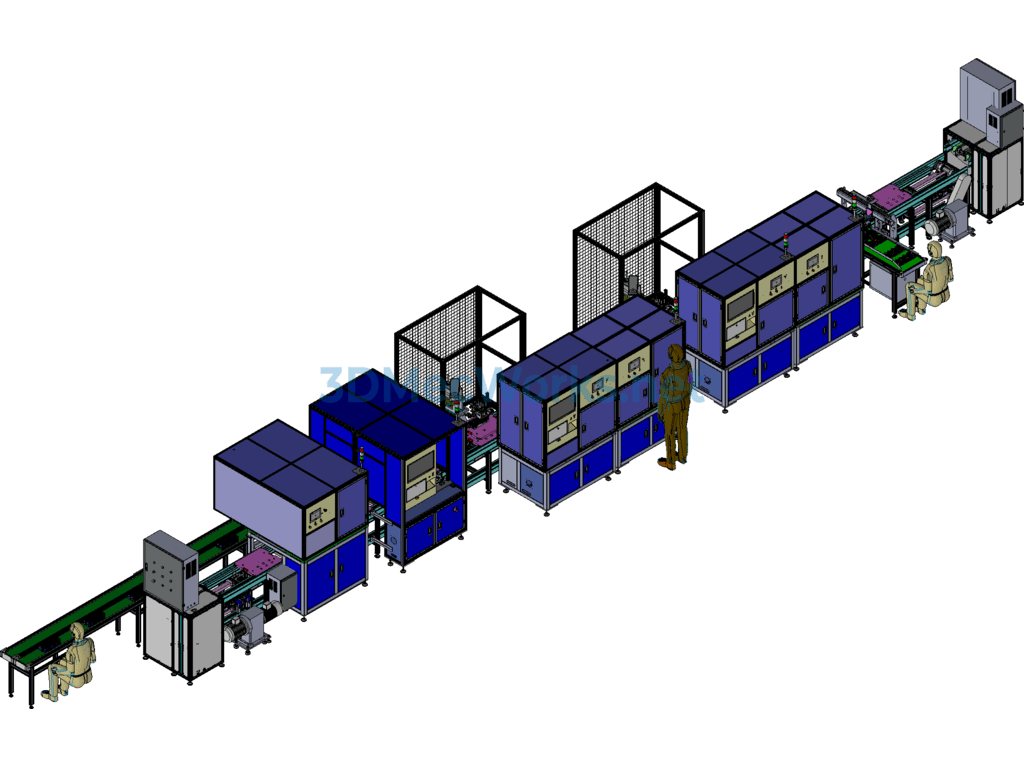

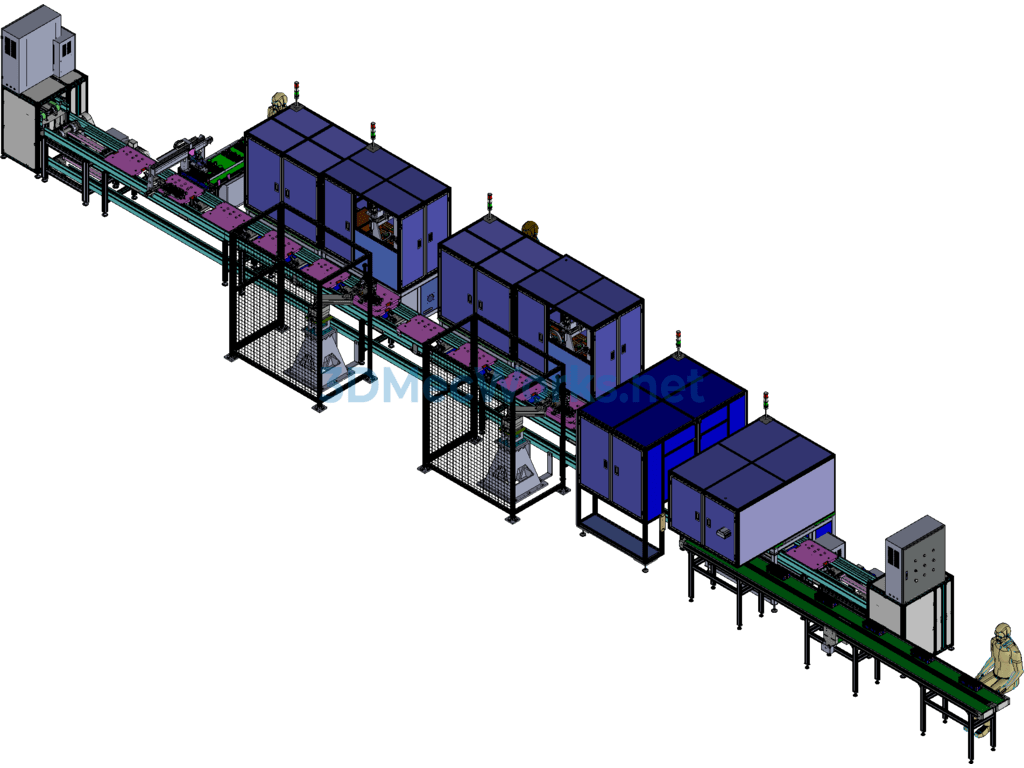

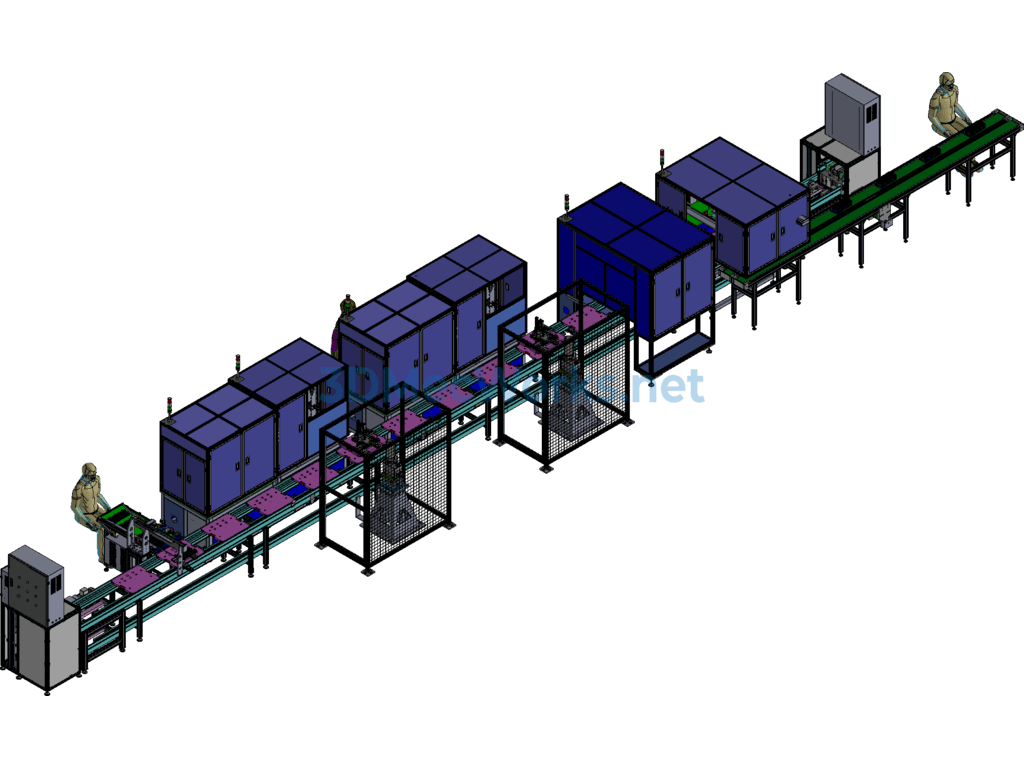

18650 Cylindrical Cell Automatic Assembly Line

1. Equipment Description

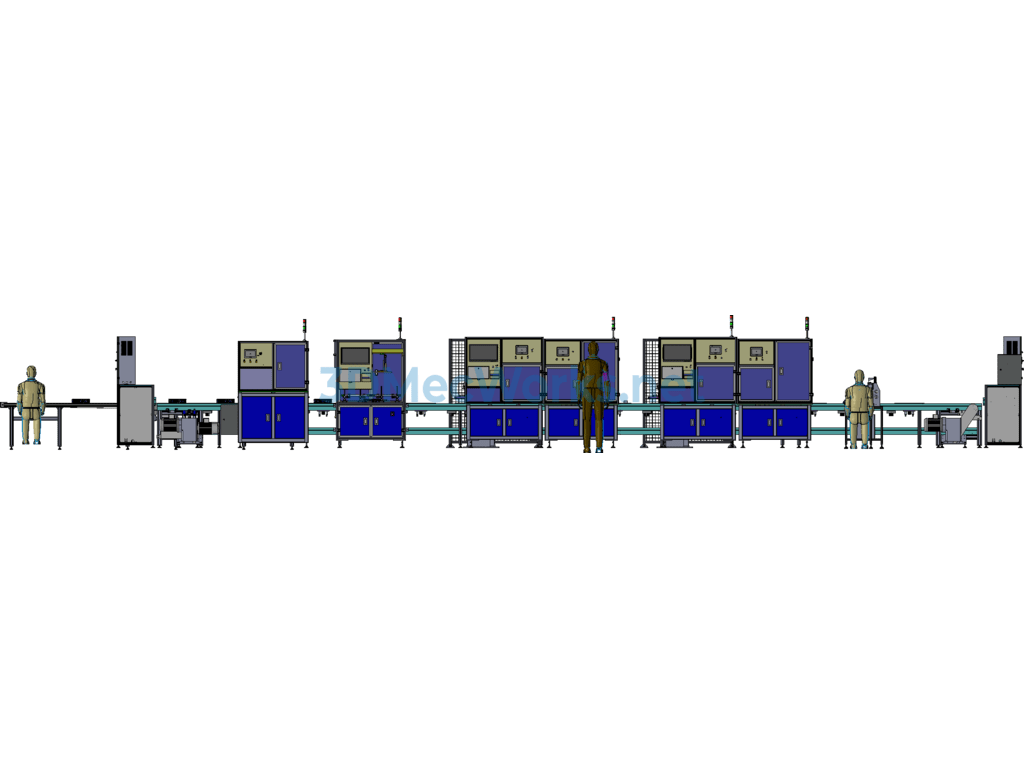

The 18650 cell automatic assembly line is used for the assembly of cylindrical batteries, such as 18650 cells, cylindrical power banks, automotive power batteries, and other cylindrical cells. This equipment is primarily an automatic assembly line for new energy power batteries: After decompressing the full set of drawings, the files are over 300MB, with more than 1000 parts in total. The equipment mainly achieves automatic feeding of the lower support. First, a worker places the cell lower support onto the feeding conveyor belt, then a robot arm grabs the lower support and places it into the tooling board of the rapid conveyor. The speed of the rapid conveyor is adjustable based on production speed, and its tooling can also accommodate various types of cells. The lower support is conveyed via the rapid conveyor to the cell insertion station.

After the battery is sorted out by the sorting machine, it proceeds to get green kraft paper tape applied. Once taped, the CCS checks for any that are not taped. This station is for cell inspection and defective handling. Subsequently, a robot arm picks up the cells with green kraft paper applied and places