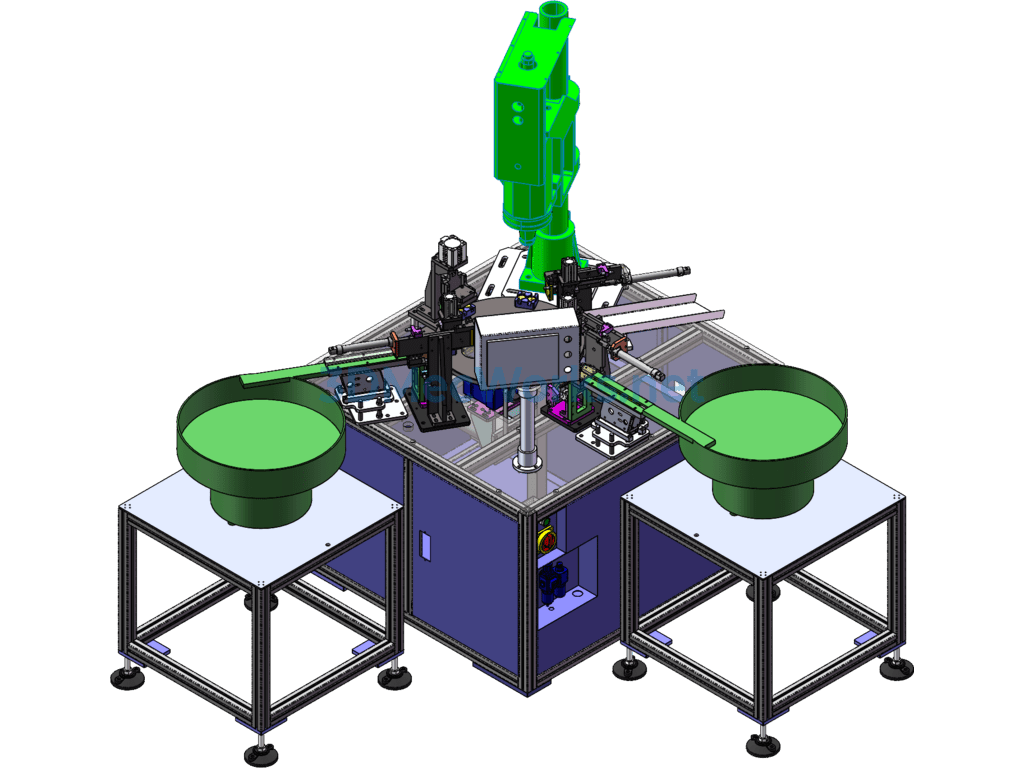

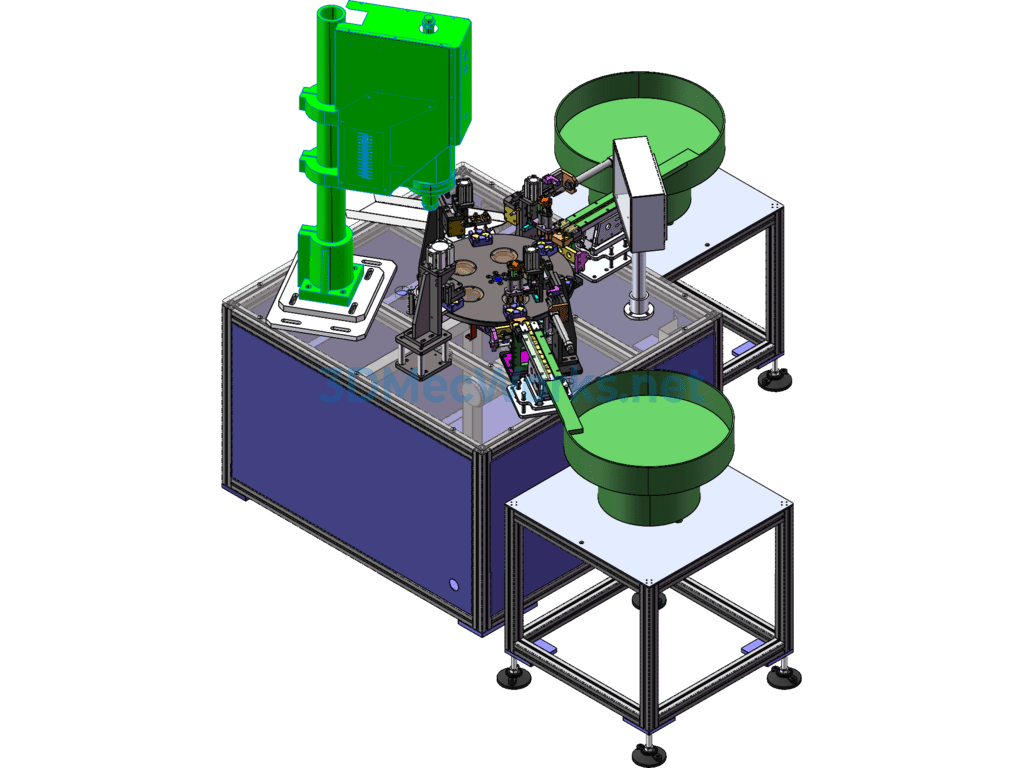

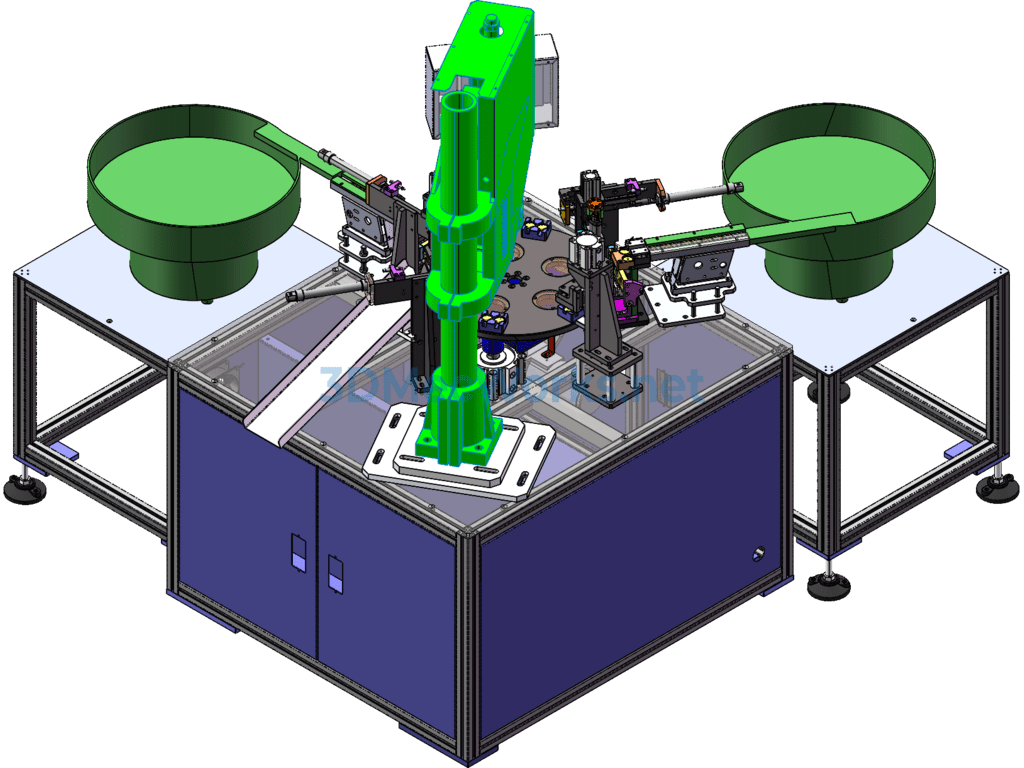

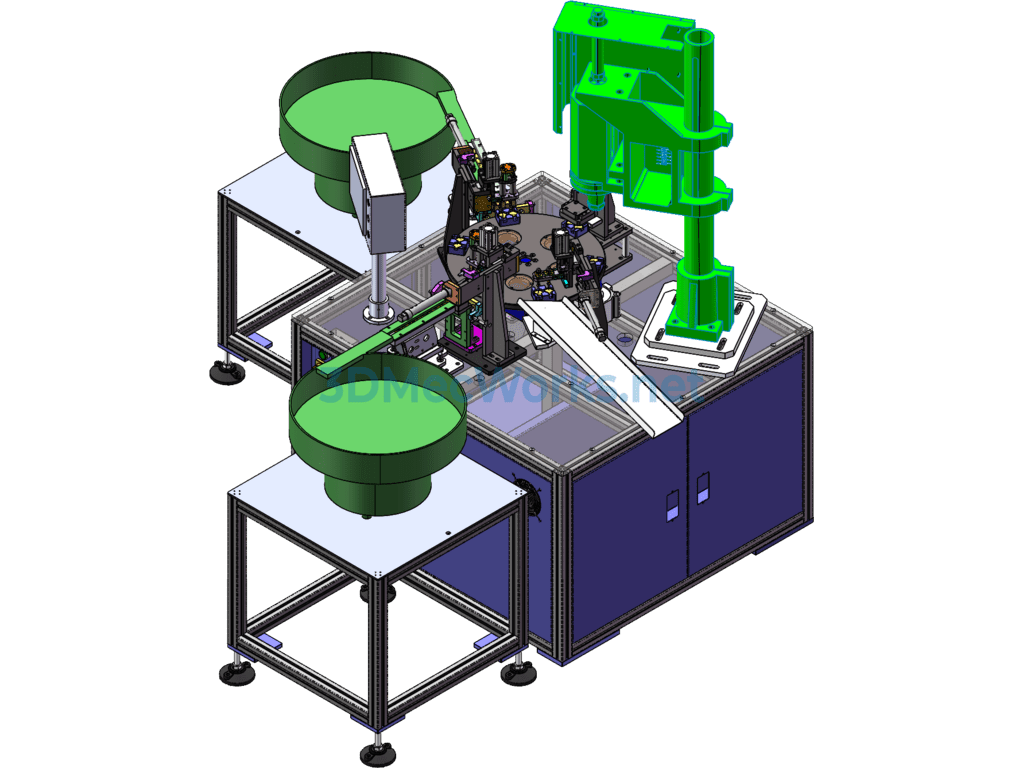

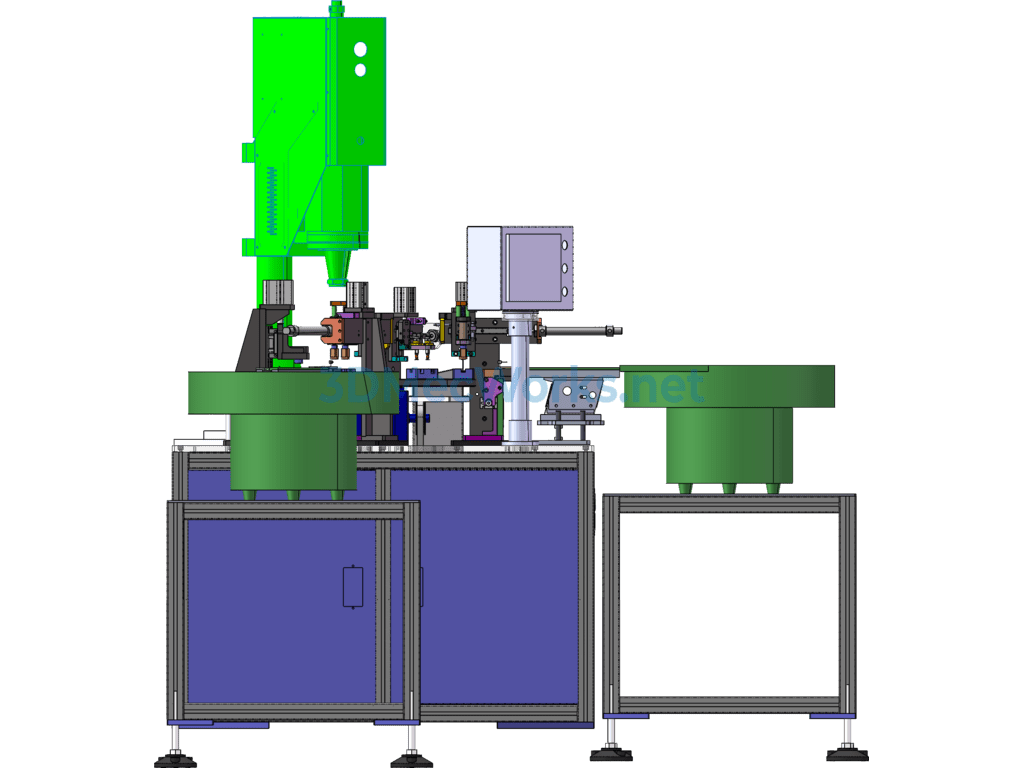

This equipment is primarily developed for products like electronic game coin keys and can be commonly used by changing the vibration plate and fixtures. The equipment is driven by a six-station rotary table. At the first station, the bottom cover is loaded. The bottom cover is transmitted by the vibration plate to the loading station, where it is picked up by a mechanical arm and placed into the high-level bottom cover loading position. The second station is reserved for adding stations in the future; the third station is for the upper cover loading station, with the same loading method as the bottom cover loading station. The vibration plate feeds the workpiece, and the mechanical arm picks up and moves it into the rotary table fixture. At the fourth station, the upper and lower covers are assembled and pressed together. At the fifth station, the assembled product is welded together using an ultrasonic welding machine. At the sixth station, the assembled product is unloaded and placed into the discharge track, flowing out from the machine for collection.

Specification: Automatic Assembly and Welding of Game Tokens

|

User Reviews

Be the first to review “Automatic Assembly and Welding of Game Tokens”

You must be logged in to post a review.

There are no reviews yet.