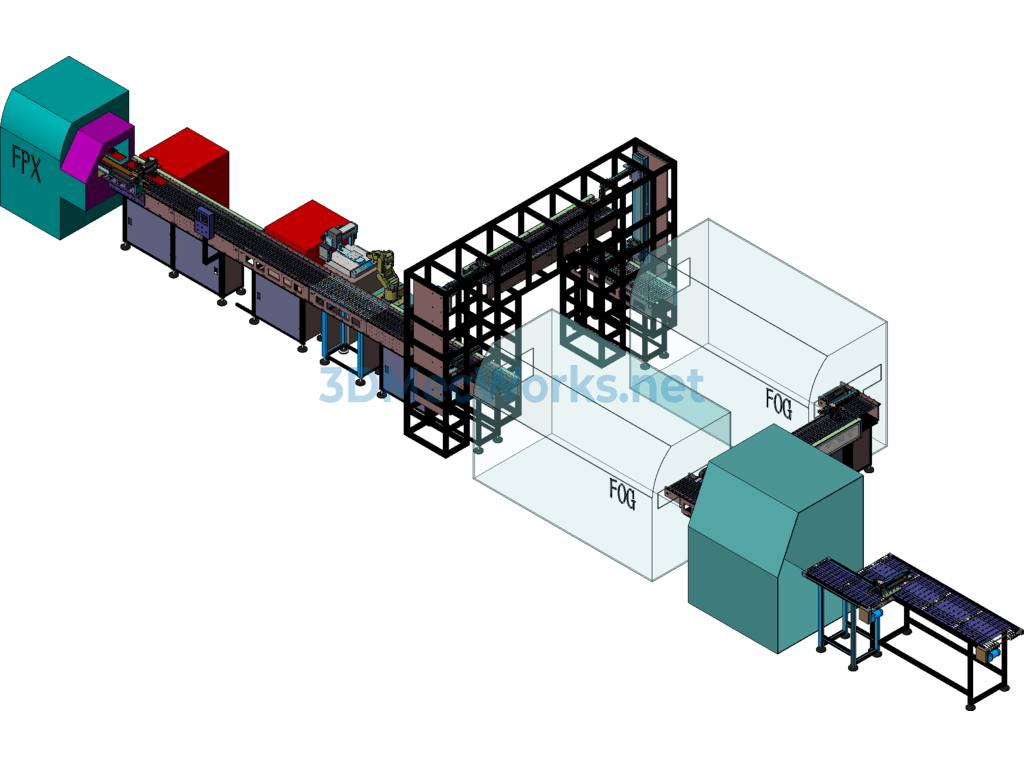

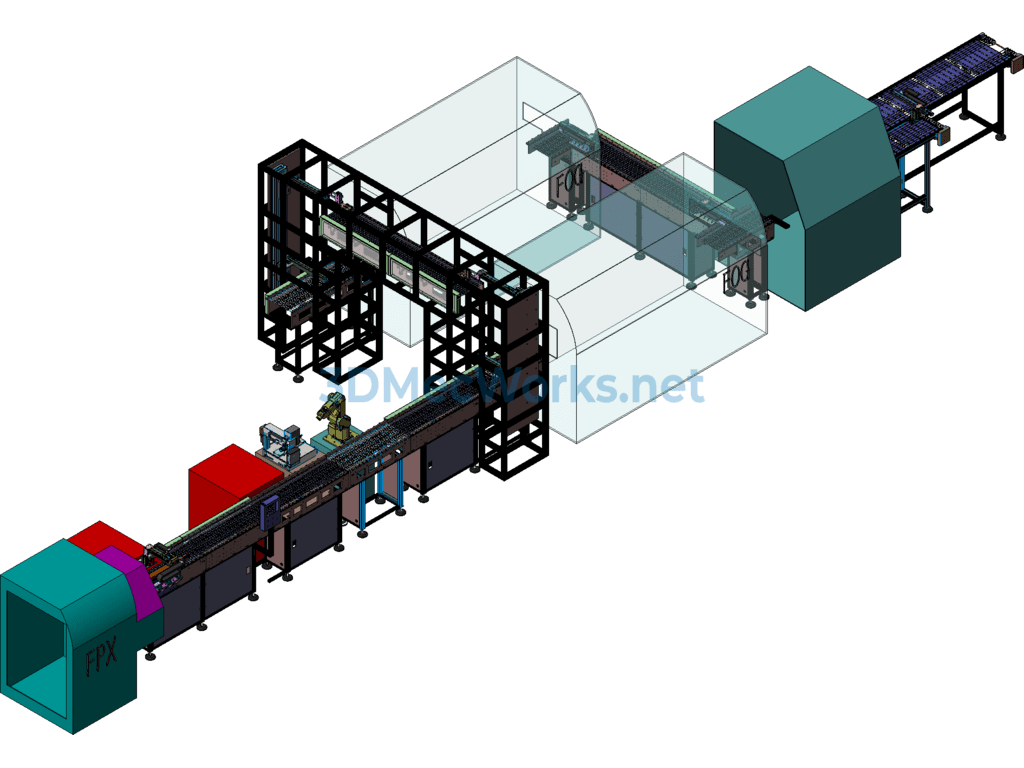

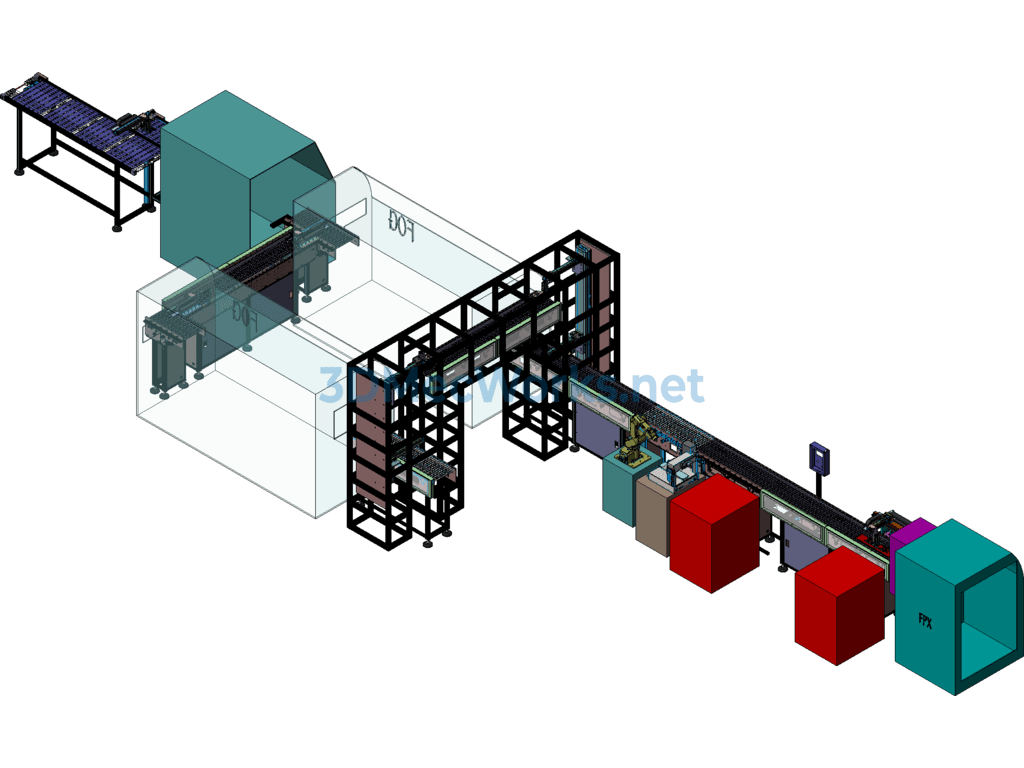

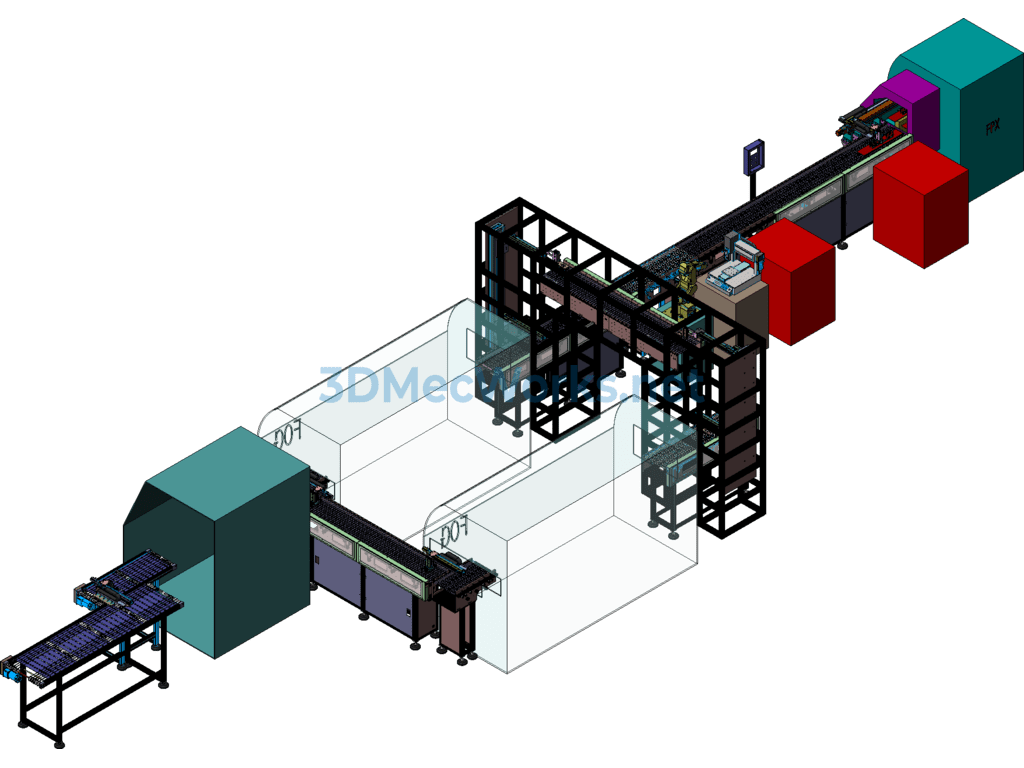

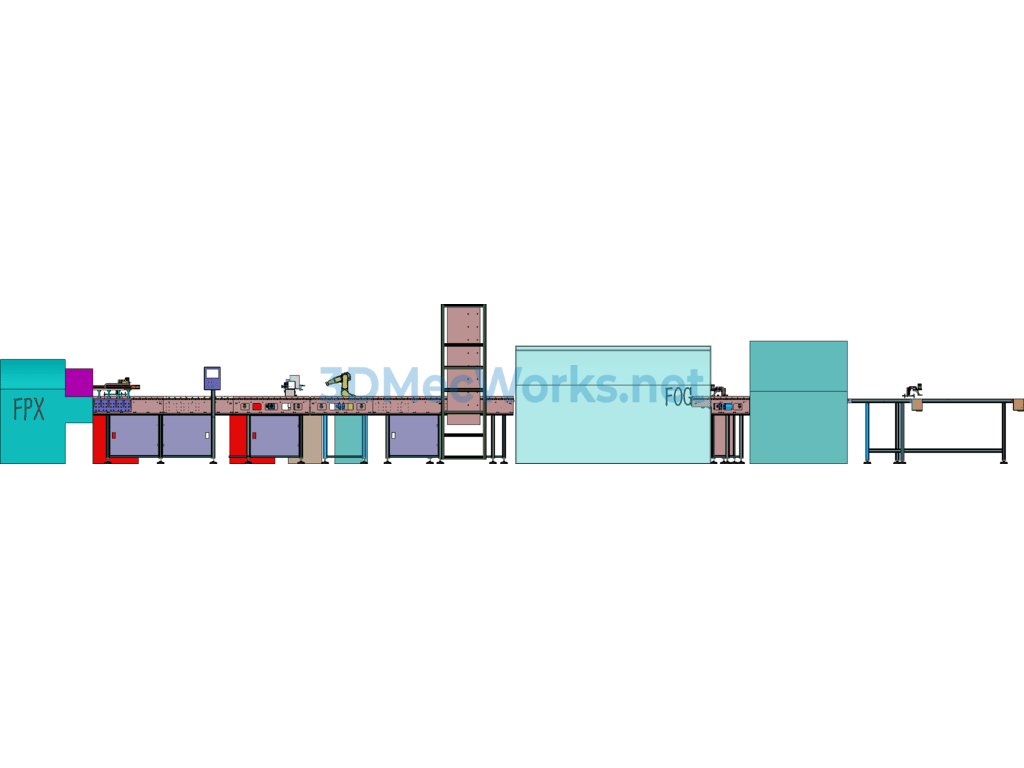

This equipment is customized for the automation workshop line transformation of a large domestic factory, mainly used for LCD handling.

The equipment consists of a conveyor cylinder positioning unit, a material picking lifting and rotating unit, a docking feeding unit, a conveyor line unit, and four major mechanical units.

Tact time can be as fast as ≤7s

– Corresponds to a large size range (4″~12.4″)

The system design adopts advanced technology, verified by the customer, with good operational quality. The executive components of the control system should have characteristics of high precision, high reliability, and quick response.

Specification: Automated Workshop In-Line Transport and Conveying Equipment

|

User Reviews

Be the first to review “Automated Workshop In-Line Transport and Conveying Equipment”

You must be logged in to post a review.

There are no reviews yet.