them onto a good-product conveyor belt line. The cells then enter the feeder machine via the belt line. At the end of the conveyor belt, there’s a feeding mechanism, where two sets of cylinders push the cells into the material belt of the vertical feeder when the cells reach the end. As the vertical feeder pulls up to the top, push material and distribution cylinders push the cells into the material tube, four cells at a time. The material tube is a plastic corrugated tube, which is not shown on the diagram. Its outlet connects directly to the feed inlet of the four-axis robot’s discharge jig. The insertion precision of the four-axis robotic cell is 0.1MM. This robot is responsible for inserting four cells at a time with the positive terminal facing up. Afterward, it proceeds to insert the cells with the negative terminal next. There are two of these cell insertion machines and robots; the one in the front inserts the positive terminals, and the one at the back inserts the negative terminals, as seen from the bus picture.

After all cells are inserted, they pass to the polarity inspection machine, which uses CCD visual inspection to check for incorrect insertions. Once inspection is complete, the cells proceed to the unloading station where all the cells have been inserted and inspected. The unloading machine is a three-axis robotic arm that clamps the entire battery pack out, the unloading conveyor has two lines, one for good products, another for placing CCD-detected defects.

After good products are conveyed out, a worker collects the material behind the conveyor. The above describes the entire action process and assembly technology of the cell insertion line. Of course, if you want to understand more specific structural designs, you need to download and study gradually. The full set of drawings is complete, and interested friends are welcome to download and learn.

4. Main Technical Parameters:

Category: Specification Parameters

Overall Machine Dimensions: 15350*1220*1700MM (L*W*H)

Input Voltage: AC—220V50Hz or AC—380V 50Hz

https://3dmec.net/

Optional Maximum Power of the whole machine: 0.9KW (with 220V)

Input Air Source Pressure: 0.4-0.6 Mpa

Gas Consumption: 1.5 L/min

Production Efficiency (C/T): ≤1.0 S/four

Equipment Utilization Rate: ≥95%

Processing Mode: Automatic Detection, Automatic Cell Insertion, Automatic Discharge

Programming Mode: Touchscreen Parameter Modification

Specification: Automatic Assembly Line for Lithium Battery Cells 18650 Cell Assembly Cylindrical Battery Lower Bracket Assembly Equipment

|

User Reviews

Be the first to review “Automatic Assembly Line for Lithium Battery Cells 18650 Cell Assembly Cylindrical Battery Lower Bracket Assembly Equipment”

You must be logged in to post a review.

There are no reviews yet.